-

基于接触生电与静电感应原理的摩擦纳米发电机(TENG)及其自供能传感器在新能源和物联网等领域有重要的应用前景. 存在电负性差异的聚合物材料在接触分离过程中, 由于电子的转移, 在聚合物周围空间会产生变化的静电场, 已有的TENG研究中, 主要利用垂直于摩擦层和电极层平面的场强产生静电感应, 忽略了聚合物周边的电场效应. 根据静电感应原理, 处于电场中的导体其内部电荷会重新分布, 这为导体在与摩擦材料不接触的情况下导体表面产生感应电信号提供了途径. 本文设计了一种利用摩擦层周围变化静电场的非接触式摩擦纳米发电机(NC-TENG), 研究了硅胶薄膜和丁腈橡胶薄膜在接触分离过程中, 导体与摩擦材料的距离、导体感应面积尺寸及导体相对于摩擦材料所处方位等参数对感应电输出性能的影响. 结果表明, 在与摩擦材料完全分离的情况下, NC-TENG可以产生稳定的电信号输出. NC-TENG的感应电压随着导体与摩擦材料距离的增大而减小, 随着导体感应面积的增大而逐渐增大, 对于尺寸为30 mm × 30 mm的摩擦材料, 导体在面积为60 mm × 45 mm时NC-TENG的电输出趋于稳定, 产生约13 V的开路电压. 此外, 导体相对于摩擦材料所处的方位对感应电输出也具有显著的影响. 本文设计的NC-TENG提供了一种新颖的电输出产生模式, 为接下来对TENG的研究及自供能传感器的应用提供了更多可能性.Triboelectric nanogenerator (TENG) and its self-powered sensor based on the principles of contact electricity generation and electrostatic induction have important application prospects in the fields of new energy and internet of things (IoT). In the contact separation process of polymer materials with different electronegativity values, due to the transfer of electrons, a changing electrostatic field will be generated in the space around the polymer. In the existing TENG research, the field strength perpendicular to the plane of the friction layer and the electrode layer is mainly used to generate electrostatic induction, and the electric field effect around the polymer is ignored. According to the principle of electrostatic induction, the internal charge of the conductor in the electric field will be redistributed, which provides a way for the conductor to generate an induced electrical signal on the surface of the conductor without contacting the friction material. In this paper, we design a non-contact triboelectric nanogenerator (NC-TENG) based on changing electrostatic field. The influence of the distance between the conductor and the friction material, the induction area of the conductor and the position of the conductor relative to the friction material on the induced electrical output performance are studied when silicone rubber and nitrile rubber are used as a friction material. The results show that the NC-TENG can produce a stable electrical signal output when the conductor is completely separated from the friction material. The induced voltage of NC-TENG decreases with the increase of the distance between the conductor and the friction material, and gradually increases with the increase of the conductor's induction area. For the friction material with a size of 30 mm × 30 mm, the electrical output of NC-TENG tends to be stable when its conductor area is 60 mm × 45 mm. In addition, the different orientation of the conductor relative to the friction material also has a significant effect on the induced electrical output. The NC-TENG designed in this paper provides a novel electrical output generation mode, which provides a higher possibility for the subsequent research on TENG and the application of self-powered sensors.

-

Keywords:

- changing electric field /

- non-contact /

- triboelectric nanogenerator /

- electrostatic induction

[1] Yin E, Li Q, Xuan Y 2019 Appl. Energy 236 560

Google Scholar

Google Scholar

[2] Bu L, Chen Z, Chen Z, Qin L, Yang F, Xu K, Han J, Wang X 2020 Nano Energy 70 104500

Google Scholar

Google Scholar

[3] Xing F, Jie Y, Cao X, Li T, Wang N 2017 Nano Energy 42 138

Google Scholar

Google Scholar

[4] Zhong W, Xu L, Wang H, Li D, Wang Z 2019 Nano Energy 66 104108

Google Scholar

Google Scholar

[5] Liu X, Cheng K, Cui P, Qi H, Qin H, Gu G, Shang W, Wang S, Cheng G, Du Z 2019 Nano Energy 66 104188

Google Scholar

Google Scholar

[6] Cheng G, Lin Z, Du Z, Wang Z 2014 ACS Nano 8 1932

Google Scholar

Google Scholar

[7] Fan F, Tian Z, Wang Z 2012 Nano Energy 1 328

Google Scholar

Google Scholar

[8] Chung J, Lee S, Yong H, Moon H, Choi D, Lee S 2016 Nano Energy 20 84

Google Scholar

Google Scholar

[9] Yang W, Wang X, Li H, Wu J, Hu Y 2018 Nano Energy 51 241

Google Scholar

Google Scholar

[10] Seol M, Han J, Moon D, Yoon K, Hwang C, Meyyappan M 2018 Nano Energy 44 82

Google Scholar

Google Scholar

[11] Jing Q, Zhu G, Bai P, Xie Y, Chen J, Han R, Wang Z 2014 ACS Nano 8 3836

Google Scholar

Google Scholar

[12] Gogurla N, Roy B, Park J, Kim S 2019 Nano Energy 62 674

Google Scholar

Google Scholar

[13] Paosangthong W, Wagih M, Torah R, Beeby S 2019 Nano Energy 66 104148

Google Scholar

Google Scholar

[14] Xi F, Pang Y, Liu G, Wang S, Li W, Zhang C, Wang Z 2019 Nano Energy 61 1

Google Scholar

Google Scholar

[15] Zhang Z, He J, Wen T, Zhai C, Han J, Mu J, Jia W, Zhang B, Zhang W, Chou X, Xue C 2017 Nano Energy 33 88

Google Scholar

Google Scholar

[16] Kim W, Bhatia D, Jeong S, Choi D 2019 Nano Energy 56 307

Google Scholar

Google Scholar

[17] 吴晔盛, 刘启, 曹杰, 李凯, 程广贵, 张忠强, 丁建宁, 蒋诗宇 2019 68 190201

Google Scholar

Google Scholar

Wu Y S, Liu Q, Cao J, Li K, Cheng G G, Zhang Z Q, Ding J N, Jiang S Y 2019 Acta Phys. Sin. 68 190201

Google Scholar

Google Scholar

[18] Liu X, Zhao K, Yang Y 2018 Nano Energy 53 622

Google Scholar

Google Scholar

[19] Kim D, Tcho I, Choi Y 2018 Nano Energy 52 256

Google Scholar

Google Scholar

[20] Lee J, Kim S, Kim T, Khan U, Kim S 2019 Nano Energy 58 579

Google Scholar

Google Scholar

[21] Yang X, Chan S, Wang L, Daoud W 2018 Nano Energy 44 388

Google Scholar

Google Scholar

[22] Cui P, Wang J, Xiong J, Li S, Zhang W, Liu X, Gu G, Guo J, Zhang B, Cheng G, Du Z 2020 Nano Energy 71 104646

Google Scholar

Google Scholar

[23] Zhang R, Hummelgård M, Örtegren J, Olsen M, Andersson H, Olin H 2019 Nano Energy 57 279

Google Scholar

Google Scholar

[24] Xia K, Zhu Z, Zhang H, Du C, Fu J, Xu Z 2019 Nano Energy 56 400

Google Scholar

Google Scholar

[25] Lin H, Liu Y, Chen S, Xu Q, Wang S, Hu T, Pan P, Wang Y, Zhang Y, Li N, Li Y, Ma Y, Xie Y, Wang L 2019 Nano Energy 65 103944

Google Scholar

Google Scholar

[26] Lim G, Kwak S, Kwon N, Kim T, Kim H, Kim S, Kim S, Lim B 2017 Nano Energy 42 300

Google Scholar

Google Scholar

[27] Feng Y, Huang X, Liu S, Guo W, Li Y, Wu H 2019 Nano Energy 62 197

Google Scholar

Google Scholar

[28] Meng X, Cheng Q, Jiang X, Fang Z, Chen X, Li S, Li C, Sun C, Wang W, Wang Z 2018 Nano Energy 51 721

Google Scholar

Google Scholar

[29] Wu C, Ding W, Liu R, Wang J, Wang A, Wang J, Li S, Zi Y, Wang Z 2018 Mater. Today 21 216

Google Scholar

Google Scholar

[30] Chen J, Pu X, Guo H, Tang Q, Feng L, Wang X, Hu C 2018 Nano Energy 43 253

Google Scholar

Google Scholar

[31] Zhang W, Wang P, Sun K, Wang C, Diao D 2019 Nano Energy 56 277

Google Scholar

Google Scholar

[32] Heo D, Kim T, Yong H, Yoo K, Lee S 2018 Nano Energy 50 1

Google Scholar

Google Scholar

[33] Zhao K, Gu G, Zhang Y, Zhang B, Yang F, Zhao L, Zheng M, Cheng G, Du Z 2018 Nano Energy 53 898

Google Scholar

Google Scholar

[34] Liu D, Yin X, Guo H, Zhou L, Li X, Zhang C, Wang J, Wang Z 2019 Sci. Adv. 005 6437

Google Scholar

Google Scholar

[35] Li S, Liu D, Zhao Z, Zhou L, Yin X, Li X, Gao Y, Zhang C, Zhang Q, Wang J, Wang Z 2020 ACS Nano 14 2475

Google Scholar

Google Scholar

[36] Jiang T, Chen X Y, Yang K D, Han C B, Tang W, Wang Z L 2016 Nano Res. 009 1057

Google Scholar

Google Scholar

[37] 程广贵, 张伟, 方俊, 蒋诗宇, 丁建宁, Pesika N S, 张忠强, 郭立强, 王莹 2016 65 060201

Google Scholar

Google Scholar

Cheng G G, Zhang W, Fang J, Jiang S Y, Ding J N, Pesika N S, Zhang Z Q, Guo L Q, Wang Y 2016 Acta Phys. Sin. 65 060201

Google Scholar

Google Scholar

[38] 王中林, 林龙, 陈俊, 牛思淼, 訾云龙 2017 摩擦纳米发电机 (北京: 科学出版社) 第14−15页

Wang Z L, Lin L, Chen J, Niu S M, Zi Y L 2017 Triboelectric Nanogenerator (Beijing: Science Press) pp14−15 (in Chinese)

-

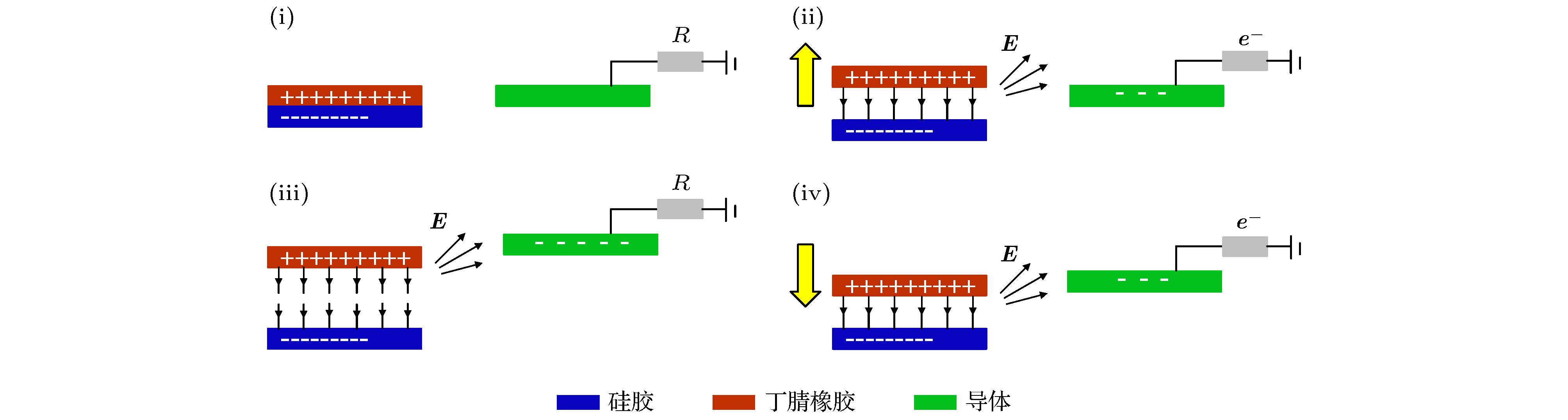

图 6 基于变化静电场的NC-TENG工作原理图 (i)初始状态, 丁腈橡胶与硅胶刚接触; (ii)丁腈橡胶与硅胶逐渐分离, 丁腈橡胶和硅胶表面所带静电荷产生静电场; (iii)丁腈橡胶和硅胶分离到最大距离, 此时丁腈橡胶和硅胶之间电势差达到最大; (iv)丁腈橡胶和硅胶分离距离逐渐减小, 彼此之间的电势差也在减小

Fig. 6. Working principle diagram of NC-TENG based on changing electrostatic field: (i) Initial state, nitrile rubber and silicone rubber are just in contact; (ii) nitrile rubber and silicone rubber are gradually separated, the surface of nitrile rubber and silicone rubber is charged and generate an electrostatic field; (iii) the nitrile rubber and the silicone rubber are separated to the maximum distance, at this time the potential difference between the nitrile rubber and the silicone rubber reaches the maximum; (iv) the separation distance between the nitrile rubber and the silicone rubber gradually decreases and the potential difference between them is also decreasing.

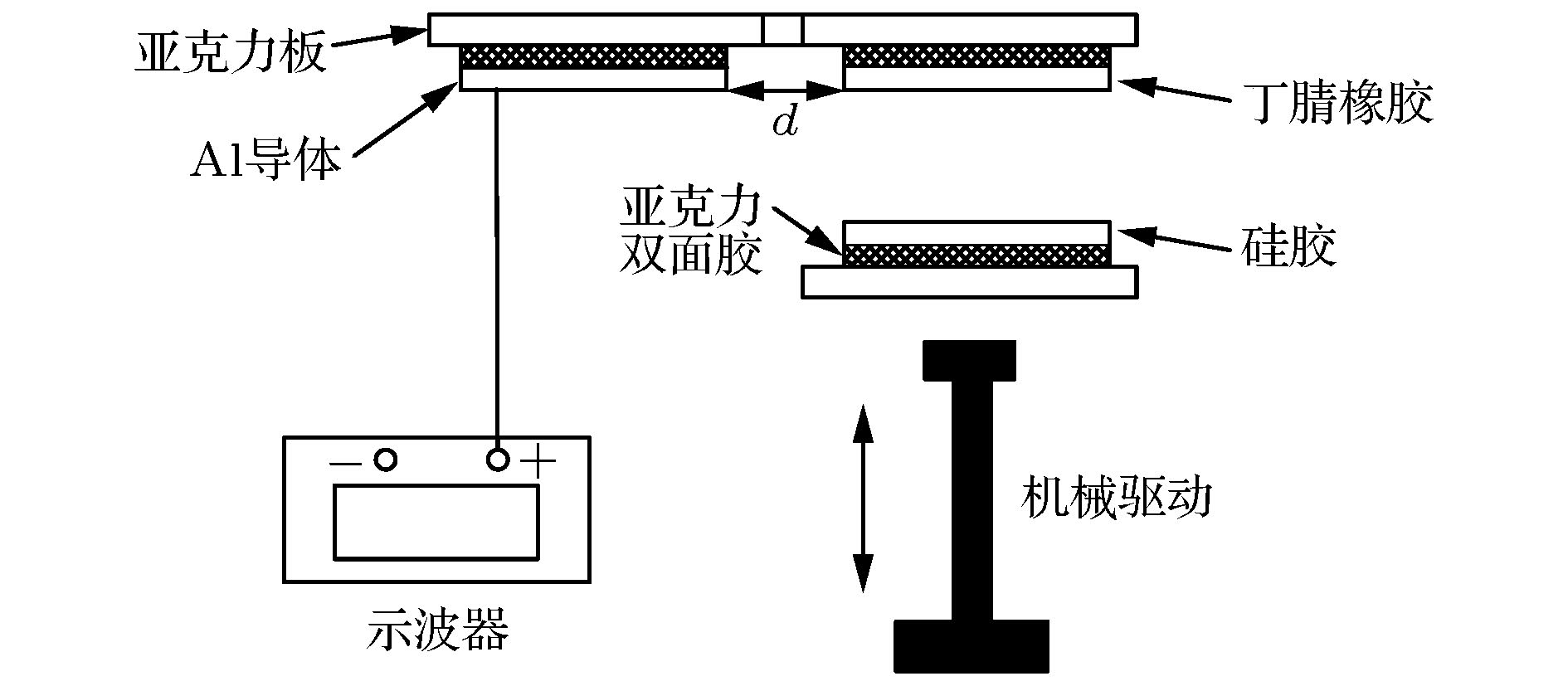

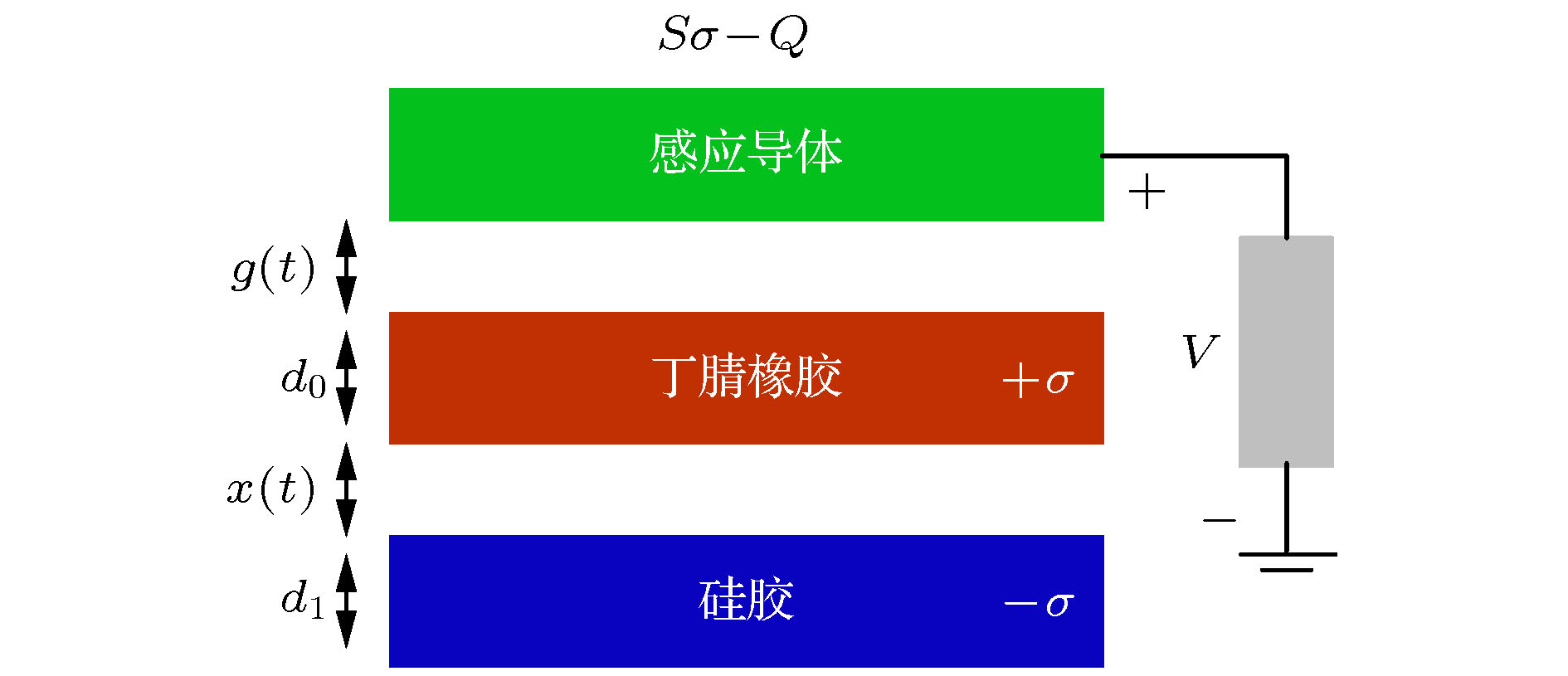

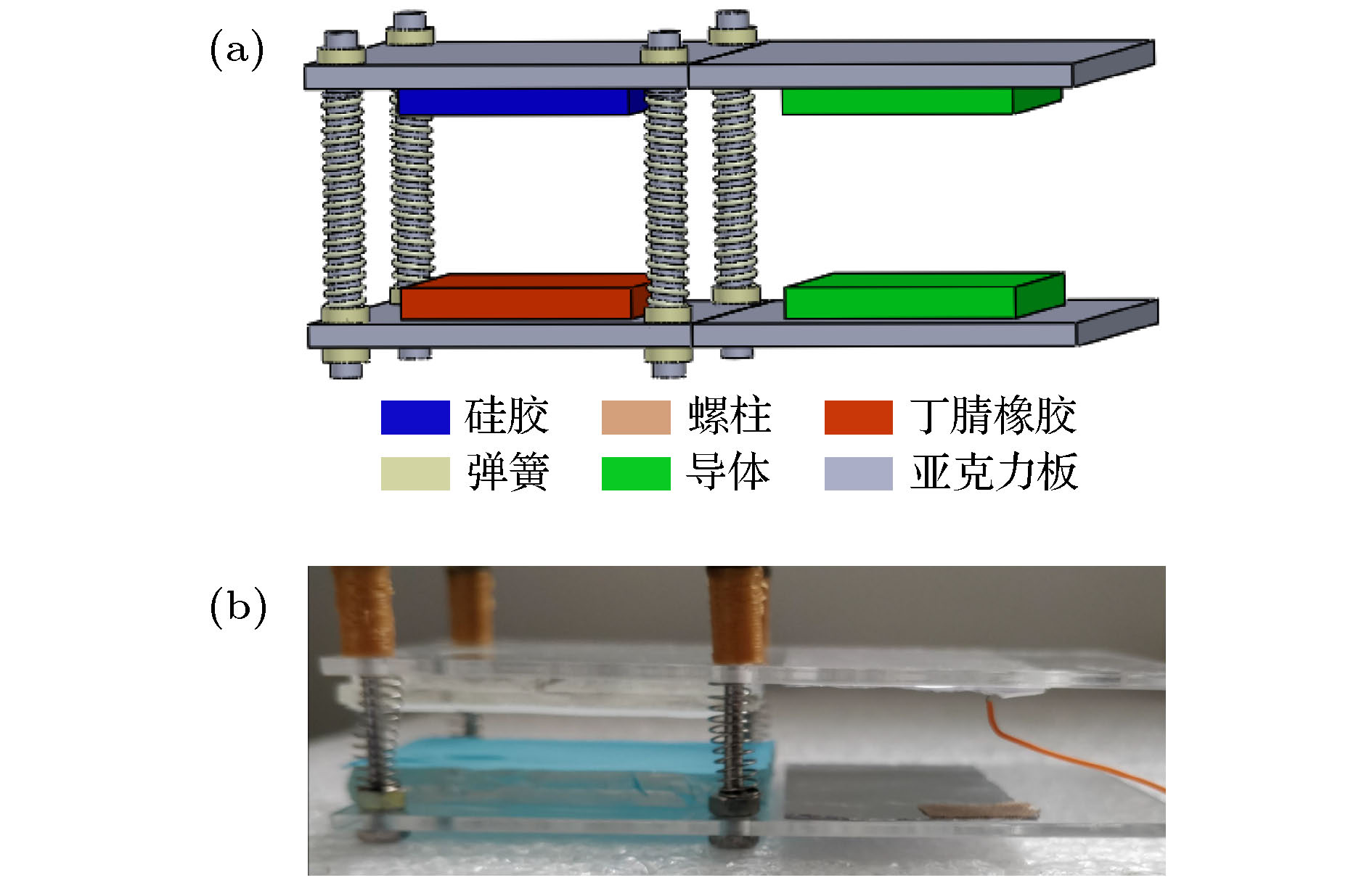

图 7 基于变化静化场的NC-TENG结构图及输出测量图 (a) NC-TENG结构图; (b) 距摩擦材料不同距离时的输出性能; (c) 不同导体面积时的输出性能

Fig. 7. Structure diagram of NC-TENG based on changing electrostatic field and electrical signal output measurement diagram: (a) Structure diagram of NC-TENG; (b) the output performance of the TENG under different distance from the friction material; (c) the output performance of the TENG under different conductor area.

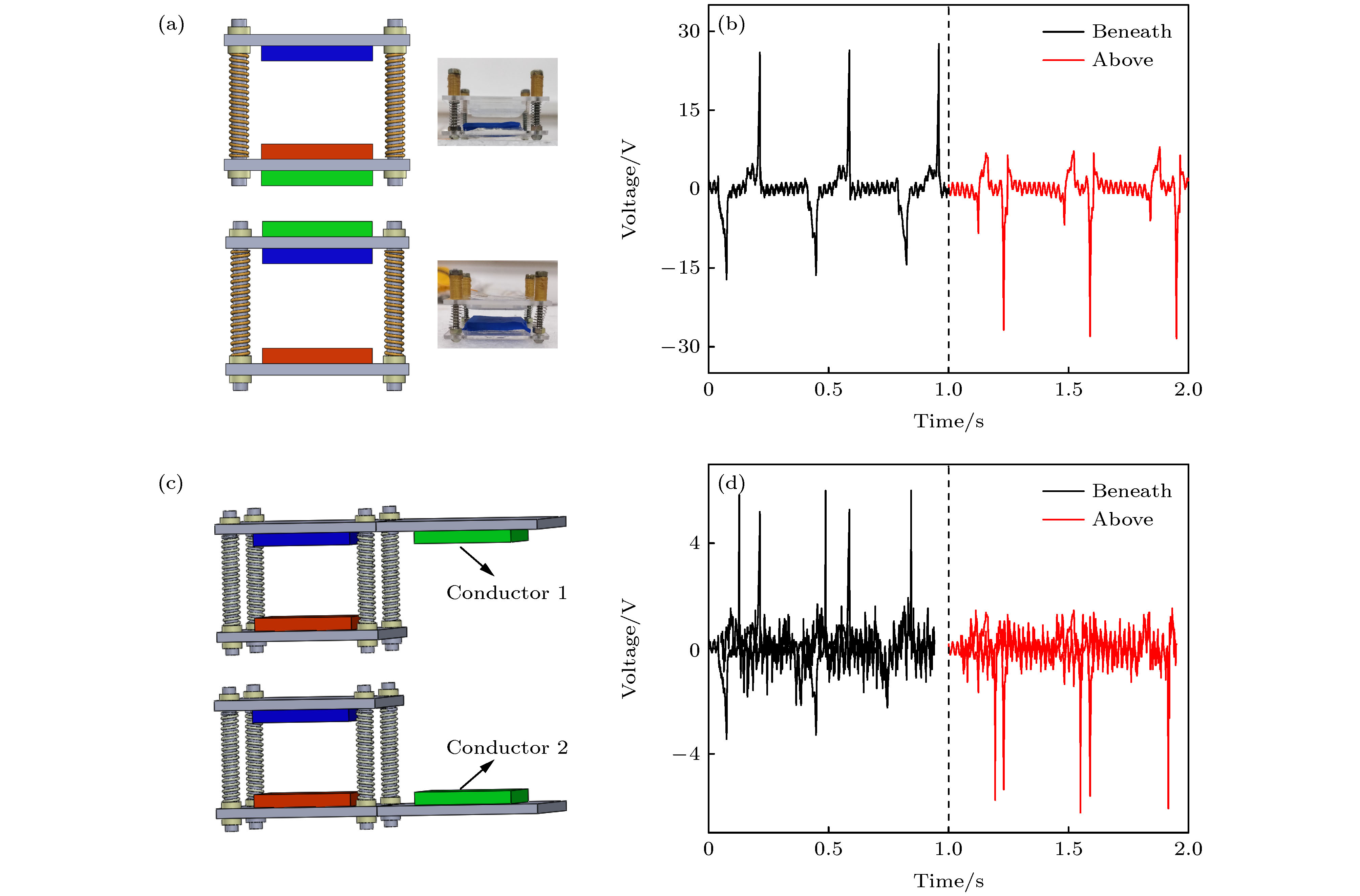

图 8 基于变化静电场的NC-TENG电信号输出与导体所处方位关系图 (a)导体处于硅胶正上方和丁腈橡胶正下方以及(b)相应的电信号输出; (c)导体距离硅胶/丁腈橡胶15 mm且分别位于硅胶同一平面和丁腈橡胶同一平面以及(d)相应的电信号输出

Fig. 8. Research on the relationship between the electrical signal output of the NC-TENG and the position of the conductor: (a) The conductor is directly above the silicone rubber and directly under the nitrile rubber and (b) the corresponding electrical signal output; (c) the conductor is 15 mm away from the silicone/nitrile rubber and is located on the same plane of silicone and nitrile rubber and (d) the corresponding electrical signal output.

-

[1] Yin E, Li Q, Xuan Y 2019 Appl. Energy 236 560

Google Scholar

Google Scholar

[2] Bu L, Chen Z, Chen Z, Qin L, Yang F, Xu K, Han J, Wang X 2020 Nano Energy 70 104500

Google Scholar

Google Scholar

[3] Xing F, Jie Y, Cao X, Li T, Wang N 2017 Nano Energy 42 138

Google Scholar

Google Scholar

[4] Zhong W, Xu L, Wang H, Li D, Wang Z 2019 Nano Energy 66 104108

Google Scholar

Google Scholar

[5] Liu X, Cheng K, Cui P, Qi H, Qin H, Gu G, Shang W, Wang S, Cheng G, Du Z 2019 Nano Energy 66 104188

Google Scholar

Google Scholar

[6] Cheng G, Lin Z, Du Z, Wang Z 2014 ACS Nano 8 1932

Google Scholar

Google Scholar

[7] Fan F, Tian Z, Wang Z 2012 Nano Energy 1 328

Google Scholar

Google Scholar

[8] Chung J, Lee S, Yong H, Moon H, Choi D, Lee S 2016 Nano Energy 20 84

Google Scholar

Google Scholar

[9] Yang W, Wang X, Li H, Wu J, Hu Y 2018 Nano Energy 51 241

Google Scholar

Google Scholar

[10] Seol M, Han J, Moon D, Yoon K, Hwang C, Meyyappan M 2018 Nano Energy 44 82

Google Scholar

Google Scholar

[11] Jing Q, Zhu G, Bai P, Xie Y, Chen J, Han R, Wang Z 2014 ACS Nano 8 3836

Google Scholar

Google Scholar

[12] Gogurla N, Roy B, Park J, Kim S 2019 Nano Energy 62 674

Google Scholar

Google Scholar

[13] Paosangthong W, Wagih M, Torah R, Beeby S 2019 Nano Energy 66 104148

Google Scholar

Google Scholar

[14] Xi F, Pang Y, Liu G, Wang S, Li W, Zhang C, Wang Z 2019 Nano Energy 61 1

Google Scholar

Google Scholar

[15] Zhang Z, He J, Wen T, Zhai C, Han J, Mu J, Jia W, Zhang B, Zhang W, Chou X, Xue C 2017 Nano Energy 33 88

Google Scholar

Google Scholar

[16] Kim W, Bhatia D, Jeong S, Choi D 2019 Nano Energy 56 307

Google Scholar

Google Scholar

[17] 吴晔盛, 刘启, 曹杰, 李凯, 程广贵, 张忠强, 丁建宁, 蒋诗宇 2019 68 190201

Google Scholar

Google Scholar

Wu Y S, Liu Q, Cao J, Li K, Cheng G G, Zhang Z Q, Ding J N, Jiang S Y 2019 Acta Phys. Sin. 68 190201

Google Scholar

Google Scholar

[18] Liu X, Zhao K, Yang Y 2018 Nano Energy 53 622

Google Scholar

Google Scholar

[19] Kim D, Tcho I, Choi Y 2018 Nano Energy 52 256

Google Scholar

Google Scholar

[20] Lee J, Kim S, Kim T, Khan U, Kim S 2019 Nano Energy 58 579

Google Scholar

Google Scholar

[21] Yang X, Chan S, Wang L, Daoud W 2018 Nano Energy 44 388

Google Scholar

Google Scholar

[22] Cui P, Wang J, Xiong J, Li S, Zhang W, Liu X, Gu G, Guo J, Zhang B, Cheng G, Du Z 2020 Nano Energy 71 104646

Google Scholar

Google Scholar

[23] Zhang R, Hummelgård M, Örtegren J, Olsen M, Andersson H, Olin H 2019 Nano Energy 57 279

Google Scholar

Google Scholar

[24] Xia K, Zhu Z, Zhang H, Du C, Fu J, Xu Z 2019 Nano Energy 56 400

Google Scholar

Google Scholar

[25] Lin H, Liu Y, Chen S, Xu Q, Wang S, Hu T, Pan P, Wang Y, Zhang Y, Li N, Li Y, Ma Y, Xie Y, Wang L 2019 Nano Energy 65 103944

Google Scholar

Google Scholar

[26] Lim G, Kwak S, Kwon N, Kim T, Kim H, Kim S, Kim S, Lim B 2017 Nano Energy 42 300

Google Scholar

Google Scholar

[27] Feng Y, Huang X, Liu S, Guo W, Li Y, Wu H 2019 Nano Energy 62 197

Google Scholar

Google Scholar

[28] Meng X, Cheng Q, Jiang X, Fang Z, Chen X, Li S, Li C, Sun C, Wang W, Wang Z 2018 Nano Energy 51 721

Google Scholar

Google Scholar

[29] Wu C, Ding W, Liu R, Wang J, Wang A, Wang J, Li S, Zi Y, Wang Z 2018 Mater. Today 21 216

Google Scholar

Google Scholar

[30] Chen J, Pu X, Guo H, Tang Q, Feng L, Wang X, Hu C 2018 Nano Energy 43 253

Google Scholar

Google Scholar

[31] Zhang W, Wang P, Sun K, Wang C, Diao D 2019 Nano Energy 56 277

Google Scholar

Google Scholar

[32] Heo D, Kim T, Yong H, Yoo K, Lee S 2018 Nano Energy 50 1

Google Scholar

Google Scholar

[33] Zhao K, Gu G, Zhang Y, Zhang B, Yang F, Zhao L, Zheng M, Cheng G, Du Z 2018 Nano Energy 53 898

Google Scholar

Google Scholar

[34] Liu D, Yin X, Guo H, Zhou L, Li X, Zhang C, Wang J, Wang Z 2019 Sci. Adv. 005 6437

Google Scholar

Google Scholar

[35] Li S, Liu D, Zhao Z, Zhou L, Yin X, Li X, Gao Y, Zhang C, Zhang Q, Wang J, Wang Z 2020 ACS Nano 14 2475

Google Scholar

Google Scholar

[36] Jiang T, Chen X Y, Yang K D, Han C B, Tang W, Wang Z L 2016 Nano Res. 009 1057

Google Scholar

Google Scholar

[37] 程广贵, 张伟, 方俊, 蒋诗宇, 丁建宁, Pesika N S, 张忠强, 郭立强, 王莹 2016 65 060201

Google Scholar

Google Scholar

Cheng G G, Zhang W, Fang J, Jiang S Y, Ding J N, Pesika N S, Zhang Z Q, Guo L Q, Wang Y 2016 Acta Phys. Sin. 65 060201

Google Scholar

Google Scholar

[38] 王中林, 林龙, 陈俊, 牛思淼, 訾云龙 2017 摩擦纳米发电机 (北京: 科学出版社) 第14−15页

Wang Z L, Lin L, Chen J, Niu S M, Zi Y L 2017 Triboelectric Nanogenerator (Beijing: Science Press) pp14−15 (in Chinese)

计量

- 文章访问数: 13909

- PDF下载量: 249

- 被引次数: 0

下载:

下载: