-

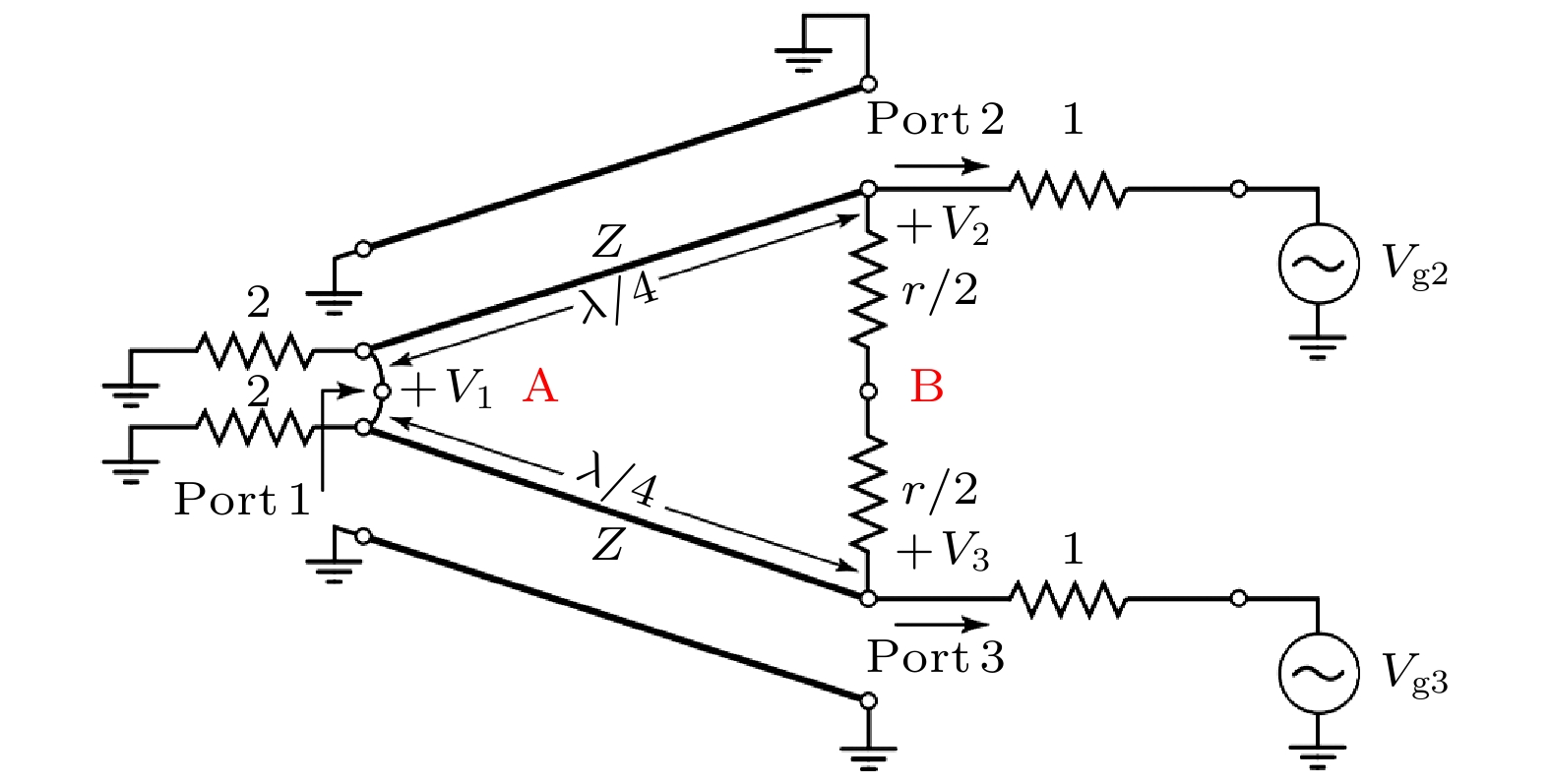

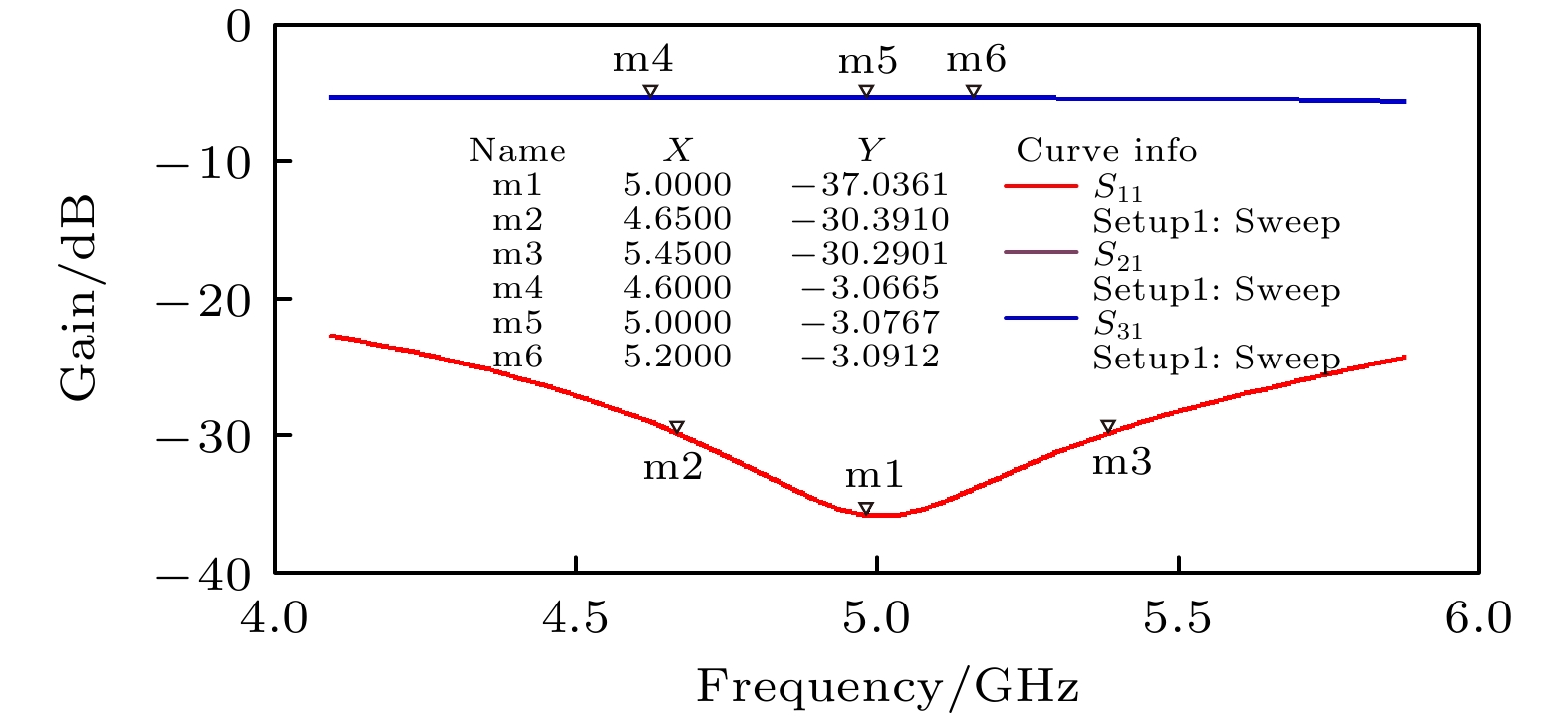

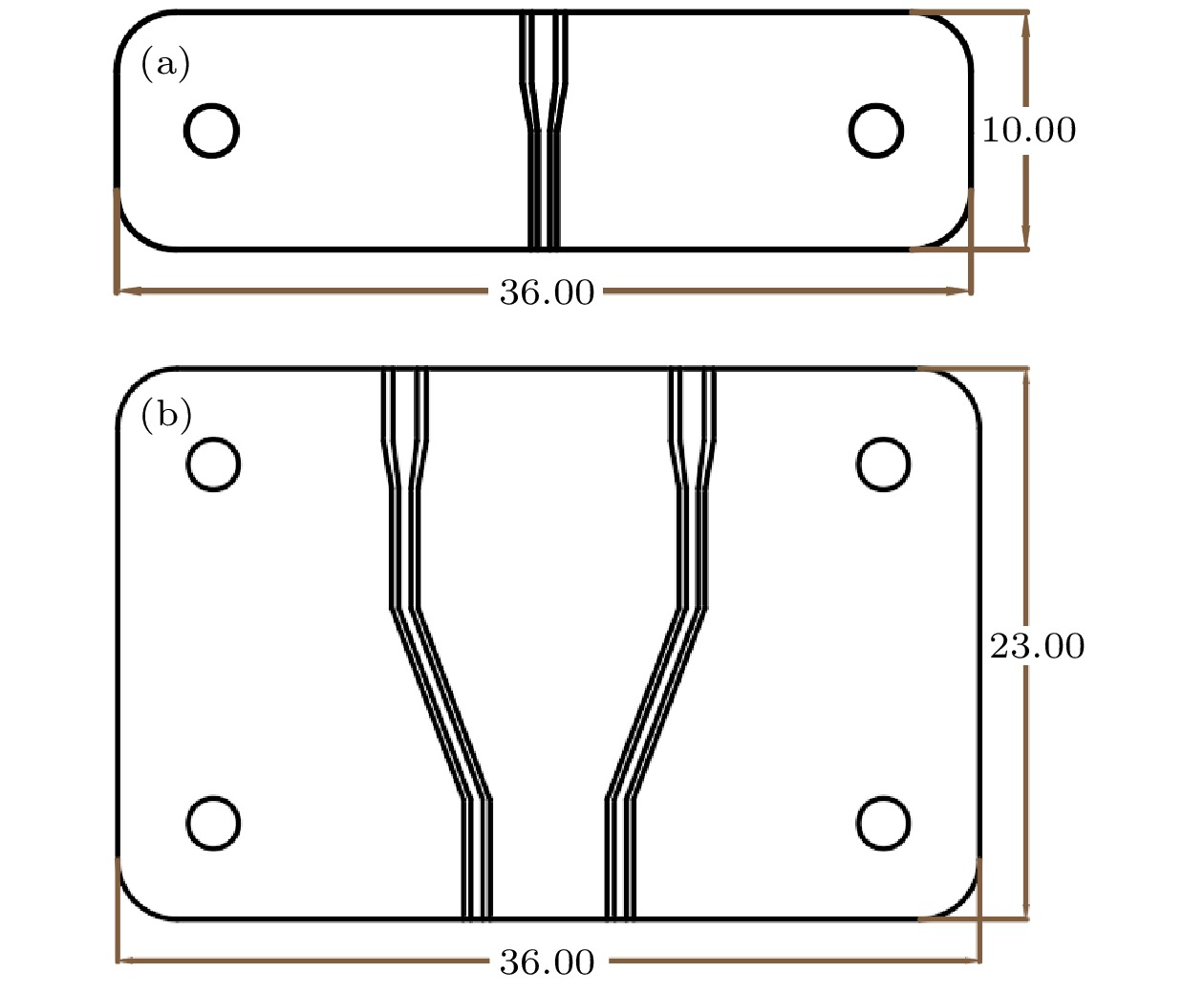

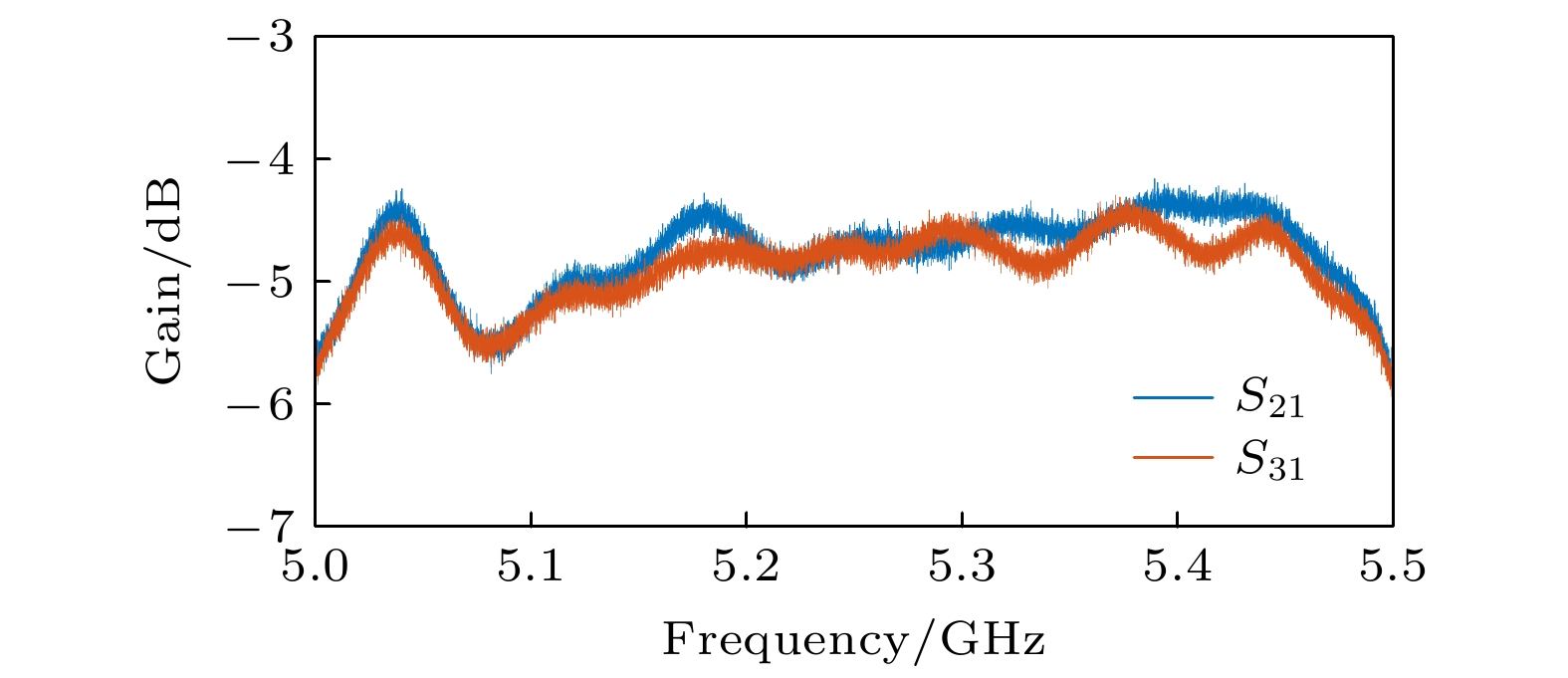

功分器是将信号按照一定比例进行功率分配的微波器件, 广泛应用于微波电路. 鉴于超导功分器是超导量子计算电路和超导微波光子探测器的重要器件单元, 本文首先采用奇偶模方法分析三端口微波网络传输特性以获取无隔离电阻功分器的参数, 其次通过商用电磁仿真软件HFSS设计了中心频率为5 GHz、功分比为等分的共面波导型超导微波功分器. 然后利用微加工技术在硅基上制备了该原型器件, 并在极低温平台对其功分特性进行了实验测试. 结果表明, 所制备的功分器在5—5.5 GHz频段内的功分参数与设计参数一致. 因此, 本文工作可推广应用于超导微波电路中其他无源器件的设计和制备.Power divider is a useful device that divides the power of signal into different subpowers at a certain ratio. The superconducting power divider plays an important role in various superconducting quantum computing circuits and superconducting microwave photon detectors. Therefore, in this paper we investigate how to design and prepare a typical coplanar waveguide superconducting microwave power divider. The parameters are designed by using the odd-even mode method to analyze the transport features of a three-port microwave network. Specifically, the microwave transport properties of the device with a center frequency of 5 GHz and 3 dB power division ratio are simulated. Then, the designed aluminum coplanar waveguide superconducting power divider on silicon is prepared by micro-processing technology and experimentally tested at low temperature. It is shown that the measurement results are consistent with the design parameters. It is noted that the center frequency of the actually prepared power divider is measured to be about 5.25 GHz, which is slightly different from the result of the design and simulation. This difference is probably due to the following main reasons. Firstly, the limited precision of the micromachining process is caused by the fact that the fabricated quarter-wave impedance matching line is etched incompletely, leading the length of the impedance matching line to be shortened. As a consequence, the frequency of the prepared power divider is slightly higher. Secondly, the simulation software is not designed specially for superconducting device simulations, thereby yielding the design parameters slightly different from those of the fabricated superconducting devices. Additionally, a series of attenuations has been used in the experimental test system of the superconducting microwave power dividers for reducing the various noises. This causes the input test signal to weaken, thus the reflected signal turns significantly small. Therefore, none of the S11 parameters of the device can be effectively measured. Finally, neither of S21 and S31 parameters measured in the experiment is the predicted –3 dB, which is mainly due to the imperfections in the welding between SMA connectors and high-frequency transmission lines, and the spot welding between high-frequency transmission lines and power divider samples, and also due to the discontinuities of the high-frequency transmission line and the power divider and so on. All these factors can yield the tested insertion loss of the device. Hopefully, the method in this work can be extended to designing and preparing other passive superconducting microwave devices.

-

Keywords:

- coplanar waveguide /

- superconducting microwave power divider /

- microfabrication /

- low temperature measurement system

[1] 李春光, 王佳, 吴云, 王旭, 孙亮, 董慧, 高波, 李浩, 尤立星, 林志荣, 任浩, 李婧, 张文, 贺青, 王轶文, 韦联福, 孙汉聪, 王华兵, 李劲劲, 屈继峰 2021 70 018501

Google Scholar

Google Scholar

Li C G, Wang J, Wu Y, Wang X, Sun L, Dong H, Gao B, Li H, You L X, Lin Z R, Ren H, Li J, Zhang W, He Q, Wang Y W, Wei L F, Sun H C, Wang H B, Li J J, Qu J F 2021 Acta Phys. Sin. 70 018501

Google Scholar

Google Scholar

[2] Chen Y F, Hover D, Sendelbach S, Maurer L, Merkel S T, Pritchett E J, Wilhelm F K, McDermott R 2011 Phys. Rev. Lett. 107 217401

Google Scholar

Google Scholar

[3] Opremcak A, Pechenezhskiy I V, Howington C, Christensen B G, Beck M A, Leonard J E, Suttle J, Wilen C, Nesterov K N, Ribeill G J, Thorbeck T, Schlenker F, Vavilov M G, Plourde B L T, McDermott R 2018 Science 361 1239

Google Scholar

Google Scholar

[4] Day P, Leduc H, Mazin B, Vayonakis A, Zmuidzinas J 2003 Nature 425 817

Google Scholar

Google Scholar

[5] Yan Z G, Zhang Y R, Gong M, Wu Y L, Zheng Y R, Li S W, Wang C, Liang F T, Lin J, Xu Y, Guo C, Sun L H, Peng C Z, Xia K Y, Deng H, Rong H, You J Q, Franco N, Fan H, Zhu X B, Pan J W 2019 Science 364 753

Google Scholar

Google Scholar

[6] Gong M, Chen M C, Zheng Y R, Wang S Y, Zha C, Deng H, Yan Z G, Rong H, Wu Y L, Li S W, Chen F S, Zhao Y W, Liang F T, Lin J, Xu Y, Guo C, Sun L H, Anthony D C, Wang H H, Peng C Z, Lu C Y, Zhu X B, Pan J W 2019 Phys. Rev. Lett. 122 110501

Google Scholar

Google Scholar

[7] Ye Y S, Ge Z Y, Wu Y L, Wang S Y, Gong M, Zhang Y R, Zhu Q L, Yang R, Li S W, Liang F T, Lin J, Xu Y, Guo C, Sun L H, Cheng C, Nvsen M, Meng Z Y, Deng H, Rong H, Lu C Y, Peng C Z, Fan H, Zhu X B, Pan J W 2019 Phys. Rev. Lett. 123 050502

Google Scholar

Google Scholar

[8] 郑东宁 2021 70 018502

Google Scholar

Google Scholar

Zheng D L 2021 Acta Phys. Sin. 70 018502

Google Scholar

Google Scholar

[9] Mazin B 2004 Ph. D. Dissertation (Pasadena: California Institute of Technology)

[10] Gao J S 2008 Ph. D. Dissertation (Pasadena: California Institute of Technology)

[11] Liu X, Guo W, Wang Y, Dai M, Wei L F, Dober B, McKenney C M, Hilton G C, Hubmay J, Austermann J E, Ullom J N, Gao J, Ullom J N 2017 Appl. Phys. Lett. 111 252601

Google Scholar

Google Scholar

[12] Guo W, Liu X, Wang Y, Wei Q, Wei L F, Hubmayr J, Fowler J, Ullom J, Vale L, Vissers M R, Gao J 2017 Appl. Phys. Lett. 110 212601

Google Scholar

Google Scholar

[13] 顾月, 官伯然 2019 微波学报 35 56

Google Scholar

Google Scholar

Gu Y, Guan B R 2019 J. Microwaves 35 56

Google Scholar

Google Scholar

[14] 毛军发, 夏彬 2020 微波学报 36 7

Google Scholar

Google Scholar

Mao J F, Xia B 2020 J. Microwaves 36 7

Google Scholar

Google Scholar

[15] Deng P H, Dai L C 2012 IEEE Trans. Microw. Theory Techn. 60 1520

Google Scholar

Google Scholar

[16] 周品嘉, 王轶文, 韦联福 2014 63 070701

Google Scholar

Google Scholar

Zhou P J, Wang Y W, Wei L F 2014 Acta Phys. Sin. 63 070701

Google Scholar

Google Scholar

[17] Li H J, Wang Y W, Wei L F, Zhou P J, Wei Q, Cao C H, Fang Y R, Yu Y, Wu P H 2013 China Sci. Bull. 58 2413

Google Scholar

Google Scholar

[18] Rainee N S 2001 Coplanar Waveguide Circuits, Components, and Systems (New York: Wiley) p2

[19] Pozar D M 2012 Microwave Engineering (4th ED) (New York: Wiley) p329

[20] Cha E, Wadefalk N, Nilsson P, Schleeh J, Moschetti G, Pourkabirian A, Tuzi S, Grahn J 2018 IEEE Trans. Microw. Theory Tech. 66 4860

Google Scholar

Google Scholar

[21] 李海杰 2013 硕士学位论文 (成都: 西南交通大学)

Li H J 2013 M. S. Thesis (Chengdu: Southwest Jiaotong University) (in Chinese)

-

图 8 测量线路, 其中DUT (device under test)表示测试样品, Attenuator为衰减器, LNA为低温低噪声放大器, Amplifier为功率放大器, VNA为矢量网络分析仪, PC为计算机[20]

Fig. 8. Measuring system. Here, DUT (device under test) means the tested sample, Attenuator is used to attenuated the measurement signals, LNA is low-temperature low-noise amplifier, Amplifier is for power amplification, VNA is the vector network analyzer, and PC is the computer[20].

表 1 共面波导型微波功分器的参数设计值

Table 1. Parameters of the designed coplanar waveguide microwave power divider.

特征

阻抗/$\Omega $椭圆积分

模数k中心导体

宽度S/μm中心导体与接地

距离W/μm$ 50 $ $ 0.458 $ $ 23 $ $ 13.5 $ $ 70.7 $ $ 0.2 $ $ 10 $ $ 20 $ 表 2 4—8 GHz射频信号测量系统指标分析

Table 2. Index analysis of the 4—8 GHz RF signal measurement system.

射频器件名称与指标 NF/dB Gain/dB 低温同轴固定衰减器1 $ < 1 $ $ -20 $ 低温同轴固定衰减器2 $ < 1 $ $ -20 $ 低温低噪声放大器 $ 0.03 $ $ 39 $ 功率放大器1 $ 3 $ $ 26 $ 微波线缆与隔离器 $ 4 $ $ -4 $ 合计 $ 18.5 $ $ 21 $ -

[1] 李春光, 王佳, 吴云, 王旭, 孙亮, 董慧, 高波, 李浩, 尤立星, 林志荣, 任浩, 李婧, 张文, 贺青, 王轶文, 韦联福, 孙汉聪, 王华兵, 李劲劲, 屈继峰 2021 70 018501

Google Scholar

Google Scholar

Li C G, Wang J, Wu Y, Wang X, Sun L, Dong H, Gao B, Li H, You L X, Lin Z R, Ren H, Li J, Zhang W, He Q, Wang Y W, Wei L F, Sun H C, Wang H B, Li J J, Qu J F 2021 Acta Phys. Sin. 70 018501

Google Scholar

Google Scholar

[2] Chen Y F, Hover D, Sendelbach S, Maurer L, Merkel S T, Pritchett E J, Wilhelm F K, McDermott R 2011 Phys. Rev. Lett. 107 217401

Google Scholar

Google Scholar

[3] Opremcak A, Pechenezhskiy I V, Howington C, Christensen B G, Beck M A, Leonard J E, Suttle J, Wilen C, Nesterov K N, Ribeill G J, Thorbeck T, Schlenker F, Vavilov M G, Plourde B L T, McDermott R 2018 Science 361 1239

Google Scholar

Google Scholar

[4] Day P, Leduc H, Mazin B, Vayonakis A, Zmuidzinas J 2003 Nature 425 817

Google Scholar

Google Scholar

[5] Yan Z G, Zhang Y R, Gong M, Wu Y L, Zheng Y R, Li S W, Wang C, Liang F T, Lin J, Xu Y, Guo C, Sun L H, Peng C Z, Xia K Y, Deng H, Rong H, You J Q, Franco N, Fan H, Zhu X B, Pan J W 2019 Science 364 753

Google Scholar

Google Scholar

[6] Gong M, Chen M C, Zheng Y R, Wang S Y, Zha C, Deng H, Yan Z G, Rong H, Wu Y L, Li S W, Chen F S, Zhao Y W, Liang F T, Lin J, Xu Y, Guo C, Sun L H, Anthony D C, Wang H H, Peng C Z, Lu C Y, Zhu X B, Pan J W 2019 Phys. Rev. Lett. 122 110501

Google Scholar

Google Scholar

[7] Ye Y S, Ge Z Y, Wu Y L, Wang S Y, Gong M, Zhang Y R, Zhu Q L, Yang R, Li S W, Liang F T, Lin J, Xu Y, Guo C, Sun L H, Cheng C, Nvsen M, Meng Z Y, Deng H, Rong H, Lu C Y, Peng C Z, Fan H, Zhu X B, Pan J W 2019 Phys. Rev. Lett. 123 050502

Google Scholar

Google Scholar

[8] 郑东宁 2021 70 018502

Google Scholar

Google Scholar

Zheng D L 2021 Acta Phys. Sin. 70 018502

Google Scholar

Google Scholar

[9] Mazin B 2004 Ph. D. Dissertation (Pasadena: California Institute of Technology)

[10] Gao J S 2008 Ph. D. Dissertation (Pasadena: California Institute of Technology)

[11] Liu X, Guo W, Wang Y, Dai M, Wei L F, Dober B, McKenney C M, Hilton G C, Hubmay J, Austermann J E, Ullom J N, Gao J, Ullom J N 2017 Appl. Phys. Lett. 111 252601

Google Scholar

Google Scholar

[12] Guo W, Liu X, Wang Y, Wei Q, Wei L F, Hubmayr J, Fowler J, Ullom J, Vale L, Vissers M R, Gao J 2017 Appl. Phys. Lett. 110 212601

Google Scholar

Google Scholar

[13] 顾月, 官伯然 2019 微波学报 35 56

Google Scholar

Google Scholar

Gu Y, Guan B R 2019 J. Microwaves 35 56

Google Scholar

Google Scholar

[14] 毛军发, 夏彬 2020 微波学报 36 7

Google Scholar

Google Scholar

Mao J F, Xia B 2020 J. Microwaves 36 7

Google Scholar

Google Scholar

[15] Deng P H, Dai L C 2012 IEEE Trans. Microw. Theory Techn. 60 1520

Google Scholar

Google Scholar

[16] 周品嘉, 王轶文, 韦联福 2014 63 070701

Google Scholar

Google Scholar

Zhou P J, Wang Y W, Wei L F 2014 Acta Phys. Sin. 63 070701

Google Scholar

Google Scholar

[17] Li H J, Wang Y W, Wei L F, Zhou P J, Wei Q, Cao C H, Fang Y R, Yu Y, Wu P H 2013 China Sci. Bull. 58 2413

Google Scholar

Google Scholar

[18] Rainee N S 2001 Coplanar Waveguide Circuits, Components, and Systems (New York: Wiley) p2

[19] Pozar D M 2012 Microwave Engineering (4th ED) (New York: Wiley) p329

[20] Cha E, Wadefalk N, Nilsson P, Schleeh J, Moschetti G, Pourkabirian A, Tuzi S, Grahn J 2018 IEEE Trans. Microw. Theory Tech. 66 4860

Google Scholar

Google Scholar

[21] 李海杰 2013 硕士学位论文 (成都: 西南交通大学)

Li H J 2013 M. S. Thesis (Chengdu: Southwest Jiaotong University) (in Chinese)

计量

- 文章访问数: 7472

- PDF下载量: 155

- 被引次数: 0

下载:

下载: