-

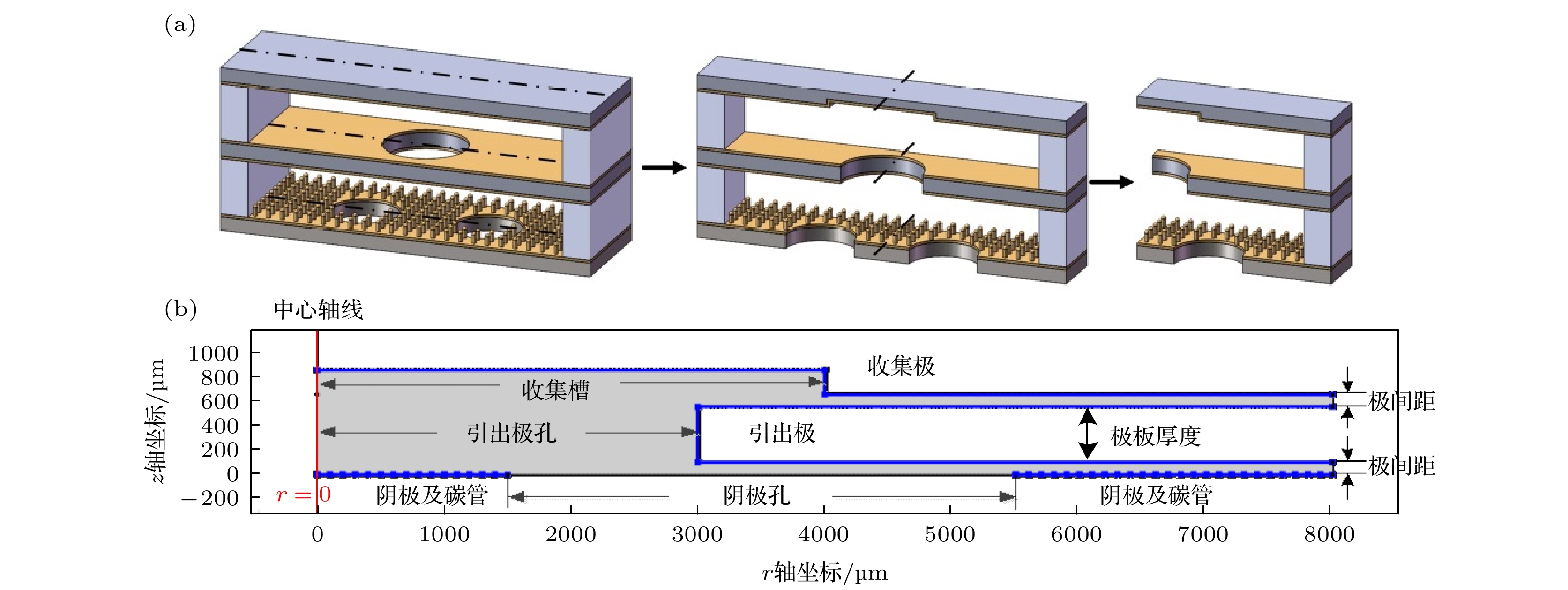

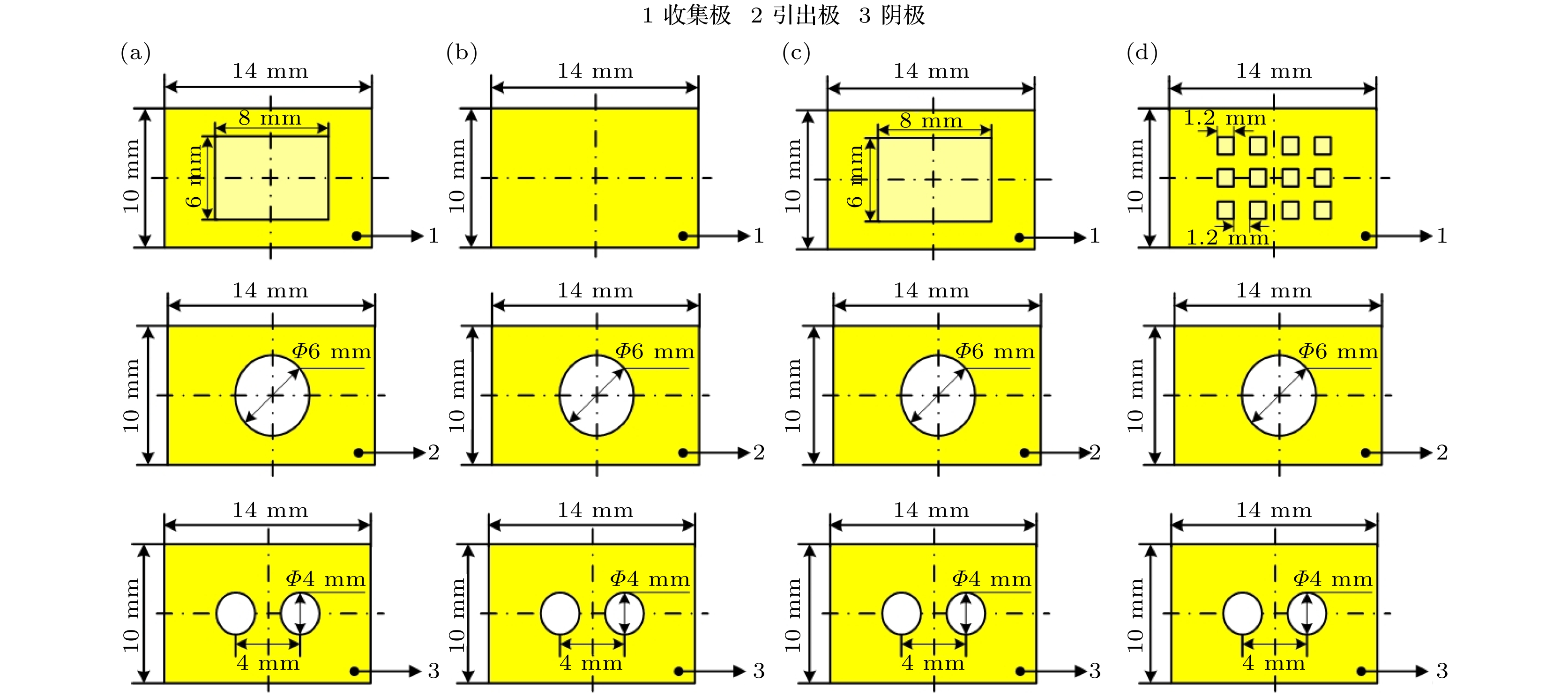

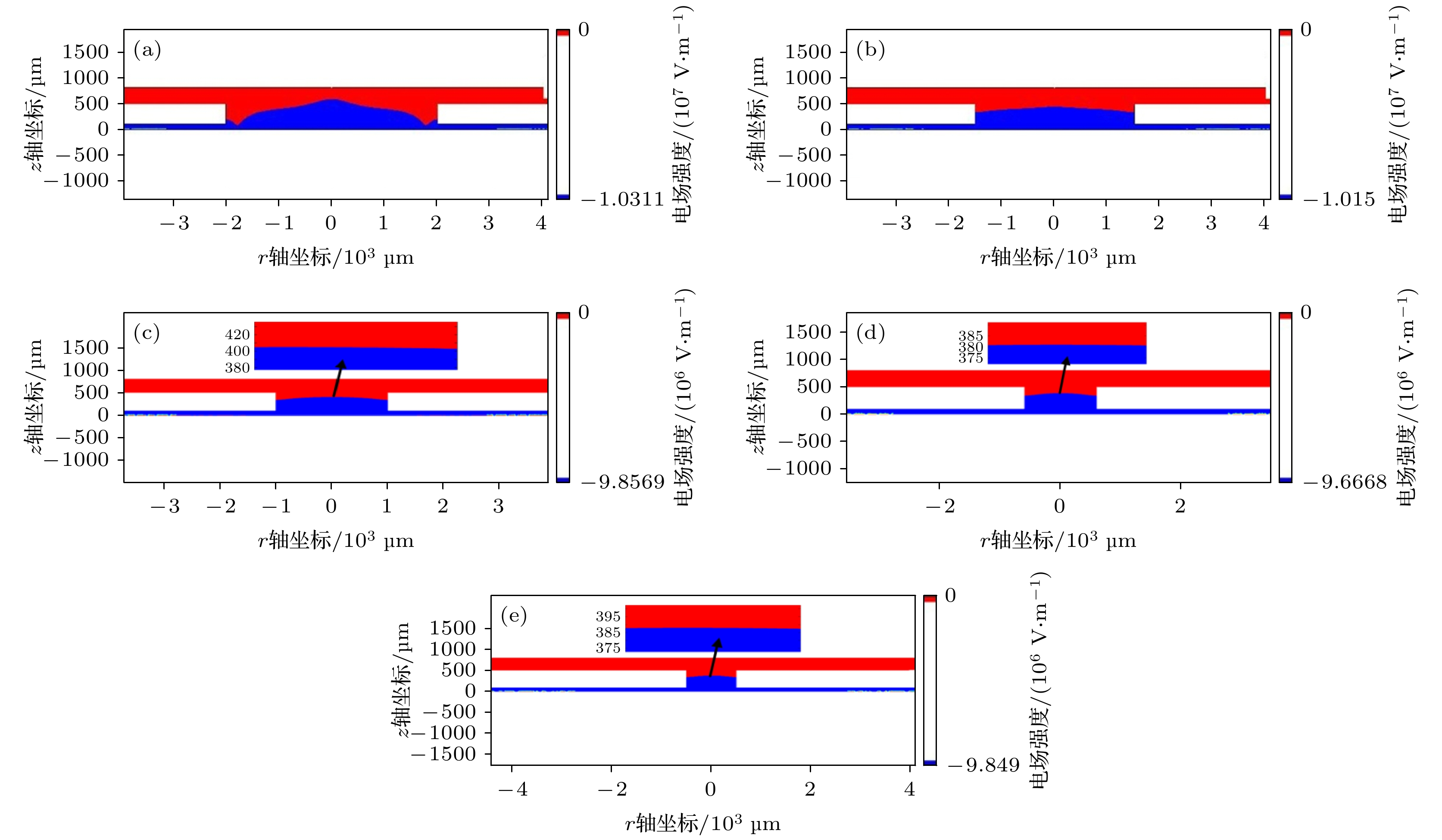

与常规电离式传感器相比, 碳纳米管三电极电离式气体传感器具有体积小、工作电压低的优势, 对智能电网、泛在物联网的发展具有重要作用, 但存在输出电流低、灵敏度低的缺点, 需要从结构上对其进行优化. 本文基于汤生放电原理, 采用COMSOL Multiphysics多物理场直接耦合分析软件, 建立了传感器二维等离子体放电流体仿真模型. 研究得到了8种不同结构的传感器, 在氮气背景中的静电场分布及传感器收集极平均电流密度. 通过对比不同结构参数下的电场强度及电流密度值, 得到了最优传感器结构. 结合仿真结果, 制备了8种优化结构的传感器进行实验验证, 最优传感器结构具有最高的收集电流密度, 与仿真结果一致, 证明了本文提出的结构优化方法的可行性. 基于最优结构, 制作了100和120 μm极间距的传感器, 获得了NO/SO2两组分混合气体的敏感特性. 与其他技术相比, 最优传感器的灵敏度比现有技术高1—2个数量级, 展示了三电极电离式碳纳米管传感器的应用潜力.

-

关键词:

- 流体模型 /

- 碳纳米管电离式传感器 /

- 结构优化 /

- 高灵敏度

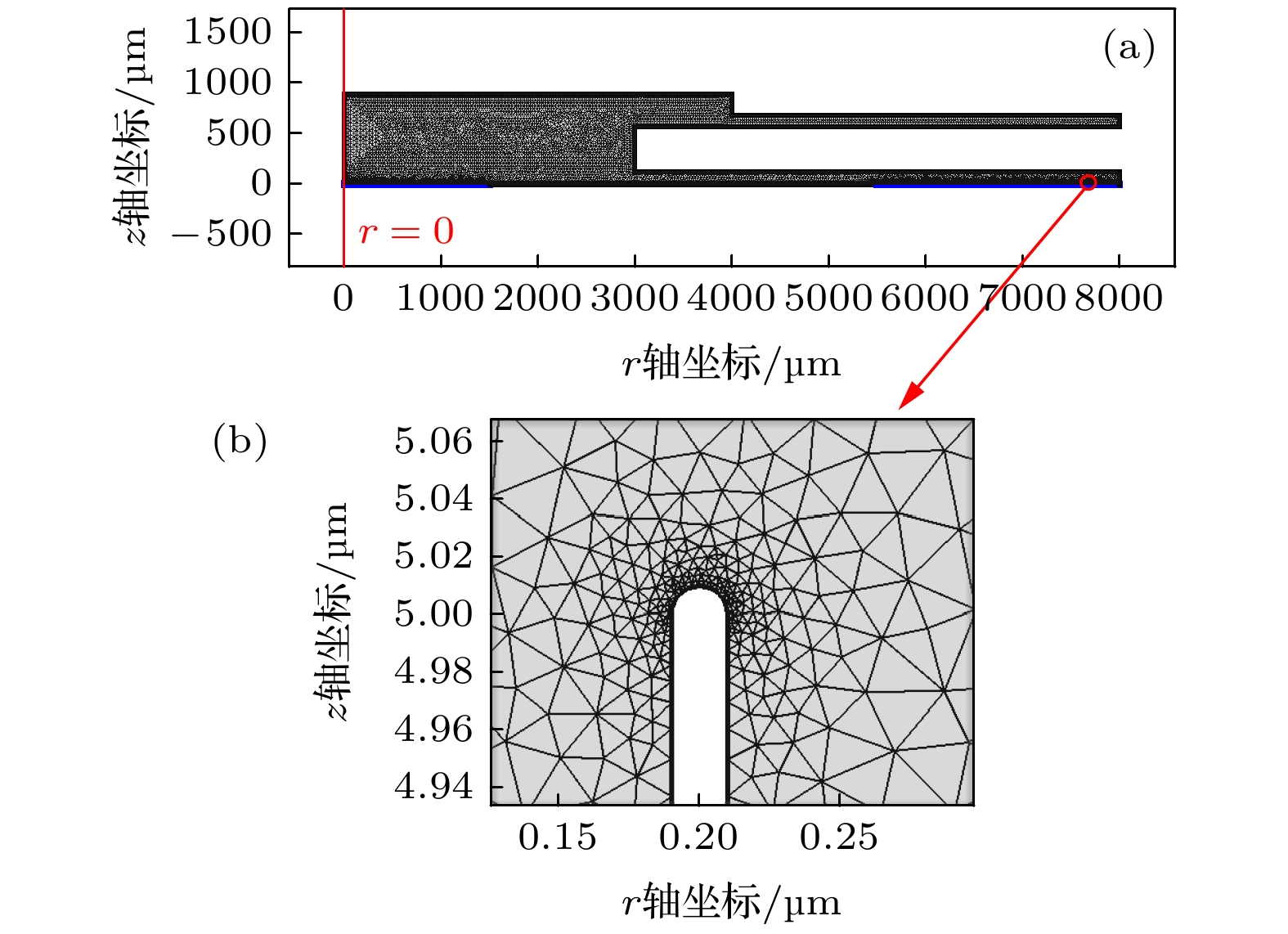

Compared with the traditional ionization sensor, triple electrode ionization gas sensor based on carbon nanotubes features excellent performances of small size and low operation voltage, and plays an important role in developing smart grids and the ubiquitous Internet of Things. However, they exhibit the disadvantages of small collecting current and low sensitivity, and need to be optimized in structure. Based on the Townsend discharge mechanism and three governing equations of particle mass conservation, electron energy conservation and Poisson equations, a two-dimensional plasma discharge fluid simulation model of the sensor is established by using the COMSOL Multiphysics software. According to gas composition, component concentration, structure of the sensor and voltage applied to the electrodes, we determine the chemical reaction, reaction rate coefficient, field control equation, initial values and boundary conditions. In order to calculate the interior distribution of charged particles inside the boundary, the inter-electrode space region is meshed. Initial values of mesh are set, such as a dense mesh of nano-meter length around the electrode having micro-nano structure, and a rough mesh of micro-meter length in the other region of inter-electrode space. The initial values of time-step are set for each mesh grid, and the discharge model of each mesh grid is numerically solved by the finite volume method. The three linkage governing equations are discretized and calculated iteratively in time and space, and the mesh values and time-steps are adjusted to make the results converged. The electrostatic field distribution and the average collecting current density of the eight kinds of sensors are obtained in the background gas of nitrogen. The optimal sensor structure is obtained by comparing the electric field intensities and current densities under different structure parameters. The eight kinds of the sensors are prepared for experimentally verifying the optimization method. The optimal structure of the 7# sensor has the highest collecting current density in the eight kind structures, which is consistent with the simulation results, and proves the feasibility of the structure optimization method proposed in the paper. Based on the optimal structure, the sensors, respectively with the electrode spacings of 100 and 120 μm, are fabricated, and the response characteristics of NO/SO2 mixture gas are obtained. Compared with other technologies, the sensor with optimal structure exhibits 1-2 orders of sensitivity higher than the others. The optimized triple electrode ionization sensor based on carbon nanotubes exhibits many potential applications.-

Keywords:

- fluid model /

- carbon nanotube based ionization sensor /

- structure optimization /

- high sensitivity

[1] Gomes J B A, Rodrigues J J P C, Rabelo R A L, Tanwar S, Al-Muhtadi J, Kozlov S 2020 Trans. Emerging Tel. Tech. 4 e3967

[2] Vijayalakshmi J, Puthilibhai G, Siddarth S R L 2019 Proceedings of the Third International Conference on I-SMAC Palladam, India, December 1–4, 2019 p778

[3] Mubin M H, Chaudhary K, Haider Z, Dabagh S, Ali J 2018 J. Comput. Theor. Nanosci. 15 1059

Google Scholar

Google Scholar

[4] Sun D J, Luo Y F, Debliquy M, Zhang C 2018 Beilstein J. Nanotechnol. 9 2832

Google Scholar

Google Scholar

[5] Zhang J, Jiang G P, Cumberland T, Xu P, Wu Y L, Delaat S, Yu A P, Chen Z W A 2019 InfoMat 1 234

Google Scholar

Google Scholar

[6] Wu M L, Shin J M, Hong Y, Jang D, Jin X S, Kwon H I, Lee J H 2018 Sens. Actuators, B 259 1058

Google Scholar

Google Scholar

[7] Sayago I, Terrado E, Lafuente E, Horrillo M C, Maser W K, Benito A M, Navarro R, Urriolabeitia E P, Martinez M T, Gutierrez J 2005 Synth. Met. 148 15

Google Scholar

Google Scholar

[8] Li C L, Su Y, Lv X Y, Xia H L, Wang Y J 2010 Sens. Actuators, B 149 427

Google Scholar

Google Scholar

[9] Zhang J Y, Zhang Y, Pan Z G, Yang S, Shi J H, Li S T, Min D M, Li X, Wang X H, Liu D X, Yang A J 2015 Appl. Phys. Lett. 107 093104

Google Scholar

Google Scholar

[10] Pan Z G, Zhang Y, Cheng Z Z, Liang B D, Zhang J Y, Li X, Wang X H, Liu D X, Yang A J, Rong M Z, Chen X W 2017 Sens. Actuators, B 245 183

Google Scholar

Google Scholar

[11] Pan Z G, Zhang Y, Cheng Z Z, Tong J M, Chen Q Y, Zhang J P, Zhang J X, Li X 2017 Sensors 17 473

Google Scholar

Google Scholar

[12] Zhang Y, Li S T, Zhang J Y, Pan Z G, Min D M, Li X, Song X P, Liu J H 2013 Sci. Rep. 3 1267

Google Scholar

Google Scholar

[13] Govardhan K, Narmada K, Grace N 2013 Proceedings of 2013 COMSOL Conference Bangalore, India, October 23–25, 2013 p182099

[14] Wilde J, Lai Y Q 2003 Microelectron. Reliab 43 345

Google Scholar

Google Scholar

[15] Atieh R K 2012 M. S. Thesis (Seri Iskandar: University Teknologi Petronas)

[16] Chivu N, Kahrizi M 2012 IEEE International Conference on Industrial Technology (ICIT) Athens, Greece, Match 19–21, 2013 p178

[17] Abdel-Salam M, Anis H, El-Morshedy A, Radwan R 2000 High-Voltage Engineering: Theory and Practice (New York: Dekker) pp11–120

[18] Sakiyama Y, Graves D B, Chang H W, Shimizu T, Morfill G E 2012 J. Phys. D: Appl. Phys. 45 425201

Google Scholar

Google Scholar

[19] Brunet H, RoccaSerra J 1985 J. Appl. Phys. 57 1574

Google Scholar

Google Scholar

[20] Guerra V, Sá P A, Loureiro J 2001 J. Phys. D.: Appl. Phys. 34 1745

Google Scholar

Google Scholar

[21] Zhao G B, Hu X D, Argyle M D, Radosz M 2004 Ind. Eng. Chem. Res. 43 5077

Google Scholar

Google Scholar

[22] Hagelaar G J M, Pitchford L C 2005 Plasma Sources Sci. Technol. 14 722

Google Scholar

Google Scholar

[23] Alphasense. NO-B1 Nitric Oxide Sensor NO Gas Sensor. https://www.isweek.com/Uploads/20160129/56ab1f1083efc.pdf

[24] City. NX1 CiTiceL Nitric Oxide Sensor NO Gas Sensor. https://www.citytech.com.cn/PDF-Datasheets/nx1.pdf.

[25] City Technology. 3SF CiTiceL Sulphur dioxide (SO2) Gas Sensor. http://www.citytech.com.cn/PDF-Datasheets/3sf.pdf.

[26] City Technology. 5SF CiTiceL Sulphur dioxide (SO2) Gas Sensor. http://www.citytech.com.cn/PDF-Datasheets/5sf.pdf.

[27] DD Scientific. GS+7SO2 Sulphur Dioxide Sensor (SO2). http://www.ddscientific.com/uploads/5/7/1/3/57136893/gs_7so2_datasheet.pdf.

-

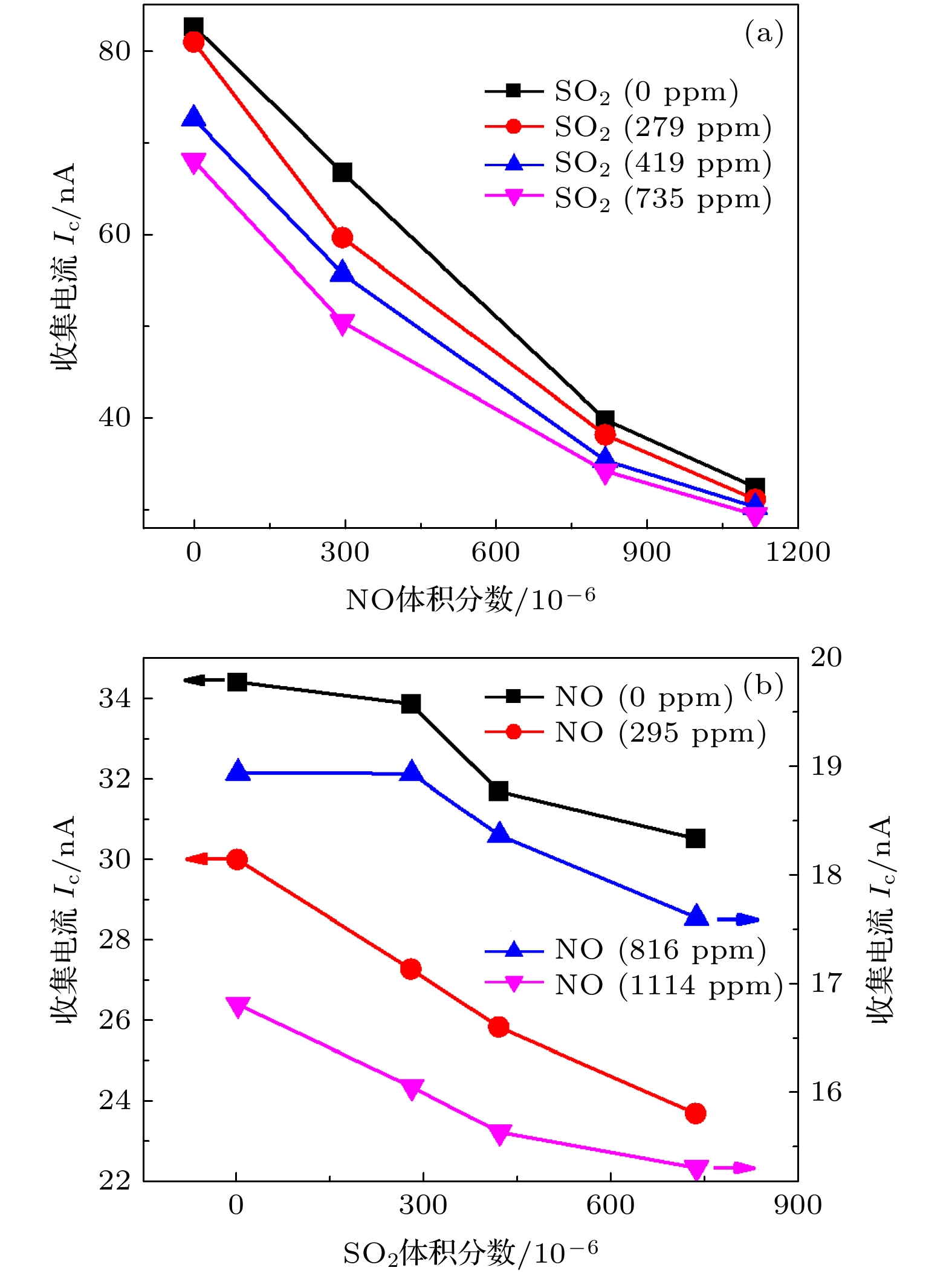

图 12 氮气背景NO和SO2混合气体敏感特性曲线 (a) 不同SO2的体积分数(1 ppm = 10–6)下100 μm极间距NO传感器收集电流与NO的体积分数的关系曲线; (b) 不同NO的体积分数下120 μm极间距SO2传感器收集电流与SO2的体积分数的关系曲线

Fig. 12. Sensitivity characteristic curves of the sensor array for measuring NO and SO2 mixture in nitrogen: (a) Collecting currents of the NO sensor with the electrode spacing of 100 μm versus volume fraction of NO under different volume fractions of SO2; (b) collecting currents of the SO2 sensor with the electrode spacing of 120 μm versus volume fraction of SO2 under different volume fractions of NO.

表 1 仿真建模参数

Table 1. Parameters of the simulation model.

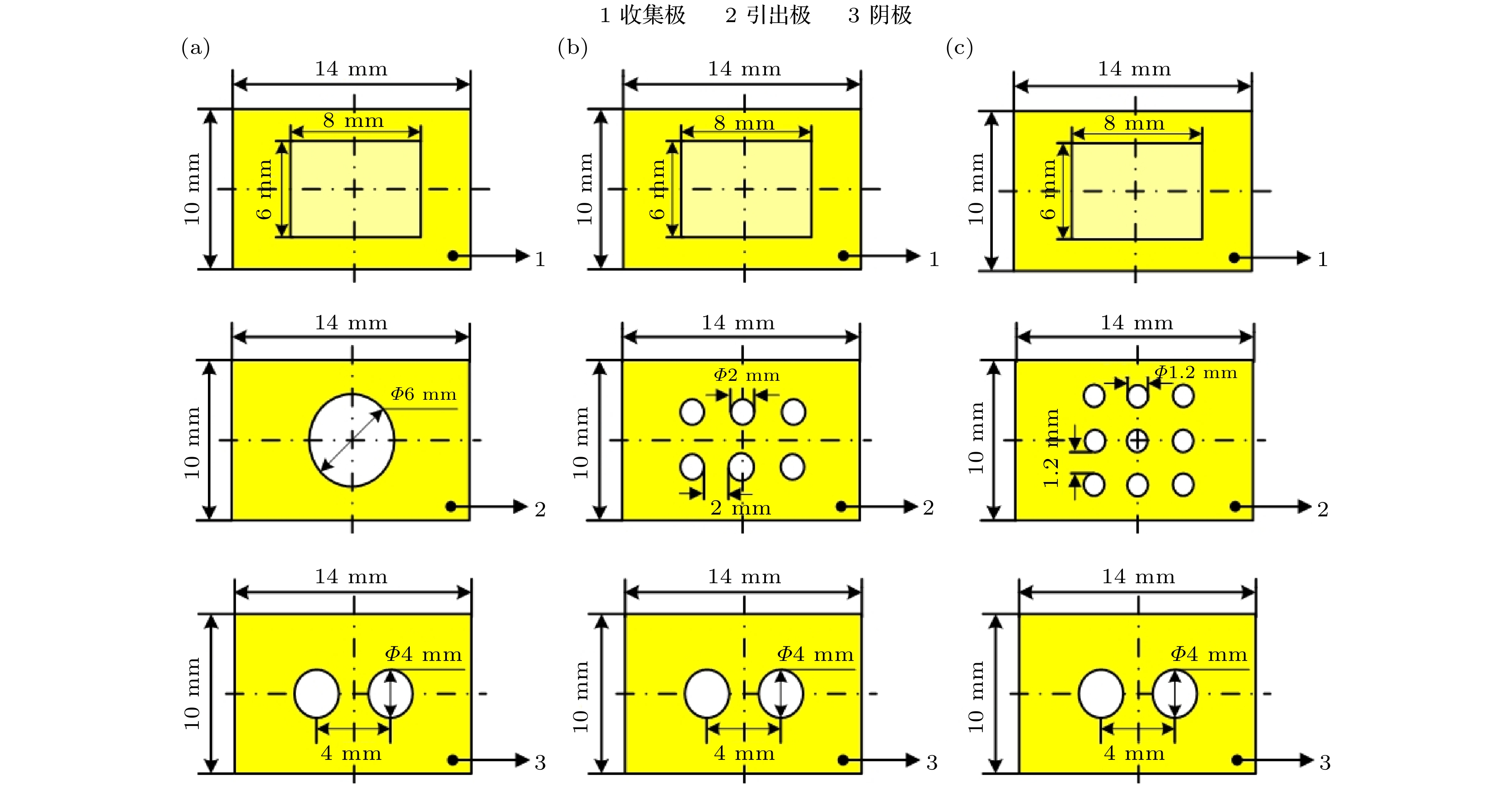

d/μm Ue/V Uc/V 极板厚度/μm 收集极槽参数 引出极孔半径/mm 阴极孔半径/mm 碳纳米管参数 数值 100 100 1 450 6 mm × 8 mm,

200 μm深3 2 长: 5 μm, 尖端半径:

10 nm, 间距: 200 nm表 2 网格剖分尺寸

Table 2. Mesh size of the model.

整体区域 阴极碳纳米管边界 阴极非碳纳米管边界 引出极、收集极边界 最大单元尺寸/μm 40 0.5 20 30 最小单元尺寸/μm 10 0.001 20 30 最大单元生长率 1.25 1.25 — — 曲率解析度 0.25 0.2 — — 狭窄区域解析度 1 1 — — 表 3 气体电离流体仿真模型的区域反应

Table 3. Regional reactions of the fluid simulation model on gas ionization.

类型 序号 反应式 反应率系数k/(m3·s–1) 参考文献 电子碰撞 R1 e + N2 → e + N2 f(Te) [18] R2 e + N2 → e + $ {\rm{N}}_{2}\left({\rm{A}}^{3}\Sigma _{\rm{u}}^{+}\right) $ f(Te) [18] R3 e + N2 → e + $ {\rm{N}}_{2}\left({\rm{a'}}^{1}\Sigma _{\rm{u}}^{-}\right) $ f(Te) [18] R4 e + N2 → 2e +$ {\rm{N}}_{2}^{+} $ f(Te) [18] R5 e +$ {\rm{N}}_{4}^{+} $ → N2 + N2 4.73 × 10–11/(Te0.53) [18] R6 e + N2 + $ {\rm{N}}_{2}^{+} $ → 2N2 3.12 × 10–35/Te1.5 [18] R7 e + e +$ {\rm{N}}_{2}^{+} $ → N2 1 × 10–31 × (Tg/Te)4.5 [18] 重粒子反应 R8 $ {\rm{N}}_{2}\left({\rm{A}}^{3}\Sigma _{\rm{u}}^{+}\right) $ + $ {\rm{N}}_{2}\left({\rm{a'}}^{1}\Sigma _{\rm{u}}^{-}\right) $ → e + N2 +$ {\rm{N}}_{2}^{+} $ 5.0 × 10–17 [19] R9 $ {\rm{N}}_{2}\left({\rm{a'}}^{1}\Sigma _{\rm{u}}^{-}\right) $ + $ {\rm{N}}_{2}\left({\rm{a'}}^{1}\Sigma _{\rm{u}}^{-}\right) $ → e + N2 +$ {\rm{N}}_{2}^{+} $ 2.0 × 10–16 [19] R10 $ {\rm{N}}_{2}\left({\rm{A}}^{3}\Sigma _{\rm{u}}^{+}\right) $ + $ {\rm{N}}_{2}\left({\rm{a'}}^{1}\Sigma _{\rm{u}}^{-}\right) $ → e + $ {\rm{N}}_{4}^{+} $ 5.0 × 10–17 [20] R11 $ {\rm{N}}_{2}\left({\rm{a'}}^{1}\Sigma _{\rm{u}}^{-}\right) $ + $ {\rm{N}}_{2}\left({\rm{a'}}^{1}\Sigma _{\rm{u}}^{-}\right) $ → e + $ {\rm{N}}_{4}^{+} $ 2.0 × 10–16 [20] R12 $ {\rm{N}}_{2}\left({\rm{A}}^{3}\Sigma _{\rm{u}}^{+}\right) $ + N2 → N2 + N2 3.0 × 10–22 [19] R13 $ {\rm{N}}_{2}\left({\rm{a'}}^{1}\Sigma _{\rm{u}}^{-}\right) $+ N2 → N2 + N2 2.3 × 10–19 [21] R14 $ {\rm{N}}_{2}^{+} $ + N2 + N2 → $ {\rm{N}}_{4}^{+} $ + N2 1 × 10–41 × (300/Te) [18] R15 $ {\rm{N}}_{4}^{+} $ + N2 → $ {\rm{N}}_{2}^{+} $ + N2 + N2 2.1 × 10–16exp(Tg/121) [18] 表 4 电极表面化学反应

Table 4. Chemical reactions on the electrode surface

序号 表面化学反应 碳纳米管

材料边界其他电

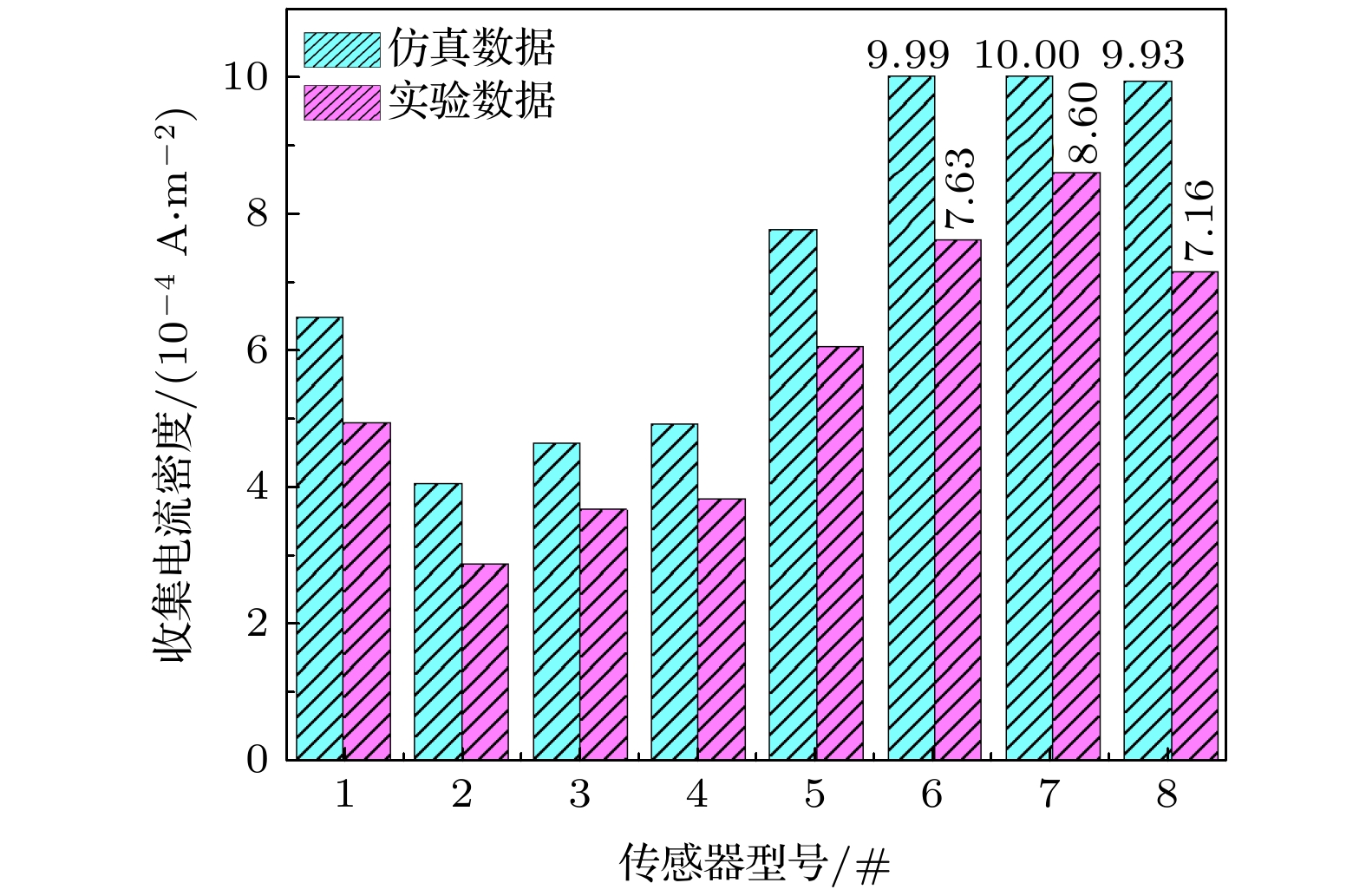

极边界γe εr/eV γe εr/eV 1 ${\rm{N} }_{2}\big({\rm{A} }^{3}\Sigma _{\rm{u} }^{+}\big)$ + 电极 → N2 0 0 0 0 2 ${\rm{N} }_{2}\big({\rm{a'} }^{1}\Sigma _{\rm{u} }^{-}\big)$ + 电极 → N2 0 0 0 0 3 $ {\rm{N}}_{2}^{+} $ + 电极 → N2 0.2 2 0 0 4 $ {\rm{N}}_{4}^{+} $+ 电极 → 2N2 0.2 2 0 0 表 5 4种不同收集极结构的传感器的仿真放电参数

Table 5. Simulation discharge parameters of the four sensors with different collecting electrode structures.

传感器

型号电子浓

度/m–3正离子

浓度/m–3平均收集电流

密度/(A·m–2)1 4.88 × 1011 9.30 × 1013 6.50 × 10-4 2 3.32 × 1011 4.85 × 1013 4.09 × 10-4 3 4.36 × 1011 6.10 × 1013 4.67 × 10-4 4 4.61 × 1011 6.29 × 1013 4.96 × 10-4 表 6 3种不同引出极结构的传感器的仿真放电参数

Table 6. Simulation discharge parameters of the three sensors with different extracting electrode structures.

传感器

型号电子浓

度/m–3正离子

浓度/m–3平均收集电流

密度/(A·m–2)1 4.88 × 1011 9.30 × 1013 6.50 × 10–4 5 6.87 × 1011 1.12 × 1014 7.77 × 10–4 6 2.15 × 1012 3.25 × 1014 9.99 × 10–4 表 7 3种不同阴极结构的传感器的仿真放电参数

Table 7. Simulation discharge parameters of the sensors with three different cathode structures.

传感器

型号电子浓

度/m–3正离子浓

度/m–3平均收集电流

密度/(A·m–2)6 2.15 × 1012 3.25 × 1014 9.99 × 10–4 7 2.28 × 1012 3.67 × 1014 1.00 × 10–3 8 1.99 × 1012 3.09 × 1014 9.93 × 10–4 表 8 传感器阵列测量NO和SO2两组分混合气体的实验条件

Table 8. Experimental conditions of NO and SO2 mixtures detection with a sensor array.

实验条件 NO传感器 SO2传感器 极间距/μm 100 120 阴极电压/V 0 引出极电压/V 150 收集极电压/V 10 NO体积分数 0—1114 × 10–6 SO2体积分数 0—735 × 10–6 表 9 碳纳米管三电极传感器与现有NO, SO2传感器的性能对比

Table 9. Performance comparison of carbon nanotube based triple electrode sensors with the existing NO and SO2 sensors.

-

[1] Gomes J B A, Rodrigues J J P C, Rabelo R A L, Tanwar S, Al-Muhtadi J, Kozlov S 2020 Trans. Emerging Tel. Tech. 4 e3967

[2] Vijayalakshmi J, Puthilibhai G, Siddarth S R L 2019 Proceedings of the Third International Conference on I-SMAC Palladam, India, December 1–4, 2019 p778

[3] Mubin M H, Chaudhary K, Haider Z, Dabagh S, Ali J 2018 J. Comput. Theor. Nanosci. 15 1059

Google Scholar

Google Scholar

[4] Sun D J, Luo Y F, Debliquy M, Zhang C 2018 Beilstein J. Nanotechnol. 9 2832

Google Scholar

Google Scholar

[5] Zhang J, Jiang G P, Cumberland T, Xu P, Wu Y L, Delaat S, Yu A P, Chen Z W A 2019 InfoMat 1 234

Google Scholar

Google Scholar

[6] Wu M L, Shin J M, Hong Y, Jang D, Jin X S, Kwon H I, Lee J H 2018 Sens. Actuators, B 259 1058

Google Scholar

Google Scholar

[7] Sayago I, Terrado E, Lafuente E, Horrillo M C, Maser W K, Benito A M, Navarro R, Urriolabeitia E P, Martinez M T, Gutierrez J 2005 Synth. Met. 148 15

Google Scholar

Google Scholar

[8] Li C L, Su Y, Lv X Y, Xia H L, Wang Y J 2010 Sens. Actuators, B 149 427

Google Scholar

Google Scholar

[9] Zhang J Y, Zhang Y, Pan Z G, Yang S, Shi J H, Li S T, Min D M, Li X, Wang X H, Liu D X, Yang A J 2015 Appl. Phys. Lett. 107 093104

Google Scholar

Google Scholar

[10] Pan Z G, Zhang Y, Cheng Z Z, Liang B D, Zhang J Y, Li X, Wang X H, Liu D X, Yang A J, Rong M Z, Chen X W 2017 Sens. Actuators, B 245 183

Google Scholar

Google Scholar

[11] Pan Z G, Zhang Y, Cheng Z Z, Tong J M, Chen Q Y, Zhang J P, Zhang J X, Li X 2017 Sensors 17 473

Google Scholar

Google Scholar

[12] Zhang Y, Li S T, Zhang J Y, Pan Z G, Min D M, Li X, Song X P, Liu J H 2013 Sci. Rep. 3 1267

Google Scholar

Google Scholar

[13] Govardhan K, Narmada K, Grace N 2013 Proceedings of 2013 COMSOL Conference Bangalore, India, October 23–25, 2013 p182099

[14] Wilde J, Lai Y Q 2003 Microelectron. Reliab 43 345

Google Scholar

Google Scholar

[15] Atieh R K 2012 M. S. Thesis (Seri Iskandar: University Teknologi Petronas)

[16] Chivu N, Kahrizi M 2012 IEEE International Conference on Industrial Technology (ICIT) Athens, Greece, Match 19–21, 2013 p178

[17] Abdel-Salam M, Anis H, El-Morshedy A, Radwan R 2000 High-Voltage Engineering: Theory and Practice (New York: Dekker) pp11–120

[18] Sakiyama Y, Graves D B, Chang H W, Shimizu T, Morfill G E 2012 J. Phys. D: Appl. Phys. 45 425201

Google Scholar

Google Scholar

[19] Brunet H, RoccaSerra J 1985 J. Appl. Phys. 57 1574

Google Scholar

Google Scholar

[20] Guerra V, Sá P A, Loureiro J 2001 J. Phys. D.: Appl. Phys. 34 1745

Google Scholar

Google Scholar

[21] Zhao G B, Hu X D, Argyle M D, Radosz M 2004 Ind. Eng. Chem. Res. 43 5077

Google Scholar

Google Scholar

[22] Hagelaar G J M, Pitchford L C 2005 Plasma Sources Sci. Technol. 14 722

Google Scholar

Google Scholar

[23] Alphasense. NO-B1 Nitric Oxide Sensor NO Gas Sensor. https://www.isweek.com/Uploads/20160129/56ab1f1083efc.pdf

[24] City. NX1 CiTiceL Nitric Oxide Sensor NO Gas Sensor. https://www.citytech.com.cn/PDF-Datasheets/nx1.pdf.

[25] City Technology. 3SF CiTiceL Sulphur dioxide (SO2) Gas Sensor. http://www.citytech.com.cn/PDF-Datasheets/3sf.pdf.

[26] City Technology. 5SF CiTiceL Sulphur dioxide (SO2) Gas Sensor. http://www.citytech.com.cn/PDF-Datasheets/5sf.pdf.

[27] DD Scientific. GS+7SO2 Sulphur Dioxide Sensor (SO2). http://www.ddscientific.com/uploads/5/7/1/3/57136893/gs_7so2_datasheet.pdf.

计量

- 文章访问数: 8343

- PDF下载量: 97

- 被引次数: 0

下载:

下载: