-

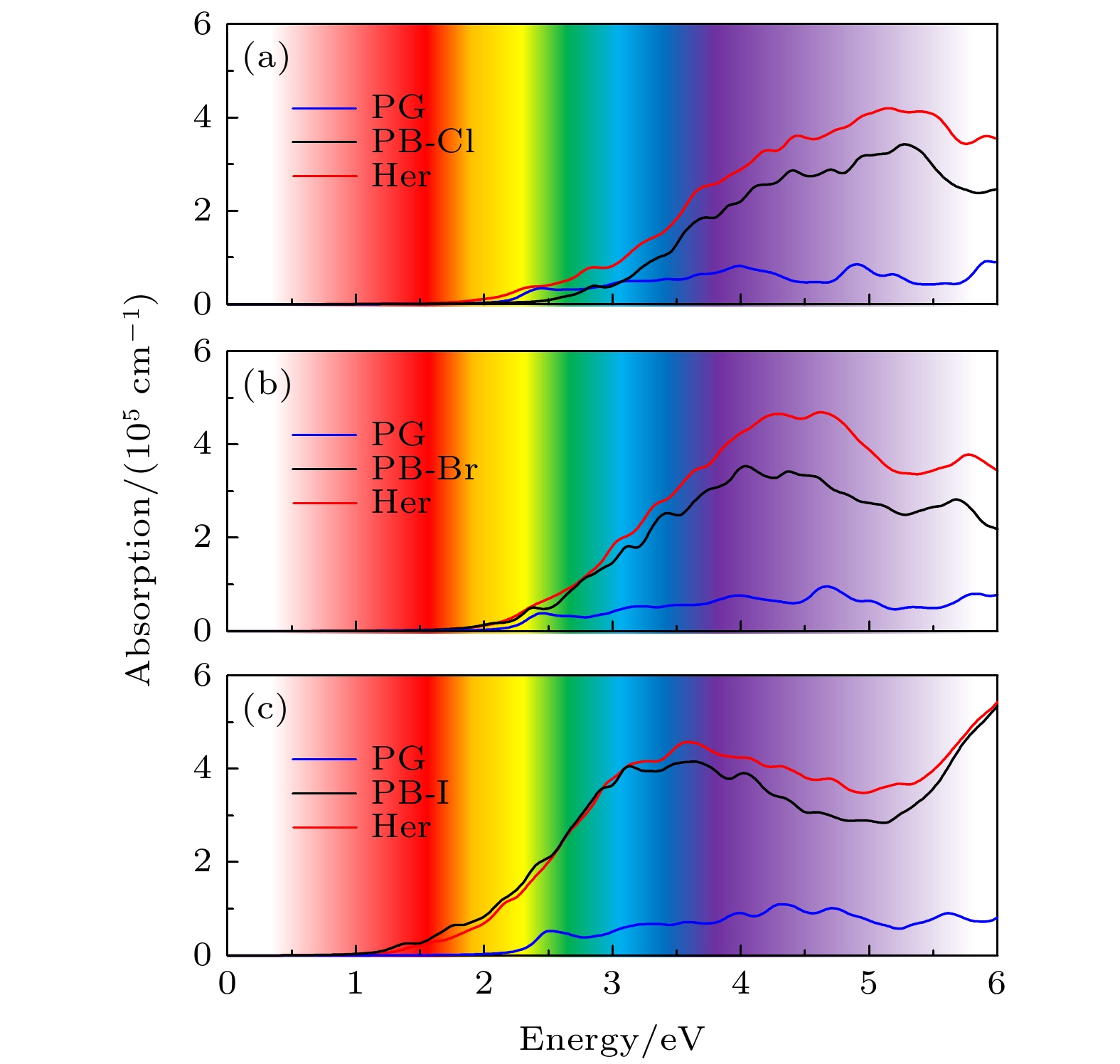

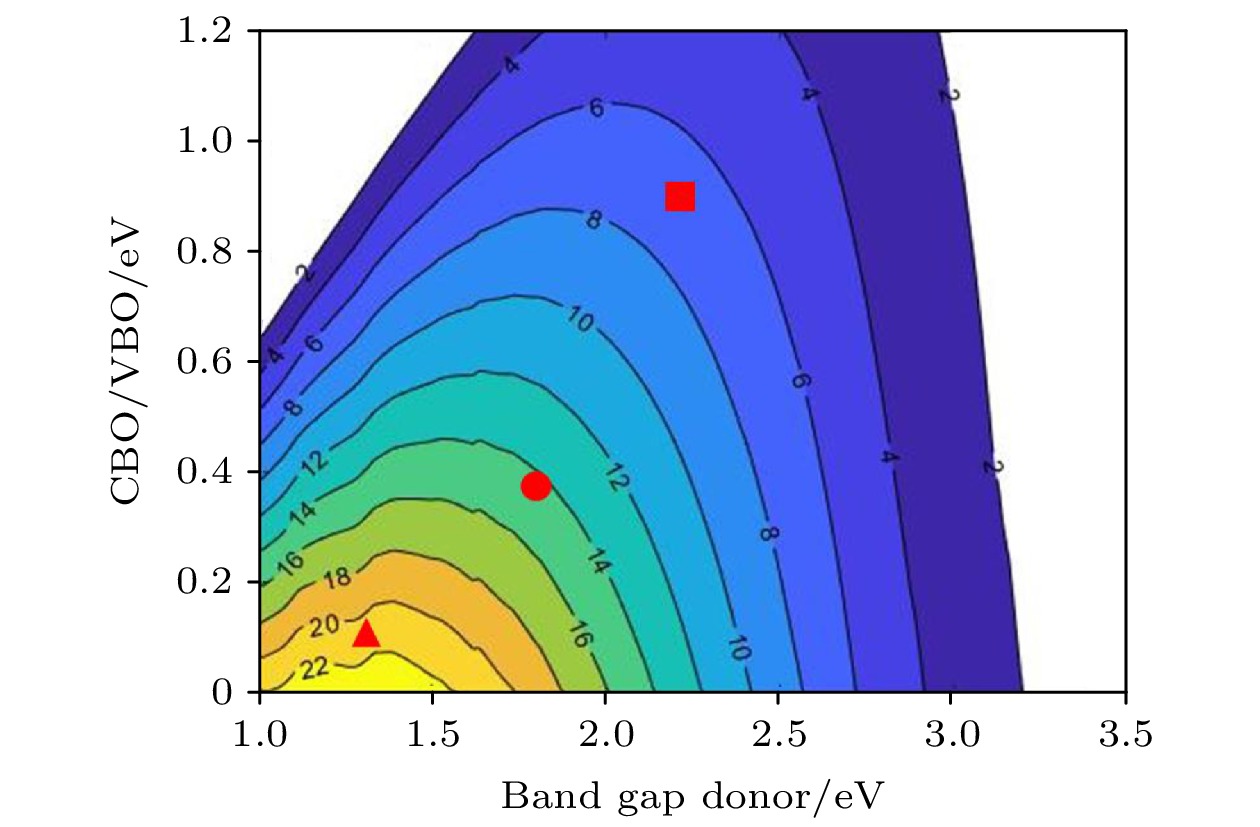

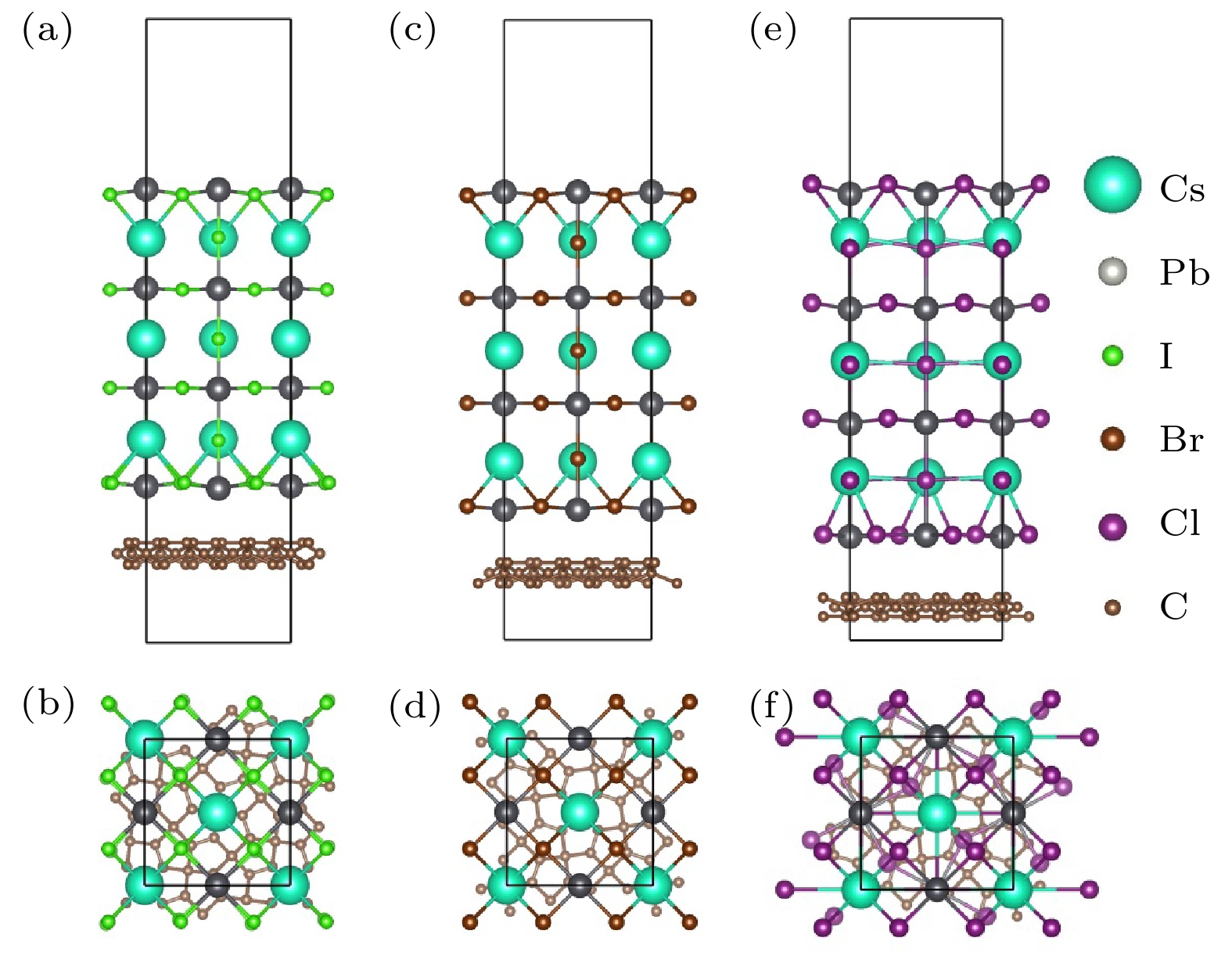

异质结工程是一种提高半导体材料光电性能的有效方法. 本文构建了全无机钙钛矿CsPbX3 (X=Cl, Br, I)和二维五环石墨烯penta-graphene (PG)的新型范德瓦耳斯(vdW)异质结, 利用第一性原理研究了CsPbX3-PG异质结不同界面接触的稳定性, 进而计算了稳定性较好的Pb-X接触界面异质结的电子结构和光电性能. 研究结果表明, CsPbX3-PG (X=Cl, Br, I)异质结具有II型能带排列特征, 能级差距由Cl向I逐渐缩小, 具有良好的光生载流子分离能力和电荷输运性质. 此外, 研究发现CsPbX3-PG异质结能有效拓宽材料的光吸收谱范围, 并能显著提高其光吸收能力, 尤其是CsPbI3具有最优的光吸收性能. 经理论估算, CsPbX3-PG的光电功率转换效率(PCE)可高达21%. 这些结果表明, 全无机金属卤化物钙钛矿CsPbX3-PG异质结可以有效地提高半导体材料的光电性能, 预期在光电转换器件中具有重要的应用潜力.Heterostructure engineering is an effective strategy to improve the optoelectronic properties of semiconductor materials. We propose a van der Waals (vdW) heterostructure based on perovskite CsPbX3 (X = Cl, Br, I) and two-dimensional penta-graphene (PG), and investigate the stabilities of two kinds of interface contacts (Pb-X and Cs-X) by first-principles calculations. And we also study the electronic structures and optoelectronic properties of CsPbX3-PG heterostructures with stabler Pb-X interface. Our results show that all the CsPbX3 (X = Cl, Br, I)-PG heterostructures possess the type-II band arrangement, that the energy level gap is gradually narrowed from Cl to I, and that there are good photogenerated carrier separation ability and charge transport property. Moreover, the absorption spectrum of CsPbX3-PG heterostructures can be broadened and the optical absorption ability is effectively improved. The power conversion efficiency (PCE) of CsPbX3-PG can increase up to 21% given by theoretical estimation. These results indicate that the optoelectronic properties of the all-inorganic metal halide perovskite CsPbX3-PG heterostructures can be effectively improved, which would become a potential candidate for high-performance photoelectric conversion devices.s.

-

Keywords:

- perovskite CsPbX3 /

- penta-graphene /

- van der Waals heterostructure /

- optoelectronic property

[1] Liu B, Long M Q, Cai M Q, Ding L M, Yang J L 2019 Nano Energy 59 715

Google Scholar

Google Scholar

[2] Afsaria M, Boochanib A, Hantezadehaa M 2016 Optik 127 11433

Google Scholar

Google Scholar

[3] Kang Yo, Han S 2018 Phys. Rev. Appl. 10 044013

Google Scholar

Google Scholar

[4] Ball J M, Lee M M, Hey A, Snaith H J 2013 Energy Environ. Sci. 6 1739

Google Scholar

Google Scholar

[5] Yang W S, Noh J H, Jeon N J, Kim Y C, Ryu S, Seo J, Seok S Ⅱ 2015 Science 348 1234

Google Scholar

Google Scholar

[6] Sahli F, Werner J, Kamino B, Bräuninger M 2018 Nat. Mater. 17 820

Google Scholar

Google Scholar

[7] Yang Y, You J B 2017 Nature 544 155

Google Scholar

Google Scholar

[8] Rahman M Z, Edvinsson T 2019 Matter 1 562

Google Scholar

Google Scholar

[9] Diao X F, Tang Y L, Xie Q 2019 Chin. Phys. B 28 017802

Google Scholar

Google Scholar

[10] Feng X X, Liu B, Long M Q, Cai M Q, Peng Y Y, Yang J L 2020 J. Phys. Chem. Lett. 11 6266

Google Scholar

Google Scholar

[11] 陆新荣, 赵颖, 刘建, 李承辉, 游效曾 2015 无机化学学报 31 1678

Google Scholar

Google Scholar

Lu X R, Zhao Y, Liu J, Li C H, You X Z 2015 Chin. J. Inorg. Chem. 31 1678

Google Scholar

Google Scholar

[12] 李少华, 李海涛, 江亚晓, 涂丽敏, 李文标, 潘玲, 杨仕娥, 陈永生 2018 67 158801

Google Scholar

Google Scholar

Li SH, Li HT, Jiang YX, Tu LM, Li WB, Pan L, Yang SE, ChenYS 2018 Acta Phys. Sin. 67 158801

Google Scholar

Google Scholar

[13] Swarnkar A, Marshall A R, Sanehira E M, Chernomordik B D, Moore D T, Christians J A, Chakrabarti T, Luther J M 2016 Science 354 92

Google Scholar

Google Scholar

[14] Wang Y, Dar M I, Ono L K, Zhang TY, Kan M, Li YW, Zhang LJ, Wang XT, Yang YG, Gao X Y, Qi Y B, Gratzel M, Zhao Y X 2019 Science 365 591

Google Scholar

Google Scholar

[15] Antonio D B 2020 Nanomaterials 10 579

Google Scholar

Google Scholar

[16] Novoselov K S, Mishchenko A, Carvalho A, Castro Neto A H 2016 Science 353 6298

Google Scholar

Google Scholar

[17] Wen Y, He P, YaoY Y, Zhang Y, Cheng R Q, Yin L, Li N N, Li J, Wang J J, Wang Z X, Liu C S, Fang X, Jiang C, Wei Z P, He J 2020 Adv. Mater. 32 1906874

Google Scholar

Google Scholar

[18] Yao M L, Wu T, Liu B, Li J L, Long M Q 2020 Phys. Lett. A 384 126614

Google Scholar

Google Scholar

[19] Liu X F, Luo Z J, Zhou X, Wei J M, Wang Y, Guo X, Lv B, Ding Z 2019 Chin. Phys. B 28 086105

Google Scholar

Google Scholar

[20] Sun J, Lee H W, Pasta M, Yuan H, Sun Q C, Wang G Q 2015 Nat. Nanotechnol. 10 980

Google Scholar

Google Scholar

[21] Hong X, Kim J, Shi S F, Zhang Y, Jin C, Sun Y, Tongay S, Wu J, Zhang Y, Wang F 2014 Nat. Nanotechnol. 9 682

Google Scholar

Google Scholar

[22] 郭丽娟, 胡吉松, 马新国, 项炬 2019 68 097101

Google Scholar

Google Scholar

Guo L J, Hu J S, Ma X G, Xiang J 2019 Acta Phys. Sin. 68 097101

Google Scholar

Google Scholar

[23] Chen B, Yu Z S, Liu K, Huang J S 2019 Joule 3 177

Google Scholar

Google Scholar

[24] Cao Y H, Li Y F, He J W, Qian C X, Zhang Q, Bai JT, Feng H J 2019 Adv. Mater. Interfaces 6 1901330

Google Scholar

Google Scholar

[25] Liu B, Long MQ, Cai MQ, Ding LM, Yang JL 2018 Appl. Phys. Lett. 112 043901

[26] Cao Y H, Deng Z Y, Wang M Z, Bai J T, Wei S H, Feng H J 2018 J. Phys. Chem. C 122 17228

Google Scholar

Google Scholar

[27] Chao F, Xu X, Yang K, Jiang F, Wang S Y, Zhang Q L 2018 Adv. Mater. 30 1804707

Google Scholar

Google Scholar

[28] Hu J S, Ji G P, Ma X G, Huang C Y 2018 Appl. Surf. Sci. 440 35

Google Scholar

Google Scholar

[29] Cao Y H, Bai J T, Feng H J 2020 Chin.Phys. Lett. 37 107301

Google Scholar

Google Scholar

[30] Zhang S H, Zhou J, Wang Q, Chen X S, Kawazoe Y, Jena P 2015 Nat. Acad. Sci. 112 2372

Google Scholar

Google Scholar

[31] Bravo S, Correa J, Chico L, Pacheco M 2018 Sci.Rep. 8 11070

Google Scholar

Google Scholar

[32] Wang Z, Dong F, Shen B, Zhang R J, Zheng Y X, Chen L Y, Wang S Y, Wang C Z, Ho K M, Fan Y J, Jin B Y, Su W S 2016 Carbon 101 77

Google Scholar

Google Scholar

[33] Wu T, Yao M Y, Li J L, Li M J, Long M Q 2020 Results Phys. 17 103103

Google Scholar

Google Scholar

[34] Xiao B, Li YC, Yu X F, Cheng J B 2016 ACS Appl. Mater. Interfaces 8 35342

Google Scholar

Google Scholar

[35] Wu X F, Varshney V, Lee J, Zhang T, Wohlwend J L, Roy A K, Luo T F 2016 Nano Lett. 16 3925

Google Scholar

Google Scholar

[36] 陈天航, 潘风明, 肖扬, 袁佳仁, 刘进超, 曹浩 2018 原子与分子 35 613

Google Scholar

Google Scholar

Chen T H, Pan F M, Xiao Y, Yuan J R, Liu J C, Cao H 2018 J. At. Mol. Phys. 35 613

Google Scholar

Google Scholar

[37] Naseri M, Lin S, Jalilian J, Gu J, Chen Z 2018 Front. Phys. 13 138102

Google Scholar

Google Scholar

[38] Yuan H, Li Z, Yang J 2018 J. Mater. Chem. C 6 9055

Google Scholar

Google Scholar

[39] Yu J, Kuang X F, Gao Y J, Wang Y P, Chen K Q, Ding Z K, Liu J, Cong C X, He J, Liu Z W, Liu Y P 2020 Nano Lett. 20 1172

Google Scholar

Google Scholar

[40] Zhao LS, Wang Y, Chen C P, Liu L L, Yu H X, Zhang Y, Chen Y, Wang X C 2017 Phys. E 91 82

Google Scholar

Google Scholar

[41] Zhao H, Peng D D, He J, Li X M, Long M Q 2018 Chin. Phys. B 27 108504

Google Scholar

Google Scholar

[42] Pan C N, Long M Q, He J 2018 Chin. Phys. B 27 068101

Google Scholar

Google Scholar

[43] Han B X, Zhang H 2019 Chin. Phys. B 28 067301

Google Scholar

Google Scholar

[44] Kang J, Li J, Li S S, Xia J B, Wang L W 2013 Nano Lett. 13 5485

Google Scholar

Google Scholar

[45] Peng Q, Wang Z, Sa B, Wu B, Sun Z 2016 Sci. Rep. 6 3199

[46] Xia C, Xue B, Wang T, Peng Y, Jia Y 2015 Appl. Phys. Lett. 107 193107

Google Scholar

Google Scholar

[47] Butler K T, Frost J M, Walsh A 2015 Mater. Horiz. 2 228

Google Scholar

Google Scholar

[48] Ravi V K, Markad G B, Nag A 2016 ACS Energy Lett. 1 665

Google Scholar

Google Scholar

[49] Du M H 2015 J. Phys. Chem. Lett. 6 1461

Google Scholar

Google Scholar

[50] Zhang M J, Pan J L, Zhou W Z 2019 J. Phys.: Condens. Matter 31 505302

Google Scholar

Google Scholar

[51] 顾芳, 孙亚飞, 张加宏, 何鹏翔, 王丽阳 2018 原子与分子 35 853

Google Scholar

Google Scholar

Gu F, Sun Y F, Zhang J H, He P X, Wang L Y 2018 J. At. Mol. Phys. 35 853

Google Scholar

Google Scholar

[52] Scharber M C, Mühlbacher D, Koppe M, Denk P, Waldauf C, Heeger A J, Brabec C J 2006 Adv. Mater. 18 789

Google Scholar

Google Scholar

[53] Bernardi M, Palummo M, Grossman J C 2012 ACS Nano 6 10082

Google Scholar

Google Scholar

[54] Cheng K, Guo Y, Han H, Jiang X, Zhang J F, Rajeev A, Su Y, Zhao J J 2018 Appl. Phys. Lett. 112 143902

Google Scholar

Google Scholar

-

图 4 CsPbX3-PG异质结的能级排列图 (a)—(c)接触前, (d)—(f) PBE计算的接触状态, (g)—(i) HSE + SOC验证的接触状态下VBM和CBM点能量本征值. 其中, 蓝色块表示PG单层和红色块分别表示CsPbX3(X = Cl, Br, I)的能级

Fig. 4. The energy level alignment diagram of the CsPbX3-PG heterostructures: (a)–(c) the pre-contact states, (d)–(f) PBE calculated contact states and (g)–(i) HSE + SOC validated the energy eigenvalues of VBM and CBM points in the contact states. The blue blocks represent the energy level of PG monolayer and the red blocks represent the energy level of CsPbX3 slabs [X = Cl, Br, I (from left to right)].

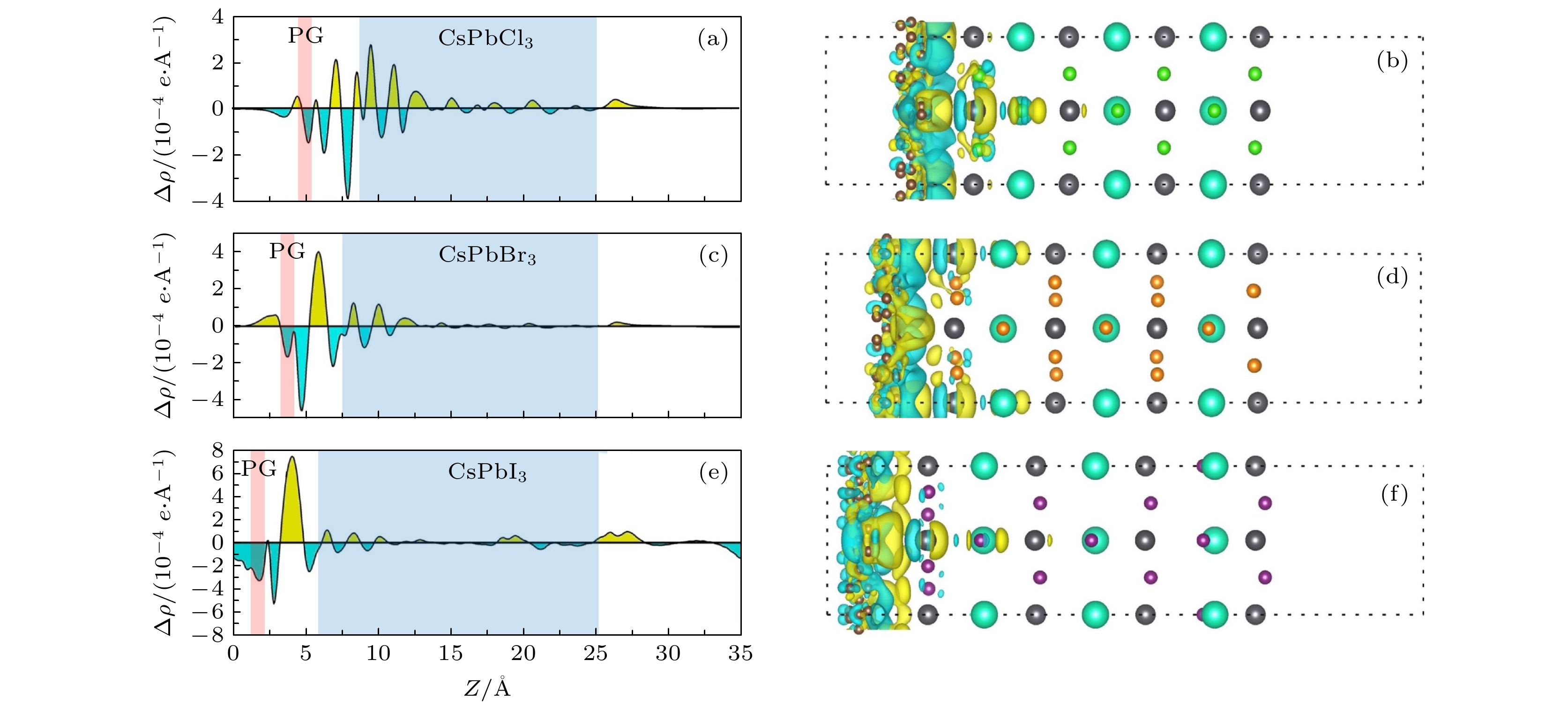

图 5 沿Z方向上的平面平均差分电荷密度 (a) CsPbCl3-PG, (c) CsPbBr3-PG, (e) CsPbI3-PG异质结(红色区域为PG, 蓝色区域为CsPbX3); 3D差分电荷密度 (b) CsPbCl3-PG, (d) CsPbBr3-PG, (f) CsPbI3-PG异质结(黄色代表增益电子, 绿色代表损耗电子)

Fig. 5. The plane-averaged electron density difference along Z direction of (a) CsPbCl3-PG, (c) CsPbBr3-PG, (e) CsPbI3-PG. 3D charge density difference of heterostructures: (b) CsPbCl3-PG, (d) CsPbBr3-PG, (f) CsPbI3-PG. (Yellow represents gain electrons, and green represents lose electrons).

图 6 光吸收谱 (a) CsPbCl3-PG; (b) CsPbBr3-PG; (c) CsPbI3-PG异质结 (红线、蓝线和黑线分别代表CsPbX3-PG (X=Cl, Br, I)异质结、CsPbX3和PG单层的光吸收率 (X=Cl, Br, I)

Fig. 6. Light absorption capacity of (a) CsPbCl3-PG, (b) CsPbBr3-PG, (c) CsPbI3-PG. The red, blue and black line represent the light absorption capacity of CsPbX3-PG heterostructures, CsPbX3 slabs and PG monolayer, respectively [X=Cl, Br, I (up-down)].

表 1 CsPbX3-PG异质结的晶格失配度和表面结合能

Table 1. Lattice mismatch ratio and surface binding energyof PbX and CsX interface in CsPbX3-PG heterostructures.

X 晶格失配度/% 界面形成能/(meV·Å–2) PbX-PG CsX-PG Cl 0.15 –1.92 12.42 Br 1.33 –6.02 0.54 I 3.46 –5.43 1.03 表 2 CsPbX3-PG异质结接触前后带隙数据

Table 2. Calculated band gaps of PG monolayer, CsPbX3 slabs and CsPbX3-PG heterostructures in the pre-contact state (left) and contact state (right) by PBE functional.

X 接触前(单结构) 接触态(异质结) PG CsPbX3 PG CsPbX3 CsPbX3-PG Cl 2.21 2.21 2.21 2.62 1.30 Br 2.28 1.77 2.28 1.79 1.62 I 2.36 1.52 2.36 1.30 1.20 -

[1] Liu B, Long M Q, Cai M Q, Ding L M, Yang J L 2019 Nano Energy 59 715

Google Scholar

Google Scholar

[2] Afsaria M, Boochanib A, Hantezadehaa M 2016 Optik 127 11433

Google Scholar

Google Scholar

[3] Kang Yo, Han S 2018 Phys. Rev. Appl. 10 044013

Google Scholar

Google Scholar

[4] Ball J M, Lee M M, Hey A, Snaith H J 2013 Energy Environ. Sci. 6 1739

Google Scholar

Google Scholar

[5] Yang W S, Noh J H, Jeon N J, Kim Y C, Ryu S, Seo J, Seok S Ⅱ 2015 Science 348 1234

Google Scholar

Google Scholar

[6] Sahli F, Werner J, Kamino B, Bräuninger M 2018 Nat. Mater. 17 820

Google Scholar

Google Scholar

[7] Yang Y, You J B 2017 Nature 544 155

Google Scholar

Google Scholar

[8] Rahman M Z, Edvinsson T 2019 Matter 1 562

Google Scholar

Google Scholar

[9] Diao X F, Tang Y L, Xie Q 2019 Chin. Phys. B 28 017802

Google Scholar

Google Scholar

[10] Feng X X, Liu B, Long M Q, Cai M Q, Peng Y Y, Yang J L 2020 J. Phys. Chem. Lett. 11 6266

Google Scholar

Google Scholar

[11] 陆新荣, 赵颖, 刘建, 李承辉, 游效曾 2015 无机化学学报 31 1678

Google Scholar

Google Scholar

Lu X R, Zhao Y, Liu J, Li C H, You X Z 2015 Chin. J. Inorg. Chem. 31 1678

Google Scholar

Google Scholar

[12] 李少华, 李海涛, 江亚晓, 涂丽敏, 李文标, 潘玲, 杨仕娥, 陈永生 2018 67 158801

Google Scholar

Google Scholar

Li SH, Li HT, Jiang YX, Tu LM, Li WB, Pan L, Yang SE, ChenYS 2018 Acta Phys. Sin. 67 158801

Google Scholar

Google Scholar

[13] Swarnkar A, Marshall A R, Sanehira E M, Chernomordik B D, Moore D T, Christians J A, Chakrabarti T, Luther J M 2016 Science 354 92

Google Scholar

Google Scholar

[14] Wang Y, Dar M I, Ono L K, Zhang TY, Kan M, Li YW, Zhang LJ, Wang XT, Yang YG, Gao X Y, Qi Y B, Gratzel M, Zhao Y X 2019 Science 365 591

Google Scholar

Google Scholar

[15] Antonio D B 2020 Nanomaterials 10 579

Google Scholar

Google Scholar

[16] Novoselov K S, Mishchenko A, Carvalho A, Castro Neto A H 2016 Science 353 6298

Google Scholar

Google Scholar

[17] Wen Y, He P, YaoY Y, Zhang Y, Cheng R Q, Yin L, Li N N, Li J, Wang J J, Wang Z X, Liu C S, Fang X, Jiang C, Wei Z P, He J 2020 Adv. Mater. 32 1906874

Google Scholar

Google Scholar

[18] Yao M L, Wu T, Liu B, Li J L, Long M Q 2020 Phys. Lett. A 384 126614

Google Scholar

Google Scholar

[19] Liu X F, Luo Z J, Zhou X, Wei J M, Wang Y, Guo X, Lv B, Ding Z 2019 Chin. Phys. B 28 086105

Google Scholar

Google Scholar

[20] Sun J, Lee H W, Pasta M, Yuan H, Sun Q C, Wang G Q 2015 Nat. Nanotechnol. 10 980

Google Scholar

Google Scholar

[21] Hong X, Kim J, Shi S F, Zhang Y, Jin C, Sun Y, Tongay S, Wu J, Zhang Y, Wang F 2014 Nat. Nanotechnol. 9 682

Google Scholar

Google Scholar

[22] 郭丽娟, 胡吉松, 马新国, 项炬 2019 68 097101

Google Scholar

Google Scholar

Guo L J, Hu J S, Ma X G, Xiang J 2019 Acta Phys. Sin. 68 097101

Google Scholar

Google Scholar

[23] Chen B, Yu Z S, Liu K, Huang J S 2019 Joule 3 177

Google Scholar

Google Scholar

[24] Cao Y H, Li Y F, He J W, Qian C X, Zhang Q, Bai JT, Feng H J 2019 Adv. Mater. Interfaces 6 1901330

Google Scholar

Google Scholar

[25] Liu B, Long MQ, Cai MQ, Ding LM, Yang JL 2018 Appl. Phys. Lett. 112 043901

[26] Cao Y H, Deng Z Y, Wang M Z, Bai J T, Wei S H, Feng H J 2018 J. Phys. Chem. C 122 17228

Google Scholar

Google Scholar

[27] Chao F, Xu X, Yang K, Jiang F, Wang S Y, Zhang Q L 2018 Adv. Mater. 30 1804707

Google Scholar

Google Scholar

[28] Hu J S, Ji G P, Ma X G, Huang C Y 2018 Appl. Surf. Sci. 440 35

Google Scholar

Google Scholar

[29] Cao Y H, Bai J T, Feng H J 2020 Chin.Phys. Lett. 37 107301

Google Scholar

Google Scholar

[30] Zhang S H, Zhou J, Wang Q, Chen X S, Kawazoe Y, Jena P 2015 Nat. Acad. Sci. 112 2372

Google Scholar

Google Scholar

[31] Bravo S, Correa J, Chico L, Pacheco M 2018 Sci.Rep. 8 11070

Google Scholar

Google Scholar

[32] Wang Z, Dong F, Shen B, Zhang R J, Zheng Y X, Chen L Y, Wang S Y, Wang C Z, Ho K M, Fan Y J, Jin B Y, Su W S 2016 Carbon 101 77

Google Scholar

Google Scholar

[33] Wu T, Yao M Y, Li J L, Li M J, Long M Q 2020 Results Phys. 17 103103

Google Scholar

Google Scholar

[34] Xiao B, Li YC, Yu X F, Cheng J B 2016 ACS Appl. Mater. Interfaces 8 35342

Google Scholar

Google Scholar

[35] Wu X F, Varshney V, Lee J, Zhang T, Wohlwend J L, Roy A K, Luo T F 2016 Nano Lett. 16 3925

Google Scholar

Google Scholar

[36] 陈天航, 潘风明, 肖扬, 袁佳仁, 刘进超, 曹浩 2018 原子与分子 35 613

Google Scholar

Google Scholar

Chen T H, Pan F M, Xiao Y, Yuan J R, Liu J C, Cao H 2018 J. At. Mol. Phys. 35 613

Google Scholar

Google Scholar

[37] Naseri M, Lin S, Jalilian J, Gu J, Chen Z 2018 Front. Phys. 13 138102

Google Scholar

Google Scholar

[38] Yuan H, Li Z, Yang J 2018 J. Mater. Chem. C 6 9055

Google Scholar

Google Scholar

[39] Yu J, Kuang X F, Gao Y J, Wang Y P, Chen K Q, Ding Z K, Liu J, Cong C X, He J, Liu Z W, Liu Y P 2020 Nano Lett. 20 1172

Google Scholar

Google Scholar

[40] Zhao LS, Wang Y, Chen C P, Liu L L, Yu H X, Zhang Y, Chen Y, Wang X C 2017 Phys. E 91 82

Google Scholar

Google Scholar

[41] Zhao H, Peng D D, He J, Li X M, Long M Q 2018 Chin. Phys. B 27 108504

Google Scholar

Google Scholar

[42] Pan C N, Long M Q, He J 2018 Chin. Phys. B 27 068101

Google Scholar

Google Scholar

[43] Han B X, Zhang H 2019 Chin. Phys. B 28 067301

Google Scholar

Google Scholar

[44] Kang J, Li J, Li S S, Xia J B, Wang L W 2013 Nano Lett. 13 5485

Google Scholar

Google Scholar

[45] Peng Q, Wang Z, Sa B, Wu B, Sun Z 2016 Sci. Rep. 6 3199

[46] Xia C, Xue B, Wang T, Peng Y, Jia Y 2015 Appl. Phys. Lett. 107 193107

Google Scholar

Google Scholar

[47] Butler K T, Frost J M, Walsh A 2015 Mater. Horiz. 2 228

Google Scholar

Google Scholar

[48] Ravi V K, Markad G B, Nag A 2016 ACS Energy Lett. 1 665

Google Scholar

Google Scholar

[49] Du M H 2015 J. Phys. Chem. Lett. 6 1461

Google Scholar

Google Scholar

[50] Zhang M J, Pan J L, Zhou W Z 2019 J. Phys.: Condens. Matter 31 505302

Google Scholar

Google Scholar

[51] 顾芳, 孙亚飞, 张加宏, 何鹏翔, 王丽阳 2018 原子与分子 35 853

Google Scholar

Google Scholar

Gu F, Sun Y F, Zhang J H, He P X, Wang L Y 2018 J. At. Mol. Phys. 35 853

Google Scholar

Google Scholar

[52] Scharber M C, Mühlbacher D, Koppe M, Denk P, Waldauf C, Heeger A J, Brabec C J 2006 Adv. Mater. 18 789

Google Scholar

Google Scholar

[53] Bernardi M, Palummo M, Grossman J C 2012 ACS Nano 6 10082

Google Scholar

Google Scholar

[54] Cheng K, Guo Y, Han H, Jiang X, Zhang J F, Rajeev A, Su Y, Zhao J J 2018 Appl. Phys. Lett. 112 143902

Google Scholar

Google Scholar

计量

- 文章访问数: 8296

- PDF下载量: 209

- 被引次数: 0

下载:

下载: