-

全固态锂电池在安全性和能量密度上都表现出极大的优势, 因而在储能领域备受关注. 有机-无机复合电解质结合了刚性无机陶瓷电解质优异的室温离子电导率和柔性有机聚合物电解质良好的可弯曲性, 被认为是全固态锂电池最理想的电解质材料之一. 然而, 传统制备方法所使用的零维或一维无机填料具有团聚趋向且填料之间被聚合物相隔离, 无法形成快速而连续的锂离子传输通道, 旨在通过增加无机填料含量来提升复合电解质综合性能的方法难见成效. 三维多孔陶瓷骨架因具有连续的锂离子快速传导网络, 且其自支撑结构能够防止无机颗粒的团聚, 近年来作为无机填料被越来越广泛地应用于复合电解质中. 针对此, 本文首先详细阐释了三维多孔陶瓷骨架对复合电解质电导率提升的机理, 综述了近年来的相关研究结果, 证实了三维多孔陶瓷骨架对复合电解质电导率和热稳定性的有利作用, 然后对三维多孔陶瓷骨架不同的制备方法进行总结, 为寻找更优的合成方法提供基础, 最后探讨三维多孔陶瓷骨架的优化方向, 在已有研究的基础上提出可行的改善策略.

-

关键词:

- 三维多孔陶瓷骨架 /

- 有机-无机复合电解质 /

- 全固态锂电池 /

- 原位聚合

All solid-state lithium batteries demonstrate excellent characteristics of high safety and energy density, which make them very promising energy storage devices. Among various kinds of solid electrolytes, rigid-flexible coupling composite electrolyte combines the advantages of rigid solid inorganic ceramic electrolytes, i.e., excellent room temperature ionic conductivity, and of flexible solid polymer electrolytes, i.e., the flexibility, and thereby is considered to be one of the most ideal electrolyte candidates for all solid-state lithium batteries. Dispersing 0- or 1-dimensional inorganic fillers is a widespread method to fabricate rigid-flexible coupling composite, where the ionic conductivity of polymer can be improved by one order of magnitude mainly due to the decreased degree of crystallinity. However, aim to further increase the ionic conductivity by increasing the filler content cannot be accomplished because of the fillers' tendency to aggregation. what's more, the highly conductive inorganic fillers are separated by the polymer phase and thus cannot form fast and continuous Li+ transportation channels. Accordingly, inorganic fillers which can provide percolated pathway for Li+ transportation and avoid aggregating are highly desirable. To this end, different from adding 0- or 1-dimensional inorganic fillers into polymer matrices, polymers can be cast into porous inorganic substrates, that is, 3-dimensional porous ceramic framework, to obtain organic-inorganic composite electrolyte, in which organic phase, inorganic phase, and organic/inorganic interfacial phase are all continuous for fast Li+ transportation. And meanwhile, its self-supported structure prevents the agglomeration of inorganic particles. In recent years, the 3-dimensional porous ceramic framework has been more and more frequently used in rigid-flexible coupling composite electrolytes. To have a deep insight into the positive function of 3-dimensional porous ceramic framework, in this review, we firstly reveal the mechanism of the huge improvement in the ionic conductivity and thermostability of the composite electrolyte. Then, we summarize the frequently used preparation methods of the 3-dimensional porous ceramic framework reported recently. Finally, for the future perspective of rigid-flexible coupling composite electrolyte development, we propose two feasible improvement strategies. This review can thereby provide great significance of designing solid electrolytes with comprehensive performance for all solid-state lithium batteries with high energy density and superior safety.-

Keywords:

- three-dimensional porous ceramic skeleton /

- organic-inorganic composite electrolyte /

- all-solid-state lithium battery /

- in-situ polymerization

[1] Goodenough J B, Park K S 2013 J. Am. Chem. Soc. 135 1167

Google Scholar

Google Scholar

[2] Ellingsen L A W, Hung C R, Majeau Bettez G, Singh B, Chen Z, Whittingham M S, Strømman A H 2016 Nat. Nanotechnol. 11 1039

Google Scholar

Google Scholar

[3] Manthiram A, Yu X W, Wang S F 2017 Nat. Rev. Mater. 2 16103

Google Scholar

Google Scholar

[4] Liu J, Bao Z N, Cui Y, Dufek E J, Goodenough J B, Khalifah P, Li Q Y, Liaw B Y, Liu P, Manthiram A, Meng Y S, Subramanian V R, Toney M F, Viswanathan V V, Whittingham M S, Xiao J, Xu W, Yang J H, Yang X Q, Zhang J G 2019 Nat. Energy 4 180

Google Scholar

Google Scholar

[5] Sun C W, Liu J, Gong Y D, Wilkinson D P, Zhang J J 2017 Nano Energy 33 363

Google Scholar

Google Scholar

[6] Wu X H, Pan K C, Jia M M, Ren Y F, He H Y, Zhang L, Zhang S J 2019 Green Energy Environ. 4 360

Google Scholar

Google Scholar

[7] Yue L P, Ma J, Zhang J J, Zhao J W, Dong S M, Liu Z H, Cui G L, Chen L Q 2016 Energy Storage Mater. 5 139

Google Scholar

Google Scholar

[8] Zeng X X, Yin Y X, Li N W, Du W C, Guo Y G, Wan L J 2016 J. Am. Chem. Soc. 138 15825

Google Scholar

Google Scholar

[9] Zhu P, Yan C Y, Dirican M, Zhu J D, Zang J, Selvan R K, Chung C C, Jia H, Li Y, Kiyak Y, Wu N Q, Zhang X W 2018 J. Mater. Chem. A 6 4279

Google Scholar

Google Scholar

[10] Croce F, Appetecchi G B, Persi L, Scrosati B 1998 Nature 394 456

Google Scholar

Google Scholar

[11] Wu J F, Guo X 2017 Solid State Ionics 310 38

Google Scholar

Google Scholar

[12] Wu J F, Pang W K, Peterson V K, Wei L, Guo X 2017 ACS Appl. Mater. Interfaces 9 12461

Google Scholar

Google Scholar

[13] Yang L Y, Wang Z J, Feng Y C, Tan R, Zuo Y X, Gao R G, Zhao Y, Han L, Wang Z Q, Pan F 2017 Adv. Energy Mater. 7 1701437

Google Scholar

Google Scholar

[14] Xuefu S, Nemori H, Mitsuoka S, Xu P, Matsui M, Takeda Y, Yamamoto O, Imanishi N 2016 Front. Energy Res. 4 1

Google Scholar

Google Scholar

[15] Dietrich C, Weber D A, Sedlmaier S J, Indris S, Culver S P, Walter D, Janek J, Zeier W G 2017 J. Mater. Chem. A 5 18111

Google Scholar

Google Scholar

[16] Ohtomo T, Hayashi A, Tatsumisago M, Tsuchida Y, Hama S, Kawamoto K 2013 J. Power Sources 233 231

Google Scholar

Google Scholar

[17] Kamaya N, Homma K, Yamakawa Y, Hirayama M, Kanno R, Yonemura M, Kamiyama T, Kato Y, Hama S, Kawamoto K, Mitsui A 2011 Nat. Mater. 10 682

Google Scholar

Google Scholar

[18] Kato Y, Hori S, Saito T, Suzuki K, Hirayama M, Mitsui A, Yonemura M, Iba H, Kanno R 2016 Nat. Energy 1 16030

Google Scholar

Google Scholar

[19] Li Y T, Xu B Y, Xu H H, Duan H N, Lü X J, Xin S, Zhou W D, Xue L G, Fu G T, Manthiram A, Goodenough J B 2017 Angew. Chem., Int. Ed. 56 753

Google Scholar

Google Scholar

[20] Zhou W D, Wang S F, Li Y T, Xin S, Manthiram A, Goodenough J B 2016 J. Am. Chem. Soc. 138 9385

Google Scholar

Google Scholar

[21] Zhang J J, Zhao J H, Yue L P, Wang Q F, Chai J C, Liu Z H, Zhou X H, Li H, Guo Y G, Cui G L, Chen L Q 2015 Adv. Energy Mater. 5 1501082

Google Scholar

Google Scholar

[22] Yu X R, Wang L L, Ma J, Sun X W, Zhou X H, Cui G L 2020 Adv. Energy Mater. 10 1903939

Google Scholar

Google Scholar

[23] Liu W, Lee S W, Lin D C, Shi F F, Wang S, Sendek A D, Cui Y 2017 Nat. Energy 2 17035

Google Scholar

Google Scholar

[24] Gong Y, Fu K, Xu S, Dai J, Hamann T R, Zhang L, Hitz G T, Fu Z, Ma Z, McOwen D W, Han X, Hu L B, Wachsman E D 2018 Mater. Today 21 594

Google Scholar

Google Scholar

[25] Zhai H W, Xu P Y, Ning M Q, Cheng Q, Mandal J, Yang Y 2017 Nano Lett. 17 3182

Google Scholar

Google Scholar

[26] Ban X Y, Zhang W Q, Chen N, Sun C W 2018 J. Phys. Chem. C 122 9852

Google Scholar

Google Scholar

[27] Li D, Chen L, Wang T S, Fan L Z 2018 ACS Appl. Mater. Interfaces 10 7069

Google Scholar

Google Scholar

[28] Li Z, Sha W X, Guo X 2019 ACS Appl. Mater. Interfaces 11 26920

Google Scholar

Google Scholar

[29] Kotobuki M, Suzuki Y, Munakata H, Kanamura K, Sato Y, Yamamoto K, Yoshida T 2010 J. Electrochem. Soc. 157 A493

Google Scholar

Google Scholar

[30] Gowda S R, Reddy A L M, Shaijumon M M, Zhan X B, Ci L J, Ajayan P M 2011 Nano Lett. 11 101

Google Scholar

Google Scholar

[31] Xie X, Hu L B, Pasta M, Wells G F, Kong D, Criddle C S, Cui Y 2011 Nano Lett. 11 291

Google Scholar

Google Scholar

[32] Jia H P, Gao P F, Yang J, Wang J L, Nuli Y, Yang Z 2011 Adv. Energy Mater. 1 1036

Google Scholar

Google Scholar

[33] Bonnet Mercier N, Wong R A, Thomas M L, Dutta A, Yamanaka K, Yogi C, Ohta T, Byon H R 2014 Sci. Rep. 4 7127

Google Scholar

Google Scholar

[34] Chen K, Shen Y, Zhang Y B, Lin Y H, Nan C W 2014 J. Power Sources 249 306

[35] Xu J T, Chou S L, Zhou C F, Gu Q F, Liu H K, Dou S X 2014 J. Power Sources 246 124

[36] Zhu X B, Zhao T S, Wei Z H, Tan P, An L 2015 Energy Environ. Sci. 8 3745

Google Scholar

Google Scholar

[37] Zhu X B, Zhao T S, Wei Z H, Tan P, Zhao G 2015 Energy Environ. Sci. 8 2782

Google Scholar

Google Scholar

[38] Fu K, Gong Y H, Dai J Q, Gong A, Han X G, Yao Y G, Wang C W, Wang Y B, Chen Y N, Yan C Y, Li Y J, Wachsman E D, Hu L B 2016 Proc. Natl. Acad. Sci. 113 7094

Google Scholar

Google Scholar

[39] Fu K, Gong Y H, Hitz G T, McOwen D W, Li Y J, Xu S M, Wen Y, Zhang L, Wang C W, Pastel G, Dai J Q, Liu B Y, Xie H, Yao Y G, Wachsman E D, Hu L B 2017 Energy Environ. Sci. 10 1568

Google Scholar

Google Scholar

[40] Jiang Z Y, Xia C R, Chen F L 2010 Electrochim. Acta 55 3595

Google Scholar

Google Scholar

[41] Cui G L 2020 Matter 2 805

Google Scholar

Google Scholar

[42] Bae J, Li Y T, Zhang J, Zhou X Y, Zhao F, Shi Y, Goodenough J B, Yu G H 2018 Angew. Chem., Int. Ed. 57 2096

Google Scholar

Google Scholar

[43] Jiang T L, He P G, Wang G X, Shen Y, Nan C W, Fan L Z 2020 Adv. Energy Mater. 10 1903376

Google Scholar

Google Scholar

[44] Ju J W, Wang Y T, Chen B B, Ma J, Dong S M, Chai J C, Qu H T, Cui L F, Wu X X, Cui G L 2018 ACS Appl. Mater. Interfaces 10 13588

Google Scholar

Google Scholar

[45] Liu W, Liu N, Sun J, Hsu P C, Li Y Z, Lee H W, Cui Y 2015 Nano Lett. 15 2740

Google Scholar

Google Scholar

[46] Wieczorek W, Such K, Wyciślik H, Płocharski J 1989 Solid State Ionics 36 255

Google Scholar

Google Scholar

[47] Wieczorek W, Florjanczyk Z, Stevens J R 1995 Electrochim. Acta 40 2251

Google Scholar

Google Scholar

[48] Bae J, Li Y T, Zhao F, Zhou X Y, Ding Y, Yu G H 2018 Energy Storage Mater. 15 46

Google Scholar

Google Scholar

[49] Xie H, Yang C P, Fu K, Yao Y G, Jiang F, Hitz E, Liu B Y, Wang S, Hu L L 2018 Adv. Energy Mater. 8 1703474

Google Scholar

Google Scholar

[50] Wu J F, Chen E Y, Yu Y, Liu L, Wu Y, Pang W K, Peterson V K, Guo X 2017 ACS Appl. Mater. Interfaces 9 1542

Google Scholar

Google Scholar

[51] Palmer M J, Kalnaus S, Dixit M B, Westover A S, Hatzell K B, Dudney N J, Chen X C 2020 Energy Storage Mater. 26 242

[52] Zekoll S, Marriner Edwards C, Hekselman A K O, Kasemchainan J, Kuss C, Armstrong D E J, Cai D, Wallace R J, Richter F H, Thijssen J H J, Bruce P G 2018 Energy Environ. Sci. 11 185

Google Scholar

Google Scholar

[53] Cai D, Wang D H, Chen Y J, Zhang S Z, Wang X L, Xia X H, Tu J P 2020 Chem. Eng. J. 394 124993

Google Scholar

Google Scholar

[54] Xie Z H, Wu Z J, An X W, Yue X Y, Xiaokaiti P, Yoshida A, Abudula A, Guan G Q 2020 J. Membr. Sci. 596 117739

Google Scholar

Google Scholar

[55] Wang X Z, Zhang Y B, Zhang X, Liu T, Lin Y H, Li L L, Shen Y, Nan C W 2018 ACS Appl. Mater. Interfaces 10 24791

Google Scholar

Google Scholar

[56] Hitz G T, McOwen D W, Zhang L, Ma Z, Fu Z, Wen Y, Gong Y, Dai J, Hamann T R, Hu L, Wachsman E D 2019 Mater. Today 22 50

Google Scholar

Google Scholar

[57] Xu S M, McOwen D W, Zhang L, Hitz G T, Wang C W, Ma Z H, Chen C J, Luo W, Dai J Q, Kuang Y D, Hitz E M, Fu K, Gong Y H, Wachsman E D, Hu L 2018 Energy Storage Mater. 15 458

Google Scholar

Google Scholar

[58] Liu B, Zhang L, Xu S, McOwen D W, Gong Y, Yang C, Pastel G R, Xie H, Fu K, Dai J, Chen C, Wachsman E D, Hu L 2018 Energy Storage Mater. 14 376

Google Scholar

Google Scholar

[59] Yao P, Zhu B, Zhai H, Liao X, Zhu Y, Xu W, Cheng Q, Jayyosi C, Li Z, Zhu J, Myers K M, Chen X, Yang Y 2018 Nano Lett. 18 6113

Google Scholar

Google Scholar

[60] Han X G, Gong Y H, Fu K, He X F, Hitz G T, Dai J Q, Pearse A, Liu B Y, Wang H, Rubloff G, Mo Y, Thangadurai V, Wachsman E D, Hu L B 2017 Nat. Mater. 16 572

Google Scholar

Google Scholar

[61] Judez X, Eshetu G G, Li C, Rodriguez Martinez L M, Zhang H, Armand M 2018 Joule 2 2208

Google Scholar

Google Scholar

[62] Wang C, Wang T, Wang L L, Hu Z L, Cui Z L, Li J D, Dong S M, Zhou X H, Cui G L 2019 Adv. Sci. 6 1901036

Google Scholar

Google Scholar

[63] Huo H Y, Chen Y, Luo J, Yang X F, Guo X X, Sun X L 2019 Adv. Energy Mater. 9 1804004

Google Scholar

Google Scholar

[64] Chen L, Li W X, Fan L Z, Nan C W, Zhang Q 2019 Adv. Funct. Mater. 29 1901047

Google Scholar

Google Scholar

-

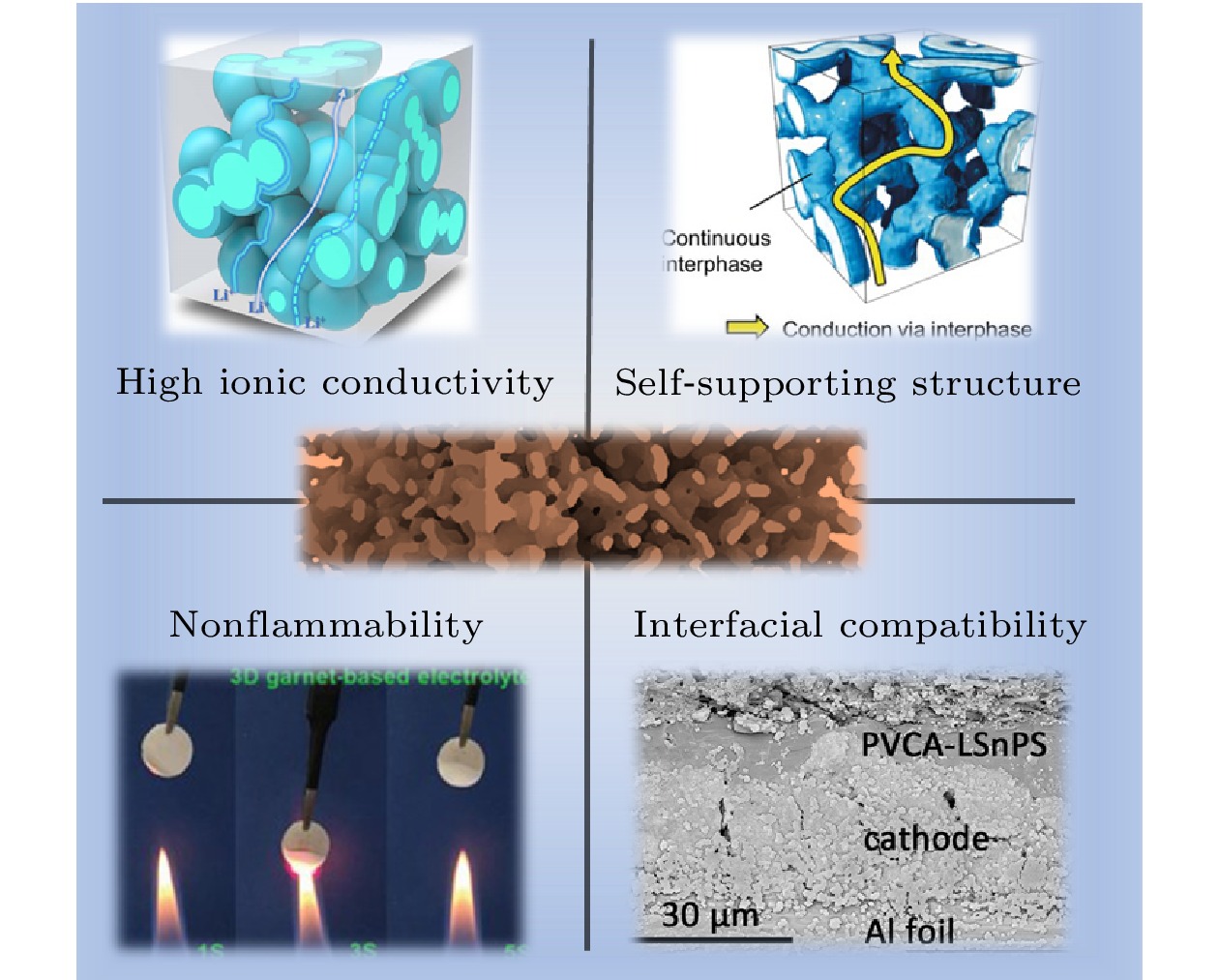

图 3 刚柔并济的有机-无机复合电解质的不同微观结构及其锂离子传输通道的示意图[41] (a) 单相传输: 有机相连续; (b) 双相传输: 有机相、有机/无机界面相连续; (c) 三相传输: 无机相、有机相、有机/无机界面相连续

Fig. 3. Schematic view of rigid-flexible coupling composites with different microstructures and various Li+ transportation pathway[41]: (a) Single-phase percolation: percolated organic phase; (b) double-phase percolation: percolated organic and organic/inorganic interfacial phase; (c) triple-phase percolation: percolated organic, inorganic, and organic/inorganic interfacial phase.

图 5 (a) 以零维颗粒和三维骨架为无机填料的复合电解质在400 ℃下加热2 h前后对比图[48]; (b) 150 ℃加热3 h对具有三维骨架的复合电解质(上)和纯聚合物电解质(下)进行加热测试[55]

Fig. 5. (a) Photographs of composite electrolytes with 0 dimensional particles and three dimensional framework before and after heating at 400 ℃ for 2 h[48]; (b) heating experiments operated at 150 ℃ for 3 h on the three dimensional composite electrolyte (top) and pure polymer electrolyte (bottom)[55].

图 6 (a) 以零维颗粒和三维骨架为无机填料的复合电解质进行燃烧测试[38]; (b) 对商用隔膜和具有三维骨架的复合电解质进行燃烧测试[43]

Fig. 6. (a) Flammability test of composite electrolytes with 0-dimensional particles and three-dimensional framework[38]; (b) flammability test of commercial separator and composite electrolyte with three-dimensional framework[43].

图 7 模板法制备三维骨架 (a) 以细菌纤维素为模板制备三维骨架的合成过程示意图[49]; (b) 以海绵作为模板制备三维骨架的合成过程示意图[53]; (c) 采用Li6.4La3Zr2Al0.2O12/PEO的LiFePO4-Li全固态电池在0.2 C下的循环性能[53]

Fig. 7. Template method to prepare three-dimensional skeleton: (a) Schematic demonstrating of the procedure to prepare three-dimensional skeleton with bacteria cellulose as a template[49]; (b) schematic illustration for the synthesis of three-dimensional skeleton with sponge as a template[53]; (c) cycle performance of LiFePO4|Li6.4La3Zr2Al0.2O12/PEO|Li battery at 0.2 C[53].

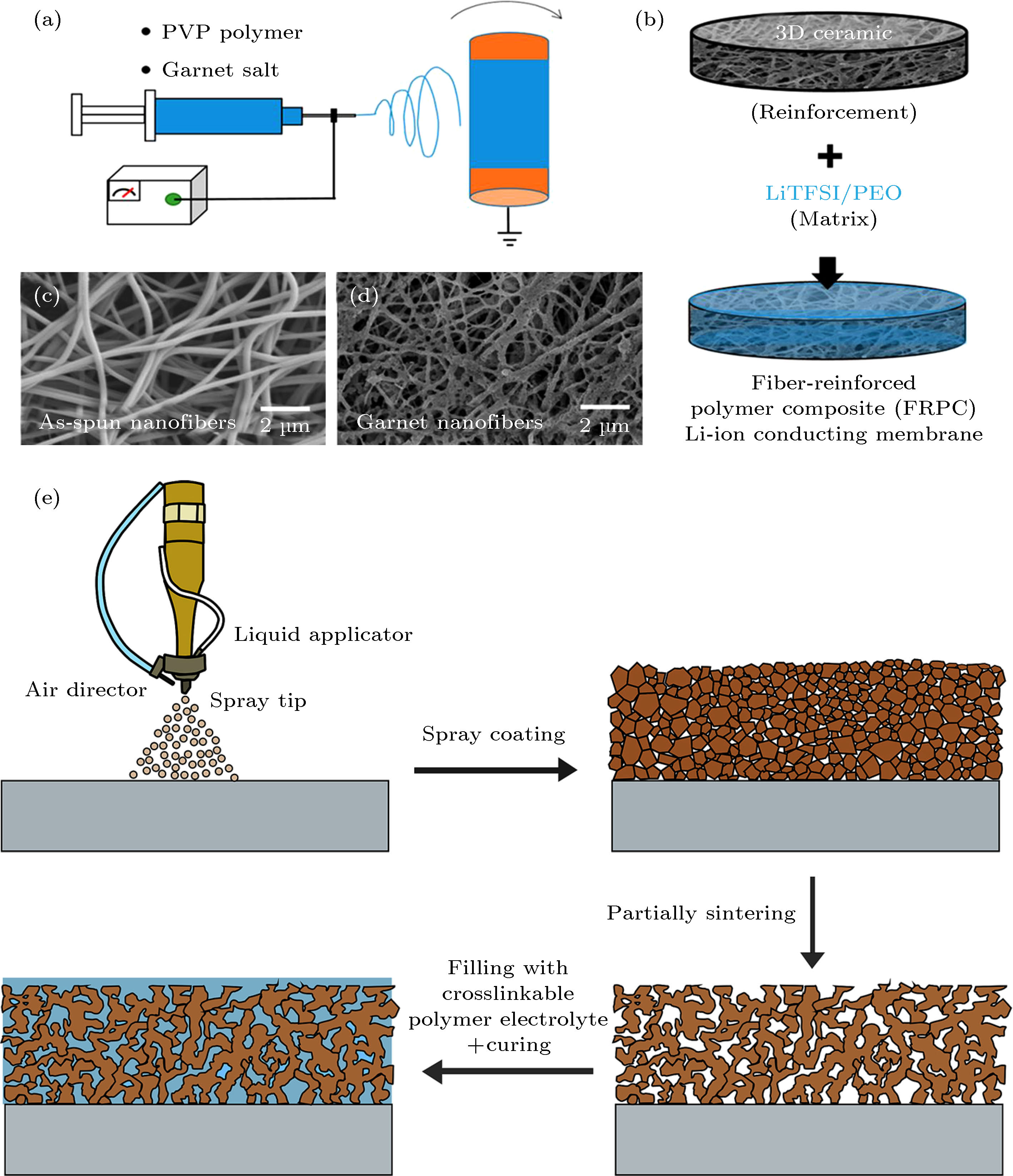

图 8 (a) 静电纺丝陶瓷-聚乙烯吡咯烷酮纳米纤维的装置示意图[38]; (b) 静电纺丝法制备纤维增强的聚合物电解质示意图[38]; (c) 纺织纳米纤维网络的扫描电子显微镜图像[38]; (d) 三维骨架网络的扫描电子显微镜图像[38]; (e) 溶液喷涂法制备复合电解质膜示意图[51]

Fig. 8. (a) Schematic setup of electrospinning garnet-PVP nanofibers[38]; (b) schematic procedure to fabricate the FRPC lithium-ion–conducting membrane[38]; (c) SEM images of the as-spun nanofiber network[38]; (d) SEM image of the garnet nanofiber network[38]; (e) schematic illustration of the fabrication procedure of the composite electrolyte film prepared by solution spraying method[51].

图 9 (a) 溶胶–凝胶法制备复合电解质的示意图[42]; (b) 3D打印法制备复合电解质的示意图及各阶段相应的SEM图像[52]

Fig. 9. (a) Schematic representation of the synthesis of composite electrolytes generated by sol-gel method[42]; (b) schematic of the templating procedure used for the synthesis of structured composite electrolyte, generated by 3D printing. Corresponding SEM images of each synthesis stage are included below each schematic[52].

图 10 (a) LFMP |PVCA-LSnPS|Li和LFMP|LSnPS|Li电池扫描电子显微镜截面图[44]; (b) LFMP |PVCA-LSnPS|Li和LFMP|LSnPS|Li电池恒电流充放电曲线[44]

Fig. 10. (a) The SEM cross-sectional view of LFMP |PVCA-LSnPS|Li cell and LFMP|LSnPS|Li cell[44]; (b) galvanostatic charge-discharge curves of LFMP|PVCA-LSnPS|Li cell and LFMP|LSnPS|Li cell[44].

表 1 不同方法制备三维骨架的优缺点

Table 1. Advantages and disadvantages of three-dimensional framework prepared by different methods.

-

[1] Goodenough J B, Park K S 2013 J. Am. Chem. Soc. 135 1167

Google Scholar

Google Scholar

[2] Ellingsen L A W, Hung C R, Majeau Bettez G, Singh B, Chen Z, Whittingham M S, Strømman A H 2016 Nat. Nanotechnol. 11 1039

Google Scholar

Google Scholar

[3] Manthiram A, Yu X W, Wang S F 2017 Nat. Rev. Mater. 2 16103

Google Scholar

Google Scholar

[4] Liu J, Bao Z N, Cui Y, Dufek E J, Goodenough J B, Khalifah P, Li Q Y, Liaw B Y, Liu P, Manthiram A, Meng Y S, Subramanian V R, Toney M F, Viswanathan V V, Whittingham M S, Xiao J, Xu W, Yang J H, Yang X Q, Zhang J G 2019 Nat. Energy 4 180

Google Scholar

Google Scholar

[5] Sun C W, Liu J, Gong Y D, Wilkinson D P, Zhang J J 2017 Nano Energy 33 363

Google Scholar

Google Scholar

[6] Wu X H, Pan K C, Jia M M, Ren Y F, He H Y, Zhang L, Zhang S J 2019 Green Energy Environ. 4 360

Google Scholar

Google Scholar

[7] Yue L P, Ma J, Zhang J J, Zhao J W, Dong S M, Liu Z H, Cui G L, Chen L Q 2016 Energy Storage Mater. 5 139

Google Scholar

Google Scholar

[8] Zeng X X, Yin Y X, Li N W, Du W C, Guo Y G, Wan L J 2016 J. Am. Chem. Soc. 138 15825

Google Scholar

Google Scholar

[9] Zhu P, Yan C Y, Dirican M, Zhu J D, Zang J, Selvan R K, Chung C C, Jia H, Li Y, Kiyak Y, Wu N Q, Zhang X W 2018 J. Mater. Chem. A 6 4279

Google Scholar

Google Scholar

[10] Croce F, Appetecchi G B, Persi L, Scrosati B 1998 Nature 394 456

Google Scholar

Google Scholar

[11] Wu J F, Guo X 2017 Solid State Ionics 310 38

Google Scholar

Google Scholar

[12] Wu J F, Pang W K, Peterson V K, Wei L, Guo X 2017 ACS Appl. Mater. Interfaces 9 12461

Google Scholar

Google Scholar

[13] Yang L Y, Wang Z J, Feng Y C, Tan R, Zuo Y X, Gao R G, Zhao Y, Han L, Wang Z Q, Pan F 2017 Adv. Energy Mater. 7 1701437

Google Scholar

Google Scholar

[14] Xuefu S, Nemori H, Mitsuoka S, Xu P, Matsui M, Takeda Y, Yamamoto O, Imanishi N 2016 Front. Energy Res. 4 1

Google Scholar

Google Scholar

[15] Dietrich C, Weber D A, Sedlmaier S J, Indris S, Culver S P, Walter D, Janek J, Zeier W G 2017 J. Mater. Chem. A 5 18111

Google Scholar

Google Scholar

[16] Ohtomo T, Hayashi A, Tatsumisago M, Tsuchida Y, Hama S, Kawamoto K 2013 J. Power Sources 233 231

Google Scholar

Google Scholar

[17] Kamaya N, Homma K, Yamakawa Y, Hirayama M, Kanno R, Yonemura M, Kamiyama T, Kato Y, Hama S, Kawamoto K, Mitsui A 2011 Nat. Mater. 10 682

Google Scholar

Google Scholar

[18] Kato Y, Hori S, Saito T, Suzuki K, Hirayama M, Mitsui A, Yonemura M, Iba H, Kanno R 2016 Nat. Energy 1 16030

Google Scholar

Google Scholar

[19] Li Y T, Xu B Y, Xu H H, Duan H N, Lü X J, Xin S, Zhou W D, Xue L G, Fu G T, Manthiram A, Goodenough J B 2017 Angew. Chem., Int. Ed. 56 753

Google Scholar

Google Scholar

[20] Zhou W D, Wang S F, Li Y T, Xin S, Manthiram A, Goodenough J B 2016 J. Am. Chem. Soc. 138 9385

Google Scholar

Google Scholar

[21] Zhang J J, Zhao J H, Yue L P, Wang Q F, Chai J C, Liu Z H, Zhou X H, Li H, Guo Y G, Cui G L, Chen L Q 2015 Adv. Energy Mater. 5 1501082

Google Scholar

Google Scholar

[22] Yu X R, Wang L L, Ma J, Sun X W, Zhou X H, Cui G L 2020 Adv. Energy Mater. 10 1903939

Google Scholar

Google Scholar

[23] Liu W, Lee S W, Lin D C, Shi F F, Wang S, Sendek A D, Cui Y 2017 Nat. Energy 2 17035

Google Scholar

Google Scholar

[24] Gong Y, Fu K, Xu S, Dai J, Hamann T R, Zhang L, Hitz G T, Fu Z, Ma Z, McOwen D W, Han X, Hu L B, Wachsman E D 2018 Mater. Today 21 594

Google Scholar

Google Scholar

[25] Zhai H W, Xu P Y, Ning M Q, Cheng Q, Mandal J, Yang Y 2017 Nano Lett. 17 3182

Google Scholar

Google Scholar

[26] Ban X Y, Zhang W Q, Chen N, Sun C W 2018 J. Phys. Chem. C 122 9852

Google Scholar

Google Scholar

[27] Li D, Chen L, Wang T S, Fan L Z 2018 ACS Appl. Mater. Interfaces 10 7069

Google Scholar

Google Scholar

[28] Li Z, Sha W X, Guo X 2019 ACS Appl. Mater. Interfaces 11 26920

Google Scholar

Google Scholar

[29] Kotobuki M, Suzuki Y, Munakata H, Kanamura K, Sato Y, Yamamoto K, Yoshida T 2010 J. Electrochem. Soc. 157 A493

Google Scholar

Google Scholar

[30] Gowda S R, Reddy A L M, Shaijumon M M, Zhan X B, Ci L J, Ajayan P M 2011 Nano Lett. 11 101

Google Scholar

Google Scholar

[31] Xie X, Hu L B, Pasta M, Wells G F, Kong D, Criddle C S, Cui Y 2011 Nano Lett. 11 291

Google Scholar

Google Scholar

[32] Jia H P, Gao P F, Yang J, Wang J L, Nuli Y, Yang Z 2011 Adv. Energy Mater. 1 1036

Google Scholar

Google Scholar

[33] Bonnet Mercier N, Wong R A, Thomas M L, Dutta A, Yamanaka K, Yogi C, Ohta T, Byon H R 2014 Sci. Rep. 4 7127

Google Scholar

Google Scholar

[34] Chen K, Shen Y, Zhang Y B, Lin Y H, Nan C W 2014 J. Power Sources 249 306

[35] Xu J T, Chou S L, Zhou C F, Gu Q F, Liu H K, Dou S X 2014 J. Power Sources 246 124

[36] Zhu X B, Zhao T S, Wei Z H, Tan P, An L 2015 Energy Environ. Sci. 8 3745

Google Scholar

Google Scholar

[37] Zhu X B, Zhao T S, Wei Z H, Tan P, Zhao G 2015 Energy Environ. Sci. 8 2782

Google Scholar

Google Scholar

[38] Fu K, Gong Y H, Dai J Q, Gong A, Han X G, Yao Y G, Wang C W, Wang Y B, Chen Y N, Yan C Y, Li Y J, Wachsman E D, Hu L B 2016 Proc. Natl. Acad. Sci. 113 7094

Google Scholar

Google Scholar

[39] Fu K, Gong Y H, Hitz G T, McOwen D W, Li Y J, Xu S M, Wen Y, Zhang L, Wang C W, Pastel G, Dai J Q, Liu B Y, Xie H, Yao Y G, Wachsman E D, Hu L B 2017 Energy Environ. Sci. 10 1568

Google Scholar

Google Scholar

[40] Jiang Z Y, Xia C R, Chen F L 2010 Electrochim. Acta 55 3595

Google Scholar

Google Scholar

[41] Cui G L 2020 Matter 2 805

Google Scholar

Google Scholar

[42] Bae J, Li Y T, Zhang J, Zhou X Y, Zhao F, Shi Y, Goodenough J B, Yu G H 2018 Angew. Chem., Int. Ed. 57 2096

Google Scholar

Google Scholar

[43] Jiang T L, He P G, Wang G X, Shen Y, Nan C W, Fan L Z 2020 Adv. Energy Mater. 10 1903376

Google Scholar

Google Scholar

[44] Ju J W, Wang Y T, Chen B B, Ma J, Dong S M, Chai J C, Qu H T, Cui L F, Wu X X, Cui G L 2018 ACS Appl. Mater. Interfaces 10 13588

Google Scholar

Google Scholar

[45] Liu W, Liu N, Sun J, Hsu P C, Li Y Z, Lee H W, Cui Y 2015 Nano Lett. 15 2740

Google Scholar

Google Scholar

[46] Wieczorek W, Such K, Wyciślik H, Płocharski J 1989 Solid State Ionics 36 255

Google Scholar

Google Scholar

[47] Wieczorek W, Florjanczyk Z, Stevens J R 1995 Electrochim. Acta 40 2251

Google Scholar

Google Scholar

[48] Bae J, Li Y T, Zhao F, Zhou X Y, Ding Y, Yu G H 2018 Energy Storage Mater. 15 46

Google Scholar

Google Scholar

[49] Xie H, Yang C P, Fu K, Yao Y G, Jiang F, Hitz E, Liu B Y, Wang S, Hu L L 2018 Adv. Energy Mater. 8 1703474

Google Scholar

Google Scholar

[50] Wu J F, Chen E Y, Yu Y, Liu L, Wu Y, Pang W K, Peterson V K, Guo X 2017 ACS Appl. Mater. Interfaces 9 1542

Google Scholar

Google Scholar

[51] Palmer M J, Kalnaus S, Dixit M B, Westover A S, Hatzell K B, Dudney N J, Chen X C 2020 Energy Storage Mater. 26 242

[52] Zekoll S, Marriner Edwards C, Hekselman A K O, Kasemchainan J, Kuss C, Armstrong D E J, Cai D, Wallace R J, Richter F H, Thijssen J H J, Bruce P G 2018 Energy Environ. Sci. 11 185

Google Scholar

Google Scholar

[53] Cai D, Wang D H, Chen Y J, Zhang S Z, Wang X L, Xia X H, Tu J P 2020 Chem. Eng. J. 394 124993

Google Scholar

Google Scholar

[54] Xie Z H, Wu Z J, An X W, Yue X Y, Xiaokaiti P, Yoshida A, Abudula A, Guan G Q 2020 J. Membr. Sci. 596 117739

Google Scholar

Google Scholar

[55] Wang X Z, Zhang Y B, Zhang X, Liu T, Lin Y H, Li L L, Shen Y, Nan C W 2018 ACS Appl. Mater. Interfaces 10 24791

Google Scholar

Google Scholar

[56] Hitz G T, McOwen D W, Zhang L, Ma Z, Fu Z, Wen Y, Gong Y, Dai J, Hamann T R, Hu L, Wachsman E D 2019 Mater. Today 22 50

Google Scholar

Google Scholar

[57] Xu S M, McOwen D W, Zhang L, Hitz G T, Wang C W, Ma Z H, Chen C J, Luo W, Dai J Q, Kuang Y D, Hitz E M, Fu K, Gong Y H, Wachsman E D, Hu L 2018 Energy Storage Mater. 15 458

Google Scholar

Google Scholar

[58] Liu B, Zhang L, Xu S, McOwen D W, Gong Y, Yang C, Pastel G R, Xie H, Fu K, Dai J, Chen C, Wachsman E D, Hu L 2018 Energy Storage Mater. 14 376

Google Scholar

Google Scholar

[59] Yao P, Zhu B, Zhai H, Liao X, Zhu Y, Xu W, Cheng Q, Jayyosi C, Li Z, Zhu J, Myers K M, Chen X, Yang Y 2018 Nano Lett. 18 6113

Google Scholar

Google Scholar

[60] Han X G, Gong Y H, Fu K, He X F, Hitz G T, Dai J Q, Pearse A, Liu B Y, Wang H, Rubloff G, Mo Y, Thangadurai V, Wachsman E D, Hu L B 2017 Nat. Mater. 16 572

Google Scholar

Google Scholar

[61] Judez X, Eshetu G G, Li C, Rodriguez Martinez L M, Zhang H, Armand M 2018 Joule 2 2208

Google Scholar

Google Scholar

[62] Wang C, Wang T, Wang L L, Hu Z L, Cui Z L, Li J D, Dong S M, Zhou X H, Cui G L 2019 Adv. Sci. 6 1901036

Google Scholar

Google Scholar

[63] Huo H Y, Chen Y, Luo J, Yang X F, Guo X X, Sun X L 2019 Adv. Energy Mater. 9 1804004

Google Scholar

Google Scholar

[64] Chen L, Li W X, Fan L Z, Nan C W, Zhang Q 2019 Adv. Funct. Mater. 29 1901047

Google Scholar

Google Scholar

计量

- 文章访问数: 15099

- PDF下载量: 626

- 被引次数: 0

下载:

下载: