-

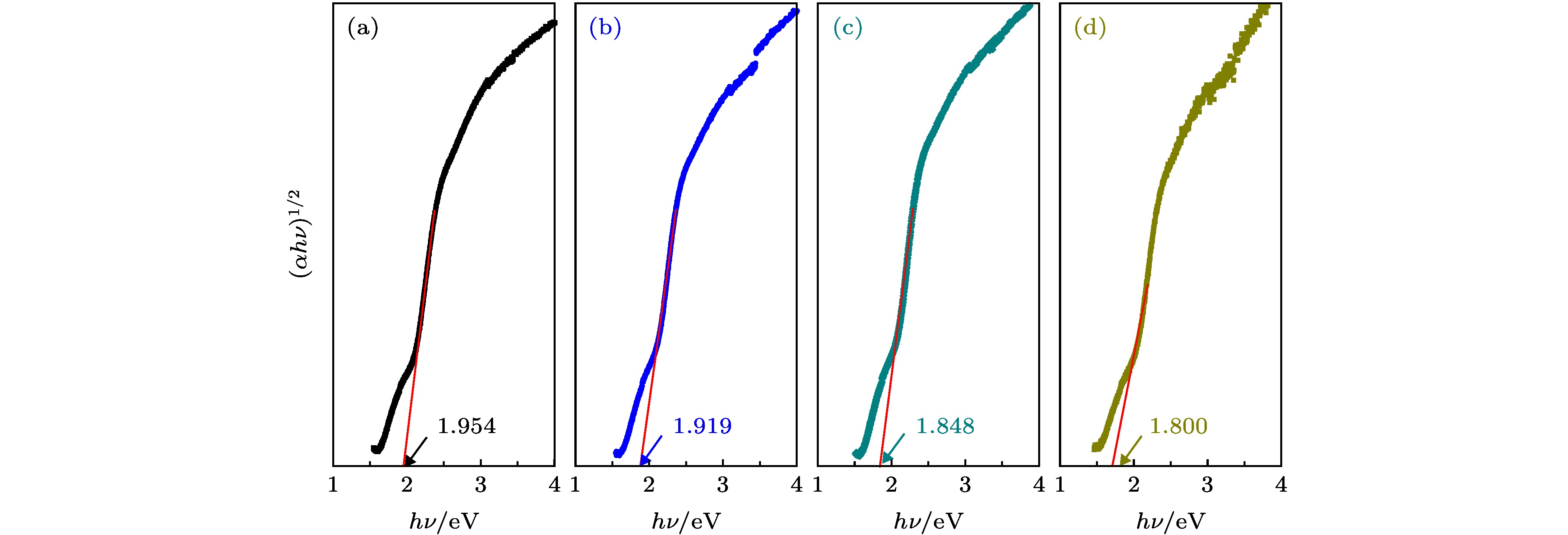

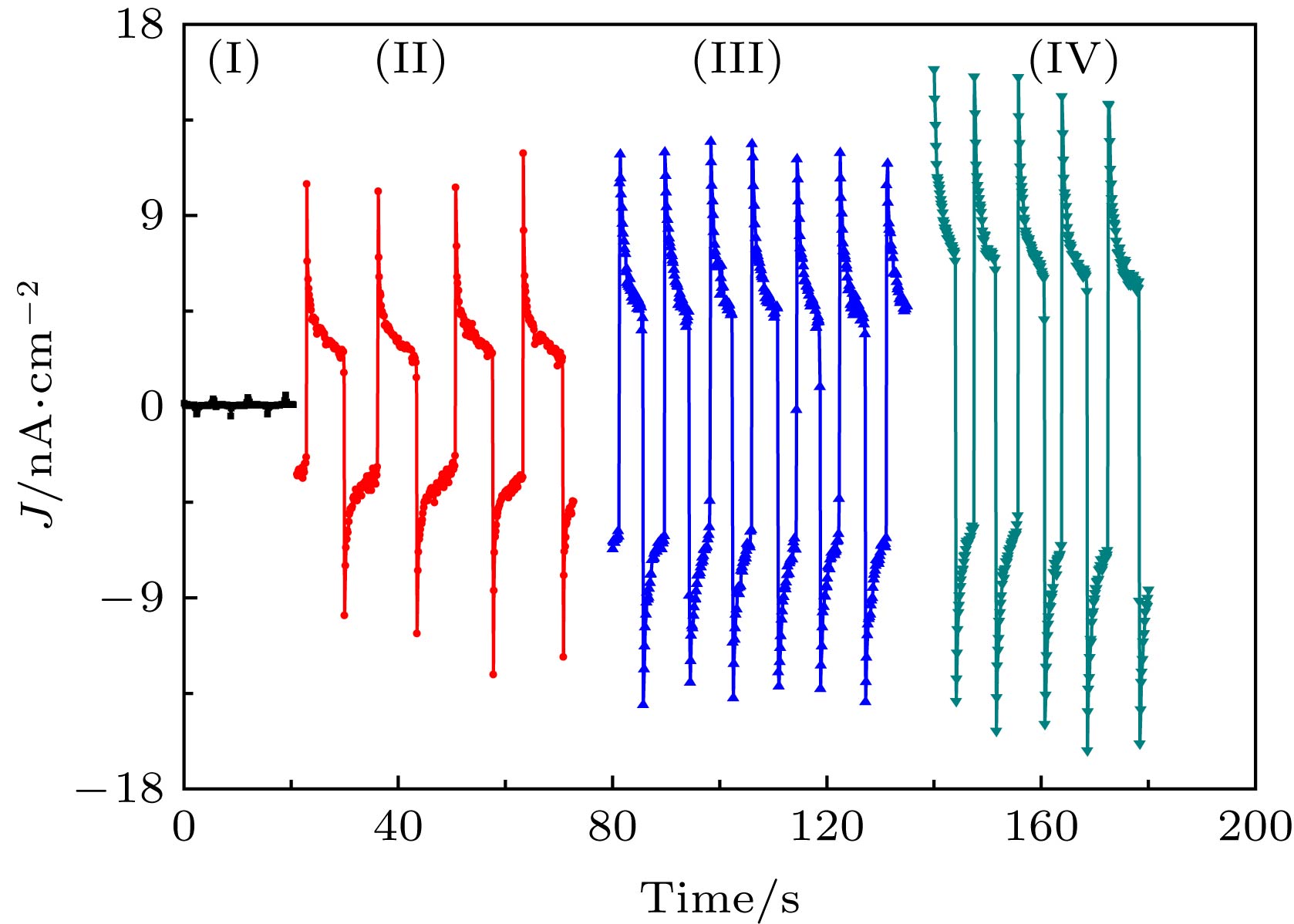

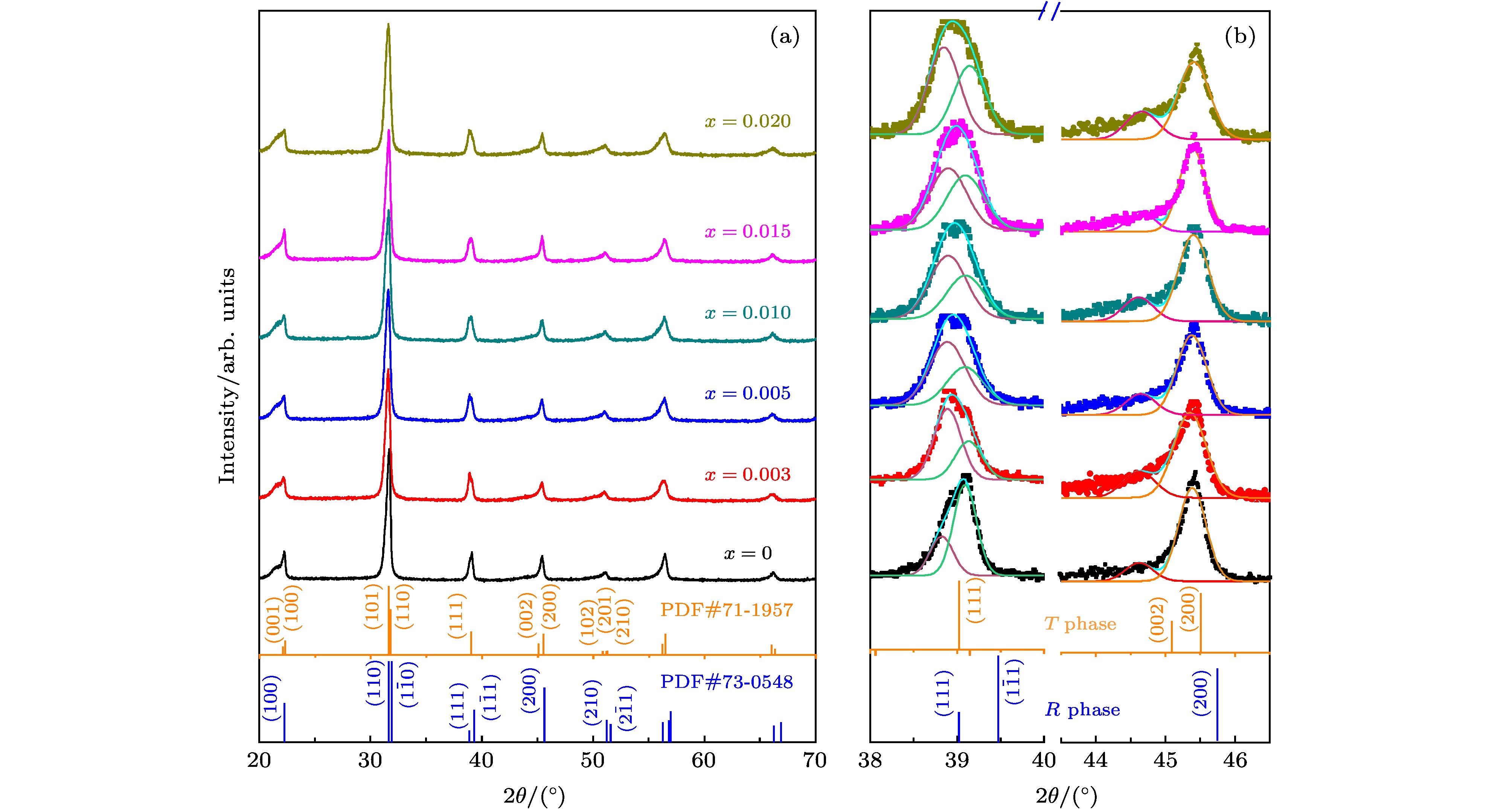

BiFeO3-BaTiO3铁电材料具有优异的压电和铁电性能, 近年来受到广泛的关注. 该材料既保持了BiFeO3体系高的自发极化强度 Ps的优点, 也克服了BiFeO3体系难以合成纯钙钛矿相等缺点, 被认为是非 常有前景的铁电、压电以及光伏材料. 本文采取传统固相法制备了Bi(Fe0.96Mg0.02–xTi0.02+x)O3-0.3BaTiO3铁电陶瓷, 并揭示了Mg2+/Ti4+比例的变化对该陶瓷样品的铁电和压电以及光电性能的影响. 由于Ti4+取代Mg2+产生电子, 导致陶瓷样品的导电性能增加, 压电和铁电性能出现恶化, 其压电系数d33从x = 0的 195 pC/N 下降至x = 0.02时的27 pC/N. 与之相反的是, Ti4+取代Mg2+扩宽了陶瓷样品的光吸收范围, 使陶瓷样品的禁带宽度由x = 0的1.954 eV下降至x = 0.02时的1.800 eV. 由于偶极子翻转构建的内偏电场和禁带宽度的降低等方面的相互作用, 陶瓷样品的光电流密度J由x = 0时的3.71 nA/cm2增加至x = 0.02时的32.45 nA/cm2.Ferroelectrics materials, as a candidate of materials, have recently received attention, for they possess applications in photovoltaic devices and can couple the light absorption with other functional properties. In these materials, the strong inversion symmetry is broken, which is because the spontaneous electric polarization promotes the desirable separation of photo-excited carriers and allows voltages higher than the band-gap, thus permitting efficiency beyond the maximum possible value in a conventional p-n junction solar cell. Much effort has been made to study the ferroelectric photovoltaic effect in several families of ferroelectric perovskite oxides, such as Pb(Zr,Ti)O3, LiNbO3, BaTiO3, KNbO3, Na0.5Bi0.5TiO3-BaTiO3, AgNbO3 and BiFeO3. However, their photo-electric conversion efficiency is now still very low though this field is being studied. The observed output photocurrent is very low due to the negative influence of a wide band-gap and small absorption coefficient, which is caused by the wide band-gaps for most of ferroelectric materials such as Pb(Zr,Ti)O3 (~3.5 eV), and BaTiO3 (~3.3 eV), especially. Although the BiFeO3 system with low band-gap (2.7 eV), which can absorb most visible light for electron transition, is considered as a potential photovoltaic material, it is difficult to synthesize pure perovskite structure. The BiFeO3-BaTiO3 (BF-BT) ferroelectric material with excellent piezoelectric and ferroelectric properties has been widely concerned by researchers in recent years. However, it is still unclear whether this system has the same advantages as BiFeO3 materials with excellent photovoltaic properties. In this work, the Bi(Fe0.96Mg0.02–xTi0.02+x)O3-0.3BaTiO3 ferroelectric ceramics are prepared by the conventional synthesis method to uncover the piezoelectric and ferroelectric properties, as well as the photovoltaic performance with different ratios of Mg2+/Ti4. Because of the electronic production caused by replacing Mg2+ ions with Ti4+ ions, the conductivity of sample increases, and thus its piezoelectric and ferroelectric properties deteriorate. The piezoelectric coefficient d33 decreases from 195 pC/N at x = 0 to 27 pC/N at x = 0.02. Conversely, the range of absorption spectrum increases when the Mg2+ ions are replaced by Ti4+ ions. The band gap of sample decreases from 1.954 eV at x = 0 to 1.800 eV at x = 0.02. The photocurrent of sample increases from 3.71 nA/cm2 at x = 0 to 32.45 nA/cm2 at x = 0.02 because of the combined action of reducing the band gap and internal bias field.

-

Keywords:

- bismuth ferrite /

- ferroelectric materials /

- photovoltaic /

- perovskite structure

[1] Lines M E, Glass A M 1971 Principles and Applications of Ferroelectrics and Related Materials (Oxford: Oxford University Press) pp110−677

[2] Jaffe B, Cook W R, Jaffe H 1971 Piezoelectric Ceramics (New York: Academic Press) pp136−337

[3] Choi T, Lee S, Choi Y J, Kiryukhin V, Cheong S W 2009 Science 324 63

Google Scholar

Google Scholar

[4] Katiyar R K, Sharma Y, Barrionuevo D, Kooriyattil S, Pavunny S P, Young J S, Morell G, Weiner B R, Katiyar R S, Scott J F 2015 Appl. Phys. Lett. 106 082903

Google Scholar

Google Scholar

[5] Agarwal R, Sharma Y, Katiyar R S 2015 Appl. Phys. Lett. 107 162904

Google Scholar

Google Scholar

[6] Zang Y Y, Xie D, Wu X, Chen Y, Lin Y X, Li M H, He T, Li X, Li Z, Zhu H W, Ren T L, Plant D 2011 Appl. Phys. Lett. 99 132904

Google Scholar

Google Scholar

[7] Wu J, Fan Z, Xiao D, Zhu J, Wang J 2016 Prog. Mater. Sci. 84 335

Google Scholar

Google Scholar

[8] Chen B, Li M, Liu Y W, Zuo Z H, Zhuge F, Zhan Q F, Li R W 2011 Nanotechnology 22 195201

Google Scholar

Google Scholar

[9] Yan T L, Chen B, Liu G, Niu R P, Shang J, Gao S, Xue W H, Jin J, Yang J R, Li R W 2017 Chin. Phys. B 26 067702

Google Scholar

Google Scholar

[10] Lee M H, Kim D J, Park J S, Kim S W, Song T K, Kim M H, Kim W J, Do D, Jeong I K 2015 Adv. Mater. 27 6976

Google Scholar

Google Scholar

[11] Zhu L F, Zhang B P, Li S, Zhao G L 2017 J. Alloy. Compd. 727 382

Google Scholar

Google Scholar

[12] Zheng T, Ding Y, Wu J 2016 RSC Adv. 6 90831

Google Scholar

Google Scholar

[13] Zhu L F, Zhang B P, Zhang Z C, Li S, Wang L J, Zheng L J 2018 J. Mater. Sci.-Mater. El. 29 2307

Google Scholar

Google Scholar

[14] Lin Y, Zhang L, Zheng W, Yu J 2015 J. Mater. Sci.-Mater. El. 26 7351

Google Scholar

Google Scholar

[15] Zhu L F, Zhang B P, Duan J Q, Xun B W, Wang N, Tang Y C, Zhao G L 2018 J. Eur. Ceram. Soc. 38 3463

Google Scholar

Google Scholar

[16] Wei J, Fu D, Cheng J, Cheng J 2017 J. Mater. Sci. 52 10726

Google Scholar

Google Scholar

[17] Zhu LF, Liu Q, Zhang B P, Cen Z Y, Wang K, Li J, Bai Y, Wang X H, Li J F 2018 RSC Adv. 8 35794

Google Scholar

Google Scholar

[18] Liu N, Liang R, Zhou Z, Dong X 2018 J. Mater. Chem. C 6 10211

Google Scholar

Google Scholar

[19] Wang D, Fan Z, Li W, Zhou D, Feteira A, Wang G, Murakami S, Sun S, Zhao Q, Tan X, Reaney I M 2018 ACS Appl. Energy Mater. 1 4403

Google Scholar

Google Scholar

[20] Li Q, Wei J X, Cheng J R, Chen J G 2017 J. Mater. Sci. 52 229

Google Scholar

Google Scholar

[21] Yang H B, Zhou C R, Liu X Y, Zhou Q, Chen G H, Li W Z, Wang H 2013 J. Eur. Ceram. Soc. 33 1177

Google Scholar

Google Scholar

[22] Pavana S V, Mocherla, Karthik C, Ubic R, Ramachandra R M S, Sudakar C 2013 Appl. Phys. Lett. 103 022910

Google Scholar

Google Scholar

[23] Liu H, Chen J, Ren Y, Zhang L X, Pan Z, Fan L L, Xing X R 2015 Adv. Electron. Mater. 1 1400051

Google Scholar

Google Scholar

[24] Xiao H, Dong W, Guo Y, Wang Y, Zhong H, Li Q, Yang M M 2019 Adv. Mater. 31 1805802

-

图 3 BFM0.02–xT0.02+x-BT陶瓷样品的(a)电滞回线, (b)剩余极化Pr和矫顽场EC随含量x的变化, (c)漏电流I-E曲线, 以及(d)压电性能d33和kp随含量x的变化

Fig. 3. Ferroelectric hysteresis loops (a), the variation of polarization (Pr) and electric field (EC) (b), leakage current density (I)-electric field (E) (c), as well as the piezoelectric coefficient d33, planar mode eletromechanical coupling coefficient kp (d) as a function of x for BFM0.02–xT0.02+x-BT (0 ≤ x ≤ 0.02).

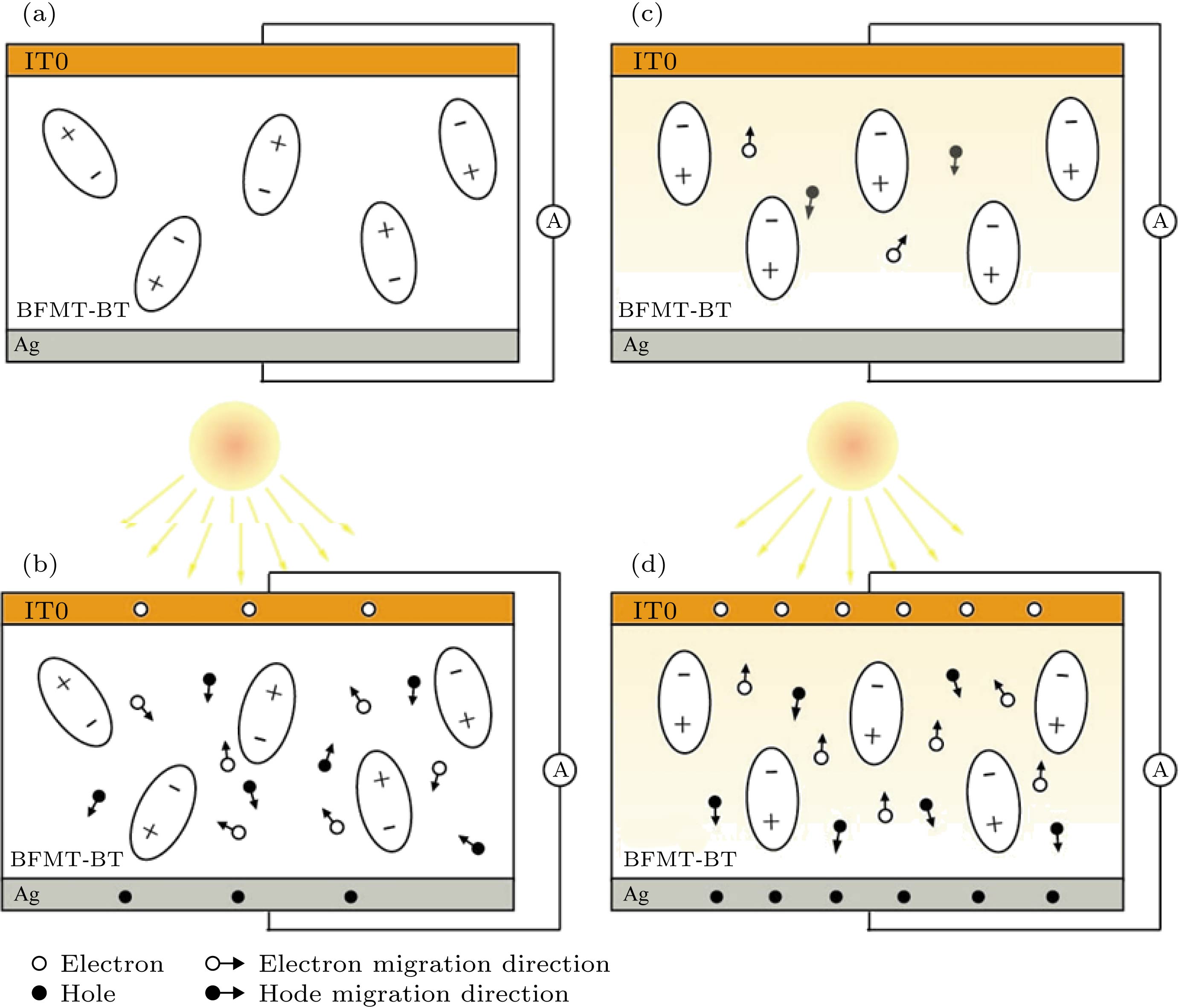

图 8 BFM0.02–xT0.02+x-BT铁电陶瓷光伏效应原理图 (a)未极化、无光条件; (b)未极化、有光条件; (c)极化、无光条件; (d)极化、光照条件

Fig. 8. Schematic diagram of photovoltaic effect for BFM0.02–xT0.02+x-BT ceramics, non-polarization and dark condition (a), non-polarization and light condition (b), polarization and dark condition (c), as well as polarization and light condition (d), respectively.

-

[1] Lines M E, Glass A M 1971 Principles and Applications of Ferroelectrics and Related Materials (Oxford: Oxford University Press) pp110−677

[2] Jaffe B, Cook W R, Jaffe H 1971 Piezoelectric Ceramics (New York: Academic Press) pp136−337

[3] Choi T, Lee S, Choi Y J, Kiryukhin V, Cheong S W 2009 Science 324 63

Google Scholar

Google Scholar

[4] Katiyar R K, Sharma Y, Barrionuevo D, Kooriyattil S, Pavunny S P, Young J S, Morell G, Weiner B R, Katiyar R S, Scott J F 2015 Appl. Phys. Lett. 106 082903

Google Scholar

Google Scholar

[5] Agarwal R, Sharma Y, Katiyar R S 2015 Appl. Phys. Lett. 107 162904

Google Scholar

Google Scholar

[6] Zang Y Y, Xie D, Wu X, Chen Y, Lin Y X, Li M H, He T, Li X, Li Z, Zhu H W, Ren T L, Plant D 2011 Appl. Phys. Lett. 99 132904

Google Scholar

Google Scholar

[7] Wu J, Fan Z, Xiao D, Zhu J, Wang J 2016 Prog. Mater. Sci. 84 335

Google Scholar

Google Scholar

[8] Chen B, Li M, Liu Y W, Zuo Z H, Zhuge F, Zhan Q F, Li R W 2011 Nanotechnology 22 195201

Google Scholar

Google Scholar

[9] Yan T L, Chen B, Liu G, Niu R P, Shang J, Gao S, Xue W H, Jin J, Yang J R, Li R W 2017 Chin. Phys. B 26 067702

Google Scholar

Google Scholar

[10] Lee M H, Kim D J, Park J S, Kim S W, Song T K, Kim M H, Kim W J, Do D, Jeong I K 2015 Adv. Mater. 27 6976

Google Scholar

Google Scholar

[11] Zhu L F, Zhang B P, Li S, Zhao G L 2017 J. Alloy. Compd. 727 382

Google Scholar

Google Scholar

[12] Zheng T, Ding Y, Wu J 2016 RSC Adv. 6 90831

Google Scholar

Google Scholar

[13] Zhu L F, Zhang B P, Zhang Z C, Li S, Wang L J, Zheng L J 2018 J. Mater. Sci.-Mater. El. 29 2307

Google Scholar

Google Scholar

[14] Lin Y, Zhang L, Zheng W, Yu J 2015 J. Mater. Sci.-Mater. El. 26 7351

Google Scholar

Google Scholar

[15] Zhu L F, Zhang B P, Duan J Q, Xun B W, Wang N, Tang Y C, Zhao G L 2018 J. Eur. Ceram. Soc. 38 3463

Google Scholar

Google Scholar

[16] Wei J, Fu D, Cheng J, Cheng J 2017 J. Mater. Sci. 52 10726

Google Scholar

Google Scholar

[17] Zhu LF, Liu Q, Zhang B P, Cen Z Y, Wang K, Li J, Bai Y, Wang X H, Li J F 2018 RSC Adv. 8 35794

Google Scholar

Google Scholar

[18] Liu N, Liang R, Zhou Z, Dong X 2018 J. Mater. Chem. C 6 10211

Google Scholar

Google Scholar

[19] Wang D, Fan Z, Li W, Zhou D, Feteira A, Wang G, Murakami S, Sun S, Zhao Q, Tan X, Reaney I M 2018 ACS Appl. Energy Mater. 1 4403

Google Scholar

Google Scholar

[20] Li Q, Wei J X, Cheng J R, Chen J G 2017 J. Mater. Sci. 52 229

Google Scholar

Google Scholar

[21] Yang H B, Zhou C R, Liu X Y, Zhou Q, Chen G H, Li W Z, Wang H 2013 J. Eur. Ceram. Soc. 33 1177

Google Scholar

Google Scholar

[22] Pavana S V, Mocherla, Karthik C, Ubic R, Ramachandra R M S, Sudakar C 2013 Appl. Phys. Lett. 103 022910

Google Scholar

Google Scholar

[23] Liu H, Chen J, Ren Y, Zhang L X, Pan Z, Fan L L, Xing X R 2015 Adv. Electron. Mater. 1 1400051

Google Scholar

Google Scholar

[24] Xiao H, Dong W, Guo Y, Wang Y, Zhong H, Li Q, Yang M M 2019 Adv. Mater. 31 1805802

计量

- 文章访问数: 15530

- PDF下载量: 269

- 被引次数: 0

下载:

下载: