-

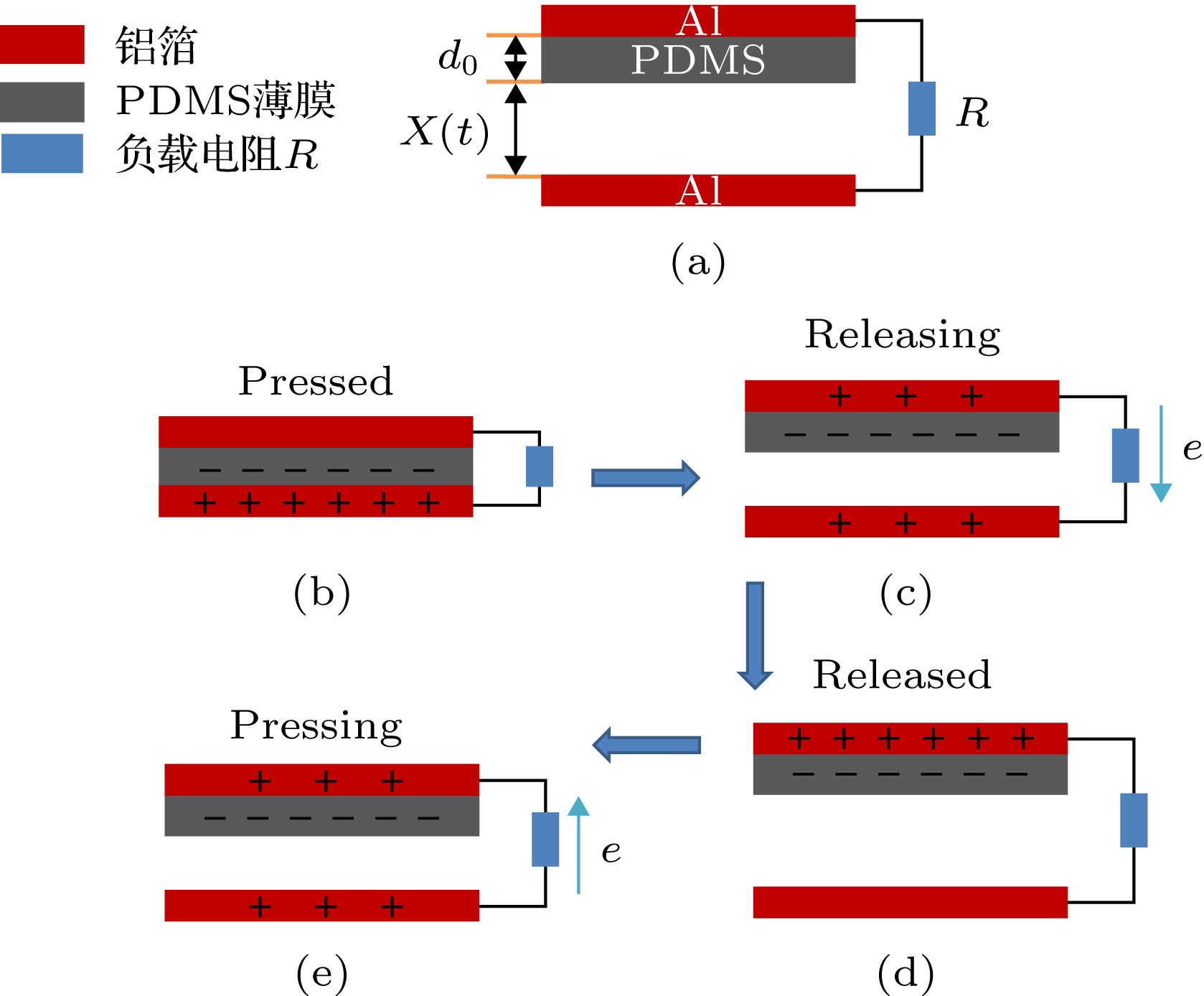

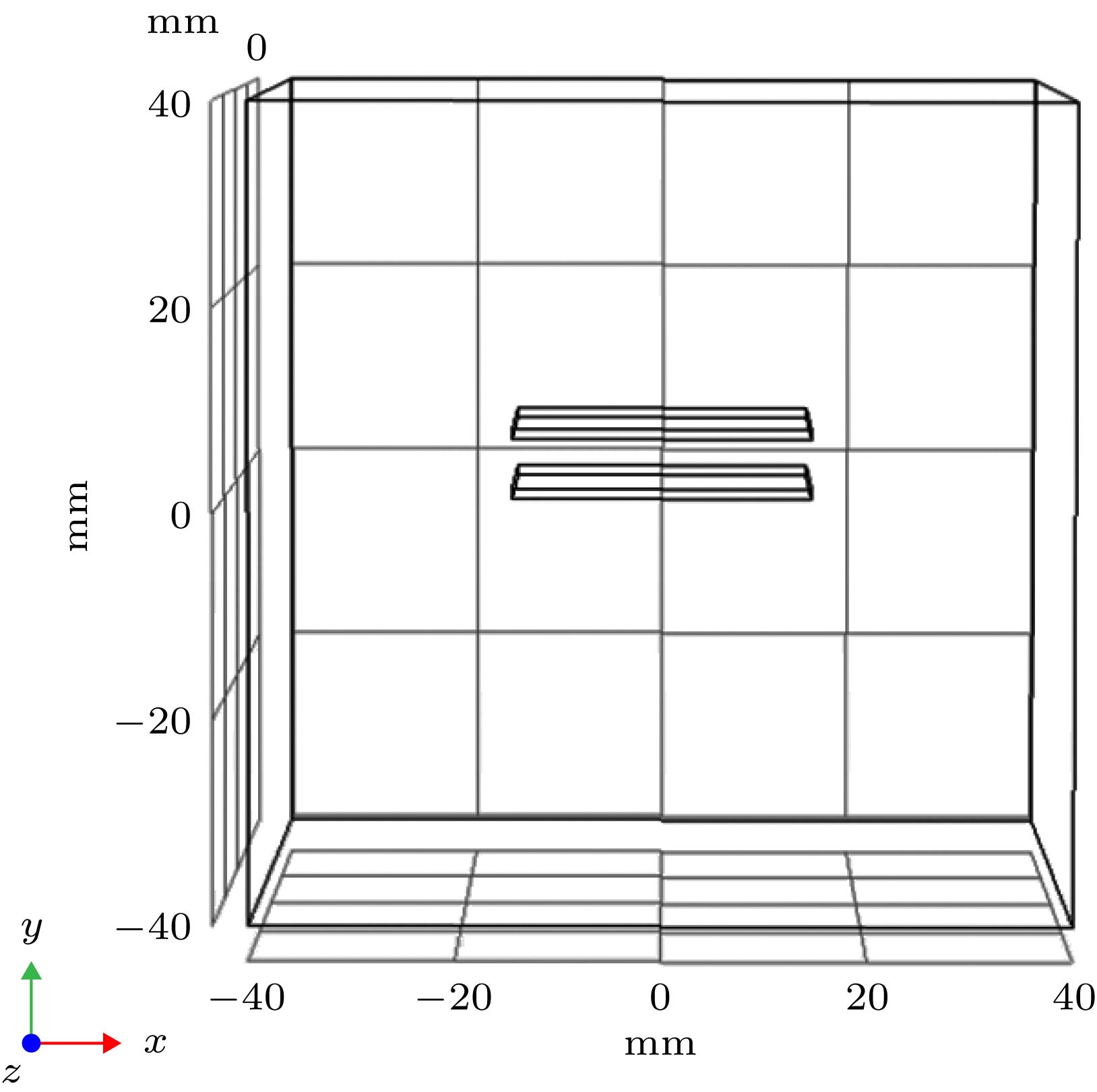

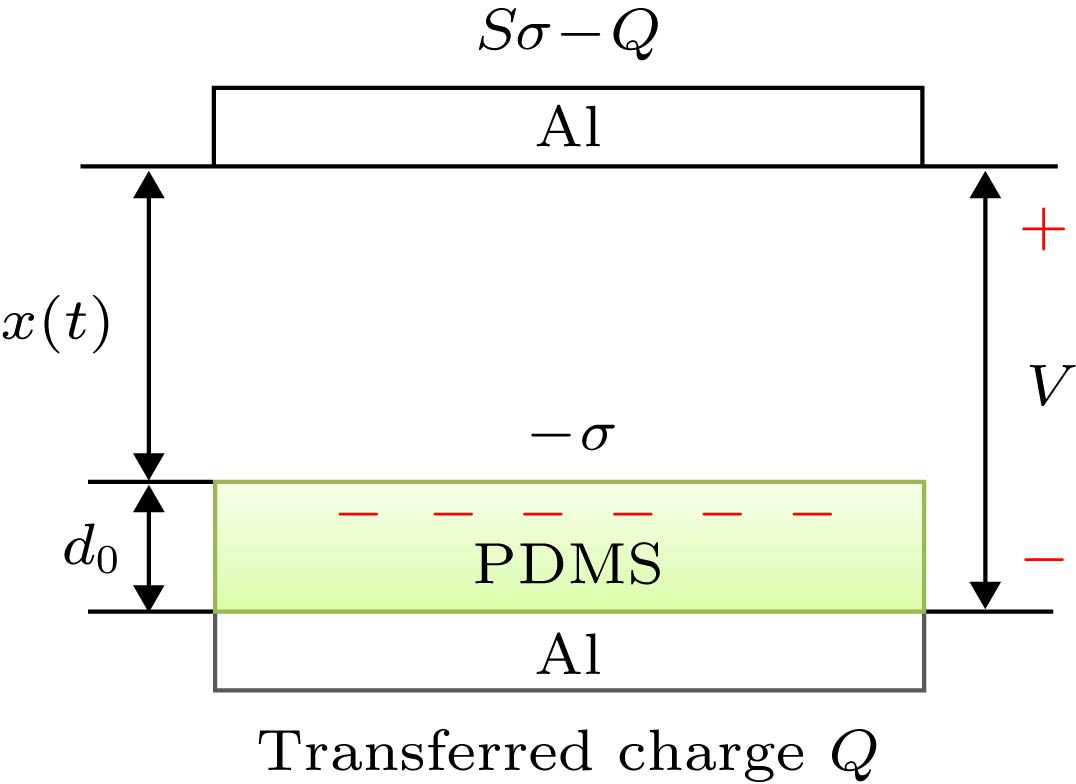

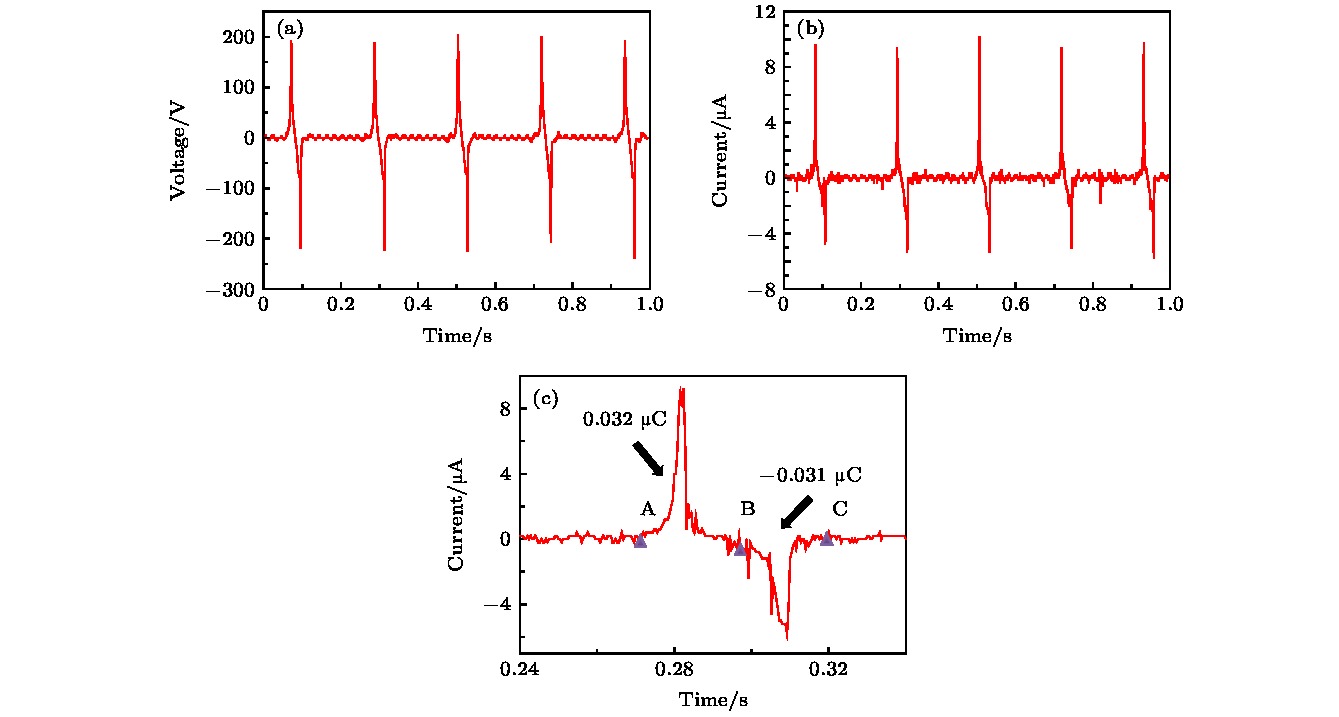

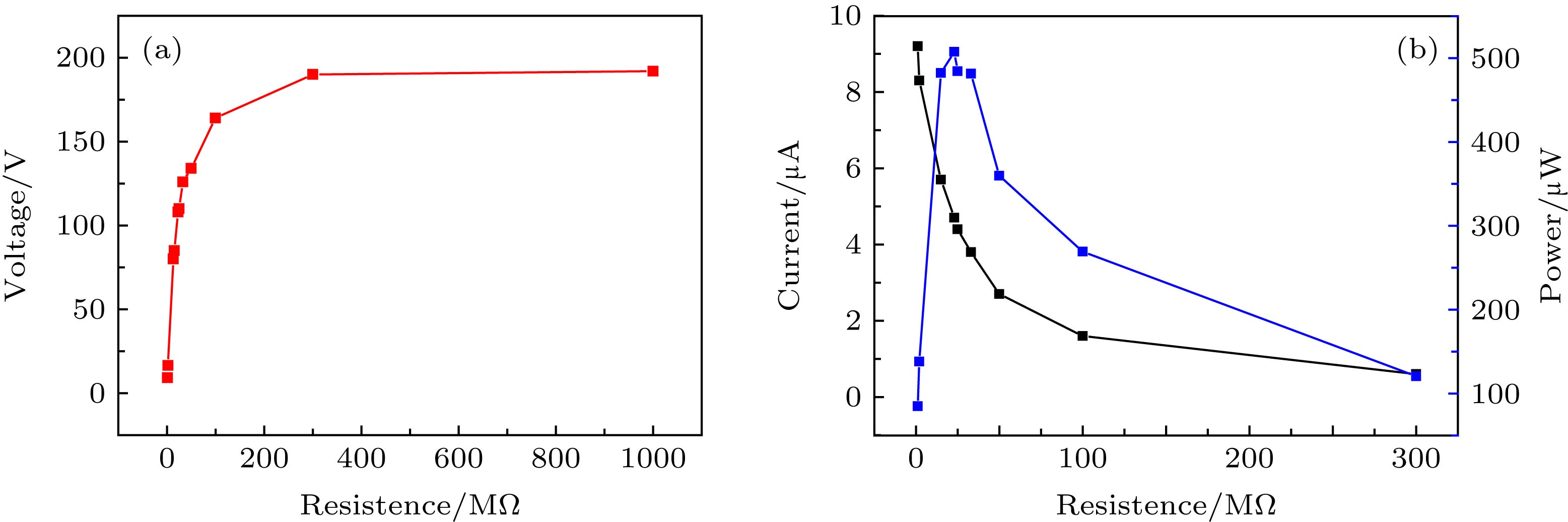

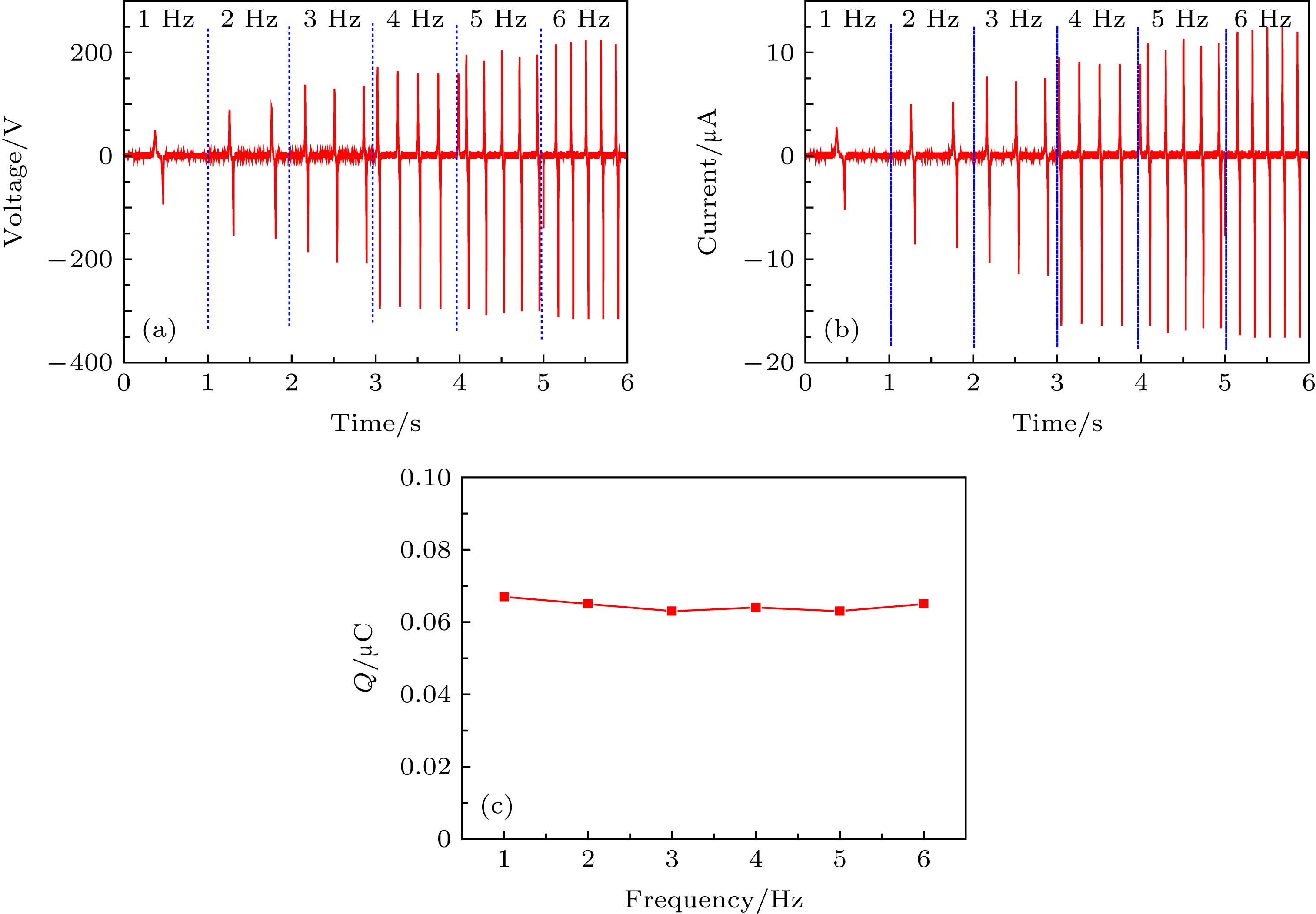

随着全球变暖和能源危机的到来, 寻找减少碳排放的可再生能源成为人类文明面临的最紧迫挑战之一. 振动作为一种常见的机械运动形式, 在人们的日常生活中普遍存在. 利用多种原理收集振动能量将其转化为电能成为研究热点. 基于接触生电和静电感应原理的摩擦纳米发电机(TENG)为收集振动能量提供了一种可行的方法. 本文设计了一种接触分离式TENG. 推导了TENG的电极间电压-转移电荷量-板间距离(V-Q-x)之间的关系, 结合实验分析了负载电阻、振动频率等因素对其输出性能的影响关系, 当振动频率为1—6 Hz时, 每个工作循环内电荷的转移量几乎相同, 而电压和电流随着频率的增大而增大, 频率为5 Hz时, 最大输出功率达到0.5 mW. 运用COMSOL软件对TENG进行模拟仿真, 揭示了其在接触分离过程中电势以及聚合物表面电荷密度的分布和变化规律, 为高效收集振动能量的摩擦纳米发电机及自供能振动传感器设计提供理论与实践支撑.With the advent of global warming and energy crisis, the search for renewable energy to reduce carbon emissions has become one of the most urgent challenges. Ithas become a research hotspot to collect or harvest various mechanical energy in nature and convert it into electric energy. Vibration is a common form of mechanical movement in our daily life. It is visible both on most working machines and in nature and is a type of potential energy. There are several methods that can convert such mechanical energy into electric energy. Triboelectric nanogenerator (TENG) based on the principle of contact electrification and electrostatic induction which first appeared in 2012 by Zhonglin Wang provides a feasible method of efficiently collecting the vibrational energy with different vibrating frequencies. In this paper, a contact-separation mode of TENG is designed and implemented. The voltage- quantity of charge- distance(V-Q-x)relation of TENG is calculated. During the experiment, the factors such as load resistance, vibration frequency, etc. which affect the output performance, are considered and analyzed. An electrically driven crank-connecting rod mechanism is employed to provide the vibration source with adjustable frequency in a range of 1-6 Hz. The result shows that the amount of charge transfer in each working cycle remains almost unchanged, while the voltage and current increase with frequency increasing. When the frequency is 5 Hz, the best power matching resistance of the TENG is about 33 MΩ and the maximum output power reaches 0.5 mW. For a further study, a COMSOL software is used to simulate the distribution rule and variation rule of the electric potential in the contact-separation process, then the theoretical charge density and the experimental charge density on the polymer surface are compared and analyzed in order to provide theoretical and practical support for the design of TENG with collected vibration energy and self-powered vibration sensor. The result shows that the electric potential is proportional to the distance between two friction layers. While as the distance between two friction layers increases, the electric potential and the charge density both show a tendency to concentrate in the middle of the friction layer. The huge difference between experimental result and the simulation predicts thatmuch work should be done continually to improve the output of the TENG. Finally, the obtained results conduce to understanding the contact electrification and electrostatic induction mechanism and also provide a new method of harvesting the vibration energy.

-

Keywords:

- triboelectric nanogenerator /

- output performance /

- vibration energy harvesting /

- contact separation /

- metal-polymer

[1] Haque R I, Farine P A, Briand D 2018 Sens. Actuators 271 88

Google Scholar

Google Scholar

[2] Lin Z M, Yang J, Li X S, Wu Y F, Wei W, Liu J, Chen J, Yang J 2018 Adv. Funct. Mater. 28 4280

[3] Chen X, Song Y, Chen H, Zhang J, Zhang H 2017 J. Mater. Chem. A 5 508

[4] Qian J, Kim D S, Lee D W 2018 Nano Energy 49 126

Google Scholar

Google Scholar

[5] Zi Y, Guo H, Wen Z, Yeh M H, Hu C, Wang Z L 2016 ACS Nano 10 4797

Google Scholar

Google Scholar

[6] Jiang T, Tang W, Chen X, Han C B, Lin L, Zi Y, Wang Z L 2016 Adv. Mater. Technol. 1 1600017

Google Scholar

Google Scholar

[7] Tang W, Jiang T, Fan F R, Yu A F, Zhang C, Cao X, Wang Z L 2015 Adv. Funct. Mater. 25 3718

Google Scholar

Google Scholar

[8] Feng Y, Zheng Y, Ma S, Wang D, Zhou F, Liu W 2016 Nano Energy 19 48

Google Scholar

Google Scholar

[9] 王中林 2013 中国科学: 化学 43 759

Wang Z L 2013 Sci. Sin. Chim. 43 759

[10] Xu L, Jiang T, Lin P, Shao J, Wang Z L 2018 ACS Nano 12 1849

Google Scholar

Google Scholar

[11] Zhao X J, Kuang S Y, Wang Z L, Zhu G 2018 ACS Nano 12 4280

Google Scholar

Google Scholar

[12] Pan L, Wang J, Wang P, Gao R, Wang Y C, Zhang X 2018 Nano Res. 1−12

[13] Dudem B, Huynh N D, Kim W, Kim D H, Hwang H J, Choi D, Yu J S 2017 Nano Energy 42 269

Google Scholar

Google Scholar

[14] Cheng G G, Jiang S Y, Li K, Zhang Z Q, Wang Y, Yuan N Y, Ding J N, Zhang W 2017 Appl. Surf. Sci. 412 350

Google Scholar

Google Scholar

[15] Wang S, Wang X, Wang Z L, Yang Y 2016 ACS Nano 10 5696

Google Scholar

Google Scholar

[16] Wang M, Zhang J H, Tang Y, Li J, Zhang B S, Liang E J, Mao Y C, Wang X D 2018 ACS Nano 12 6156

Google Scholar

Google Scholar

[17] Wu C, Kima T W, Sung S, Park J H, Li F 2018 Nano Energy 44 279

Google Scholar

Google Scholar

[18] Mao Y C, Geng D L, Liang E J, Wang X D 2015 Nano Energy 15 227

Google Scholar

Google Scholar

[19] 程广贵, 张伟, 方俊, 蒋诗宇, 丁建宁, Noshir S P, 张忠强, 郭立强, 王莹 2016 65 060201

Google Scholar

Google Scholar

Cheng G G, Zhang W, Fang J, Jiang S Y, Ding J N, Noshir S P, Zhang Z Q, Guo L Q, Wang Y 2016 Acta Phys. Sin. 65 060201

Google Scholar

Google Scholar

[20] Wu Y, Hu Y, Huang Z, Hu Y, Peng Z, Li X, Wang F 2018 Sens. Actuators 271 364

Google Scholar

Google Scholar

[21] Chen S N, Chen C H, Lin Z H, Tsao Y H, Liu C P 2018 Nano Energy 45 311

Google Scholar

Google Scholar

[22] 温涛, 何剑, 张增星, 田竹梅, 穆继亮, 韩建强, 丑修建, 薛晨阳 2017 66 228401

Google Scholar

Google Scholar

Wen T, He J, Zhang Z X, Tian Z M, Mu J L, Han J Q, Chou X J, Xue C Y 2017 Acta Phys. Sin. 66 228401

Google Scholar

Google Scholar

[23] Ren X, Fan H, Wang C, Ma J, Lei S, Zhao Y 2017 Nano Energy 35 233

Google Scholar

Google Scholar

[24] Shao H Y, Wen Z, Cheng P, Sun N, Shen Q Q, Zhou C J, Peng M F, Yang Y Q, Xie X K, Su X H 2017 Nano Energy 39 608

Google Scholar

Google Scholar

[25] Yang J, Yang F, Zhao L, Shang W, Qin H, Wang S, Jiang X, Cheng G, Du Z 2018 Nano Energy 46 220

Google Scholar

Google Scholar

[26] Cheng G, Zheng H, Yang F, Zhao L, Zheng M, Yang J, Qin H, Du Z, Wang Z L 2018 Nano Energy 44 208

Google Scholar

Google Scholar

[27] Wu Y, Jing Q S, Chen J, Bai P, Bai J J, Zhu G, Su Y J, Wang Z L 2015 Adv. Funct. Mater. 25 2166

Google Scholar

Google Scholar

[28] Wang J, Ding W, Pan L, Wu C, Yu H, Yang L, Liao R, Wang Z L 2018 ACS Nano 12 3954

Google Scholar

Google Scholar

[29] Wu Z, Ding W, Dai Y, Dong K, Wu C, Zhang L, Lin Z, Cheng J, Wang Z L 2018 ACS Nano 12 5726

Google Scholar

Google Scholar

[30] Wang P H, Liu R Y, Ding W B, Zhang P, Pan L, Dai G Z, Zou H Y, Dong K, Xu C, Wang Z L 2018 Adv. Funct. Mater. 28 1705808

Google Scholar

Google Scholar

[31] Ren Z W, Nie J H, Shao J J, Lai Q S, Wang L F, Chen J, Chen X Y, Wang Z L 2018 Adv. Funct. Mater. 28 1802989

Google Scholar

Google Scholar

[32] Zheng Q, Shi B J, Fan F R, Wang X X, Yan L, Yuan W W, Wang S H, Liu H, Li Z, Wang Z L 2014 Adv. Mater. 26 5851

Google Scholar

Google Scholar

[33] Zhong J W, Zhang Y, Zhong Q, Hu Q Y, Hu B, Wang Z L, Zhou J 2014 ACS Nano 8 6273

Google Scholar

Google Scholar

-

-

[1] Haque R I, Farine P A, Briand D 2018 Sens. Actuators 271 88

Google Scholar

Google Scholar

[2] Lin Z M, Yang J, Li X S, Wu Y F, Wei W, Liu J, Chen J, Yang J 2018 Adv. Funct. Mater. 28 4280

[3] Chen X, Song Y, Chen H, Zhang J, Zhang H 2017 J. Mater. Chem. A 5 508

[4] Qian J, Kim D S, Lee D W 2018 Nano Energy 49 126

Google Scholar

Google Scholar

[5] Zi Y, Guo H, Wen Z, Yeh M H, Hu C, Wang Z L 2016 ACS Nano 10 4797

Google Scholar

Google Scholar

[6] Jiang T, Tang W, Chen X, Han C B, Lin L, Zi Y, Wang Z L 2016 Adv. Mater. Technol. 1 1600017

Google Scholar

Google Scholar

[7] Tang W, Jiang T, Fan F R, Yu A F, Zhang C, Cao X, Wang Z L 2015 Adv. Funct. Mater. 25 3718

Google Scholar

Google Scholar

[8] Feng Y, Zheng Y, Ma S, Wang D, Zhou F, Liu W 2016 Nano Energy 19 48

Google Scholar

Google Scholar

[9] 王中林 2013 中国科学: 化学 43 759

Wang Z L 2013 Sci. Sin. Chim. 43 759

[10] Xu L, Jiang T, Lin P, Shao J, Wang Z L 2018 ACS Nano 12 1849

Google Scholar

Google Scholar

[11] Zhao X J, Kuang S Y, Wang Z L, Zhu G 2018 ACS Nano 12 4280

Google Scholar

Google Scholar

[12] Pan L, Wang J, Wang P, Gao R, Wang Y C, Zhang X 2018 Nano Res. 1−12

[13] Dudem B, Huynh N D, Kim W, Kim D H, Hwang H J, Choi D, Yu J S 2017 Nano Energy 42 269

Google Scholar

Google Scholar

[14] Cheng G G, Jiang S Y, Li K, Zhang Z Q, Wang Y, Yuan N Y, Ding J N, Zhang W 2017 Appl. Surf. Sci. 412 350

Google Scholar

Google Scholar

[15] Wang S, Wang X, Wang Z L, Yang Y 2016 ACS Nano 10 5696

Google Scholar

Google Scholar

[16] Wang M, Zhang J H, Tang Y, Li J, Zhang B S, Liang E J, Mao Y C, Wang X D 2018 ACS Nano 12 6156

Google Scholar

Google Scholar

[17] Wu C, Kima T W, Sung S, Park J H, Li F 2018 Nano Energy 44 279

Google Scholar

Google Scholar

[18] Mao Y C, Geng D L, Liang E J, Wang X D 2015 Nano Energy 15 227

Google Scholar

Google Scholar

[19] 程广贵, 张伟, 方俊, 蒋诗宇, 丁建宁, Noshir S P, 张忠强, 郭立强, 王莹 2016 65 060201

Google Scholar

Google Scholar

Cheng G G, Zhang W, Fang J, Jiang S Y, Ding J N, Noshir S P, Zhang Z Q, Guo L Q, Wang Y 2016 Acta Phys. Sin. 65 060201

Google Scholar

Google Scholar

[20] Wu Y, Hu Y, Huang Z, Hu Y, Peng Z, Li X, Wang F 2018 Sens. Actuators 271 364

Google Scholar

Google Scholar

[21] Chen S N, Chen C H, Lin Z H, Tsao Y H, Liu C P 2018 Nano Energy 45 311

Google Scholar

Google Scholar

[22] 温涛, 何剑, 张增星, 田竹梅, 穆继亮, 韩建强, 丑修建, 薛晨阳 2017 66 228401

Google Scholar

Google Scholar

Wen T, He J, Zhang Z X, Tian Z M, Mu J L, Han J Q, Chou X J, Xue C Y 2017 Acta Phys. Sin. 66 228401

Google Scholar

Google Scholar

[23] Ren X, Fan H, Wang C, Ma J, Lei S, Zhao Y 2017 Nano Energy 35 233

Google Scholar

Google Scholar

[24] Shao H Y, Wen Z, Cheng P, Sun N, Shen Q Q, Zhou C J, Peng M F, Yang Y Q, Xie X K, Su X H 2017 Nano Energy 39 608

Google Scholar

Google Scholar

[25] Yang J, Yang F, Zhao L, Shang W, Qin H, Wang S, Jiang X, Cheng G, Du Z 2018 Nano Energy 46 220

Google Scholar

Google Scholar

[26] Cheng G, Zheng H, Yang F, Zhao L, Zheng M, Yang J, Qin H, Du Z, Wang Z L 2018 Nano Energy 44 208

Google Scholar

Google Scholar

[27] Wu Y, Jing Q S, Chen J, Bai P, Bai J J, Zhu G, Su Y J, Wang Z L 2015 Adv. Funct. Mater. 25 2166

Google Scholar

Google Scholar

[28] Wang J, Ding W, Pan L, Wu C, Yu H, Yang L, Liao R, Wang Z L 2018 ACS Nano 12 3954

Google Scholar

Google Scholar

[29] Wu Z, Ding W, Dai Y, Dong K, Wu C, Zhang L, Lin Z, Cheng J, Wang Z L 2018 ACS Nano 12 5726

Google Scholar

Google Scholar

[30] Wang P H, Liu R Y, Ding W B, Zhang P, Pan L, Dai G Z, Zou H Y, Dong K, Xu C, Wang Z L 2018 Adv. Funct. Mater. 28 1705808

Google Scholar

Google Scholar

[31] Ren Z W, Nie J H, Shao J J, Lai Q S, Wang L F, Chen J, Chen X Y, Wang Z L 2018 Adv. Funct. Mater. 28 1802989

Google Scholar

Google Scholar

[32] Zheng Q, Shi B J, Fan F R, Wang X X, Yan L, Yuan W W, Wang S H, Liu H, Li Z, Wang Z L 2014 Adv. Mater. 26 5851

Google Scholar

Google Scholar

[33] Zhong J W, Zhang Y, Zhong Q, Hu Q Y, Hu B, Wang Z L, Zhou J 2014 ACS Nano 8 6273

Google Scholar

Google Scholar

计量

- 文章访问数: 24715

- PDF下载量: 592

- 被引次数: 0

下载:

下载: