-

针对低频复杂的环境振动能量, 本文提出一种非谐振式低频电磁-摩擦电复合能量收集器件. 该能量收集器以旋转陀螺为核心部件, 具有结构简单、俘能灵敏、鲁棒性强、可360°全方位俘能等优点. 通过理论分析与软件仿真, 阐述了器件的工作原理; 基于线性电机平台, 系统研究了振荡频率、振荡幅度对器件输出性能的影响, 较好地证明了器件收集振动能量的能力. 在2 Hz的振动环境下, 摩擦发电单元在20 MΩ负载下的峰值功率约为0.084 mW, 电磁发电单元在800 Ω负载下峰值功率约为4.61 mW, 系统机电转换效率为0.45%. 最后结合人体运动能收集, 成功验证了该复合能量收集器对低频复杂机械能的收集能力, 并通过能量存储单元, 实现了计步器自供能的正常工作. 本项研究不仅为低频振动能量的高效采集与转换提供了一个崭新的思路, 而且在自供电传感网络节点方面具有潜在应用价值.As the age of the internet of everything begins, the demand for various sensors to communicate with each other is soaring. As the lifeblood of the sensing system, reliable energy supply is the key consideration. Environmental mechanical energy harvesting has been a key technology for self-powering sensing system, which can convert mechanical energy into electric energy. Here, we present a non-resonant triboelectric-electromagnetic hybridized nanogenerator, which can scavenge low-frequency vibration energy from environmental vibration. In the device a rotating gyro is used as a core component. An embedded magnet and four coils arranged evenly around at the bottom of the shell form an electromagnetic generator (EMG), and a piece of triboelectric film pasted on the outer surface of the gyro together with a bottom electrode constitutes a triboelectric nanogenerator, (TENG). With the design of rotating gyro, a high sensitive energy capture can be realized under low frequency and irregular vibration. Under the rotation and revolution of the gyro, the triboelectric and electromagnetic energy will be generated. Through theoretical analysis and software simulation, the working principle of the device is expounded. Based on a linear motor platform, the influences of oscillation frequency and amplitude are systematically studied, and the maximum power of 0.084 mW under a loading resistance of 20 MΩ and 4.61 mW under 800 Ω are obtained at a driving frequency of 2 Hz by the TENG and EMG, respectively. The energy conversion efficiency of the system is 0.45%. Moreover, by placing the devices on the legs and arms of the human body respectively, the ability of the hybridized nanogenerator to capture the simple movement energy of the human body is further verified. After that, a self-powering pedometer module is successfully integrated with the energy storage unit. Under the excitation provided by running a body, the hybridized nanogenerator can provide a 20-s pedometer normal operation after charging a capacitance of 100 μF to 3.2 V. This research not only provides a new idea for the efficient acquisition of vibration energy, but also has potential applications in the energy supply of self-powered sensors.

-

Keywords:

- non-resonant /

- hybridized nanogenerator /

- vibration energy

[1] Bai Y, Xu L, He C, Zhu L P, Yang X D, Jiang T, Nie J H, Zhong W, Wang Z L 2019 Nano Energy 66 104117

Google Scholar

Google Scholar

[2] Xia F B, Pang Y K, Liu G X, Wang S W, Li W, Zhang C, Wang Z L 2019 Nano Energy 61 1

Google Scholar

Google Scholar

[3] An J, Wang Z M, Jiang T, Liang X, Wang Z L 2019 Adv. Funct. Mater. 29 1904867

Google Scholar

Google Scholar

[4] Liu G L, Guo H Y, Xu S X, Hu C G, Wang Z L 2019 Adv. Energy Mater. 9 1900801

[5] Xu M Y, Zhao T C, Wang C, S. L. Zhang S L, Li Z, Pan X X, Wang Z L 2019 ACS Nano 13 1932

[6] Guo H, Wen Z, Zi Y, Yeh M, Wang J, Zhu L, Hu C, Wang Z L 2016 Adv. Energy Mater. 6 1501593

Google Scholar

Google Scholar

[7] Wen Z, Guo H, Zi Y, Yeh M, Wang X, Deng J, Wang J, Li S, Hu C, Zhu L, Wang Z L 2016 ACS Nano 10 6526

Google Scholar

Google Scholar

[8] Gao L X, Lu S, Xie W B, Chen X, Wu L K, Wang T T, Wang A B, Yue C Q, Tong D Q, Lei W Q, Yu H, He X B, Mu X J, Wang Z L, Yang Y 2020 Nano Energy 72 104684

Google Scholar

Google Scholar

[9] Shao H, Cheng P, Chen R, Xie L, Sun N, Shen Q, Chen X, Zhu Q, Zhang Y, Liu Y, Wen Z, Sun X 2018 Nano-Micro Lett. 10 54

Google Scholar

Google Scholar

[10] Gao L X, Hu D L, Qi M K, Gong J, Zhou H, Chen X, Chen J F, Cai J, Wu L K, Hu N, Yang Y, Mu X J 2018 Nanoscale 10 19781

Google Scholar

Google Scholar

[11] Gao L X, Chen X, Lu S, Zhou H, Xie W B, Chen J F, Qi M K, Yu H, Mu X J, Wang Z L, Yang Y 2019 Adv. Energy Mater. 10 1902725

[12] Saha C, Donnell T, Wang N, McCloskey P 2017 Sensors & Actuat. A-Phys. 147 248

[13] Koukharenko E, Beeby S, Tudor M, White N, Donnell T, Saha C, Kulkarni S, Roy S 2006 Microsyst. Technolo. 12 1071

Google Scholar

Google Scholar

[14] Grishchuk P 2003 Physics 6 0306013

[15] Liu H C, Hou C, Lin J H, Li Y F, Shi Q F, Chen T, Sun L N, Lee C K 2018 Appl. Phys. Lett. 113 203901

Google Scholar

Google Scholar

[16] Wang Z L 2017 Nature 542 159

Google Scholar

Google Scholar

[17] Wang J Y, Pan L, Guo H Y, Zhang B B, Zhang R R, Wu Z Y, Wu C S, Yang L J, Liao R J, Wang Z L 2019 Adv. Energy Mater. 9 1802892

Google Scholar

Google Scholar

[18] Hao C C, He J, Zhai C, Jia W, Song L L, Cho J D, Chou X J, Xue C Y 2019 Nano Energy 58 147

[19] Hou C, Chen T, Li Y F, Huang M J, Shi Q F, Liu H C, Sun L N, Lee C K 2019 Nano Energy 63 103871

Google Scholar

Google Scholar

[20] Chen X, Gao L X, Chen J F, Lu S, Zhou H, Wang T T, Wang A B, Zhang Z F, Guo S F, Mu X J, Wang Z L, Yang Y 2020 Nano Energy 69 104440

Google Scholar

Google Scholar

[21] Davies D K 1969 J. Phys. D: Appl. Phys. 2 1533

Google Scholar

Google Scholar

[22] Niu S M, Liu Y, Wang S H, Lin L, Zhou Y S, Hu Y F, Wang Z L 2013 Adv. Mater. 25 6184

Google Scholar

Google Scholar

[23] Zhang C, Tang W, Han C B, Fan F R, Wang Z L 2014 Adv. Mater. 26 3580

Google Scholar

Google Scholar

-

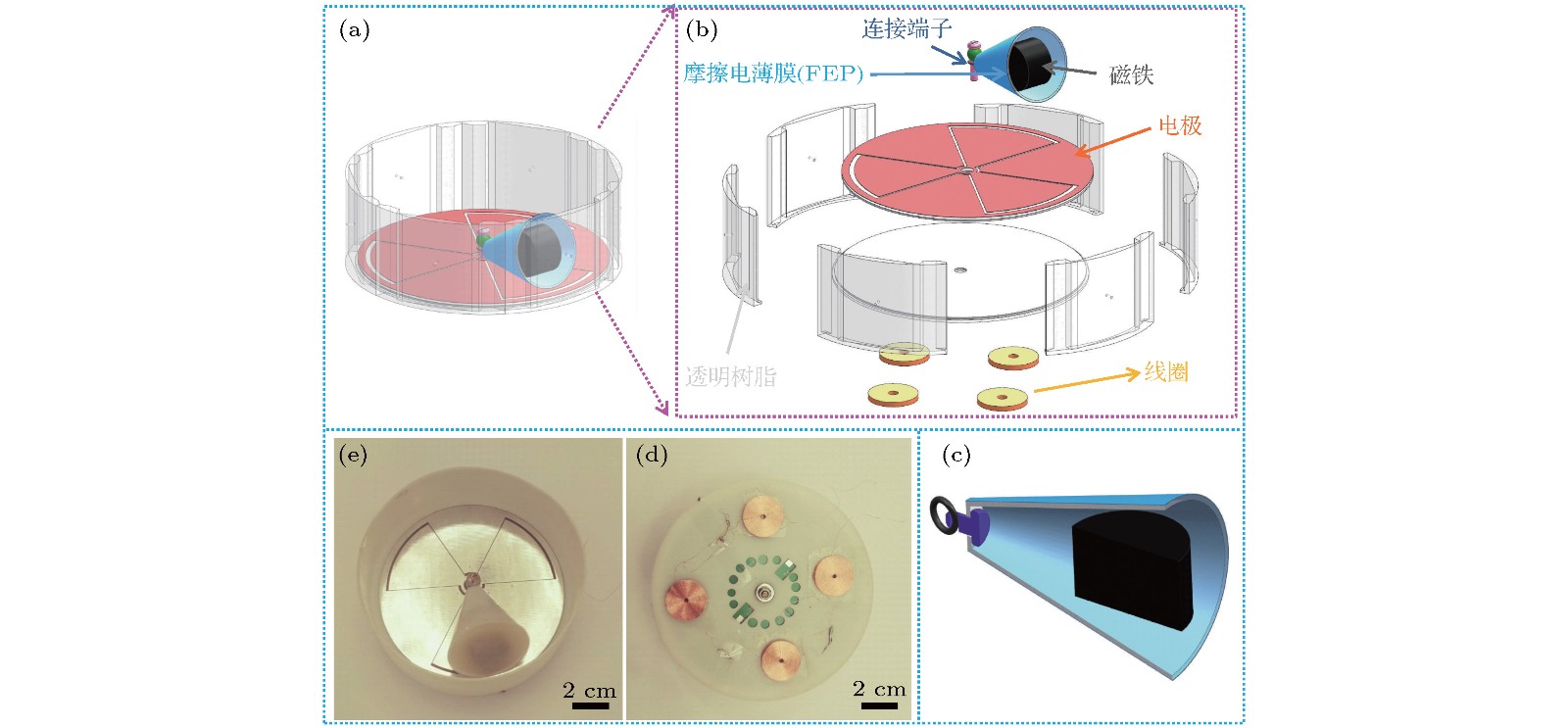

图 1 系统结构模型 (a)电磁-摩擦复合能量收集器模型图; (b) 复合能量收集器结构分解示意图; (c) 陀螺刨面图; (d), (e) 电磁-摩擦复合能量收集器的正反面照片

Fig. 1. The structure model of the system: (a) The model diagram of the hybridized nanogenerator; (b) schematic diagram of structural decomposition of the hybridized nanogenerator; (c) the cross-section of the gyro; (d), (e) digital photograph of the TENG and EMG hybridized nanogenerator.

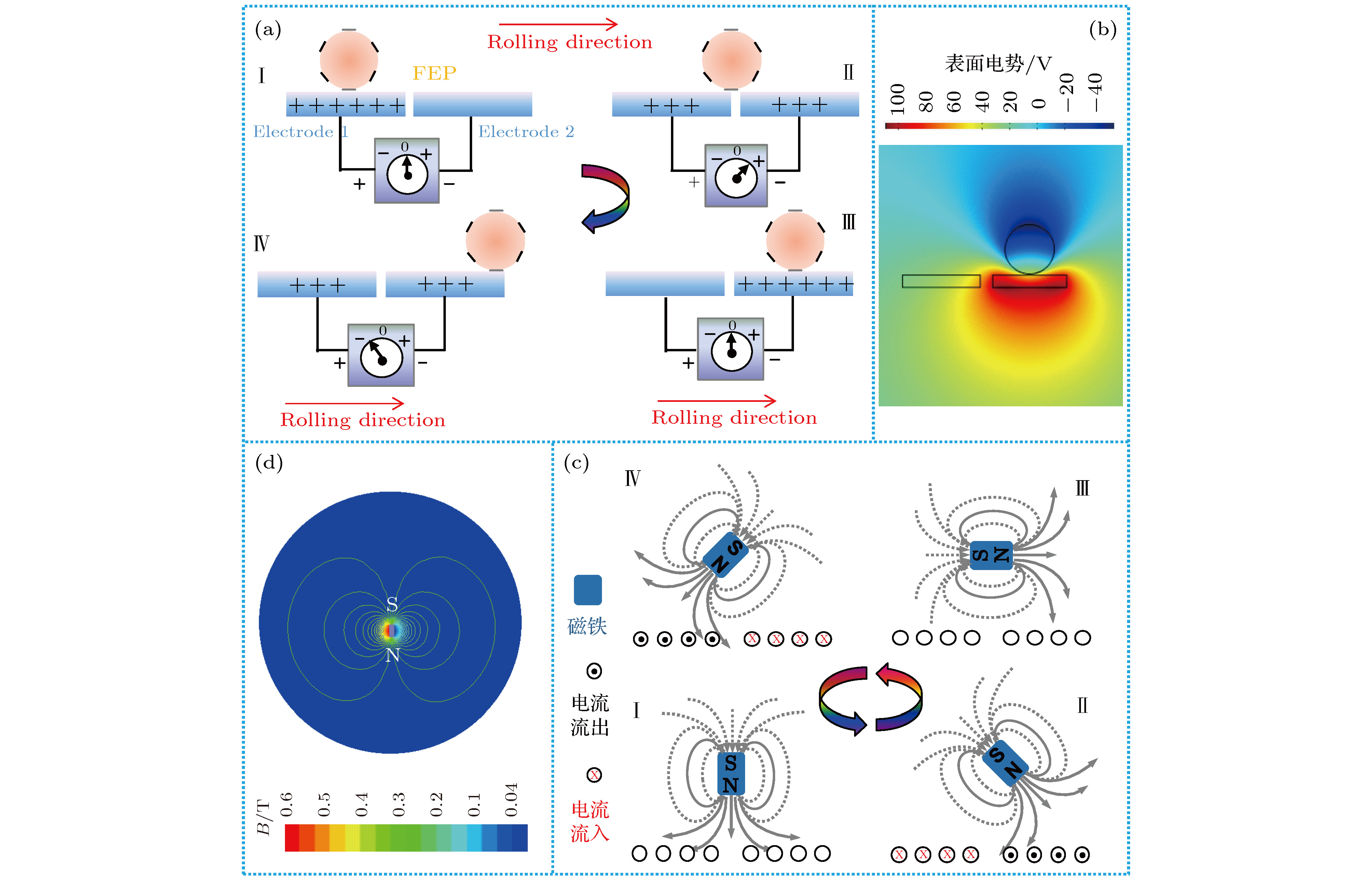

图 2 复合能量收集器的工作原理及其仿真 (a) 摩擦发电单元的工作原理; (b) 摩擦发电单元的仿真; (c)电磁发电单元的工作原理; (d) 电磁发电单元的其仿真

Fig. 2. The operating principle and simulation of the hybridized nanogenerator: (a) The operating principle of the TENG; (b) the simulation of the TENG; (c) the operating principle of the EMG; (d) the simulation of the EMG.

图 3 摩擦发电机的输出与陀螺滚动速度的关系 (a) 摩擦发电机的电流与陀螺滚动速度的关系; (b) 摩擦发电机的电压与陀螺滚动速度的关系

Fig. 3. The relation between the output performance of TENG and the rolling speed of gyro: (a) The relation between the output current of TENG and the rolling speed of gyro; (b) the relation between the output voltage of TENG and the rolling speed of gyro.

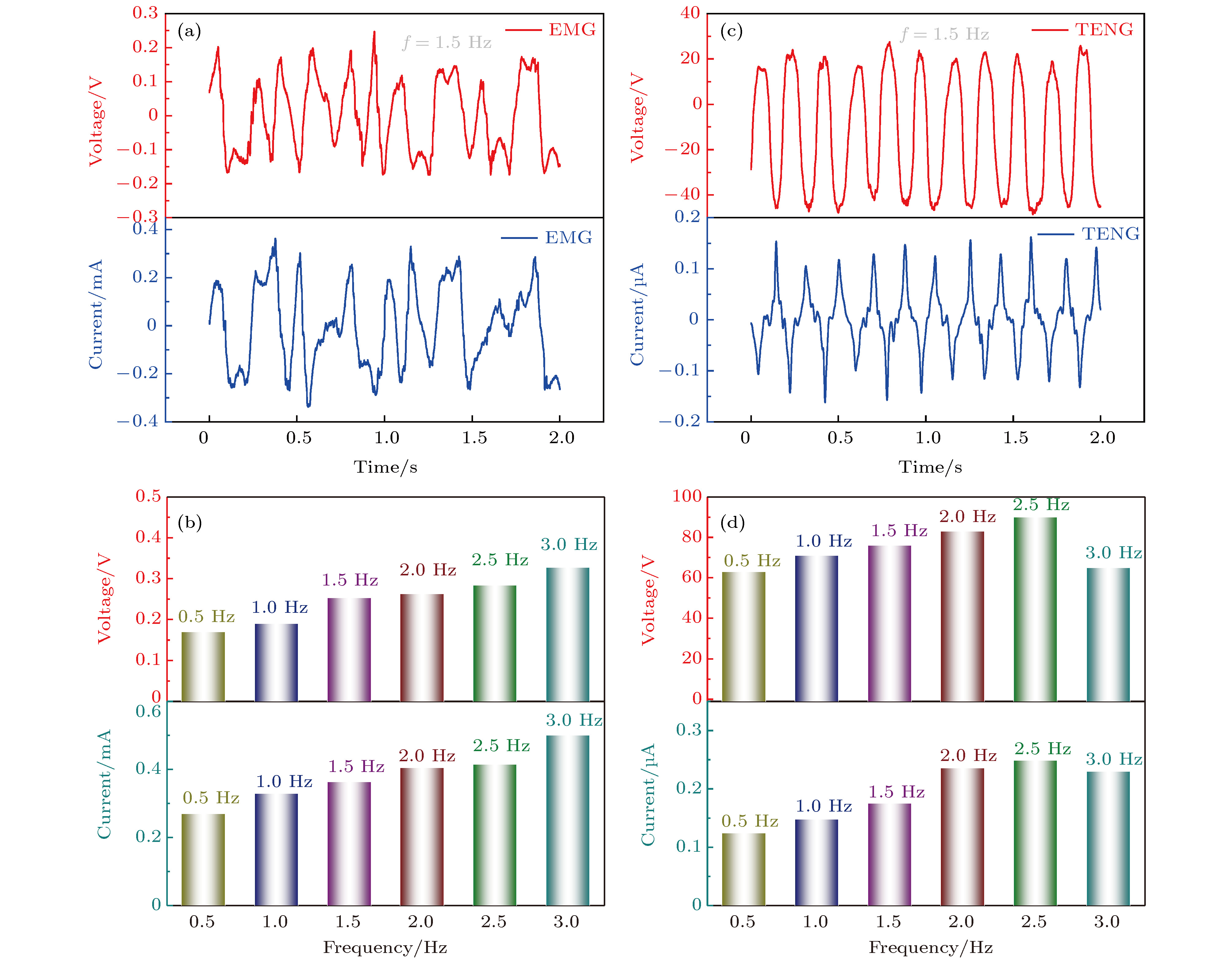

图 4 在线性马达不同激励频率下复合能量收集器的输出特性 (a) 1.5 Hz频率下电磁发电机的输出特性; (b) 不同频率下电磁发电机的输出特性; (c) 1.5 Hz频率下摩擦发电机的输出特性; (d) 不同频率下摩擦发电机的输出特性

Fig. 4. The output characteristics of the hybridized nanogenerator excited by a linear motor: (a) The output characteristics of the EMG in 1.5 Hz; (b) the output characteristics of the EMG in different frequencies; (c) the output characteristics of the TENG in 1.5 Hz; (d) the output characteristics of the TENG in different frequencies.

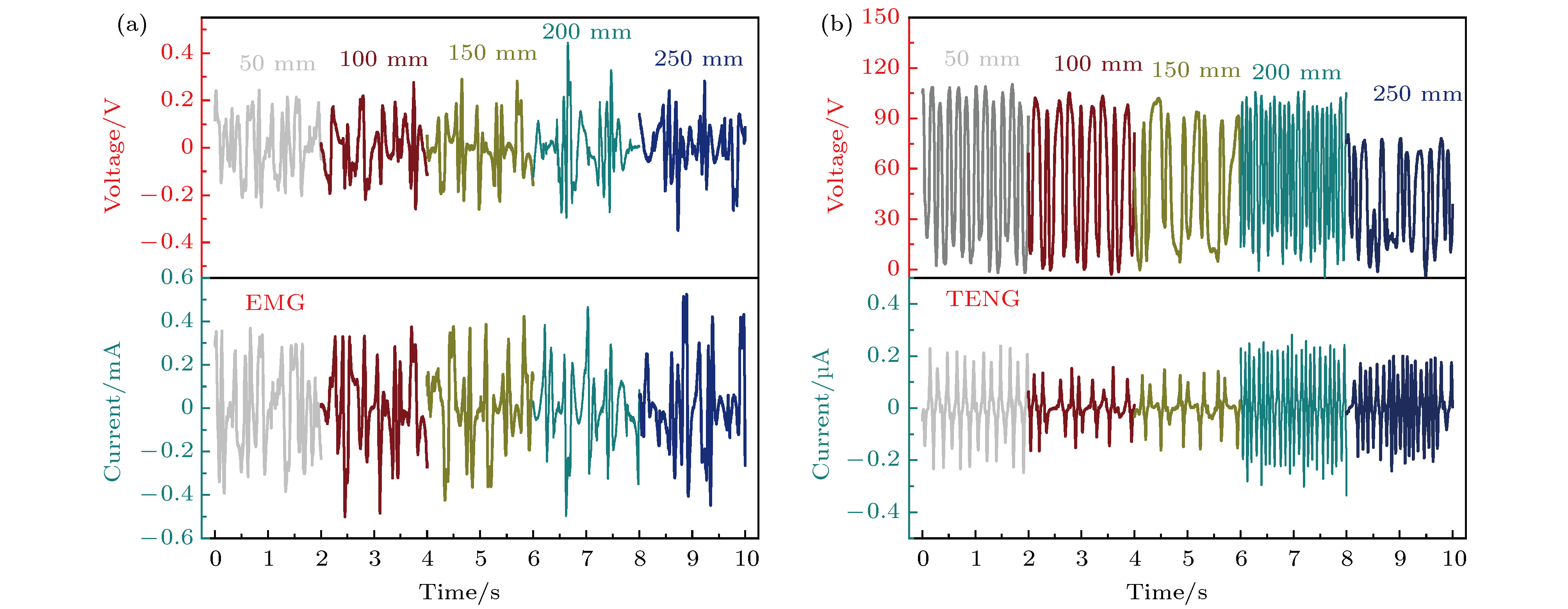

图 5 线性马达不同往复行程激励下复合能量收集器的输出特性 (a) 不同振动幅度下电磁发电机的输出特性; (b) 不同振动幅度下摩擦发电机的输出特性

Fig. 5. The output characteristics of the hybridized nanogenerator under the excitation of different reciprocating stroke of the linear motor: (a) The output characteristics of the EMG under different amplitude; (b) output characteristics of TENG at different amplitudes.

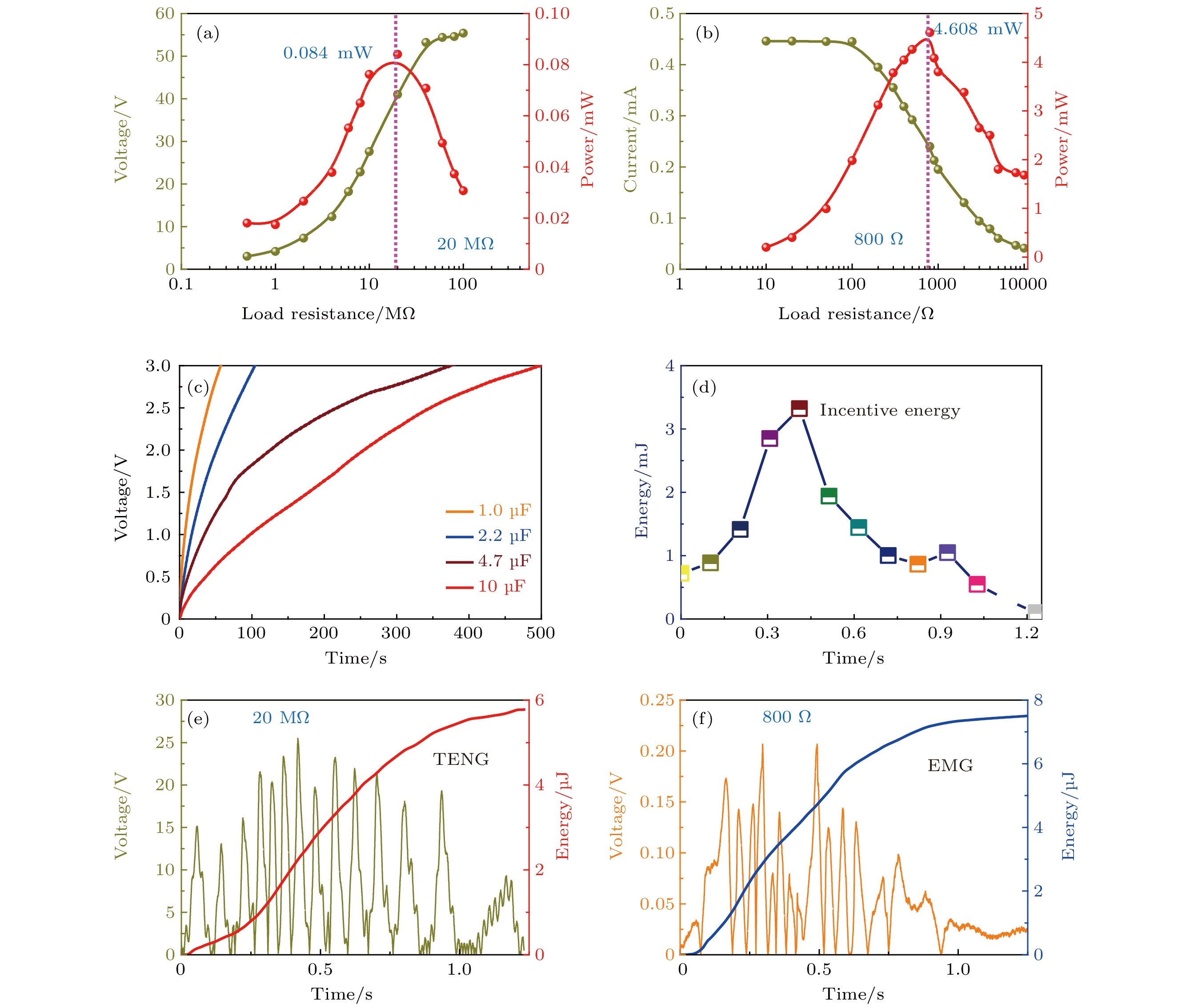

图 6 复合能量收集器的功率与能量 (a) 摩擦发电机在不同负载下的输出电压与输出功率; (b) 电磁发电机在不同负载下的输出电压与输出功率; (c) 复合能量收集器对不同电容的充电曲线; (d) 单次外部激励的机械能量; (e) 摩擦发电机在20 MΩ下的俘能曲线; (f) 电磁发电机在800 Ω下的俘能曲线

Fig. 6. The power and energy of the hybridized nanogenerator: (a) The voltage and power curves of TENG under different loads; (b) the voltage and power curves of EMG under different loads; (c) the charging curves of the hybridized nanogenerator for different capacitors; (d) the incentive energy of a single excitation; (e) the output energy of the TENG under 20 MΩ; (f) the output energy of the EMG under 800 Ω.

图 7 复合能量收集器对人体运动能的收集能力 (a) 置于腿部, 电磁发电机对人体能量收集的输出曲线; (b) 置于腿部, 摩擦发电机对人体能量收集的输出曲线; (c) 置于手臂, 电磁发电机对人体能量收集的输出曲线; (d) 置于手臂, 摩擦发电机对人体能量收集的输出曲线

Fig. 7. The ability of the hybridized nanogenerator to the kinetic energy of the human body: (a) The outputs of the EMG from human body when it is placed on the leg; (b) the outputs of the TENG from human body when it is placed on the leg; (c) the outputs of the EMG from human body when it is placed on the arm; (d) the outputs of the TENG from human body when it is placed on the arm.

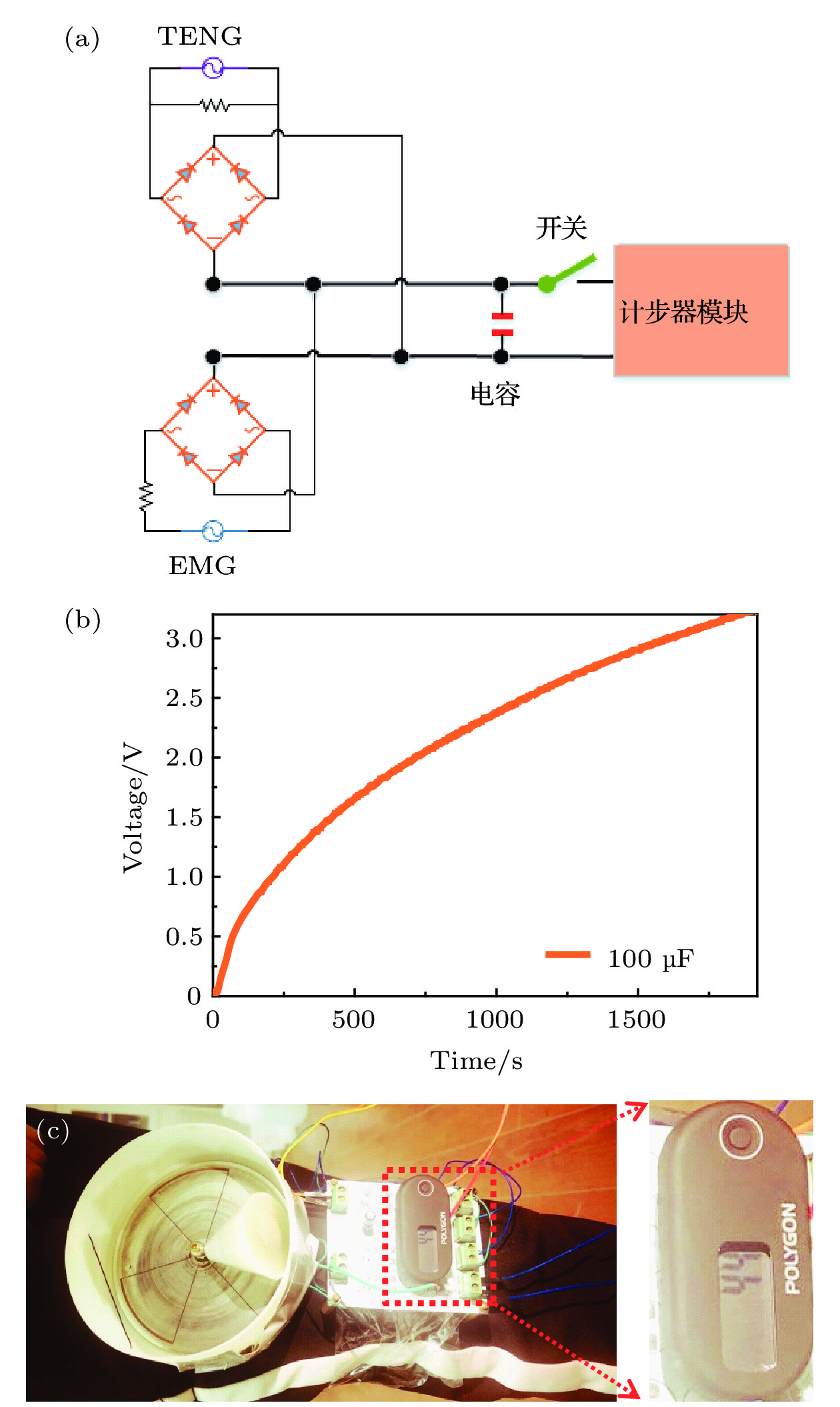

图 8 复合能量收集器在自供电传感器中的应用实验 (a) 自供电计步器模块图; (b) 复合能量收集器对100 µF电容的充电曲线; (c) 自供电计步器实物图

Fig. 8. The application of the hybridized nanogenerator in self-powered sensor: (a) The diagram of self-powered pedometer module; (b) the charging curves of the hybridized nanogenerator for a capacitor of 100 µF; (c) the photograph of self-powered pedometer module.

-

[1] Bai Y, Xu L, He C, Zhu L P, Yang X D, Jiang T, Nie J H, Zhong W, Wang Z L 2019 Nano Energy 66 104117

Google Scholar

Google Scholar

[2] Xia F B, Pang Y K, Liu G X, Wang S W, Li W, Zhang C, Wang Z L 2019 Nano Energy 61 1

Google Scholar

Google Scholar

[3] An J, Wang Z M, Jiang T, Liang X, Wang Z L 2019 Adv. Funct. Mater. 29 1904867

Google Scholar

Google Scholar

[4] Liu G L, Guo H Y, Xu S X, Hu C G, Wang Z L 2019 Adv. Energy Mater. 9 1900801

[5] Xu M Y, Zhao T C, Wang C, S. L. Zhang S L, Li Z, Pan X X, Wang Z L 2019 ACS Nano 13 1932

[6] Guo H, Wen Z, Zi Y, Yeh M, Wang J, Zhu L, Hu C, Wang Z L 2016 Adv. Energy Mater. 6 1501593

Google Scholar

Google Scholar

[7] Wen Z, Guo H, Zi Y, Yeh M, Wang X, Deng J, Wang J, Li S, Hu C, Zhu L, Wang Z L 2016 ACS Nano 10 6526

Google Scholar

Google Scholar

[8] Gao L X, Lu S, Xie W B, Chen X, Wu L K, Wang T T, Wang A B, Yue C Q, Tong D Q, Lei W Q, Yu H, He X B, Mu X J, Wang Z L, Yang Y 2020 Nano Energy 72 104684

Google Scholar

Google Scholar

[9] Shao H, Cheng P, Chen R, Xie L, Sun N, Shen Q, Chen X, Zhu Q, Zhang Y, Liu Y, Wen Z, Sun X 2018 Nano-Micro Lett. 10 54

Google Scholar

Google Scholar

[10] Gao L X, Hu D L, Qi M K, Gong J, Zhou H, Chen X, Chen J F, Cai J, Wu L K, Hu N, Yang Y, Mu X J 2018 Nanoscale 10 19781

Google Scholar

Google Scholar

[11] Gao L X, Chen X, Lu S, Zhou H, Xie W B, Chen J F, Qi M K, Yu H, Mu X J, Wang Z L, Yang Y 2019 Adv. Energy Mater. 10 1902725

[12] Saha C, Donnell T, Wang N, McCloskey P 2017 Sensors & Actuat. A-Phys. 147 248

[13] Koukharenko E, Beeby S, Tudor M, White N, Donnell T, Saha C, Kulkarni S, Roy S 2006 Microsyst. Technolo. 12 1071

Google Scholar

Google Scholar

[14] Grishchuk P 2003 Physics 6 0306013

[15] Liu H C, Hou C, Lin J H, Li Y F, Shi Q F, Chen T, Sun L N, Lee C K 2018 Appl. Phys. Lett. 113 203901

Google Scholar

Google Scholar

[16] Wang Z L 2017 Nature 542 159

Google Scholar

Google Scholar

[17] Wang J Y, Pan L, Guo H Y, Zhang B B, Zhang R R, Wu Z Y, Wu C S, Yang L J, Liao R J, Wang Z L 2019 Adv. Energy Mater. 9 1802892

Google Scholar

Google Scholar

[18] Hao C C, He J, Zhai C, Jia W, Song L L, Cho J D, Chou X J, Xue C Y 2019 Nano Energy 58 147

[19] Hou C, Chen T, Li Y F, Huang M J, Shi Q F, Liu H C, Sun L N, Lee C K 2019 Nano Energy 63 103871

Google Scholar

Google Scholar

[20] Chen X, Gao L X, Chen J F, Lu S, Zhou H, Wang T T, Wang A B, Zhang Z F, Guo S F, Mu X J, Wang Z L, Yang Y 2020 Nano Energy 69 104440

Google Scholar

Google Scholar

[21] Davies D K 1969 J. Phys. D: Appl. Phys. 2 1533

Google Scholar

Google Scholar

[22] Niu S M, Liu Y, Wang S H, Lin L, Zhou Y S, Hu Y F, Wang Z L 2013 Adv. Mater. 25 6184

Google Scholar

Google Scholar

[23] Zhang C, Tang W, Han C B, Fan F R, Wang Z L 2014 Adv. Mater. 26 3580

Google Scholar

Google Scholar

计量

- 文章访问数: 9030

- PDF下载量: 139

- 被引次数: 0

下载:

下载: