-

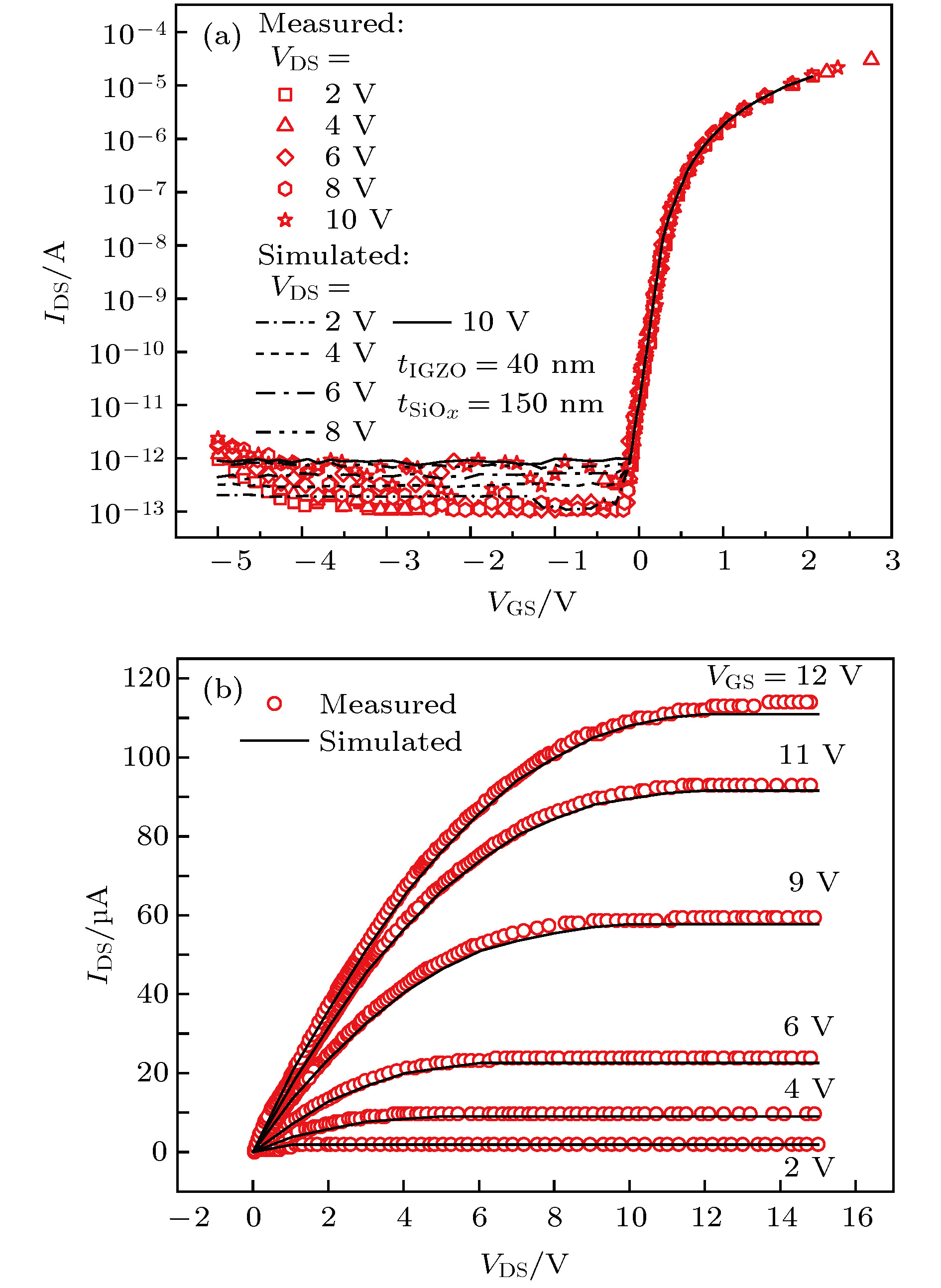

研究了非晶氧化锌镓铟薄膜晶体管(amorphous InGaZnO thin-film transistor, InGaZnO TFT)的泄漏电流模型. 基于Poole-Frenkel热发射效应和热离子场致发射效应的泄漏电流产生机制, 分别得到了高电场和低电场条件下的载流子产生-复合率. 在此基础上推导得到了InGaZnO TFT的分段式泄漏电流-电压数学模型, 并利用平滑函数得到了关断区和亚阈区连续统一的泄漏电流模型. 所提出的泄漏电流模型的计算值和TCAD模拟值与实验结果较为吻合. 利用所提出的InGaZnO TFT泄漏电流模型和TCAD模拟, 讨论了InGaZnO TFT不同的沟道宽度、沟道长度和栅介质层厚度对泄漏电流值的影响. 研究结果对InGaZnO TFT集成传感电路的设计具有一定参考价值.

-

关键词:

- InGaZnO /

- 泄漏电流 /

- thin-film transistor /

- 器件模型

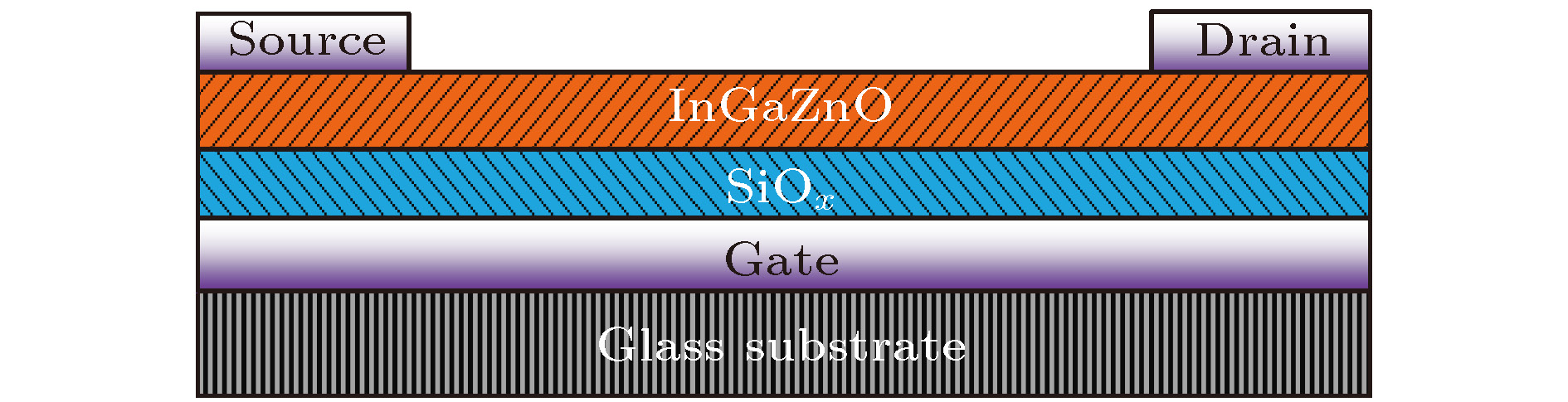

In recent years, amorphous InGaZnO thin-film transistor (InGaZnO TFT) has attracted intensive attention. Due to its high mobility, low off-state current, and excellent uniformity over large fabrication area, the InGaZnO TFTs promise to replace silicon-based TFTs in flat panel displays, optical image sensors, touch sensing and fingerprint sensing area. The on-state performances of InGaZnO TFT are used in thin film transistor liquid crystal display, active-matrix organic light emitting display, etc. Consequently, numerous on-current models have been proposed previously. However, for lots of the emerging sensing applications such as optical image sensors, the leakage current of InGaZnO TFTs is critical. Previous literature has shown that the leakage current generation mechanisms in TFTs include trap-assisted thermal emission, trap-assisted field emission, inter-band tunneling, and auxiliary thermal electron field emission containing Poole-Frenkel effect. However, up to now, there has been few reports on the leakage current model of InGaZnO TFT, which hinders further the development of emerging applications in InGaZnO TFTs for sensor and imagers integrated in display panels. In this paper, the leakage current model of InGaZnO TFT is established on the basis of carrier generation recombination rate. The feasibility of the proposed model is proved by comparing the TCAD simulations with the measured results. In addition, the influences of geometrical parameters on the leakage current of InGaZnO TFT, i.e. the channel width, the active layer thickness, and the gate dielectric thickness, are analyzed in detail. This research gives insightful results for designing the sensors and circuits by using the InGaZnO TFTs. -

Keywords:

- InGaZnO /

- leakage current /

- thin-film transistor /

- device model

[1] Kim Y, Kim Y, Lee H 2014 J. Disp. Technol. 10 80

Google Scholar

Google Scholar

[2] Qian C, Sun J, Zhang L, Huang H, Yang J, Gao Y 2015 J. Phys. Chem. C 119 14965

Google Scholar

Google Scholar

[3] Zhang C, Luo Q, Wu H, Li H, Lai J, Ji G, Yan L, Wang X, Zhang D, Lin J, Chen L, Yang J, Ma C 2017 Org. Electron. 45 190

Google Scholar

Google Scholar

[4] Zheng Z, Jiang J, Guo J, Sun J, Yang J 2016 Org. Electron. 33 311

Google Scholar

Google Scholar

[5] Liu F, Qian C, Sun J, Liu P, Huang Y, Gao Y, Yang J 2016 Appl. Phys. A: Mater. 122 311

Google Scholar

Google Scholar

[6] Zhao C, Kanicki J 2014 Med. Phys. 41 091902

Google Scholar

Google Scholar

[7] Seo W K, Pi J E, Cho S H, Kang S Y, Ahn S D, Hwang C S, Jeon H S, Kim J U, Lee M H 2018 Sensors 18 293

Google Scholar

Google Scholar

[8] Geng D, Chen Y F, Mativenga M, Jang J 2017 IEEE Electr. Dev. Lett. 38 391

[9] Kumomi H, Yaginuma S, Omura H, Goyal A, Sato A, Watanabe M, Shimada M, Kaji N, Takahashi K, Ofuji M, Watanabe T, Itagaki N, Shimizu H, Abe K, Tateishi Y, Yabuta H, Iwasaki T, Hayashi R, Aiba T, Sano M 2009 J. Disp. Technol. 5 531

Google Scholar

Google Scholar

[10] 覃婷, 黄生祥, 廖聪维, 于天宝, 邓联文 2017 66 097101

Google Scholar

Google Scholar

Qin T, Huang S X, Liao C W, Yu T B, Deng L W 2017 Acta Phys. Sin. 66 097101

Google Scholar

Google Scholar

[11] 覃婷, 黄生祥, 廖聪维, 于天宝, 罗衡, 刘胜, 邓联文 2018 67 047302

Google Scholar

Google Scholar

Qin T, Huang S X, Liao C W, Yu T B, Liu S, Luo H 2018 Acta Phys. Sin. 67 047302

Google Scholar

Google Scholar

[12] Qin T, Liao C W, Huang S X, Yu T B, Deng L W 2018 Jpn. J. Appl. Phys. 57 014301

Google Scholar

Google Scholar

[13] Mcdaid L J, Hall S, Eccleston W, Alderman J C 1989 IEEE European Solid State Device Research Conference, Berlin, Germany, September 11–14, 1989 p759

[14] Faughnan B, Ipri A C 1989 IEEE Trans. Electron Dev. 36 101

Google Scholar

Google Scholar

[15] Kim C H, Sohn K S, Jin J 1997 J. Appl. Phys. 81 8084

Google Scholar

Google Scholar

[16] Dimitriadis C A, Farmakis F V, Brini J, Kamarinos G 2000 J. Appl. Phys. 88 2648

Google Scholar

Google Scholar

[17] Seki S, Kogure O, Tsujiyama B 1987 IEEE Electr. Dev. Lett. 8 434

Google Scholar

Google Scholar

[18] Lui O K B, Migliorato P 1997 Solid-State Electron. 41 575

Google Scholar

Google Scholar

[19] Wu W J, Yao R H, Li S H, Hu Y F, Deng W L 2007 IEEE Trans. Electron Dev. 54 2975

Google Scholar

Google Scholar

[20] Servati P, Nathan A 2002 IEEE Trans. Electron Dev. 49 812

Google Scholar

Google Scholar

[21] Kamiya T, Nomura K, Hosono H 2010 Sci. Technol. Adv. Mat. 11 044305

Google Scholar

Google Scholar

[22] Rottländer P, Hehn M, Schuhl A 2002 Phys. Rev. B 65 054422

Google Scholar

Google Scholar

[23] Brotherton S D, Ayres J R, Young N D 1991 Solid-State Electron. 34 671

Google Scholar

Google Scholar

[24] Kim C H, Sohn K S, Jin J 1997 J. Appl. Phys. 81 8084

Google Scholar

Google Scholar

[25] Jacunski M D, Shur M S, Owusu A A, Ytterdal T, Hack M, Iniguez B 1999 IEEE Trans. Electron Dev. 46 1146

Google Scholar

Google Scholar

[26] Hurkx G A M, Klaassen D B M, Knuvers M P G 1992 IEEE Trans. Electron Dev. 39 331

Google Scholar

Google Scholar

[27] Bhattacharya S S, Banerjee S K, Nguyen B Y, Tobin P J 1994 IEEE Trans. Electron Dev. 41 221

Google Scholar

Google Scholar

[28] Li C, Liao C W, Yu T B, Ke J Y, Huang S X, Deng L W 2018 Chin. Phys. Lett. 35 027032

[29] Yoon J K, Jang Y H, Kim B K, Choi H S, Ahn B C, Lee C 1993 J. Non-Cryst. Solids 164 747

-

表 1 InGaZnO TFT器件结构的几何参数

Table 1. Geometric parameters of InGaZnO TFT device structure.

参数 数值 栅介质层厚度/nm 150 a-InGaZnO半导体层厚度/nm 40 沟道宽度/${\text{μ}}{\rm{m}}$ 300 沟道长度/${\text{μ}}{\rm{m}}$ 50 表 2 InGaZnO缺陷态密度模型参数

Table 2. Density of states model parameters for InGaZnO.

参数 描述 数值 单位 nta 导带尾类受主能态密度 1.04 × 1019 cm–3·eV–1 ntd 价带尾类施主能态密度 5.0 × 1020 cm–3·eV–1 wta 类受主态特征能量 0.04 eV wtd 类施主态特征能量 0.1 eV nga 高斯分布的受主态密度 0 cm–3·eV–1 ngd 高斯分布的施主态密度 2.0 × 1016 cm–3·eV–1 egd 高斯分布施主能态峰值能量 2.9 eV wgd 高斯分布施主能态特征能量 0.1 eV -

[1] Kim Y, Kim Y, Lee H 2014 J. Disp. Technol. 10 80

Google Scholar

Google Scholar

[2] Qian C, Sun J, Zhang L, Huang H, Yang J, Gao Y 2015 J. Phys. Chem. C 119 14965

Google Scholar

Google Scholar

[3] Zhang C, Luo Q, Wu H, Li H, Lai J, Ji G, Yan L, Wang X, Zhang D, Lin J, Chen L, Yang J, Ma C 2017 Org. Electron. 45 190

Google Scholar

Google Scholar

[4] Zheng Z, Jiang J, Guo J, Sun J, Yang J 2016 Org. Electron. 33 311

Google Scholar

Google Scholar

[5] Liu F, Qian C, Sun J, Liu P, Huang Y, Gao Y, Yang J 2016 Appl. Phys. A: Mater. 122 311

Google Scholar

Google Scholar

[6] Zhao C, Kanicki J 2014 Med. Phys. 41 091902

Google Scholar

Google Scholar

[7] Seo W K, Pi J E, Cho S H, Kang S Y, Ahn S D, Hwang C S, Jeon H S, Kim J U, Lee M H 2018 Sensors 18 293

Google Scholar

Google Scholar

[8] Geng D, Chen Y F, Mativenga M, Jang J 2017 IEEE Electr. Dev. Lett. 38 391

[9] Kumomi H, Yaginuma S, Omura H, Goyal A, Sato A, Watanabe M, Shimada M, Kaji N, Takahashi K, Ofuji M, Watanabe T, Itagaki N, Shimizu H, Abe K, Tateishi Y, Yabuta H, Iwasaki T, Hayashi R, Aiba T, Sano M 2009 J. Disp. Technol. 5 531

Google Scholar

Google Scholar

[10] 覃婷, 黄生祥, 廖聪维, 于天宝, 邓联文 2017 66 097101

Google Scholar

Google Scholar

Qin T, Huang S X, Liao C W, Yu T B, Deng L W 2017 Acta Phys. Sin. 66 097101

Google Scholar

Google Scholar

[11] 覃婷, 黄生祥, 廖聪维, 于天宝, 罗衡, 刘胜, 邓联文 2018 67 047302

Google Scholar

Google Scholar

Qin T, Huang S X, Liao C W, Yu T B, Liu S, Luo H 2018 Acta Phys. Sin. 67 047302

Google Scholar

Google Scholar

[12] Qin T, Liao C W, Huang S X, Yu T B, Deng L W 2018 Jpn. J. Appl. Phys. 57 014301

Google Scholar

Google Scholar

[13] Mcdaid L J, Hall S, Eccleston W, Alderman J C 1989 IEEE European Solid State Device Research Conference, Berlin, Germany, September 11–14, 1989 p759

[14] Faughnan B, Ipri A C 1989 IEEE Trans. Electron Dev. 36 101

Google Scholar

Google Scholar

[15] Kim C H, Sohn K S, Jin J 1997 J. Appl. Phys. 81 8084

Google Scholar

Google Scholar

[16] Dimitriadis C A, Farmakis F V, Brini J, Kamarinos G 2000 J. Appl. Phys. 88 2648

Google Scholar

Google Scholar

[17] Seki S, Kogure O, Tsujiyama B 1987 IEEE Electr. Dev. Lett. 8 434

Google Scholar

Google Scholar

[18] Lui O K B, Migliorato P 1997 Solid-State Electron. 41 575

Google Scholar

Google Scholar

[19] Wu W J, Yao R H, Li S H, Hu Y F, Deng W L 2007 IEEE Trans. Electron Dev. 54 2975

Google Scholar

Google Scholar

[20] Servati P, Nathan A 2002 IEEE Trans. Electron Dev. 49 812

Google Scholar

Google Scholar

[21] Kamiya T, Nomura K, Hosono H 2010 Sci. Technol. Adv. Mat. 11 044305

Google Scholar

Google Scholar

[22] Rottländer P, Hehn M, Schuhl A 2002 Phys. Rev. B 65 054422

Google Scholar

Google Scholar

[23] Brotherton S D, Ayres J R, Young N D 1991 Solid-State Electron. 34 671

Google Scholar

Google Scholar

[24] Kim C H, Sohn K S, Jin J 1997 J. Appl. Phys. 81 8084

Google Scholar

Google Scholar

[25] Jacunski M D, Shur M S, Owusu A A, Ytterdal T, Hack M, Iniguez B 1999 IEEE Trans. Electron Dev. 46 1146

Google Scholar

Google Scholar

[26] Hurkx G A M, Klaassen D B M, Knuvers M P G 1992 IEEE Trans. Electron Dev. 39 331

Google Scholar

Google Scholar

[27] Bhattacharya S S, Banerjee S K, Nguyen B Y, Tobin P J 1994 IEEE Trans. Electron Dev. 41 221

Google Scholar

Google Scholar

[28] Li C, Liao C W, Yu T B, Ke J Y, Huang S X, Deng L W 2018 Chin. Phys. Lett. 35 027032

[29] Yoon J K, Jang Y H, Kim B K, Choi H S, Ahn B C, Lee C 1993 J. Non-Cryst. Solids 164 747

计量

- 文章访问数: 13661

- PDF下载量: 290

- 被引次数: 0

下载:

下载: