-

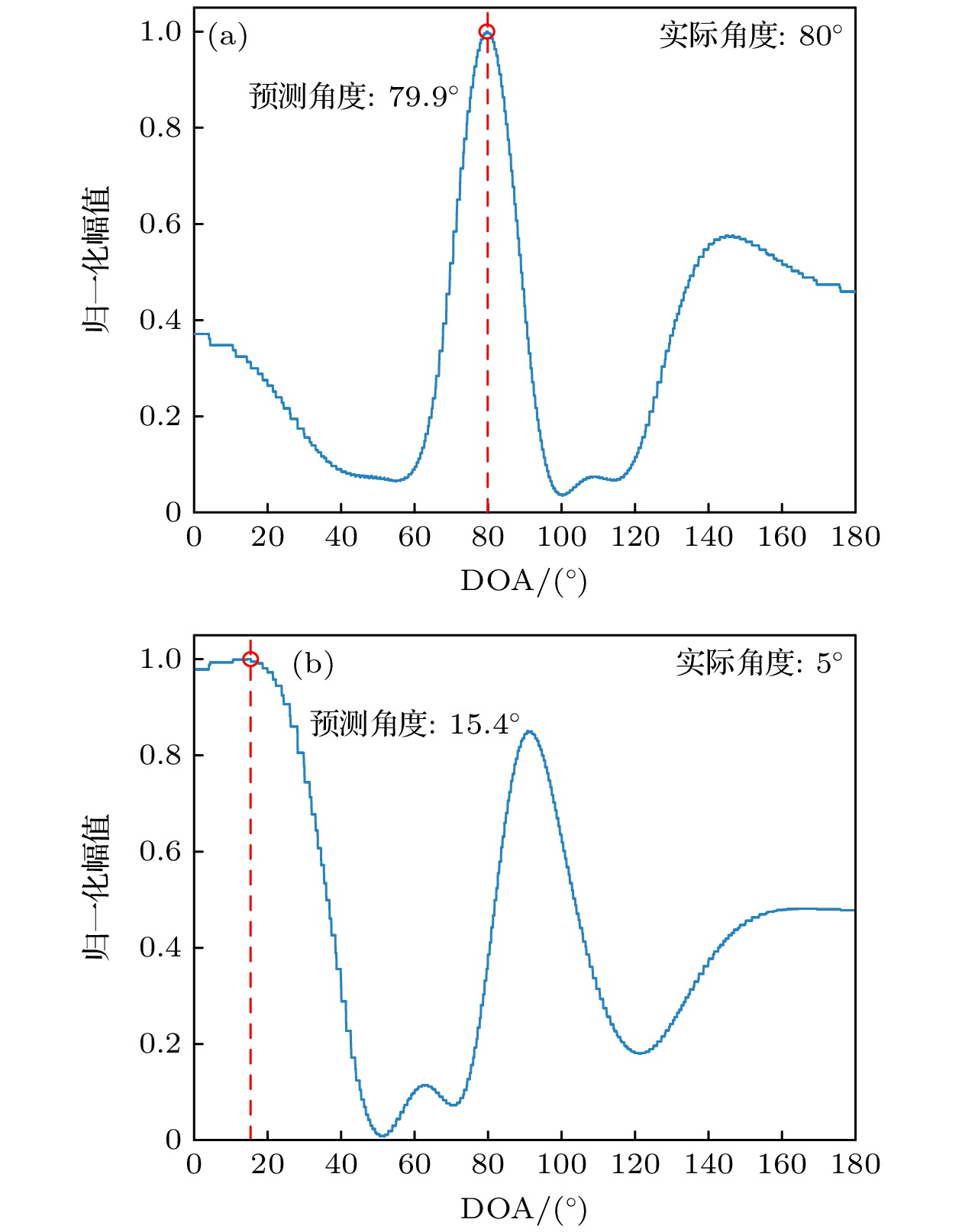

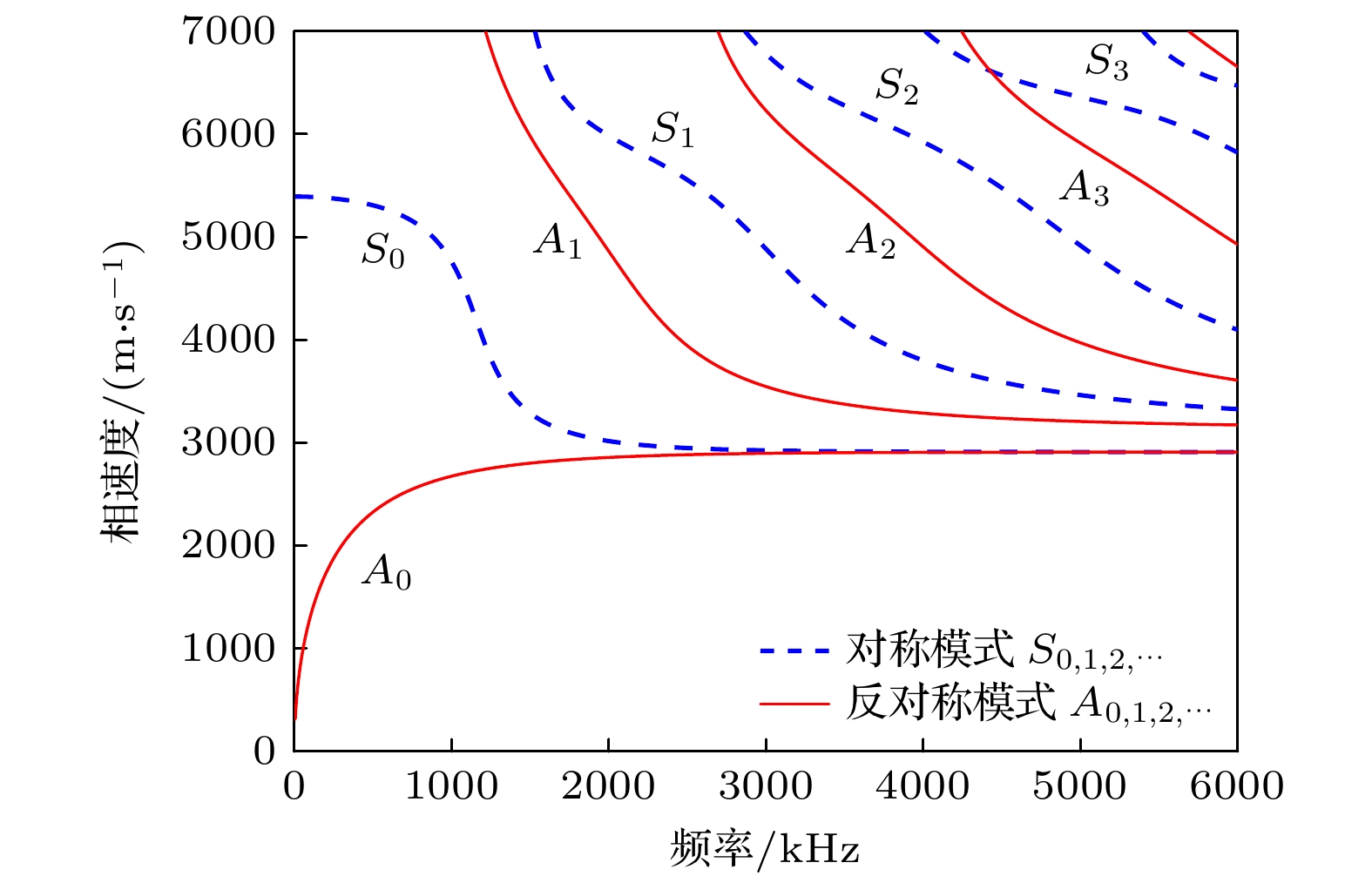

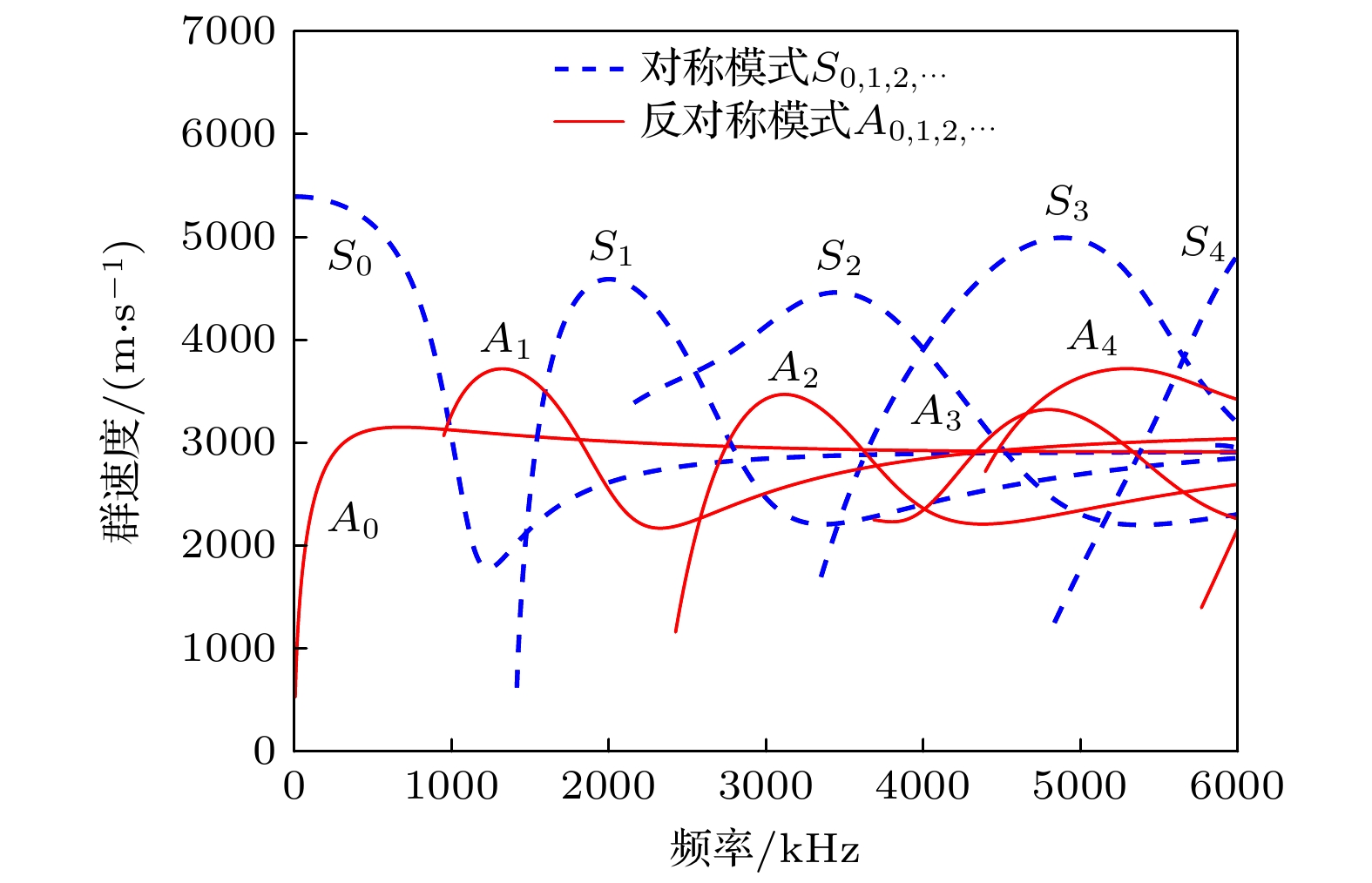

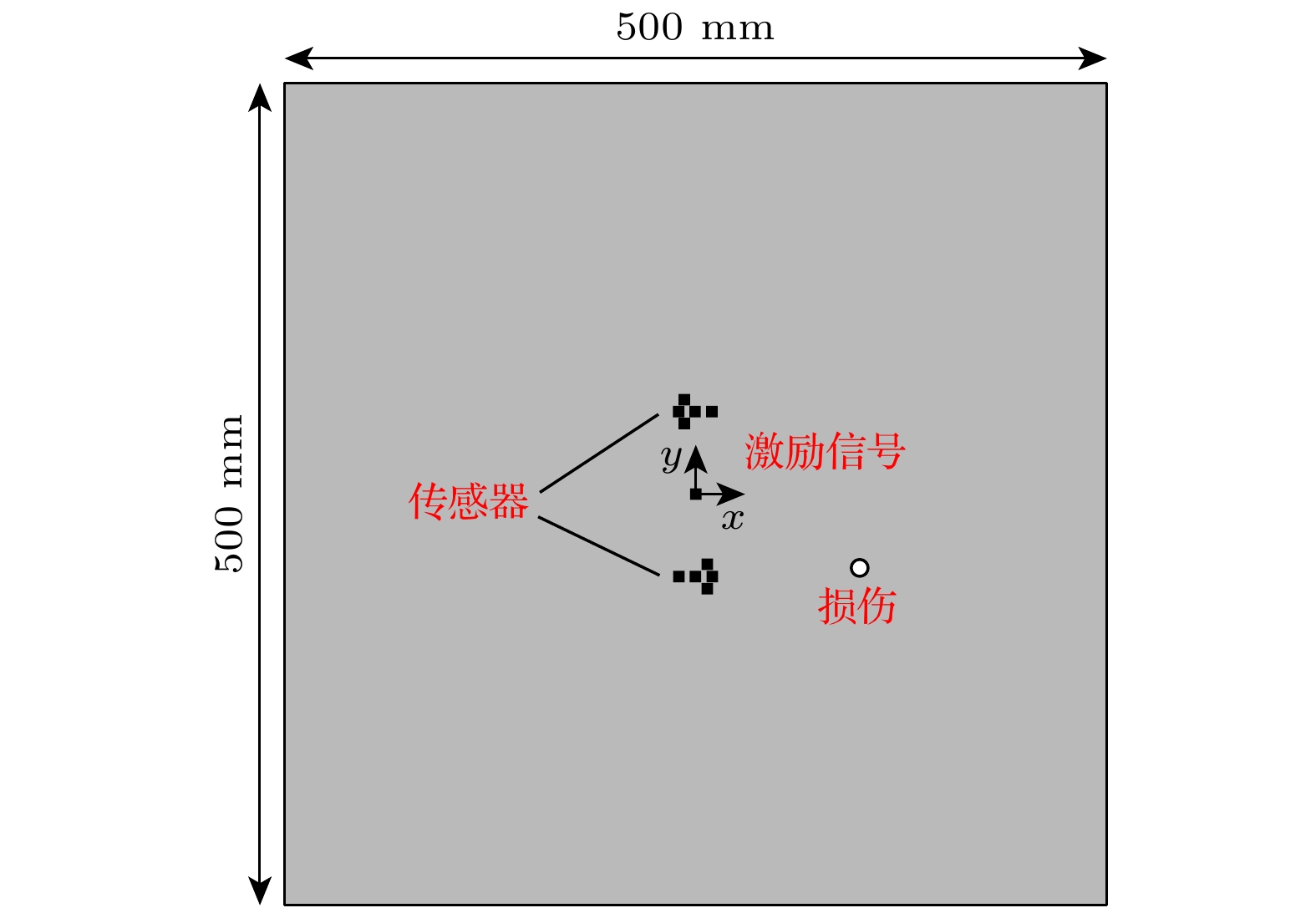

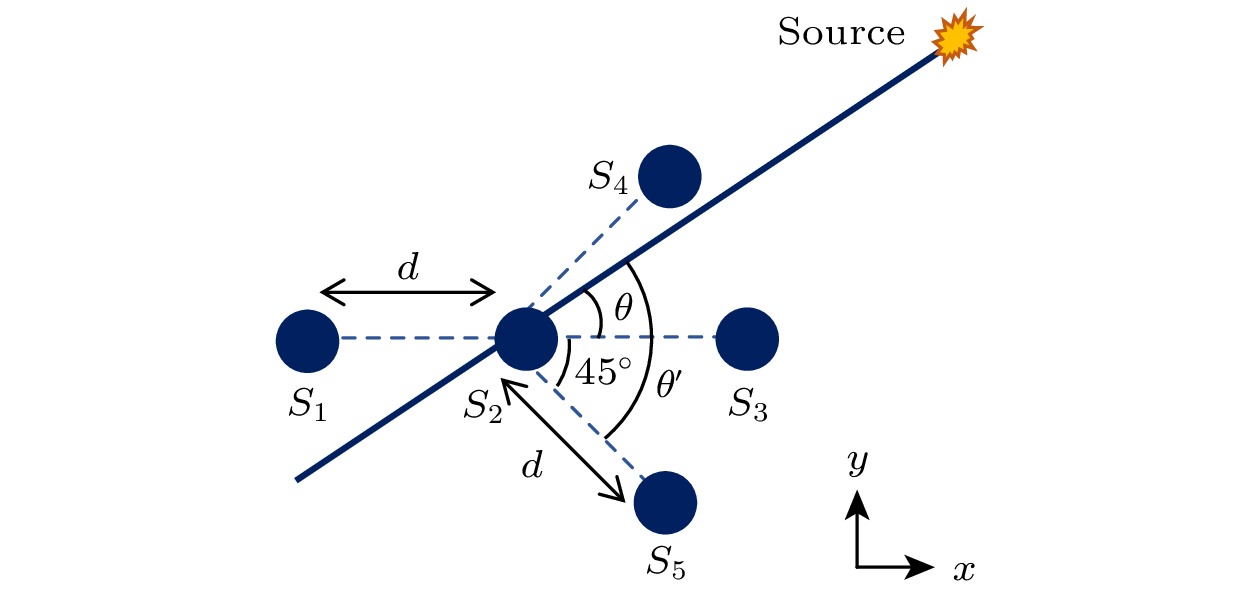

利用波束成形或L形传感器簇定位方法对板类结构上的损伤进行定位时存在盲区. 本文结合波束成形与L形传感器簇定位方法, 通过将5个传感器排列成扇形的方式, 提出了一种扇形传感器簇损伤定位方法, 可以有效减少损伤定位盲区. 使用两组扇形传感器簇以及一个用于发射激励信号的传感器即可准确检测出板中损伤的位置. 通过仿真和实验验证了扇形传感器簇损伤定位方法的可行性, 并与采用T形传感器簇时的预测结果进行比较, 结果表明扇形传感器簇损伤定位方法可以更准确地识别不同位置的损伤. 仿真和实验结果表明, 扇形传感器簇损伤定位方法可以减少损伤定位盲区, 提高损伤定位的精度.

Plate structures are widely used in large-scale engineering fields such as aerospace, hull manufacturing, and construction. However, the plate structure is easily damaged during long-term service or when it is impacted by foreign objects. Such a damage may lead to serious safety accidents. Beamforming and L-shaped sensor cluster (LSSC) localization method can be used to locate the damage on the plate. However, when using beamforming method or LSSC localization method to locate the damages on plate-like structures, there exists blind area. In this paper, by combining the beamforming method and LSSC localization method, a fan-shaped sensor cluster localization method is proposed through arranging five sensors in a fan shape, which can effectively reduce the blind areas. The positions of damages in the plate can be accurately detected by using two groups of fan-shaped sensor clusters and one sensor for transmitting the excitation signal. The feasibility of the fan-shaped sensor cluster localization method is verified through numerical simulations and experiments, and the results are compared with those obtained by using the T-shaped sensor cluster. The results show that the fan-shaped sensor cluster localization method can more accurately identify the damages at different positions. Both simulation and experimental results indicate that the fan-shaped sensor cluster localization method can reduce the blind area and improve the accuracy of damage location. [1] 胡海峰 2011 博士学位论文 (长沙: 国防科学技术大学)

Hu H F 2011 Ph. D. Dissertation (Changsha: National University of Defense Technology

[2] 冉启芳 1999 无损检测 21 75

Ran Q F 1999 Nondestr. Test 21 75

[3] 邬冠华, 熊鸿建 2016 仪器仪表学报 37 1683

Google Scholar

Google Scholar

Wu G H, Xiong H J 2016 Chin. J. Sci. Instrum. 37 1683

Google Scholar

Google Scholar

[4] 马国, 贾华东, 卢长煜, 陈理想, 张贵芝, 张立平, 杨超 2019 无损检测 41 62

Google Scholar

Google Scholar

Ma G, Jia H D, Lu C Y, Chen L X, Zhang G Z, Zhang L P, Yang C 2019 Nondestr. Test 41 62

Google Scholar

Google Scholar

[5] 赵金玲 2017 博士学位论文 (南京: 南京航空航天大学)

Zhao J L 2017 Ph. D. Dissertation (Nanjing: Nanjing University of Aeronautics and Astronautics

[6] 孙明健, 刘婷, 程星振, 陈德应, 闫锋刚, 冯乃章 2016 65 167802

Google Scholar

Google Scholar

Sun M J, Liu T, Cheng X Z, Chen D Y, Yan F G, Feng N Z 2016 Acta Phys. Sin. 65 167802

Google Scholar

Google Scholar

[7] Humeida Y, Wilcox P D, Todd M D 2014 NDT E Int. 68 43

Google Scholar

Google Scholar

[8] Luo K, Liu Y J, Liang W 2024 NDT & E Int. 143 103047

Google Scholar

Google Scholar

[9] Chen S J, Zhou S P, Li Y, Xiang Y X, Qi M X 2017 Chin. Phys. Lett. 34 044301

Google Scholar

Google Scholar

[10] 王强, 袁慎芳 2008 航空学报 29 1061

Google Scholar

Google Scholar

Wang Q, Yuan S F 2008 Acta Aeronaut. Astronaut. Sin. 29 1061

Google Scholar

Google Scholar

[11] 刘增华, 徐营赞, 何存富, 吴斌 2014 工程力学 31 232

Google Scholar

Google Scholar

Liu Z H, Xu Y Z, He C F, Wu B 2014 Eng. Mech. 31 232

Google Scholar

Google Scholar

[12] 张海燕, 孙修立, 曹亚萍, 陈先华, 于建波 2010 59 7111

Google Scholar

Google Scholar

Zhang H Y, Sun X L, Cao Y P, Chen X H, Yu J B 2010 Acta Phys. Sin. 59 7111

Google Scholar

Google Scholar

[13] Zhang G D, Kundu T, Deymier P A, Runge K 2025 Ultrasonics 145 107492

Google Scholar

Google Scholar

[14] Xu C B, Wang Q, Gao Q J, Deng M X 2025 Mech. Syst. Signal Proc. 223 11926

Google Scholar

Google Scholar

[15] 张海燕, 杨杰, 范国鹏, 朱文发, 柴晓冬 2017 66 214301

Google Scholar

Google Scholar

Zhang H Y, Yang J, Fan G P, Zhu W F, Chai X D 2017 Acta Phys. Sin. 66 214301

Google Scholar

Google Scholar

[16] Ambrozinski L, Stepinski T, Uhl T, Ochonski J, Klepka A 2012 Key Eng. Mater. 518 87

Google Scholar

Google Scholar

[17] 杨益新, 孙超, 鄢社锋, 马远良, 肖国有 2003 声学学报 28 504

Google Scholar

Google Scholar

Yang Y X, Sun C, Yan S F, Ma Y L, Xiao G Y 2003 Acta Acust. 28 504

Google Scholar

Google Scholar

[18] McLaskey G C, Glaser S D, Grosse C U 2010 J. Sound Vib. 329 2384

Google Scholar

Google Scholar

[19] Wang W Q, Shao H Z 2014 IEEE J. Sel. Top. Signal Process. 8 106

Google Scholar

Google Scholar

[20] Cantero C S, Aranguren G, Malik M K, Etxaniz J, Martín de la Escalera F 2020 Sensors 20 1445

Google Scholar

Google Scholar

[21] He T, Pan Q, Liu Y G, Liu X D, Hu D Y 2012 Ultrasonics 52 587

Google Scholar

Google Scholar

[22] Li L, Yang K, Bian X Y, Liu Q H, Yang Y Z, Ma F Y 2019 Sensors 19 3152

Google Scholar

Google Scholar

[23] Zhang Z H, Zhong Y T, Xiang J W, Jiang Y Y, Wang Z L 2020 IEEE Sens J. 20 14932

Google Scholar

Google Scholar

[24] Jung H K, Zhou S J, Park G 2019 J. Intell. Mater. Syst. Struct. 30 351

Google Scholar

Google Scholar

[25] Wang Z L, Yuan S F, Qiu L, Liu B 2015 J. Vibroeng. 17 2338

[26] Zhong Y T, Xiang J W 2019 Smart. Struct. Syst. 24 173

Google Scholar

Google Scholar

[27] Yu L, Giurgiutiu V 2008 Ultrasonics 48 117

Google Scholar

Google Scholar

[28] Kundu T 2012 European Workshop on Structural Health Monitoring Dresden, Germany, July 3–6, 2012 p2

[29] Kundu T, Nakatani H, Takeda N 2012 Ultrasonics 52 740

Google Scholar

Google Scholar

[30] Ma C N, Zhou Z X, Liu J X, Cui Z W, Kundu T 2023 Ultrasonics 132 107020

Google Scholar

Google Scholar

[31] Yin S X, Cui Z W, Kundu T 2018 Ultrasonics 84 34

Google Scholar

Google Scholar

[32] Yin S X, Xiao H P, Xu C B, Wang J S, Deng M X, Kundu T 2022 Ultrasonics 124 106770

Google Scholar

Google Scholar

[33] Sen N, Gawroński M, Packo P, Uhl T, Kundu T 2021 Mech. Syst. Signal Proc. 153 107489

Google Scholar

Google Scholar

[34] Zhou Z X, Cui Z W, Liu J X, Kundu T 2023 Eng. Fract. Mech. 277 108995

Google Scholar

Google Scholar

[35] Gao Q, Jeon J Y, Park G, Kong Y, Shen Y D, Xiang J W 2021 J. Intell. Mater. Syst. Struct. 33 1028

Google Scholar

Google Scholar

[36] Gao Q, Jeon J Y, Park G, Shen Y D, Xiang J W 2021 Struct. Health. Monit. 21 451

Google Scholar

Google Scholar

[37] Gao Q, Jeon J Y, Xiang J W, Park G 2023 IEEE Sens. J. 23 2970

Google Scholar

Google Scholar

[38] Xue C R, Xu G, Wang X K, Gao J C, Gao D J 2021 Ultrasonics 115 106438

Google Scholar

Google Scholar

-

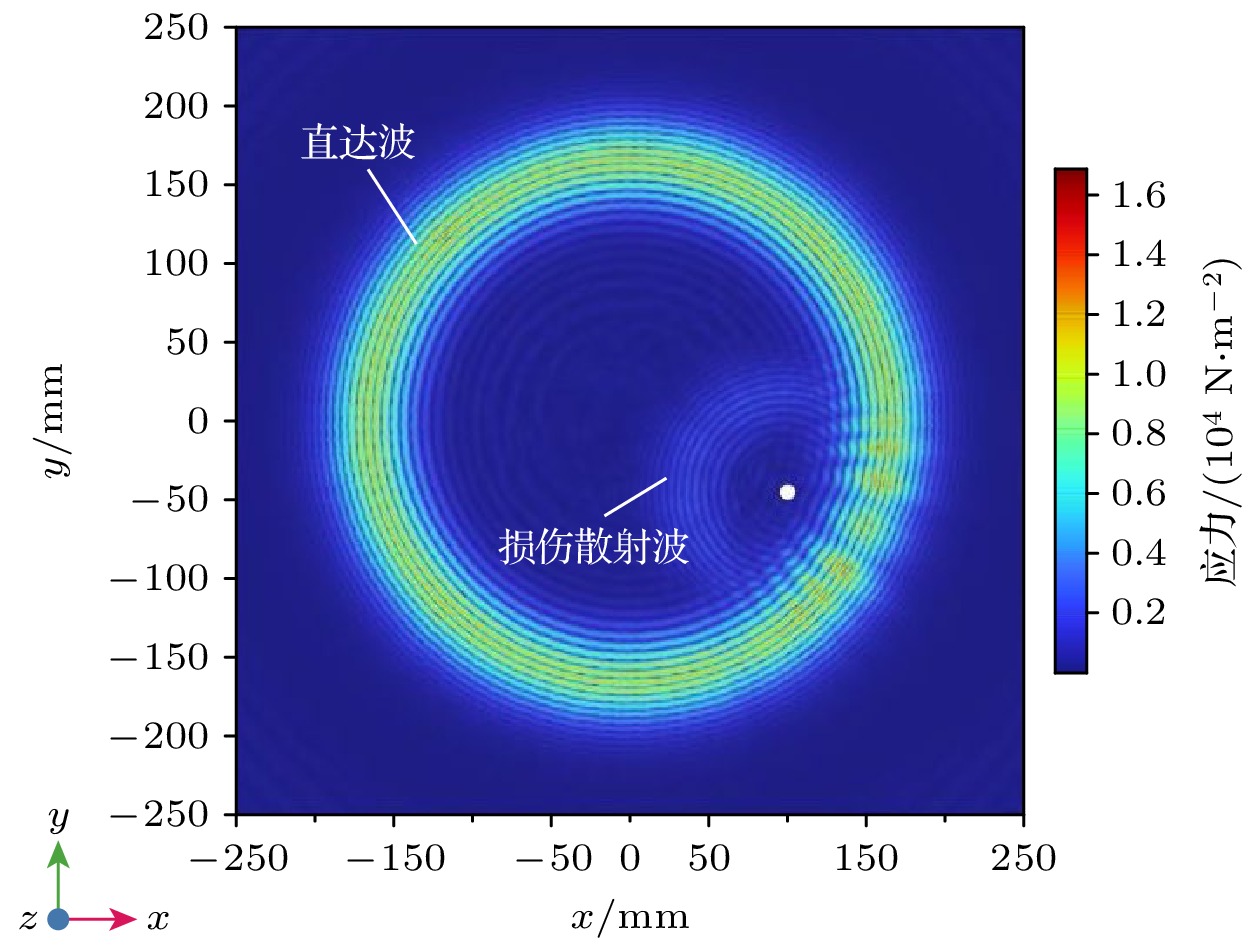

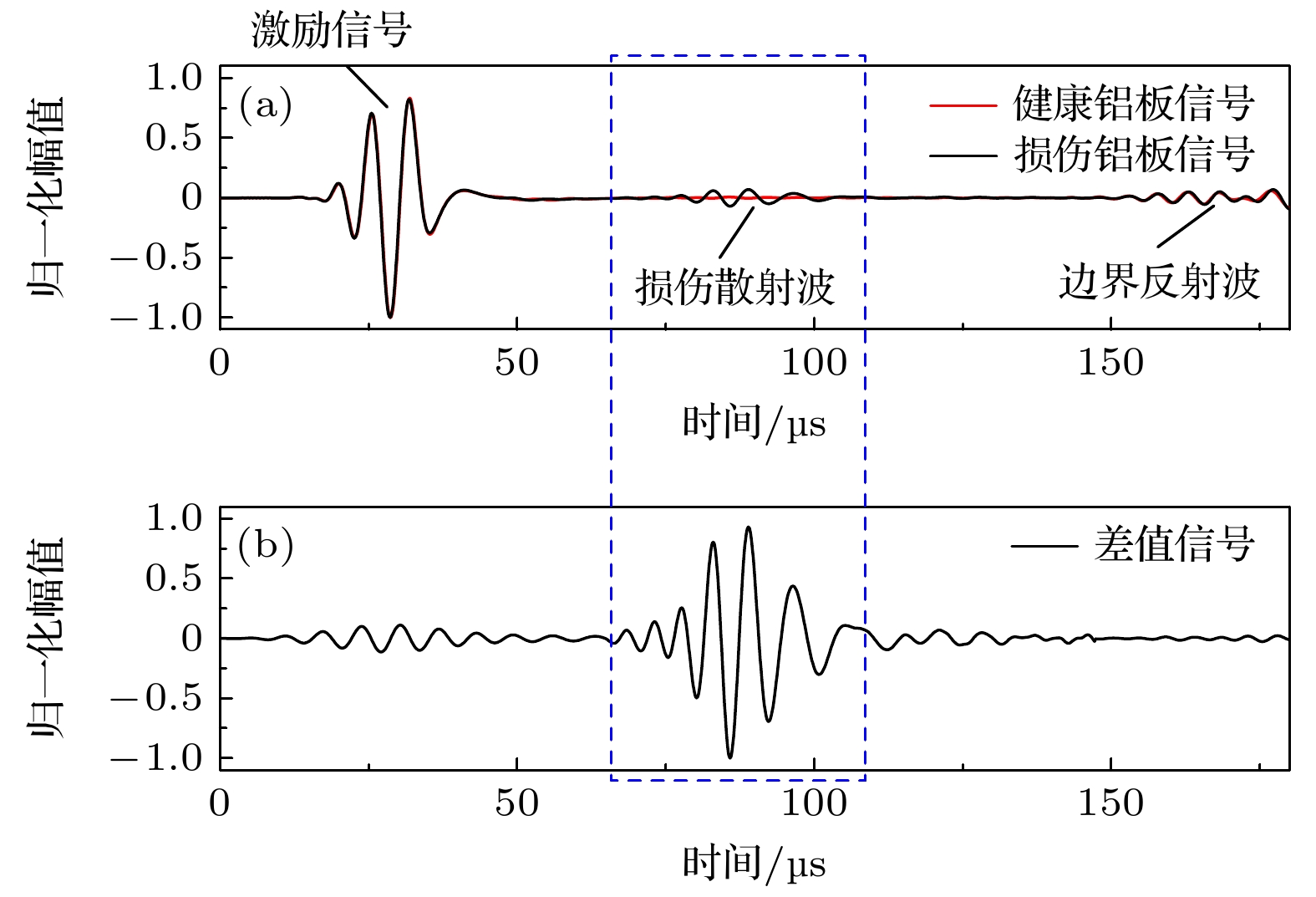

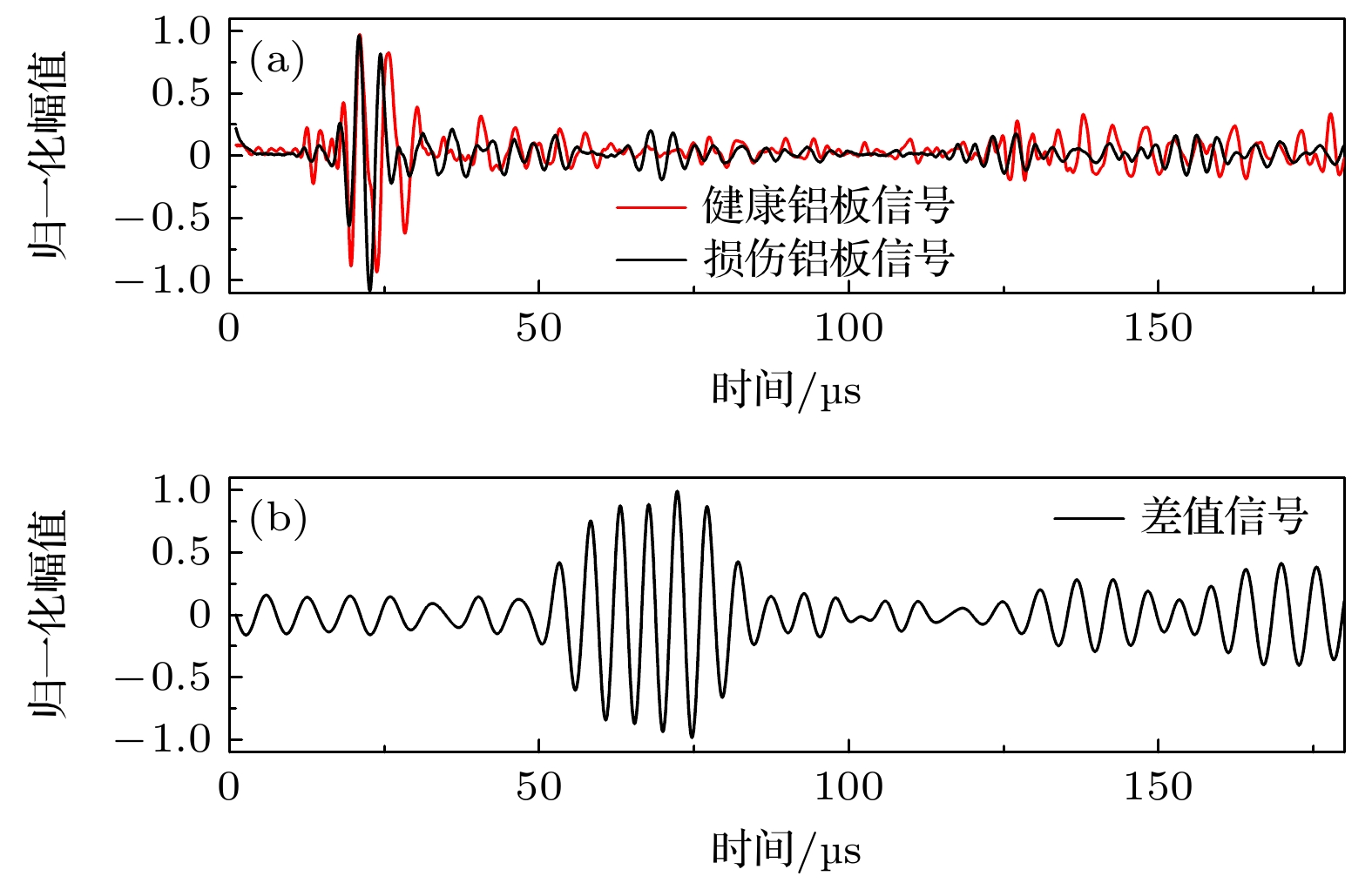

图 7 (a)损伤位于(100, –45)时, 传感器S1接收到的损伤信号与无损时的基线信号对比; (b)利用传感器S1接收到的有损信号减去基线信号得到的差值信号

Fig. 7. (a) Damaged signal and the healthy signal received by the S1 when the damage is located at (100, –45); (b) the differential signal obtained by subtracting the healthy signal from the damaged signal received by the sensor S1.

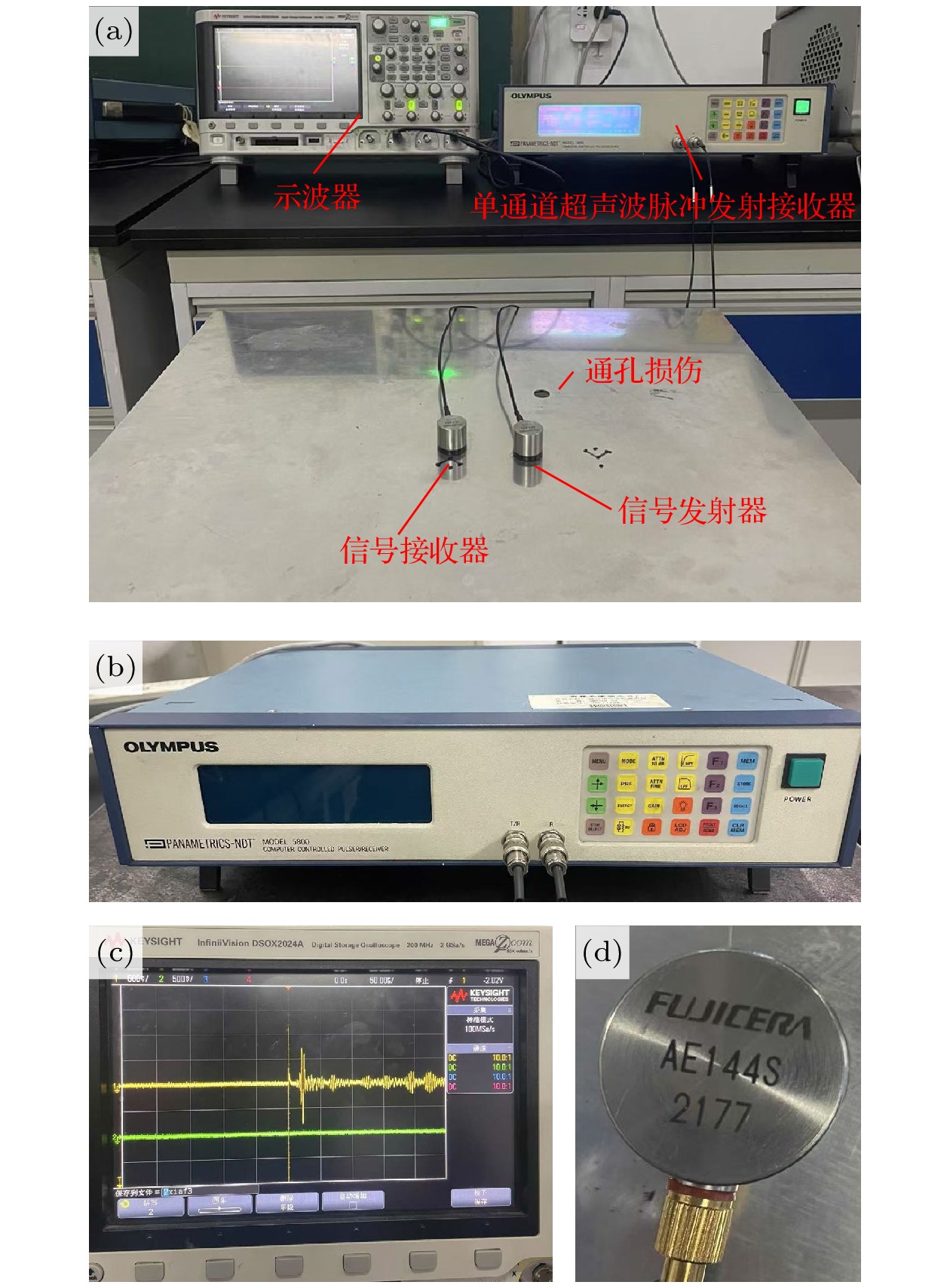

图 10 (a)损伤位于(105, –10)时, 下方扇形传感器簇中的S3接收到的损伤信号与无损时的基线信号对比; (b)经过滤波后, 利用传感器S3接收到的有损信号减去基线信号得到的差值信号

Fig. 10. (a) Damaged aluminum signal and the healthy aluminum signal received by the S3 of the fan-shaped sensor cluster on the lower side when the damage is located at (105, –10); (b) the differential signal obtained by subtracting the healthy signal from the damaged signal received by the sensor S3 after filtering.

表 1 铝板材料属性

Table 1. Material parameters of aluminum plate.

材料属性 数值 密度$\rho $/(kg·m–3) 2700 泊松比$\sigma $ 0.33 杨氏模量 E/GPa 70 表 2 传感器的位置坐标

Table 2. Coordinates of sensors.

传感器标记 坐标/mm 传感器标记 坐标/mm S1 (–10.00, –50.00) S6 (–10.00, 50.00) S2 (0.00, –50.00) S7 (0.00, 50.00) S3 (10.00, –50.00) S8 (10.00, 50.00) S4 (7.07, –42.93) S9 (–7.07, 57.07) S5 (7.07, –57.07) S10 (–7.07, 42.93) 表 3 仿真定位结果与误差

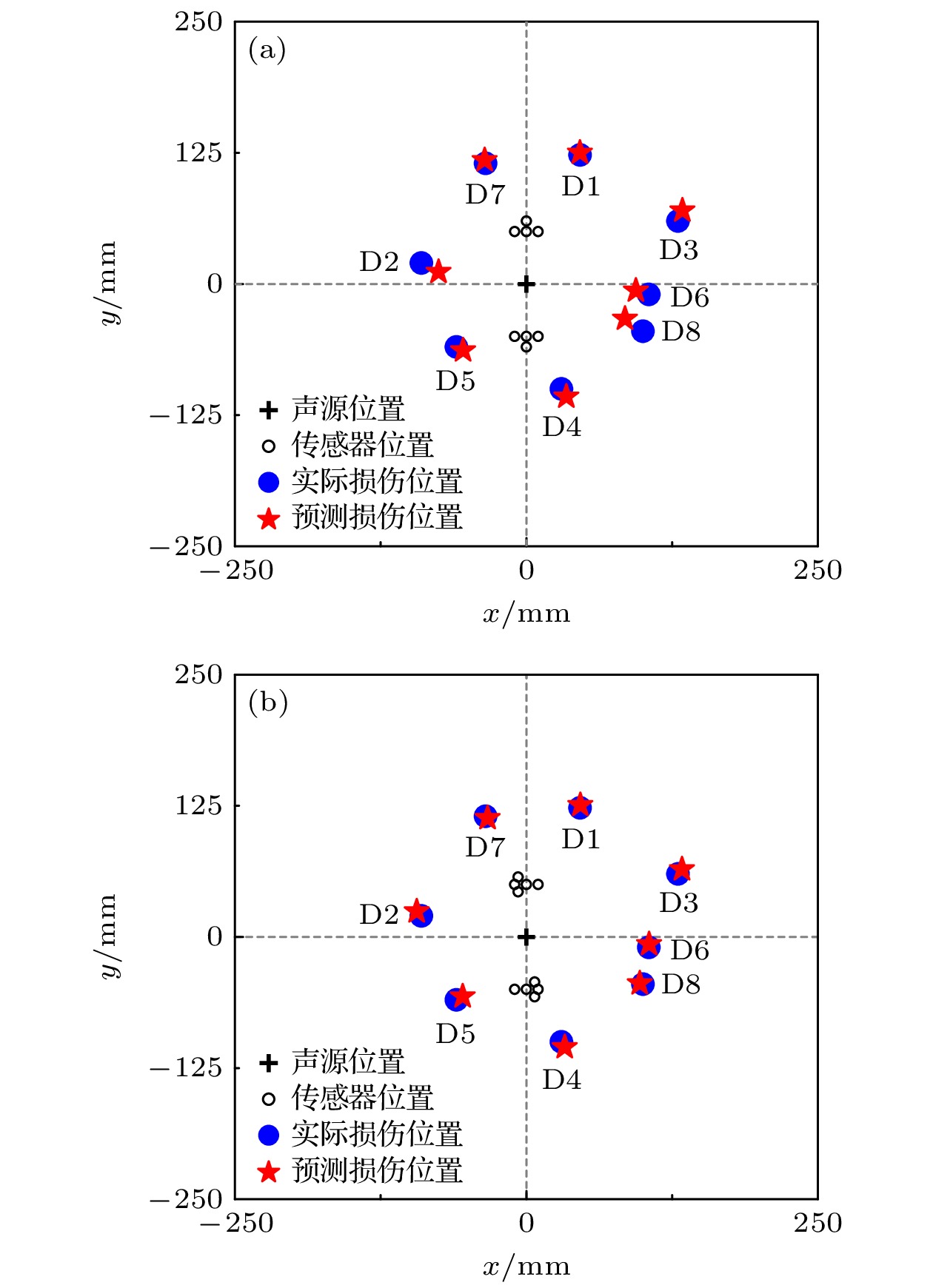

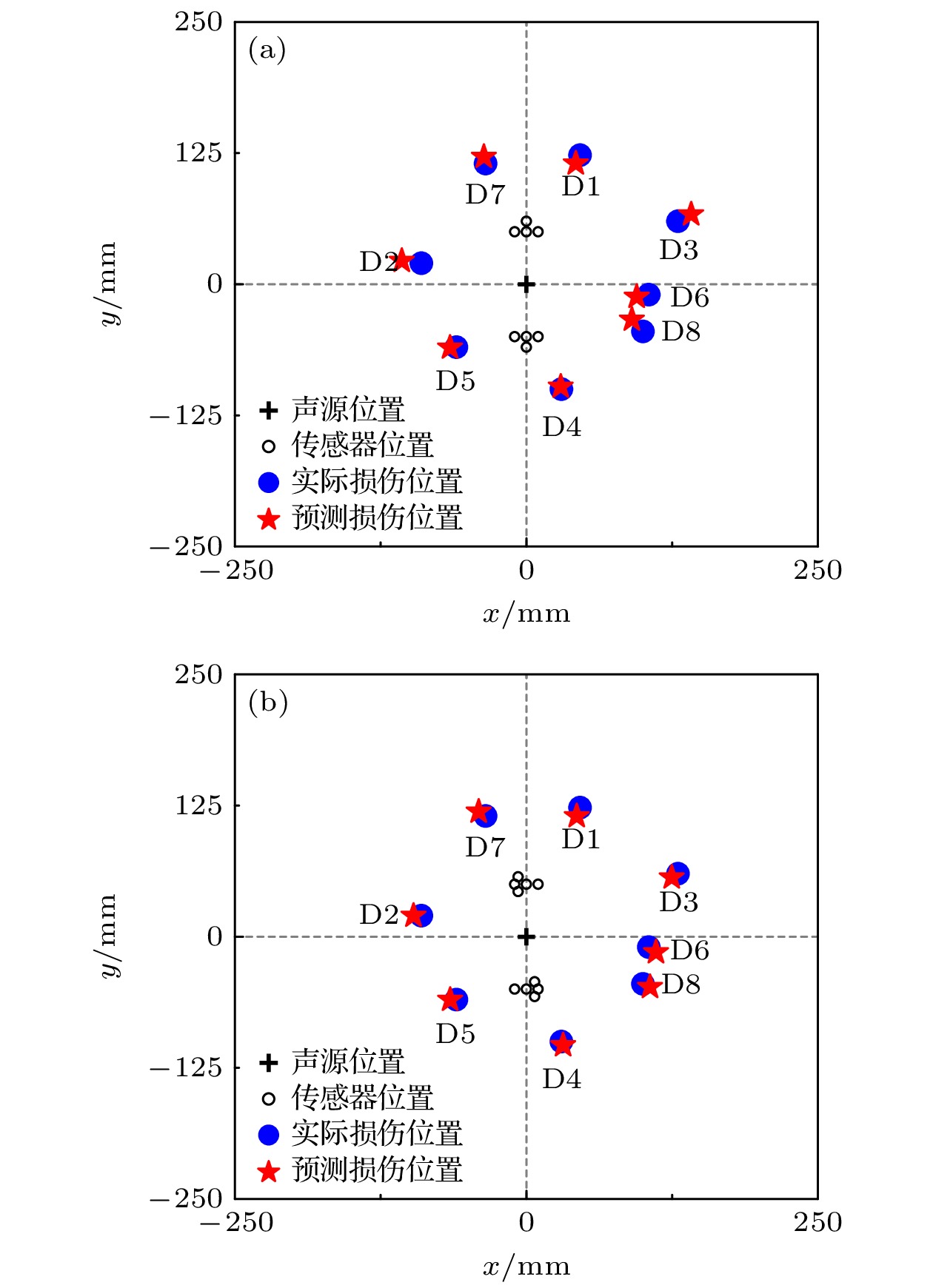

Table 3. Simulation localization results and errors.

编号 实际损伤坐标/mm T形传感器簇 扇形传感器簇 预测损伤坐标/mm 误差/mm 预测损伤坐标/mm 误差/mm D1 (46.00, 123.00) (45.93, 125.16) 2.16 (46.29, 125.73) 2.75 D2 (–90.00, 20.00) (–75.34, 11.45) 16.97 (–94.02, 24.28) 5.87 D3 (130.00, 60.00) (133.83, 70.07) 10.77 (133.48, 64.39) 5.61 D4 (30.00, –100.00) (34.30, –107.32) 8.49 (32.96, –105.08) 5.88 D5 (–60.00, –60.00) (–54.31, –63.35) 9.27 (–54.58, –56.65) 6.37 D6 (105.00, –10.00) (93.94, –6.28) 11.67 (105.19, –6.87) 3.14 D7 (–35.00, 115.00) (–35.72, 118.03) 3.11 (–33.22, 113.27) 2.48 D8 (100.00, –45.00) (84.55, –33.09) 19.51 (97.29, –44.28) 2.80 表 4 实验定位结果与误差

Table 4. Experimental localization results and errors.

编号 实际损伤坐标/mm T形传感器簇 扇形传感器簇 预测损伤坐标/mm 误差/mm 预测损伤坐标/mm 误差/mm D1 (46.00, 123.00) (42.39, 115.11) 8.68 (43.22, 114.82) 8.64 D2 (–90.00, 20.00) (–106.88, 22.25) 17.03 (–96.76, 20.04) 6.76 D3 (130.00, 60.00) (141.36, 66.56) 13.12 (124.69, 56.48) 6.37 D4 (30.00, –100.00) (29.52, –97.61) 2.44 (31.51, –103.49) 3.80 D5 (–60.00, –60.00) (–65.45, –60.33) 5.46 (–65.40, –60.12) 5.40 D6 (105.00, –10.00) (94.63, –12.02) 10.56 (111.13, –14.78) 7.77 D7 (–35.00, 115.00) (–36.40, 121.49) 6.64 (–40.94, 119.23) 7.29 D8 (100.00, –45.00) (90.54, –33.69) 14.74 (106.07, –47.88) 6.72 -

[1] 胡海峰 2011 博士学位论文 (长沙: 国防科学技术大学)

Hu H F 2011 Ph. D. Dissertation (Changsha: National University of Defense Technology

[2] 冉启芳 1999 无损检测 21 75

Ran Q F 1999 Nondestr. Test 21 75

[3] 邬冠华, 熊鸿建 2016 仪器仪表学报 37 1683

Google Scholar

Google Scholar

Wu G H, Xiong H J 2016 Chin. J. Sci. Instrum. 37 1683

Google Scholar

Google Scholar

[4] 马国, 贾华东, 卢长煜, 陈理想, 张贵芝, 张立平, 杨超 2019 无损检测 41 62

Google Scholar

Google Scholar

Ma G, Jia H D, Lu C Y, Chen L X, Zhang G Z, Zhang L P, Yang C 2019 Nondestr. Test 41 62

Google Scholar

Google Scholar

[5] 赵金玲 2017 博士学位论文 (南京: 南京航空航天大学)

Zhao J L 2017 Ph. D. Dissertation (Nanjing: Nanjing University of Aeronautics and Astronautics

[6] 孙明健, 刘婷, 程星振, 陈德应, 闫锋刚, 冯乃章 2016 65 167802

Google Scholar

Google Scholar

Sun M J, Liu T, Cheng X Z, Chen D Y, Yan F G, Feng N Z 2016 Acta Phys. Sin. 65 167802

Google Scholar

Google Scholar

[7] Humeida Y, Wilcox P D, Todd M D 2014 NDT E Int. 68 43

Google Scholar

Google Scholar

[8] Luo K, Liu Y J, Liang W 2024 NDT & E Int. 143 103047

Google Scholar

Google Scholar

[9] Chen S J, Zhou S P, Li Y, Xiang Y X, Qi M X 2017 Chin. Phys. Lett. 34 044301

Google Scholar

Google Scholar

[10] 王强, 袁慎芳 2008 航空学报 29 1061

Google Scholar

Google Scholar

Wang Q, Yuan S F 2008 Acta Aeronaut. Astronaut. Sin. 29 1061

Google Scholar

Google Scholar

[11] 刘增华, 徐营赞, 何存富, 吴斌 2014 工程力学 31 232

Google Scholar

Google Scholar

Liu Z H, Xu Y Z, He C F, Wu B 2014 Eng. Mech. 31 232

Google Scholar

Google Scholar

[12] 张海燕, 孙修立, 曹亚萍, 陈先华, 于建波 2010 59 7111

Google Scholar

Google Scholar

Zhang H Y, Sun X L, Cao Y P, Chen X H, Yu J B 2010 Acta Phys. Sin. 59 7111

Google Scholar

Google Scholar

[13] Zhang G D, Kundu T, Deymier P A, Runge K 2025 Ultrasonics 145 107492

Google Scholar

Google Scholar

[14] Xu C B, Wang Q, Gao Q J, Deng M X 2025 Mech. Syst. Signal Proc. 223 11926

Google Scholar

Google Scholar

[15] 张海燕, 杨杰, 范国鹏, 朱文发, 柴晓冬 2017 66 214301

Google Scholar

Google Scholar

Zhang H Y, Yang J, Fan G P, Zhu W F, Chai X D 2017 Acta Phys. Sin. 66 214301

Google Scholar

Google Scholar

[16] Ambrozinski L, Stepinski T, Uhl T, Ochonski J, Klepka A 2012 Key Eng. Mater. 518 87

Google Scholar

Google Scholar

[17] 杨益新, 孙超, 鄢社锋, 马远良, 肖国有 2003 声学学报 28 504

Google Scholar

Google Scholar

Yang Y X, Sun C, Yan S F, Ma Y L, Xiao G Y 2003 Acta Acust. 28 504

Google Scholar

Google Scholar

[18] McLaskey G C, Glaser S D, Grosse C U 2010 J. Sound Vib. 329 2384

Google Scholar

Google Scholar

[19] Wang W Q, Shao H Z 2014 IEEE J. Sel. Top. Signal Process. 8 106

Google Scholar

Google Scholar

[20] Cantero C S, Aranguren G, Malik M K, Etxaniz J, Martín de la Escalera F 2020 Sensors 20 1445

Google Scholar

Google Scholar

[21] He T, Pan Q, Liu Y G, Liu X D, Hu D Y 2012 Ultrasonics 52 587

Google Scholar

Google Scholar

[22] Li L, Yang K, Bian X Y, Liu Q H, Yang Y Z, Ma F Y 2019 Sensors 19 3152

Google Scholar

Google Scholar

[23] Zhang Z H, Zhong Y T, Xiang J W, Jiang Y Y, Wang Z L 2020 IEEE Sens J. 20 14932

Google Scholar

Google Scholar

[24] Jung H K, Zhou S J, Park G 2019 J. Intell. Mater. Syst. Struct. 30 351

Google Scholar

Google Scholar

[25] Wang Z L, Yuan S F, Qiu L, Liu B 2015 J. Vibroeng. 17 2338

[26] Zhong Y T, Xiang J W 2019 Smart. Struct. Syst. 24 173

Google Scholar

Google Scholar

[27] Yu L, Giurgiutiu V 2008 Ultrasonics 48 117

Google Scholar

Google Scholar

[28] Kundu T 2012 European Workshop on Structural Health Monitoring Dresden, Germany, July 3–6, 2012 p2

[29] Kundu T, Nakatani H, Takeda N 2012 Ultrasonics 52 740

Google Scholar

Google Scholar

[30] Ma C N, Zhou Z X, Liu J X, Cui Z W, Kundu T 2023 Ultrasonics 132 107020

Google Scholar

Google Scholar

[31] Yin S X, Cui Z W, Kundu T 2018 Ultrasonics 84 34

Google Scholar

Google Scholar

[32] Yin S X, Xiao H P, Xu C B, Wang J S, Deng M X, Kundu T 2022 Ultrasonics 124 106770

Google Scholar

Google Scholar

[33] Sen N, Gawroński M, Packo P, Uhl T, Kundu T 2021 Mech. Syst. Signal Proc. 153 107489

Google Scholar

Google Scholar

[34] Zhou Z X, Cui Z W, Liu J X, Kundu T 2023 Eng. Fract. Mech. 277 108995

Google Scholar

Google Scholar

[35] Gao Q, Jeon J Y, Park G, Kong Y, Shen Y D, Xiang J W 2021 J. Intell. Mater. Syst. Struct. 33 1028

Google Scholar

Google Scholar

[36] Gao Q, Jeon J Y, Park G, Shen Y D, Xiang J W 2021 Struct. Health. Monit. 21 451

Google Scholar

Google Scholar

[37] Gao Q, Jeon J Y, Xiang J W, Park G 2023 IEEE Sens. J. 23 2970

Google Scholar

Google Scholar

[38] Xue C R, Xu G, Wang X K, Gao J C, Gao D J 2021 Ultrasonics 115 106438

Google Scholar

Google Scholar

计量

- 文章访问数: 882

- PDF下载量: 32

- 被引次数: 0

下载:

下载: