-

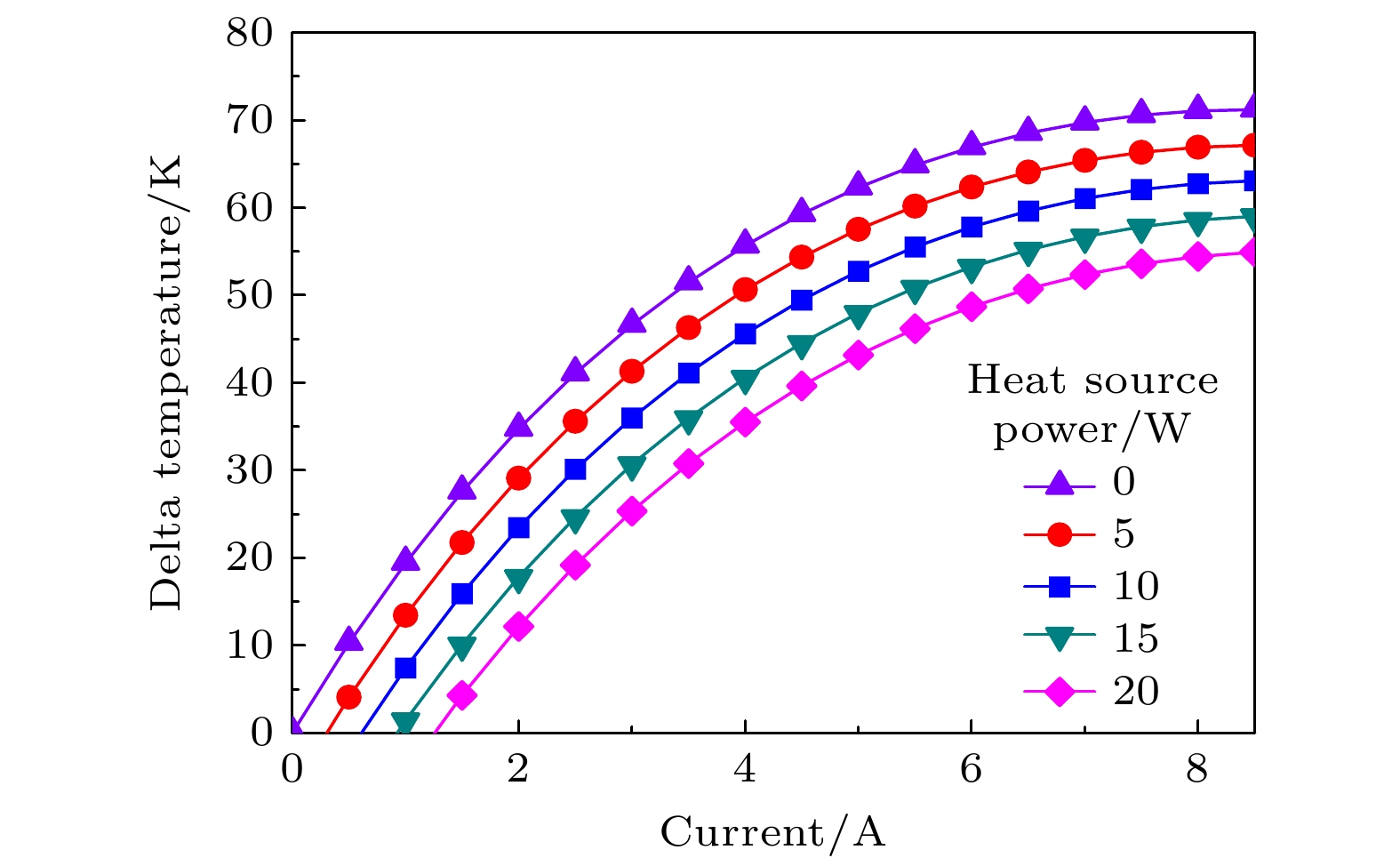

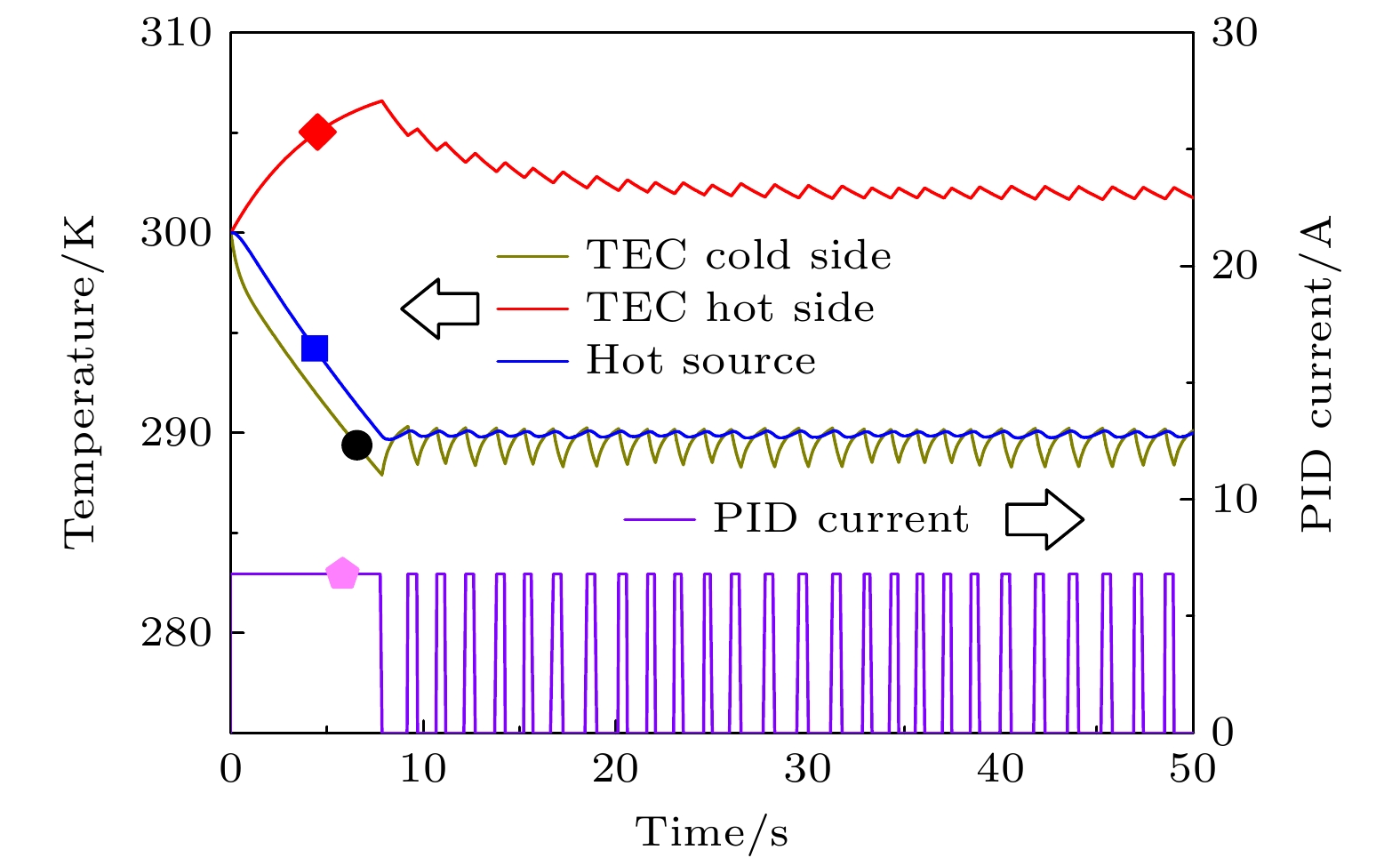

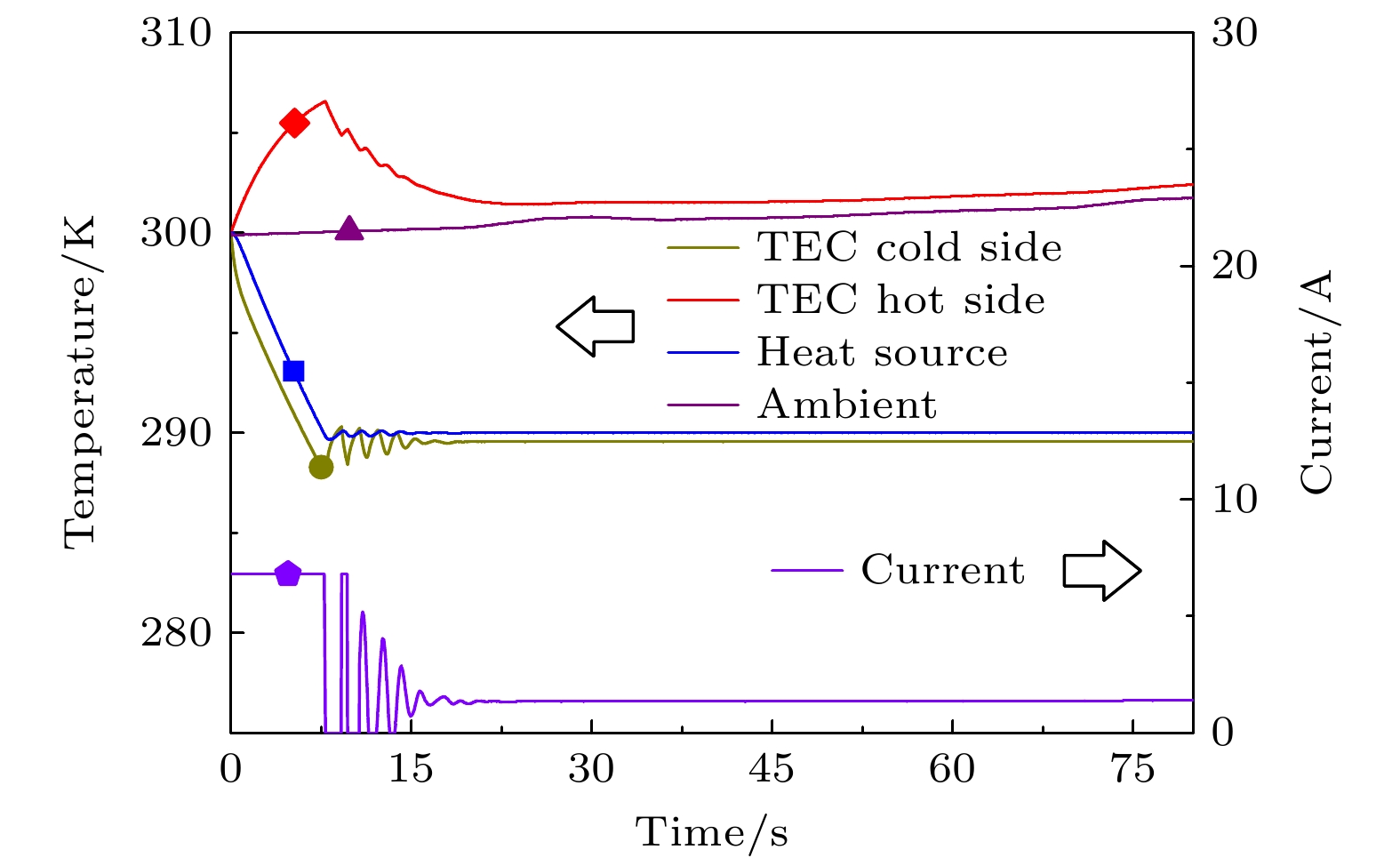

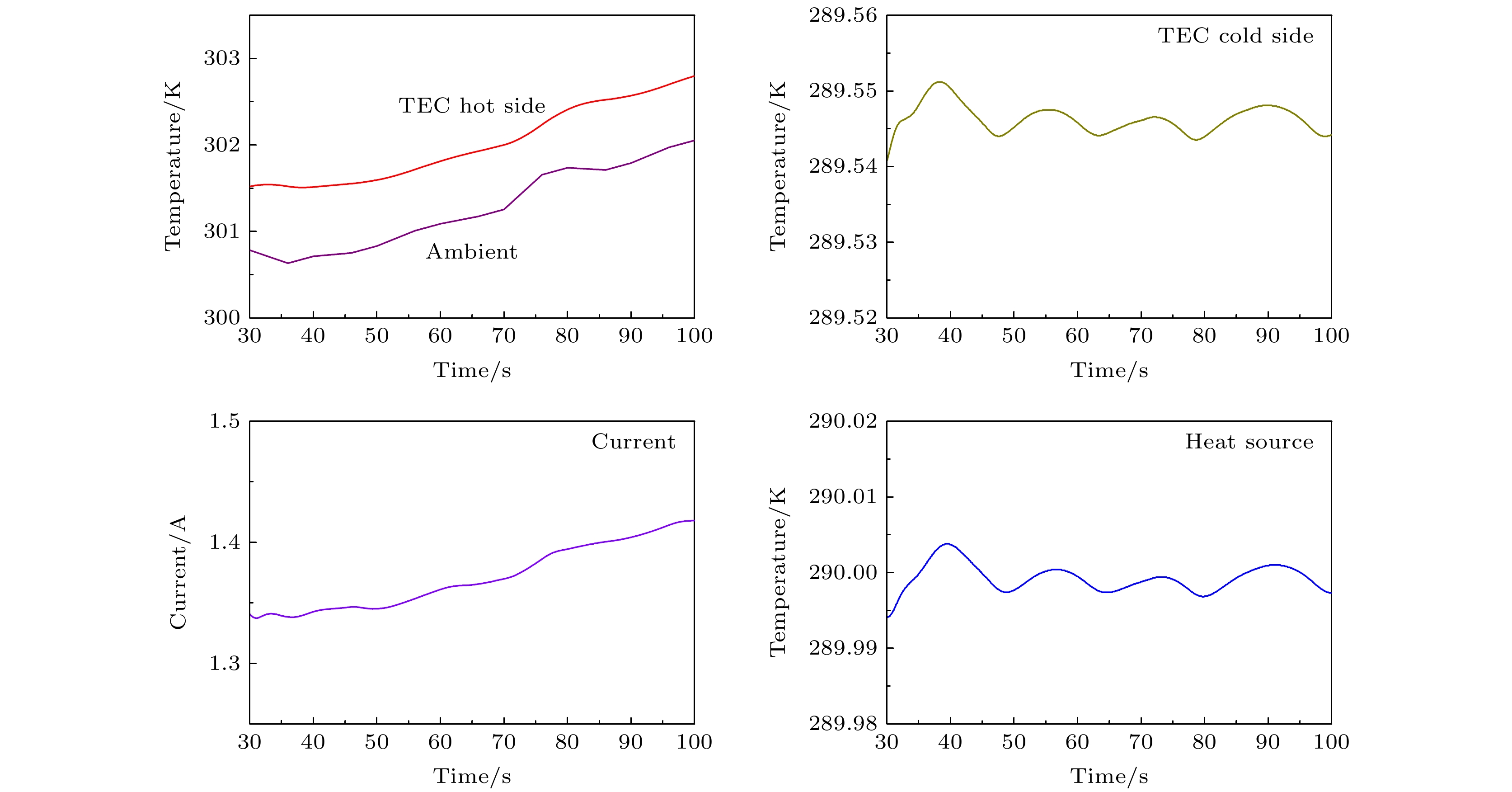

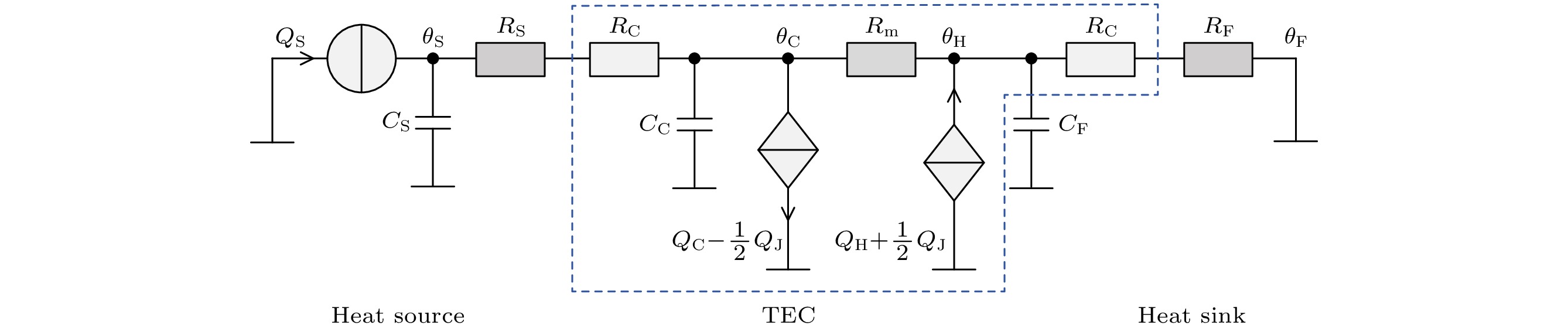

热电制冷(thermometric cooler, TEC)高精度温控技术广泛应用于精密半导体光电器件领域, 其控制精度对器件稳定运行至关重要. 然而, 传统比例-积分-微分(proportional integral derivative, PID)控制算法在毫开尔文级别的高精度温控应用中易出现超调与振荡现象, 难以满足应用需求. 本文深入分析TEC内部的电热耦合与热传导机制, 构建并验证了精确的TEC等效电路模型. 在此基础上, 提出了一种带动态直流偏置的自适应PID高精度温控算法, 算法通过实时计算温控误差及输出电流均值, 动态调整PID控制输出, 有效地抑制环境温度扰动引起的温控误差, 提高了温控系统的稳定性. 通过仿真分析验证了算法的高精度温控特性, 并且创新性地引入双路温度检测与补偿机制, 进一步提升了温控性能. 算法对PID参数具有较强鲁棒性, 核心逻辑简洁高效, 硬件实现复杂度低, 在工程实际中具有广泛适用性和良好的推广价值.

High-precision temperature control systems based on thermoelectric cooling (TEC) have important applications in maintaining the stability and operational precision of advanced semiconductor optoelectronic devices, including single-frequency semiconductor lasers, optical frequency combs, and photometric measurement systems. However, the intrinsic high thermal inertia and nonlinear electro-thermal coupling characteristics of TEC systems make it challenging for traditional proportional-integral-derivative (PID) control algorithms to achieve the required millikelvin-level (mK) precision due to their tendency toward overshoot and oscillation. In response to these issues, the internal electro-thermal conversion mechanisms, heat conduction, and dissipation dynamics of TEC systems are investigated in this work, and a high-precision temperature control approach is proposed based on an equivalent circuit model. By accurately constructing and verifying this equivalent circuit model, the oscillation characteristics and limitations inherent in traditional PID control are studied. Subsequently, an adaptive PID algorithm incorporating dynamic DC bias for enhanced precision is introduced. Specifically, the algorithm utilizes a traditional PID strategy to rapidly approximate the target temperature in the initial control stage. As the system approaches the target temperature and the temperature fluctuation decreases, it will automatically switch to an adaptive high-precision PID mode with dynamic DC bias. In this adaptive mode, the system continuously calculates the average output current and integrates temperature control errors over nearest time intervals. The overall control output is dynamically adjusted through adaptive weighting and deviation calculation to effectively counteract asymptotic and transient environmental disturbances. Additionally, the algorithm adopts an enhanced control strategy that combines dual-temperature sensing, primarily leveraging dynamic analysis of the hot-side temperature measurement to anticipate and counteract thermal disturbances. This predictive feedforward compensation, based on analyzing the rapid dynamic trends of the hot-side temperature, enables the controller to react preemptively to fast-changing disturbances before they significantly affect the controlled object, thereby substantially improving overall system stability and precision. Simulation results demonstrate that the proposed adaptive PID algorithm with dynamic DC bias can consistently maintain temperature control accuracy at a millikelvin level. It effectively mitigates transient and gradual environmental temperature disturbances, exhibiting excellent robustness against varying PID parameter settings. Furthermore, the core logic of the algorithm remains straightforward, computationally efficient, and hardware-friendly, making it particularly suitable for embedded system implementation and practical engineering deployment. In conclusion, the high-precision adaptive PID temperature control strategy presented herein possesses significant theoretical and practical value by addressing inherent TEC system challenges through detailed internal modeling and adaptive control strategies, contributing both theoretically and practically to high-precision temperature control engineering. -

Keywords:

- thermoelectric cooling /

- high-precision temperature control /

- dynamic DC bias /

- dual-temperature compensation

[1] Lu Y J, Wang H T, Guo J, Xu Y H, Hu Y C, Li W J, Zhang J N, Ma J, Shen D Y 2025 Photonics Res. 13 417

Google Scholar

Google Scholar

[2] Lü R D, Chen T, Huang J, Sun Z H, Hou Y X, Si J H, Zhou Y, Du Y, Hou X 2024 Appl. Opt. 63 2004

Google Scholar

Google Scholar

[3] Huang J Z, Li D D, Zhang J L, Dun X, Jiao H F, Xue D B, Xing Y J, Wang X Q, Cheng X B, Wang Z S 2024 Appl. Opt. 63 5457

Google Scholar

Google Scholar

[4] 徐雨萌, 辛国锋, 陈迪俊, 孙广伟, 胡晨雯, 朱芸洁, 陶立, 侯霞, 陈卫标 2025 中国激光 52 1001004

Google Scholar

Google Scholar

Xu Y M, Xin G F, Chen D J, Sun G W, Hu C W, Zhu Y J, Tao L, Hou X, Chen W B 2025 Chin. J. Lasers 52 1001004

Google Scholar

Google Scholar

[5] Wang Z, Zhou Y, Jiang B, Zhang J, Zhou T, Su Y 2024 IEEE Trans. Electron Devices 71 3888

Google Scholar

Google Scholar

[6] Yang S, Ji L, Zhao S, Sun Q, Xu J, Wu C 2025 IEEE Sens. J. 25 390

Google Scholar

Google Scholar

[7] Ganesh S, Zhang S N, Tiwari B S, Singh Y 2024 Opt. Express 32 43239

Google Scholar

Google Scholar

[8] 靳晓丽, 苏静, 靳丕铦, 王文哲, 彭堃墀 2015 中国激光 42 0902010

Google Scholar

Google Scholar

Jin X L, Su J, Jin P X, Wang W Z, Peng K C 2015 Chin. J. Lasers 42 0902010

Google Scholar

Google Scholar

[9] Choi G, Gin A, Su J 2022 Opt. Express 30 8690

Google Scholar

Google Scholar

[10] Yu H, Zhang X, Zhang J, Wu Z, Jiao L, Li K, Zheng W 2024 Micromachines 15 1095

Google Scholar

Google Scholar

[11] Han J, Zhang J, Zhang Y, Peng H, Zhang J, Ye S, Wang L 2025 Opt. Laser Technol. 183 112409

Google Scholar

Google Scholar

[12] 夏志昌, 于永爱, 尚建华 2023 光子学报 52 0814002

Google Scholar

Google Scholar

Xia Z C, Yu Y A, Shang J H 2023 Acta Photonica Sin. 52 0814002

Google Scholar

Google Scholar

[13] 韩天, 张雨霖, 缪存孝, 刘建丰, 薛帅 2020 红外与激光工程 49 20190461

Google Scholar

Google Scholar

Han T, Zhang Y L, Miao C X, Liu J F, Xue S 2020 Infrared Laser Eng. 49 20190461

Google Scholar

Google Scholar

[14] Luo J J, Lee J 2024 J. Appl. Phys. 135 244503

Google Scholar

Google Scholar

[15] 张安迪, 张艳荣, 李涛 2021 光学学报 41 1214003

Google Scholar

Google Scholar

Zhang A D, Zhang Y R, Li T 2021 Acta Opt. Sin. 41 1214003

Google Scholar

Google Scholar

[16] Huang B J, Duang C L 2000 Int. J. Refrig. 23 197

Google Scholar

Google Scholar

[17] Chen Z, Xu X, Zhang J, Yuan Y, Shen P, Mou X 2024 Energy 308 132932

Google Scholar

Google Scholar

[18] 杨明伟, 许文海, 唐文彦 2007 红外与激光工程 136 281

Google Scholar

Google Scholar

Yang M W, Xu W H, Tang W Y 2007 Infrared Laser Eng. 136 281

Google Scholar

Google Scholar

[19] Dziurdzia P, Bratek P, Markiewicz M 2024 Energies 17 204

Google Scholar

Google Scholar

[20] Lineykin S, Ben-Yaakov S 2007 IEEE Trans. Ind. Appl. 43 505

Google Scholar

Google Scholar

[21] 朱仁江, 潘英俊, 蒋茂华, 范嗣强, 张鹏 2015 华南理工大学学报(自然科学版) 43 143

Google Scholar

Google Scholar

Zhu R J, Pan Y J, Jiang M H, Fan S Q, Zhang P 2015 J. South China Univ. Technol. (Nat. Sci. Ed.) 43 143

Google Scholar

Google Scholar

[22] 辛文辉, 方林, 樊建鑫, 任卓勇, 李仕春, 乐静 2022 测控技术 41 31

Google Scholar

Google Scholar

Xin W H, Fang L, Fan J X, Ren Z Y, Li S C, Yue J 2022 Meas. Control Technol. 41 31

Google Scholar

Google Scholar

-

表 1 温控系统仿真中各模块的相关参数

Table 1. Relevant parameters of each module in the temperature control system simulation.

名称 规格/(mm×mm×mm) 热导率/(W·m–1·K–1) 密度/(g·cm–3) 比热容/(J·g–1·K–1) 等效热阻/Ω 等效热容/F 热源铜热沉 40×40×5 400 8.96 0.39 0.0078 27.96 TEC陶瓷层 40×40×1.2 20 — — 0.0375 10 TEC热电偶层 40×40×1.6 0.8027 — — 1.246 — TEC铜散热器 40×40×15 400 8.96 0.39 0.023 83.87 表 2 环境温度的瞬时扰动幅度对温控精度的影响

Table 2. Influence of instantaneous environmental temperature disturbance amplitude on temperature control accuracy.

随机扰动幅度/K 单路温度检测 双路温度检测 标准差/mK 最大偏差/mK 标准差/mK 最大偏差/mK 0.2 2 5 1 3 0.4 3 7 2 4 0.6 4 9 3 5 0.8 5 9 3 6 1.0 5 10 4 7 1.2 6 12 4 8 -

[1] Lu Y J, Wang H T, Guo J, Xu Y H, Hu Y C, Li W J, Zhang J N, Ma J, Shen D Y 2025 Photonics Res. 13 417

Google Scholar

Google Scholar

[2] Lü R D, Chen T, Huang J, Sun Z H, Hou Y X, Si J H, Zhou Y, Du Y, Hou X 2024 Appl. Opt. 63 2004

Google Scholar

Google Scholar

[3] Huang J Z, Li D D, Zhang J L, Dun X, Jiao H F, Xue D B, Xing Y J, Wang X Q, Cheng X B, Wang Z S 2024 Appl. Opt. 63 5457

Google Scholar

Google Scholar

[4] 徐雨萌, 辛国锋, 陈迪俊, 孙广伟, 胡晨雯, 朱芸洁, 陶立, 侯霞, 陈卫标 2025 中国激光 52 1001004

Google Scholar

Google Scholar

Xu Y M, Xin G F, Chen D J, Sun G W, Hu C W, Zhu Y J, Tao L, Hou X, Chen W B 2025 Chin. J. Lasers 52 1001004

Google Scholar

Google Scholar

[5] Wang Z, Zhou Y, Jiang B, Zhang J, Zhou T, Su Y 2024 IEEE Trans. Electron Devices 71 3888

Google Scholar

Google Scholar

[6] Yang S, Ji L, Zhao S, Sun Q, Xu J, Wu C 2025 IEEE Sens. J. 25 390

Google Scholar

Google Scholar

[7] Ganesh S, Zhang S N, Tiwari B S, Singh Y 2024 Opt. Express 32 43239

Google Scholar

Google Scholar

[8] 靳晓丽, 苏静, 靳丕铦, 王文哲, 彭堃墀 2015 中国激光 42 0902010

Google Scholar

Google Scholar

Jin X L, Su J, Jin P X, Wang W Z, Peng K C 2015 Chin. J. Lasers 42 0902010

Google Scholar

Google Scholar

[9] Choi G, Gin A, Su J 2022 Opt. Express 30 8690

Google Scholar

Google Scholar

[10] Yu H, Zhang X, Zhang J, Wu Z, Jiao L, Li K, Zheng W 2024 Micromachines 15 1095

Google Scholar

Google Scholar

[11] Han J, Zhang J, Zhang Y, Peng H, Zhang J, Ye S, Wang L 2025 Opt. Laser Technol. 183 112409

Google Scholar

Google Scholar

[12] 夏志昌, 于永爱, 尚建华 2023 光子学报 52 0814002

Google Scholar

Google Scholar

Xia Z C, Yu Y A, Shang J H 2023 Acta Photonica Sin. 52 0814002

Google Scholar

Google Scholar

[13] 韩天, 张雨霖, 缪存孝, 刘建丰, 薛帅 2020 红外与激光工程 49 20190461

Google Scholar

Google Scholar

Han T, Zhang Y L, Miao C X, Liu J F, Xue S 2020 Infrared Laser Eng. 49 20190461

Google Scholar

Google Scholar

[14] Luo J J, Lee J 2024 J. Appl. Phys. 135 244503

Google Scholar

Google Scholar

[15] 张安迪, 张艳荣, 李涛 2021 光学学报 41 1214003

Google Scholar

Google Scholar

Zhang A D, Zhang Y R, Li T 2021 Acta Opt. Sin. 41 1214003

Google Scholar

Google Scholar

[16] Huang B J, Duang C L 2000 Int. J. Refrig. 23 197

Google Scholar

Google Scholar

[17] Chen Z, Xu X, Zhang J, Yuan Y, Shen P, Mou X 2024 Energy 308 132932

Google Scholar

Google Scholar

[18] 杨明伟, 许文海, 唐文彦 2007 红外与激光工程 136 281

Google Scholar

Google Scholar

Yang M W, Xu W H, Tang W Y 2007 Infrared Laser Eng. 136 281

Google Scholar

Google Scholar

[19] Dziurdzia P, Bratek P, Markiewicz M 2024 Energies 17 204

Google Scholar

Google Scholar

[20] Lineykin S, Ben-Yaakov S 2007 IEEE Trans. Ind. Appl. 43 505

Google Scholar

Google Scholar

[21] 朱仁江, 潘英俊, 蒋茂华, 范嗣强, 张鹏 2015 华南理工大学学报(自然科学版) 43 143

Google Scholar

Google Scholar

Zhu R J, Pan Y J, Jiang M H, Fan S Q, Zhang P 2015 J. South China Univ. Technol. (Nat. Sci. Ed.) 43 143

Google Scholar

Google Scholar

[22] 辛文辉, 方林, 樊建鑫, 任卓勇, 李仕春, 乐静 2022 测控技术 41 31

Google Scholar

Google Scholar

Xin W H, Fang L, Fan J X, Ren Z Y, Li S C, Yue J 2022 Meas. Control Technol. 41 31

Google Scholar

Google Scholar

计量

- 文章访问数: 595

- PDF下载量: 32

- 被引次数: 0

下载:

下载: