-

Bi2Te3基化合物是目前唯一实现商业化应用的热电材料, 但对其研究大多都集中于室温及以上温区, 针对室温以下的低温区研究较少. 本工作系统研究了Bi/Sb相对含量调控和Se固溶对BixSb2–xTe3和Bi0.4Sb1.6Te3–ySey化合物在低温区电热输运性能的影响规律. 在BixSb2–xTe3体系中, 固溶Bi2Te3减小了材料的带隙, 并降低了SbTe反位缺陷的浓度, 使材料的峰值ZT温度向低温区偏移, 但显著增强的载流子点缺陷散射, 导致材料的载流子迁移率和电传输性能劣化, 功率因子从Bi0.4Sb1.6Te3的4.58 mW/(m·K2)下降至Bi0.58Sb1.42Te3的1.12 mW/(m·K2). 为了进一步提升材料低温区热电性能, 选取Bi0.4Sb1.6Te3为基体, 在Te位固溶Se, Se的固溶使SeTe+BiSb的缺陷形成能更低, 抑制了反位缺陷SbTe的产生, 降低了材料的载流子浓度. 少量Se固溶使材料能保持优异的电传输性能同时, 显著增强了点缺陷声子散射, 降低材料的晶格热导率, 在宽温区范围提升了材料的热电性能. Bi0.4Sb1.6Te3材料在220 K时, ZT值为0.80, 在350 K时ZT峰值为1.17, 少量Se固溶Bi0.4Sb1.6Te2.97Se0.03样品在220 K时ZT值增至0.93. 在350 K时ZT峰值达到1.31, 相比分别提升了约16%和12%. 该研究为BiSbTe基热电材料低温区热电性能提升提供了重要的指导, 对BiSbTe基热电材料低温区的应用具有重要意义.

-

关键词:

- Bi2Te3基化合物 /

- 低温热电性能 /

- 能带工程 /

- 缺陷工程

Bi2Te3-based compounds are the thermoelectric materials available only commercially, but the research on their low-temperature performances below 300 K are still insufficient. The influences of Bi/Sb ratio modulation and Se substitution on the electrical and thermal transport properties of BixSb2–xTe3 and Bi0.4Sb1.6Te3–ySey materials are systematically investigated in this work, aiming to optimize their thermoelectric performance in cryogenic regions through combined bandgap tuning and defect engineering. Materials are synthesized using a melt-quenching and spark plasma sintering process, and then phase analysis is conducted via X-ray diffraction and microstructural characterization by electron probe microanalysis. First-principles calculations and Hall effect measurements are used to investigate their defect formation mechanisms and carrier transport behaviors. In the BixSb2–xTe3 system, the increase of Bi content reduces the bandgap from 0.168 eV for Bi0.4Sb1.6Te3 to 0.113 eV for Bi0.58Sb1.42Te3, shifting the peak ZT temperature to lower ranges. However, the enhancement of alloy scattering leads the carrier mobility to decrease from 332 to 109 cm2/(V·s) and power factor to fall from 4.58 to 1.12 mW/(m·K2). To solve this problem, Se is substituted for the Te lattice of Bi0.4Sb1.6Te3. First-principles calculations reveal that the Se substitution reduces the formation energy of SeTe + BiSb complex, thus effectively suppressing SbTe antisite defects. This will result in the carrier concentration decreasing from 3.32×1019 to 2.64×1019 cm–3 while maintaining high mobility at 279 cm2/(V·s). Concurrently, Se-induced point defects enhance phonon scattering, reducing lattice thermal conductivity from 0.46 to 0.38 W/(m·K), a decrease of 17%. Bi0.4Sb1.6Te2.97Se0.03 sample achieves a ZT value of 0.93 at 220 K, which is 16% higher than the pristine Bi0.4Sb1.6Te3 sample with a ZT value of 0.80. The peak ZT increases from 1.17 to 1.31 at 350 K, an increase of 12%. These improvements arise from the synergistic effects of band engineering, where flattened valence band edges increase effective mass, and defect engineering, where antisite defects and strengthens phonon scattering are suppressed. This work provides a dual optimization strategy for BiSbTe-based materials, i.e. balancing bandgap reduction by controlling defects to improve cryogenic performance. The findings are particularly significant for the applications of BiSbTe-based materials in infrared detectors and multistage thermoelectric cooling systems.-

Keywords:

- Bi2Te3-based compounds /

- low-temperature thermoelectric properties /

- band engineering /

- defect engineering

[1] Han Y N, Zhang A K 2022 Sci. Rep. 12 2349

Google Scholar

Google Scholar

[2] Tong X, Qiu J, Li J P, Xie K Y, Chen J Y, Huai Y, Li S F, Huang Y B, Dong W 2024 Cryogenics 143 103929

Google Scholar

Google Scholar

[3] Qin B C, Wang D Y, Liu X X, Qin Y X, Dong J F, Luo J F, Li J W, Liu W, Tan G J, Tang X F, Li J F, He J Q, Zhao L D 2021 Science 373 556

Google Scholar

Google Scholar

[4] Rogalski A, Martyniuk P, Kopytko M, Hu W D 2021 Appl. Sci. 11 501

Google Scholar

Google Scholar

[5] Tang J, Ni H, Peng R L, Wang N, Zuo L 2023 J. Power. Sources 562 232785

Google Scholar

Google Scholar

[6] Sun J C, Zhang Y, Fan Y T, Tang X F, Tan G J 2022 Chem. Eng. J. 431 133699

Google Scholar

Google Scholar

[7] Peng G Y, Hu L, Qu W B, Zhang C L, Li S R, Liu Z Y, Liu J C, Guo S W, Xiao Y, Gao Z B, Zhang Z, Zhang Y, Wu H J, Pennycook S J, Sun J, Ding X D 2023 Interdiscip. Mater. 2 30

Google Scholar

Google Scholar

[8] Huang Y L, Lyu T, Zeng M T, Wang M R, Yu Y, Zhang C H, Liu F S, Hong M, Hu L P 2024 Interdiscip. Mater. 3 607

Google Scholar

Google Scholar

[9] Hu C L, Xia K Y, Fu C G, Zhao X B, Zhu T J 2022 Energy Environ. Sci. 15 1406

Google Scholar

Google Scholar

[10] Zhang Y, Sun J C, Shuai J, Tang X F, Tan G J 2021 Mater. Today Phys. 19 100405

Google Scholar

Google Scholar

[11] Liu Z T, Hong T, Xu L Q, Wang S N, Gao X, Chang C, Ding X D, Xiao Y, Zhao L D 2023 Interdiscip. Mater. 2 161

Google Scholar

Google Scholar

[12] Choi S, Han U, Cho H, Lee H 2018 Appl. Therm. Eng. 132 560

Google Scholar

Google Scholar

[13] Reddy B V K, Barry M, Li J, Chyu M K 2014 Energy Conv. Manag. 77 458

Google Scholar

Google Scholar

[14] Yang D W, Xing Y B, Wang J, Hu K, Xiao Y N, Tang K C, Lyu J N, Li J H, Liu Y T, Zhou P, Yu Y, Yan Y G, Tang X F 2024 Interdiscip. Mater. 3 326

Google Scholar

Google Scholar

[15] Feng J H, Li J, Liu R H 2024 Nano Energy 126 109651

Google Scholar

Google Scholar

[16] Lyu J N, Yang D W, Liu Y T, Li J H, Zhang Z N, Li Z M, Liu M Y, Liu W, Ren Z G, Liu H J, Wu J S, Tang X F, Yan Y G 2024 ACS Appl. Mater. Interfaces 16 16505

Google Scholar

Google Scholar

[17] Mao J, Chen G, Ren Z F 2021 Nat. Mater. 20 454

Google Scholar

Google Scholar

[18] Luo T T, Wang S Y, Li H, Tang X F 2013 Intermetallics 32 96

Google Scholar

Google Scholar

[19] Chen Z, Zhou M, Huang R J, Song C M, Zhou Y, Li L F 2012 J. Alloy. Compd. 511 85

Google Scholar

Google Scholar

[20] Combe E, Funahashi R, Takeuchi T, Barbier T, Yubuta K 2017 J. Alloy. Compd. 692 563

Google Scholar

Google Scholar

[21] Chung D Y, Hogan T, Brazis P, Rocci-Lane M, Kannewurf C, Bastea M, Uher C, Kanatzidis M G 2000 Science 287 1024

Google Scholar

Google Scholar

[22] Xie W J, Tang X F, Yan Y G, Zhang Q J, Tritt T M 2009 Appl. Phys. Lett. 94 102111

Google Scholar

Google Scholar

[23] 李睿英, 罗婷婷, 李貌, 陈硕, 鄢永高, 吴劲松, 苏贤礼, 张清杰, 唐新峰 2024 73 097101

Google Scholar

Google Scholar

Li R Y, Luo T T, Li M, Chen S, Yan Y G, Wu J S, Su X L, Zhang Q J, Tang X F 2024 Acta Phys. Sin. 73 097101

Google Scholar

Google Scholar

[24] 李强, 陈硕, 刘可可, 鲁志强, 胡芹, 冯丽萍, 张清杰, 吴劲松, 苏贤礼, 唐新峰 2023 72 097101

Google Scholar

Google Scholar

Li Q, Chen S, Liu K K, Lu Z Q, Hu Q, Feng L P, Zhang Q J, Wu J S, Su X L, Tang X F 2023 Acta Phys. Sin. 72 097101

Google Scholar

Google Scholar

[25] Chen S, Luo T T, Yang Z, Zhong S L, Su X L, Yan Y G, Wu J S, Poudeu P F, Zhang Q J, Tang X F 2024 Mater. Today Phys. 46 101524

Google Scholar

Google Scholar

[26] 鲁志强, 刘可可, 李强, 胡芹, 冯丽萍, 张清杰, 吴劲松, 苏贤礼, 唐新峰 2023 无机材料学报 38 1311

Google Scholar

Google Scholar

Lu Z Q, Liu K K, Li Q, Hu Q, Feng L P, Zhang Q J, Wu J S, Su X L, Tang X F 2023 J. Inorg. Mater. 38 1311

Google Scholar

Google Scholar

[27] Goldsmid H J, Sharp J W 1999 J. Electro. Mater. 28 869

Google Scholar

Google Scholar

[28] Yang J, Morelli D T, Meisner G, Chen W, Dyck J, Uher C 2002 Phys. Rev. B 65 094115

Google Scholar

Google Scholar

[29] Wu G, Zhang Q, Fu Y T, Tan X J, Noudem J G, Zhang Z W, Cui C, Sun P, Hu H Y, Wu J H, Liu G Q, Jiang J 2023 Adv. Funct. Mater. 33 2305686

Google Scholar

Google Scholar

[30] Lee K H, Kim S I, Lim J C, Cho J Y, Yang H, Kim H S 2022 Adv. Funct. Mater. 32 2203852

Google Scholar

Google Scholar

[31] Xu B, Xia Q, Ma S S, Zhang J, Wang Y S, Li J F, Gu Z H, Yi L 2022 FlatChem 34 100394

Google Scholar

Google Scholar

[32] Saberi Y, Sajjadi S A 2022 J. Alloy. Compd. 904 163918

Google Scholar

Google Scholar

-

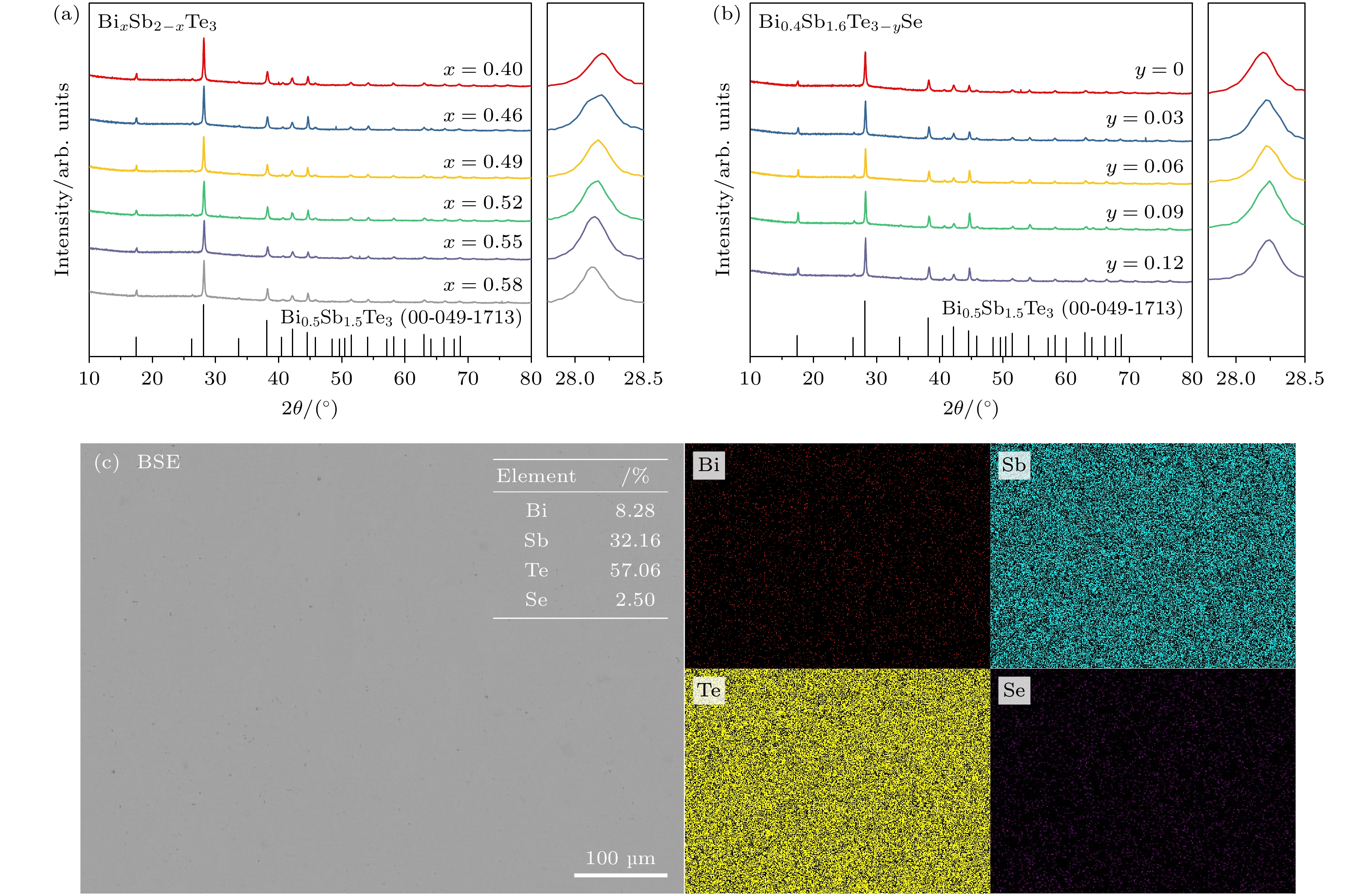

图 1 (a)制备的BixSb2–xTe3样品粉末X射线衍射图谱; (b) 制备的Bi0.4Sb1.6Te3–ySey样品粉末X射线衍射图谱; (c) Bi0.4Sb1.6Te2.88Se0.12样品表面背散射电子图像(单位原子百分比)以及对应区域Bi, Sb, Se和Te等元素的面分布图像

Fig. 1. (a) Powder X-ray diffraction patterns of the prepared BixSb2–xTe3 samples; (b) powder X-ray diffraction patterns of the prepared Bi0.4Sb1.6Te3–ySey samples; (c) backscattered electron image of the surface of the Bi0.4Sb1.6Te2.88Se0.12 sample and the planar distribution images of elements for Bi, Sb, Se and Te in the corresponding regions.

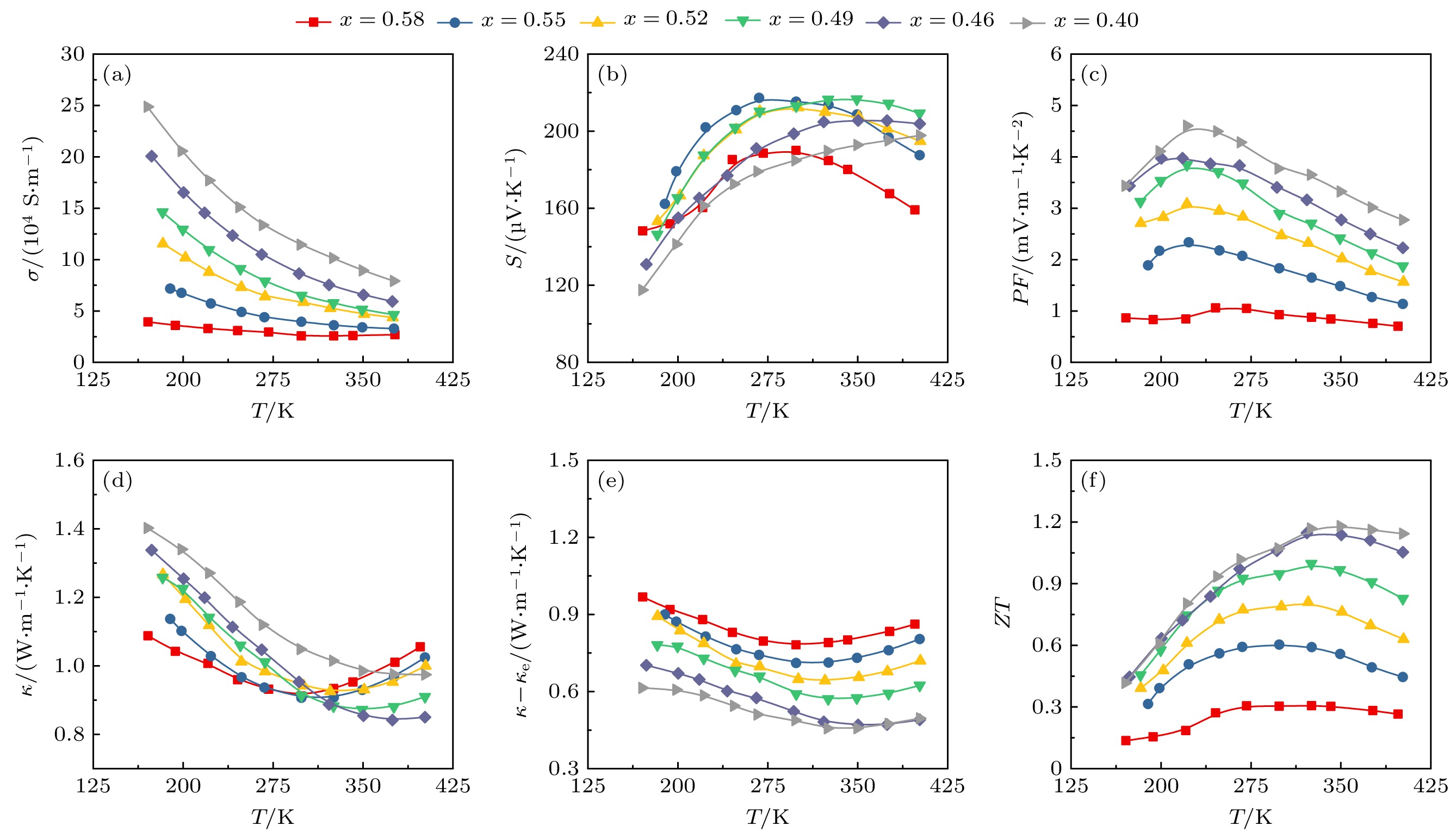

图 2 BixSb2–xTe3样品的电热输运性能 (a) 电导率; (b) Seebeck系数; (c) 功率因子; (d) 总热导率; (e) 总热导率减电子热导率; (f) ZT值

Fig. 2. Temperature-dependent electronic transport properties for BixSb2–xTe3 samples: (a) Electrical conductivity; (b) Seebeck coefficient; (c) power factor; (d) total thermal conductivity; (e) thermal conductivity κ – κe; (f) ZT.

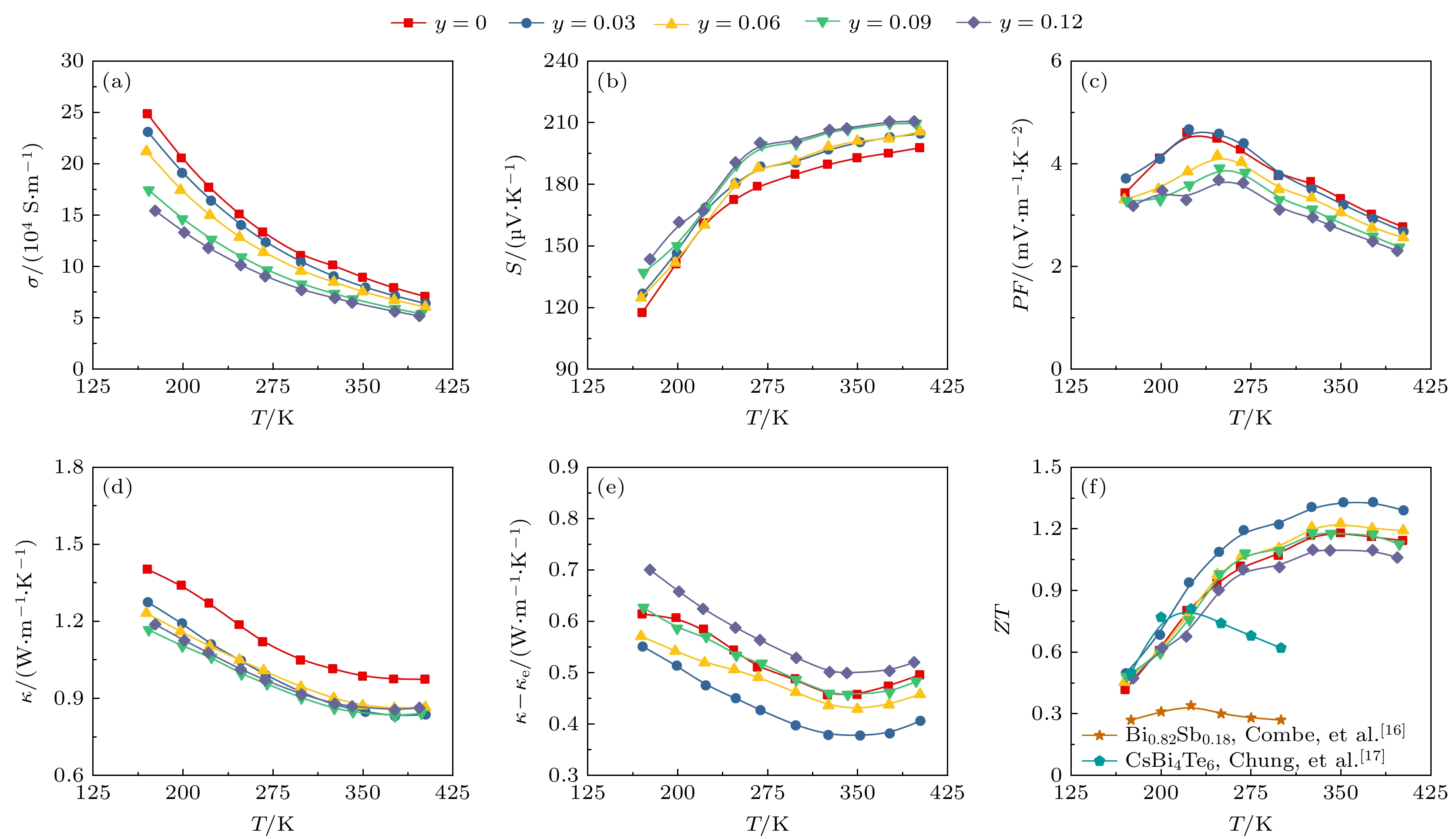

图 3 Bi0.4Sb1.6Te3–ySey样品的电热输运性能 (a) 电导率; (b) Seebeck系数; (c) 功率因子; (d) 总热导率; (e) 总热导率减电子热导率; (f) ZT值

Fig. 3. Temperature-dependent electronic transport properties for Bi0.4Sb1.6Te3–ySey samples: (a) Electrical conductivity; (b) Seebeck coefficient; (c) power factor; (d) total thermal conductivity; (e) thermal conductivity κ – κe; (f) ZT.

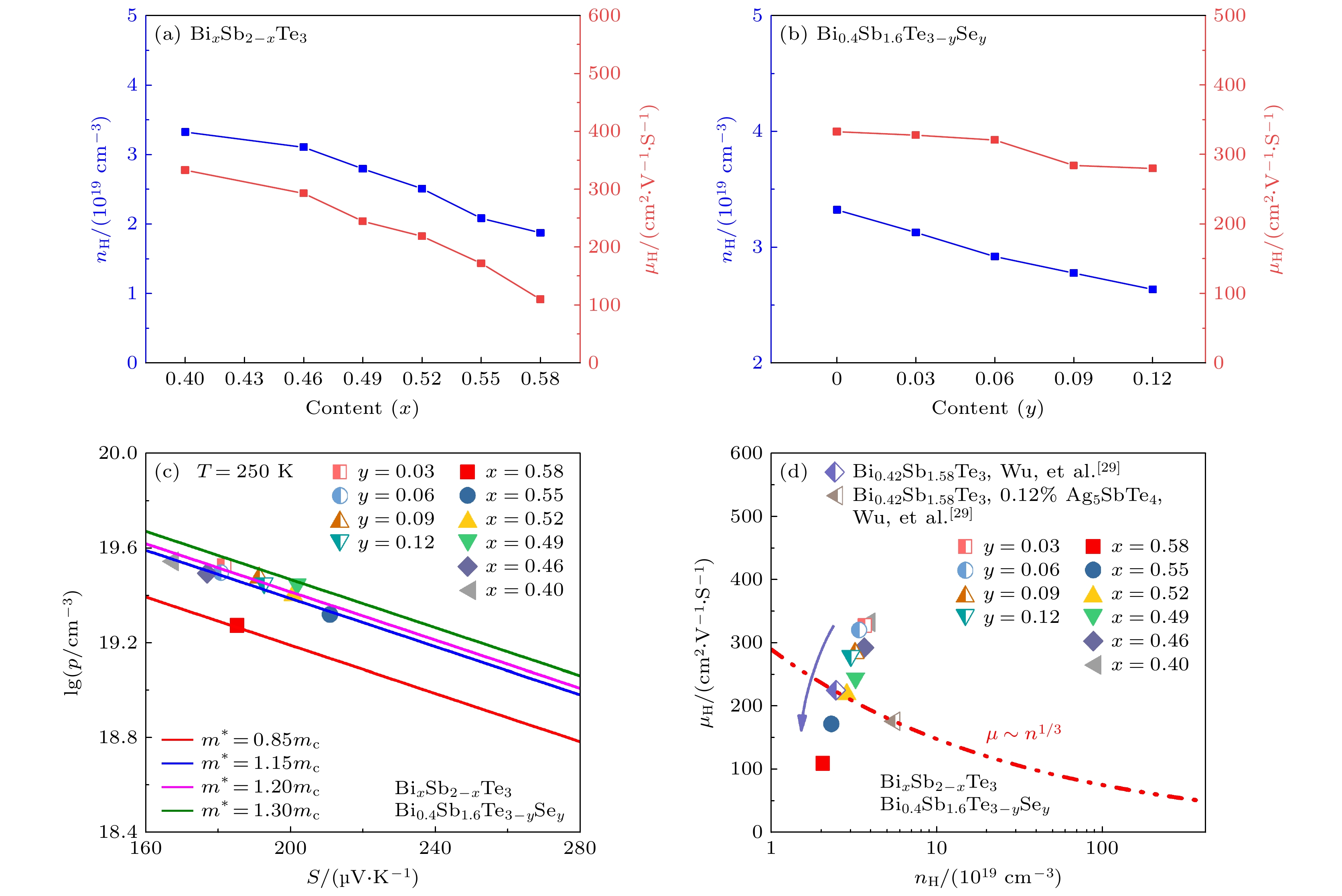

图 4 (a), (b) 250 K时载流子浓度和载流子迁移率随Bi, Se含量的变化; (c) 250 K时样品载流子浓度与Seebeck系数的关系; (d) 250 K时样品载流子迁移率与载流子浓度的关系

Fig. 4. (a), (b) Hall carrier mobility and concentration change with respect to the Bi, Se content; (c) Seebeck coefficients as a function of the charge carrier concentration at 250 K; (d) the carrier mobility as a function of the charge carrier concentration at 250 K.

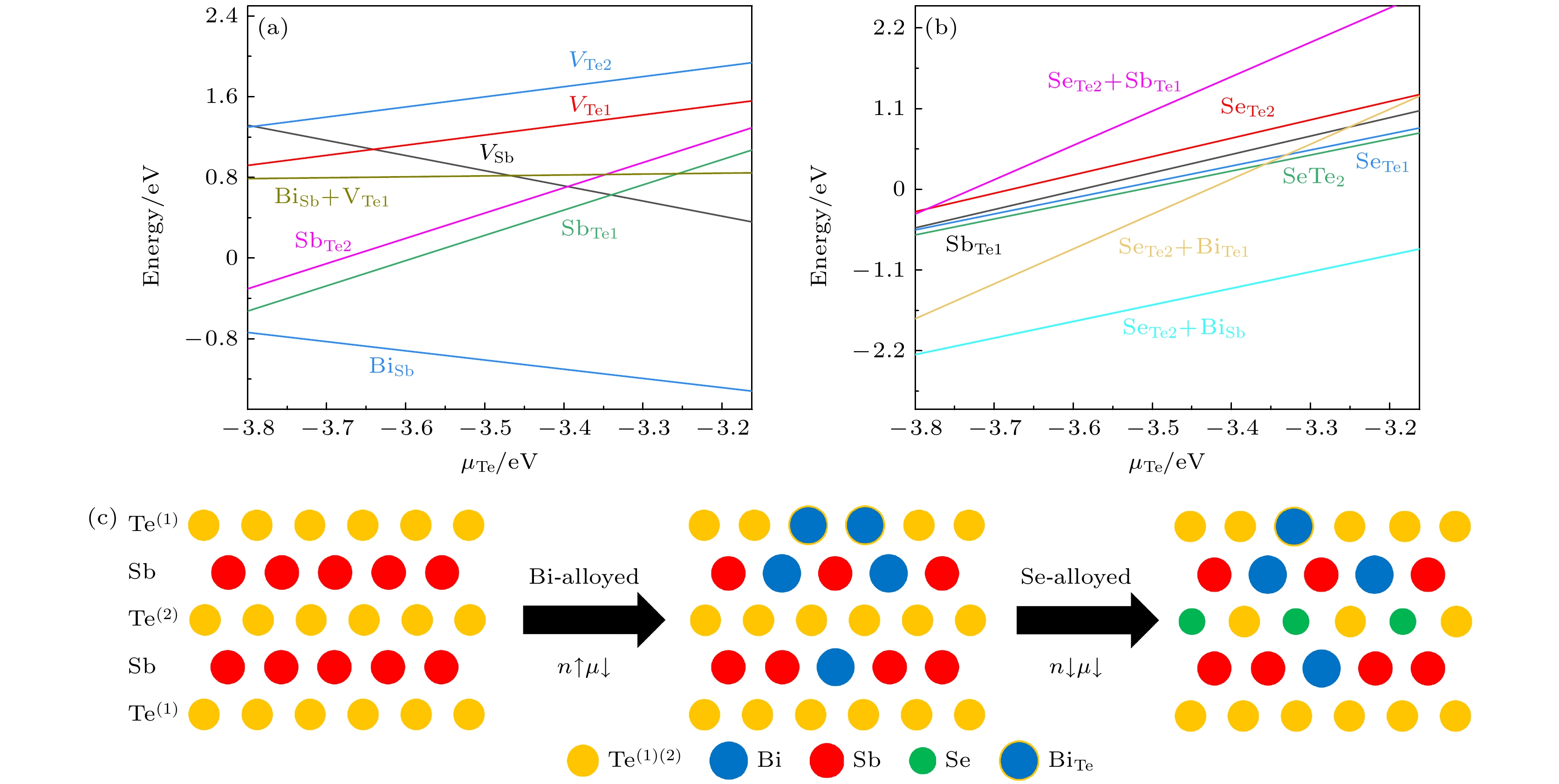

图 5 Bi2Te3基化合物中不同的点缺陷形成能 (a) BixSb2–xTe3; (b) Bi0.4Sb1.6Te3–ySey. (c) BixSb2–xTe3–ySey固溶体缺陷演化过程

Fig. 5. Theoretically calculated formation energies of different point defects in different solid solution: (a) BixSb2–xTe3; (b) Bi0.4Sb1.6Te3–ySey. (c) Defect evolution process for BixSb2–xTe3–ySey solid solution.

-

[1] Han Y N, Zhang A K 2022 Sci. Rep. 12 2349

Google Scholar

Google Scholar

[2] Tong X, Qiu J, Li J P, Xie K Y, Chen J Y, Huai Y, Li S F, Huang Y B, Dong W 2024 Cryogenics 143 103929

Google Scholar

Google Scholar

[3] Qin B C, Wang D Y, Liu X X, Qin Y X, Dong J F, Luo J F, Li J W, Liu W, Tan G J, Tang X F, Li J F, He J Q, Zhao L D 2021 Science 373 556

Google Scholar

Google Scholar

[4] Rogalski A, Martyniuk P, Kopytko M, Hu W D 2021 Appl. Sci. 11 501

Google Scholar

Google Scholar

[5] Tang J, Ni H, Peng R L, Wang N, Zuo L 2023 J. Power. Sources 562 232785

Google Scholar

Google Scholar

[6] Sun J C, Zhang Y, Fan Y T, Tang X F, Tan G J 2022 Chem. Eng. J. 431 133699

Google Scholar

Google Scholar

[7] Peng G Y, Hu L, Qu W B, Zhang C L, Li S R, Liu Z Y, Liu J C, Guo S W, Xiao Y, Gao Z B, Zhang Z, Zhang Y, Wu H J, Pennycook S J, Sun J, Ding X D 2023 Interdiscip. Mater. 2 30

Google Scholar

Google Scholar

[8] Huang Y L, Lyu T, Zeng M T, Wang M R, Yu Y, Zhang C H, Liu F S, Hong M, Hu L P 2024 Interdiscip. Mater. 3 607

Google Scholar

Google Scholar

[9] Hu C L, Xia K Y, Fu C G, Zhao X B, Zhu T J 2022 Energy Environ. Sci. 15 1406

Google Scholar

Google Scholar

[10] Zhang Y, Sun J C, Shuai J, Tang X F, Tan G J 2021 Mater. Today Phys. 19 100405

Google Scholar

Google Scholar

[11] Liu Z T, Hong T, Xu L Q, Wang S N, Gao X, Chang C, Ding X D, Xiao Y, Zhao L D 2023 Interdiscip. Mater. 2 161

Google Scholar

Google Scholar

[12] Choi S, Han U, Cho H, Lee H 2018 Appl. Therm. Eng. 132 560

Google Scholar

Google Scholar

[13] Reddy B V K, Barry M, Li J, Chyu M K 2014 Energy Conv. Manag. 77 458

Google Scholar

Google Scholar

[14] Yang D W, Xing Y B, Wang J, Hu K, Xiao Y N, Tang K C, Lyu J N, Li J H, Liu Y T, Zhou P, Yu Y, Yan Y G, Tang X F 2024 Interdiscip. Mater. 3 326

Google Scholar

Google Scholar

[15] Feng J H, Li J, Liu R H 2024 Nano Energy 126 109651

Google Scholar

Google Scholar

[16] Lyu J N, Yang D W, Liu Y T, Li J H, Zhang Z N, Li Z M, Liu M Y, Liu W, Ren Z G, Liu H J, Wu J S, Tang X F, Yan Y G 2024 ACS Appl. Mater. Interfaces 16 16505

Google Scholar

Google Scholar

[17] Mao J, Chen G, Ren Z F 2021 Nat. Mater. 20 454

Google Scholar

Google Scholar

[18] Luo T T, Wang S Y, Li H, Tang X F 2013 Intermetallics 32 96

Google Scholar

Google Scholar

[19] Chen Z, Zhou M, Huang R J, Song C M, Zhou Y, Li L F 2012 J. Alloy. Compd. 511 85

Google Scholar

Google Scholar

[20] Combe E, Funahashi R, Takeuchi T, Barbier T, Yubuta K 2017 J. Alloy. Compd. 692 563

Google Scholar

Google Scholar

[21] Chung D Y, Hogan T, Brazis P, Rocci-Lane M, Kannewurf C, Bastea M, Uher C, Kanatzidis M G 2000 Science 287 1024

Google Scholar

Google Scholar

[22] Xie W J, Tang X F, Yan Y G, Zhang Q J, Tritt T M 2009 Appl. Phys. Lett. 94 102111

Google Scholar

Google Scholar

[23] 李睿英, 罗婷婷, 李貌, 陈硕, 鄢永高, 吴劲松, 苏贤礼, 张清杰, 唐新峰 2024 73 097101

Google Scholar

Google Scholar

Li R Y, Luo T T, Li M, Chen S, Yan Y G, Wu J S, Su X L, Zhang Q J, Tang X F 2024 Acta Phys. Sin. 73 097101

Google Scholar

Google Scholar

[24] 李强, 陈硕, 刘可可, 鲁志强, 胡芹, 冯丽萍, 张清杰, 吴劲松, 苏贤礼, 唐新峰 2023 72 097101

Google Scholar

Google Scholar

Li Q, Chen S, Liu K K, Lu Z Q, Hu Q, Feng L P, Zhang Q J, Wu J S, Su X L, Tang X F 2023 Acta Phys. Sin. 72 097101

Google Scholar

Google Scholar

[25] Chen S, Luo T T, Yang Z, Zhong S L, Su X L, Yan Y G, Wu J S, Poudeu P F, Zhang Q J, Tang X F 2024 Mater. Today Phys. 46 101524

Google Scholar

Google Scholar

[26] 鲁志强, 刘可可, 李强, 胡芹, 冯丽萍, 张清杰, 吴劲松, 苏贤礼, 唐新峰 2023 无机材料学报 38 1311

Google Scholar

Google Scholar

Lu Z Q, Liu K K, Li Q, Hu Q, Feng L P, Zhang Q J, Wu J S, Su X L, Tang X F 2023 J. Inorg. Mater. 38 1311

Google Scholar

Google Scholar

[27] Goldsmid H J, Sharp J W 1999 J. Electro. Mater. 28 869

Google Scholar

Google Scholar

[28] Yang J, Morelli D T, Meisner G, Chen W, Dyck J, Uher C 2002 Phys. Rev. B 65 094115

Google Scholar

Google Scholar

[29] Wu G, Zhang Q, Fu Y T, Tan X J, Noudem J G, Zhang Z W, Cui C, Sun P, Hu H Y, Wu J H, Liu G Q, Jiang J 2023 Adv. Funct. Mater. 33 2305686

Google Scholar

Google Scholar

[30] Lee K H, Kim S I, Lim J C, Cho J Y, Yang H, Kim H S 2022 Adv. Funct. Mater. 32 2203852

Google Scholar

Google Scholar

[31] Xu B, Xia Q, Ma S S, Zhang J, Wang Y S, Li J F, Gu Z H, Yi L 2022 FlatChem 34 100394

Google Scholar

Google Scholar

[32] Saberi Y, Sajjadi S A 2022 J. Alloy. Compd. 904 163918

Google Scholar

Google Scholar

计量

- 文章访问数: 2127

- PDF下载量: 74

- 被引次数: 0

下载:

下载: