-

热电器件微型化对组成热电元件的界面性能提出了更高要求, 获得低的界面接触电阻率和高的界面结合强度的异质结合界面, 是成功制备高性能、高可靠性Bi2Te3基微型热电器件的前提条件. 本研究采用酸洗方法对Bi0.4Sb1.6Te3材料进行表面修饰, 实现了Bi0.4Sb1.6Te3/Ni热电元件界面性能的协同优化. 酸洗过程有效调控了Bi0.4Sb1.6Te3材料的表面功函数, 显著降低了Ni层与Bi0.4Sb1.6Te3材料间的接触势垒, 从未酸洗处理的0.22 eV降至0.02 eV, 势垒的降低使界面接触电阻率从未酸洗处理的14.2 μΩ·cm2大幅降至0.22 μΩ·cm2. 此外, 酸洗过程还能有效调控基体表面粗糙度, 在基体表面形成2—5 μm的V型凹坑, 产生钉扎效应, 极大地增强了材料表面与Ni层的物理结合, 与约50 nm厚Ni/Bi0.4Sb1.6Te3界面扩散反应区形成的冶金结合共同作用, 使界面结合强度从未酸洗处理的7.14 MPa大幅增至22.34 MPa. 这种优异的界面性能在微型热电器件中得到了进一步证实, 采用该工艺处理后热电元件制备的4.7 × 4.9 mm2微型热电器件, 在热面温度300 K下的最大制冷温差达到56.5 K, 在10 K温差下最大输出功率达到882 μW. 该研究为实现界面性能的协同优化提供了一种新策略, 并为微型热电器件的性能优化开辟了新途径.

-

关键词:

- Bi2Te3基微型热电器件 /

- Bi0.4Sb1.6Te3/Ni热电元件 /

- 表面修饰工程 /

- 界面接触电阻率 /

- 界面结合强度

The miniaturization of thermoelectric devices raises a strong requirement for the excellent interfacial properties of thermoelectric elements. Thus, achieving a heterogeneous interface with low interfacial contact resistivity and high interfacial bonding strength is a prerequisite for the successful fabrication of high-performance and high-reliability Bi2Te3-based micro thermoelectric devices. In this work, we adopt the acid pickling method to modify the surface structure of Bi0.4Sb1.6Te3 material to synergistically optimize the interfacial properties of Bi0.4Sb1.6Te3/Ni thermoelectric elements. The acid pickling process effectively modulates the work function of Bi0.4Sb1.6Te3 material, which dramatically reduces the contact barrier height of Ni/Bi0.4Sb1.6Te3 heterojunction from 0.22 to 0.02 eV. As a consequence, the corresponding interfacial contact resistivity of the element is greatly reduced from 14.2 to 0.22 μΩ·cm2. Moreover, the acid pickling process effectively adjusts the surface roughness of the matrix, forming a V-shaped pit of 2–5 μm in depth on the substrate surface and leading to a pinning effect. This significantly enhances the physical bonding between the material surface and the Ni layer, which, together with the metallurgical bond formed by the interfacial diffusion reaction zone of about 50-nm-thick Ni/Bi0.4Sb1.6Te3, greatly enhances the interfacial bond strength from 7.14 to 22.34 MPa. The excellent interfacial properties are further validated by the micro-thermoelectric devices. The maximum cooling temperature difference of 4.7 mm× 4.9 mm micro thermoelectric device fabricated by this process achieves 56.5 K, with hot side temperature setting at 300 K, and the maximum output power reaches 882 μW under the temperature gradient of 10 K. This work provides a new strategy for realizing the synergetic optimization of interfacial properties and opens up a new avenue for improving the performance of micro thermoelectric devices.-

Keywords:

- Bi2Te3-based micro thermoelectric devices /

- Bi0.4Sb1.6Te3/Ni thermoelectric elements /

- surface modification engineering /

- interfacial contact resistivity /

- interfacial bonding strength

[1] Snyder G J, Toberer E S 2008 Nat. Mater. 7 105

Google Scholar

Google Scholar

[2] 陶颖, 祁宁, 王波, 陈志权, 唐新峰 2018 67 197201

Google Scholar

Google Scholar

Tao Y, Qi N, W B, Chen Z Q, Tang X F 2018 Acta Phys. Sin. 67 197201

Google Scholar

Google Scholar

[3] Mao J, Chen G, Ren Z 2020 Nat. Mater. 20 454

Google Scholar

Google Scholar

[4] 范人杰, 江先燕, 陶奇睿, 梅期才, 唐颖菲, 陈志权, 苏贤礼, 唐新峰 2021 70 137102

Google Scholar

Google Scholar

Fan R J, Jiang X Y, Tao Q R, Mei Q C, Tang Y F, Chen Z Q, Su X L, Tang X F 2021 Acta Phys. Sin. 70 137102

Google Scholar

Google Scholar

[5] 杨东旺, 罗婷婷, 苏贤礼, 吴劲松, 唐新峰 2021 无机材料学报 36 991

Google Scholar

Google Scholar

Yang D W, Luo T T, Su X L, Wu J S, Tang X F 2021 J. Inorg. Mater. 36 991

Google Scholar

Google Scholar

[6] Tang X, Li Z, Liu W, Zhang Q, Uher C 2022 Interdisciplin. Mater. 1 88

Google Scholar

Google Scholar

[7] Venkatasubramanian R, Watkins C, Stokes D, Posthill J, Caylor C 2007 IEEE International Electron Devices Meeting Washington, USA, December 10–12, 2007, p367

[8] Liu D, Zhao F Y, Yang H X, Tang G F 2015 Energy 83 29

Google Scholar

Google Scholar

[9] Yan J, Liao X, Yan D, Chen Y 2018 J. Microelectromech. Syst. 27 1

Google Scholar

Google Scholar

[10] Liu Q L, Li G D, Zhu H T, Zhao H Z 2022 Chin. Phys. B 31 047204

Google Scholar

Google Scholar

[11] Yu Y, Guo Z, Zhu W, Zhou J, Guo S, Wang Y, Deng Y 2022 Nano Energy 93 106818

Google Scholar

Google Scholar

[12] Aswal D K, Basu R, Singh A 2016 Energy Convers. Manage. 114 50

Google Scholar

Google Scholar

[13] Zhang Q H, Huang X Y, Bai S Q, Shi X, Uher C, Chen L D 2016 Adv. Eng. Mater. 18 194

Google Scholar

Google Scholar

[14] He R, Schierning G, Nielsch K 2018 Adv. Mater. Technol. 3 1700256

Google Scholar

Google Scholar

[15] Liu W, Bai S 2019 J. Materiomics 5 321

Google Scholar

Google Scholar

[16] 胡晓凯, 张双猛, 赵府, 刘勇, 刘玮书 2019 无机材料学报 34 269

Google Scholar

Google Scholar

Hu X K, Zhang S M, Zhao F, Liu Y, Liu W S 2019 J. Inorg. Mater. 34 269

Google Scholar

Google Scholar

[17] Hatzikraniotis E, Zorbas K, Samaras I, Kyratsi T, Paraskevopoulos K 2010 J. Electron. Mater. 39 2112

Google Scholar

Google Scholar

[18] Park W, Barako M T, Marconnet A M, Asheghi M, Goodson K E 13 th InterSociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems San Diego, USA, May 30–June 1, 2012, p107

[19] Barako M T, Park W, Marconnet A M, Asheghi M, Goodson K E 13 th InterSociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems San Diego, USA, May 30–June 1, 2012, p86

[20] Gupta R, White J, Iyore O, Chakrabarti U, Alshareef H N, Gnade B 2009 Electrochem. Solid-State Lett. 12 H302

Google Scholar

Google Scholar

[21] Iyore O D, Lee T H, Gupta R P, White J B, Alshareef H N, Kim M J, Gnade B E 2010 Surf. Interface Anal. 41 440

Google Scholar

Google Scholar

[22] Feng H-P, Yu B, Chen S, Collins K, He C, Ren Z, Chen G 2011 Electrochim. Acta 56 3079

Google Scholar

Google Scholar

[23] Taylor P J, Maddux J R, Meissner G, Venkatasubramanian R, Bulman G, Pierce J, Gupta R, Bierschenk J, Caylor C, D’Angelo J 2013 Appl. Phys. Lett. 103 043902

Google Scholar

Google Scholar

[24] Weitzman L H 1967 US Patent 3 338 765

[25] Kozlov A O, Korchagin E P, Mustafoev B R, Babich A V, Rogachev M S 2021 IEEE Conference of Russian Young Researchers in Electrical and Electronic Engineering (ElConRus) St. Petersburg, Moscow, Russia, January 26–29, 2021, p2451

[26] Vikhor L M, Anatychuk L I, Gorskyi P V 2019 J. Appl. Phys. 126 164503

Google Scholar

Google Scholar

[27] Schottky W 1938 Naturwissenschaften 26 843

Google Scholar

Google Scholar

[28] Monroy E, Calle F, Ranchal R, Palacios T, Moerman I 2002 Semicond. Sci. Technol. 17 L47

Google Scholar

Google Scholar

[29] Kim H S, Lee K H, Yoo J, Shin W H, Roh J W, Hwang J Y, Kim S W, Kim S I 2018 J. Alloys Compd. 741 869

Google Scholar

Google Scholar

[30] Liu W, Jie Q, Kim H S, Ren Z 2015 Acta Mater. 87 357

Google Scholar

Google Scholar

[31] Tang H, Bai H, Yang X, Cao Y, Tang K, Zhang Z, Chen S, Yang D, Su X, Yan Y 2022 J. Alloys Compd. 896 163090

Google Scholar

Google Scholar

[32] Liu W, Wang H, Wang L, Wang X, Joshi G, Chen G, Ren Z 2013 J. Mater. Chem. A 1 13093

Google Scholar

Google Scholar

-

图 A3 不同酸洗时间后的Bi0.4Sb1.6Te3/Ni界面接触电阻率测试结果 (a) 0 min; (b) 2 min; (c) 4 min; (d) 6 min; (e) 8 min; (f) 10 min

Fig. A3. The results of interfacial contact resistivity of Bi0.4Sb1.6Te3/Ni thermoelectric elements after different pickling time: (a) 0 min; (b) 2 min; (c) 4 min; (d) 6 min; (e) 8 min; (f) 10 min.

图 1 Bi0.4Sb1.6Te3/Ni热电元件的(a) 界面结合强度和(b) 界面接触电阻率随酸洗时间变化的关系, 其中红色虚线代表现有商业化水平; (c) 器件内阻随酸洗时间的变化关系, 其中右上角为微型热电器件实物照片; (d) 器件的最大制冷温差随酸洗时间的变化关系; 不同酸洗时间制备的器件在10 K温差下的 (e) 开路电压和(f) 输出功率随电流的变化关系

Fig. 1. The pickling time dependences of (a) the interfacial bonding strength and (b) the interfacial contact resistivity for Bi0.4Sb1.6Te3/Ni thermoelectric elements, the red dotted line represents the commercial level. (c) The relationship between the internal resistance of the devices and the pickling time, the upper right corner is the photograph of the micro thermoelectric device; (d) the relationship between the maximum cooling temperature difference of the device and pickling time; the current dependences of (e) open-circuit voltage and (f) output power of the devices prepared by different pickling time under 10 K temperature difference.

图 4 (a) Bi0.4Sb1.6Te3/Ni热电元件的界面HAADF-STEM图像, 区域1和区域2分别表示界面区域和基体的选区电子衍射; (b) 界面区域的元素面分布图谱, 其中紫色为Ni, 绿色为Te, 红色为Bi和蓝色为Sb; (c)—(f) 区域1的TEM图像, 界面相为Ni3Te2 and NiTe2

Fig. 4. (a) HAADF-STEM images of the Ni/Bi0.4Sb1.6Te3 thermoelectric element contact interface, area 1 and 2 represents the selected area electron diffraction of the interface and the matrix, respectively; (b) EDS mapping of (a), purple: Ni, green: Te, red: Bi, blue: Sb; (c)–(f) TEM images of area 1 in Figure (a) and the interface phases are Ni3Te2 and NiTe2 compounds.

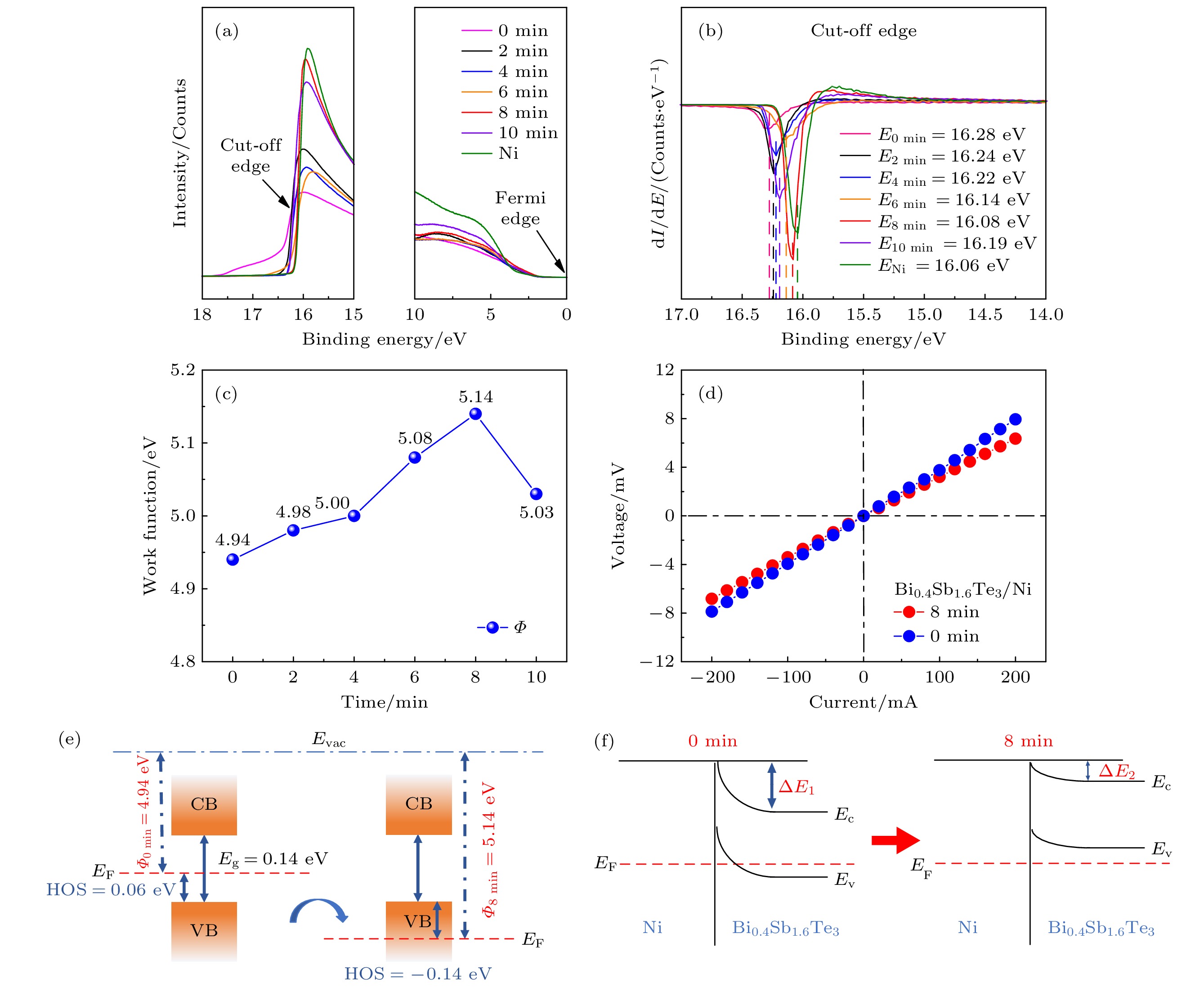

图 5 不同酸洗时间后的材料表面的(a) UPS光谱以及(b) 截止边强度的结合能微分; (c) 材料表面功函数随酸洗时间变化的关系; 酸洗8 min前后的(d) Bi0.4Sb1.6Te3/Ni热电元件的I-V曲线和(e) 能带结构示意图以及(f) 与Ni层界面接触势垒高度的变化示意图

Fig. 5. (a) UPS spectra and (b) the binding energy differential of the cut-off edge intensity for the materials surface after different pickling time; (c) I-V curve for the Bi0.4Sb1.6Te3/Ni thermoelectric elements and (d) surface energy band structure diagram and (e) schematic diagram of the height change of the contact barrier at the interface with Ni layer before and after pickling for 8 min.

表 A1 不同酸洗时间制备出的Bi0.4Sb1.6Te3/Ni热电元件和N-Bi2Te3/Ni热电元件的五次界面结合强度测试结果

Table A1. The five repeated results of interfacial bonding strength for Bi0.4Sb1.6Te3/Ni thermoelectric elements with different pickling time and N-Bi2Te3/Ni thermoelectric elements.

Sample 1# 2# 3# 4# 5# Average/MPa 0 min 7.25 6.75 7.50 6.93 7.27 7.14 2 min 14.00 13.73 13.25 13.75 13.50 13.65 4 min 16.25 14.75 14.95 15.50 15.00 15.29 6 min 17.55 18.08 17.25 14.75 16.00 16.73 8 min 22.05 20.75 23.75 23.25 21.90 22.34 10 min 13.13 14.28 12.00 13.03 13.75 13.24 N-Bi2Te3/Ni 14.33 13.85 16.40 14.28 16.80 15.13 -

[1] Snyder G J, Toberer E S 2008 Nat. Mater. 7 105

Google Scholar

Google Scholar

[2] 陶颖, 祁宁, 王波, 陈志权, 唐新峰 2018 67 197201

Google Scholar

Google Scholar

Tao Y, Qi N, W B, Chen Z Q, Tang X F 2018 Acta Phys. Sin. 67 197201

Google Scholar

Google Scholar

[3] Mao J, Chen G, Ren Z 2020 Nat. Mater. 20 454

Google Scholar

Google Scholar

[4] 范人杰, 江先燕, 陶奇睿, 梅期才, 唐颖菲, 陈志权, 苏贤礼, 唐新峰 2021 70 137102

Google Scholar

Google Scholar

Fan R J, Jiang X Y, Tao Q R, Mei Q C, Tang Y F, Chen Z Q, Su X L, Tang X F 2021 Acta Phys. Sin. 70 137102

Google Scholar

Google Scholar

[5] 杨东旺, 罗婷婷, 苏贤礼, 吴劲松, 唐新峰 2021 无机材料学报 36 991

Google Scholar

Google Scholar

Yang D W, Luo T T, Su X L, Wu J S, Tang X F 2021 J. Inorg. Mater. 36 991

Google Scholar

Google Scholar

[6] Tang X, Li Z, Liu W, Zhang Q, Uher C 2022 Interdisciplin. Mater. 1 88

Google Scholar

Google Scholar

[7] Venkatasubramanian R, Watkins C, Stokes D, Posthill J, Caylor C 2007 IEEE International Electron Devices Meeting Washington, USA, December 10–12, 2007, p367

[8] Liu D, Zhao F Y, Yang H X, Tang G F 2015 Energy 83 29

Google Scholar

Google Scholar

[9] Yan J, Liao X, Yan D, Chen Y 2018 J. Microelectromech. Syst. 27 1

Google Scholar

Google Scholar

[10] Liu Q L, Li G D, Zhu H T, Zhao H Z 2022 Chin. Phys. B 31 047204

Google Scholar

Google Scholar

[11] Yu Y, Guo Z, Zhu W, Zhou J, Guo S, Wang Y, Deng Y 2022 Nano Energy 93 106818

Google Scholar

Google Scholar

[12] Aswal D K, Basu R, Singh A 2016 Energy Convers. Manage. 114 50

Google Scholar

Google Scholar

[13] Zhang Q H, Huang X Y, Bai S Q, Shi X, Uher C, Chen L D 2016 Adv. Eng. Mater. 18 194

Google Scholar

Google Scholar

[14] He R, Schierning G, Nielsch K 2018 Adv. Mater. Technol. 3 1700256

Google Scholar

Google Scholar

[15] Liu W, Bai S 2019 J. Materiomics 5 321

Google Scholar

Google Scholar

[16] 胡晓凯, 张双猛, 赵府, 刘勇, 刘玮书 2019 无机材料学报 34 269

Google Scholar

Google Scholar

Hu X K, Zhang S M, Zhao F, Liu Y, Liu W S 2019 J. Inorg. Mater. 34 269

Google Scholar

Google Scholar

[17] Hatzikraniotis E, Zorbas K, Samaras I, Kyratsi T, Paraskevopoulos K 2010 J. Electron. Mater. 39 2112

Google Scholar

Google Scholar

[18] Park W, Barako M T, Marconnet A M, Asheghi M, Goodson K E 13 th InterSociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems San Diego, USA, May 30–June 1, 2012, p107

[19] Barako M T, Park W, Marconnet A M, Asheghi M, Goodson K E 13 th InterSociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems San Diego, USA, May 30–June 1, 2012, p86

[20] Gupta R, White J, Iyore O, Chakrabarti U, Alshareef H N, Gnade B 2009 Electrochem. Solid-State Lett. 12 H302

Google Scholar

Google Scholar

[21] Iyore O D, Lee T H, Gupta R P, White J B, Alshareef H N, Kim M J, Gnade B E 2010 Surf. Interface Anal. 41 440

Google Scholar

Google Scholar

[22] Feng H-P, Yu B, Chen S, Collins K, He C, Ren Z, Chen G 2011 Electrochim. Acta 56 3079

Google Scholar

Google Scholar

[23] Taylor P J, Maddux J R, Meissner G, Venkatasubramanian R, Bulman G, Pierce J, Gupta R, Bierschenk J, Caylor C, D’Angelo J 2013 Appl. Phys. Lett. 103 043902

Google Scholar

Google Scholar

[24] Weitzman L H 1967 US Patent 3 338 765

[25] Kozlov A O, Korchagin E P, Mustafoev B R, Babich A V, Rogachev M S 2021 IEEE Conference of Russian Young Researchers in Electrical and Electronic Engineering (ElConRus) St. Petersburg, Moscow, Russia, January 26–29, 2021, p2451

[26] Vikhor L M, Anatychuk L I, Gorskyi P V 2019 J. Appl. Phys. 126 164503

Google Scholar

Google Scholar

[27] Schottky W 1938 Naturwissenschaften 26 843

Google Scholar

Google Scholar

[28] Monroy E, Calle F, Ranchal R, Palacios T, Moerman I 2002 Semicond. Sci. Technol. 17 L47

Google Scholar

Google Scholar

[29] Kim H S, Lee K H, Yoo J, Shin W H, Roh J W, Hwang J Y, Kim S W, Kim S I 2018 J. Alloys Compd. 741 869

Google Scholar

Google Scholar

[30] Liu W, Jie Q, Kim H S, Ren Z 2015 Acta Mater. 87 357

Google Scholar

Google Scholar

[31] Tang H, Bai H, Yang X, Cao Y, Tang K, Zhang Z, Chen S, Yang D, Su X, Yan Y 2022 J. Alloys Compd. 896 163090

Google Scholar

Google Scholar

[32] Liu W, Wang H, Wang L, Wang X, Joshi G, Chen G, Ren Z 2013 J. Mater. Chem. A 1 13093

Google Scholar

Google Scholar

计量

- 文章访问数: 7929

- PDF下载量: 171

- 被引次数: 0

下载:

下载: