-

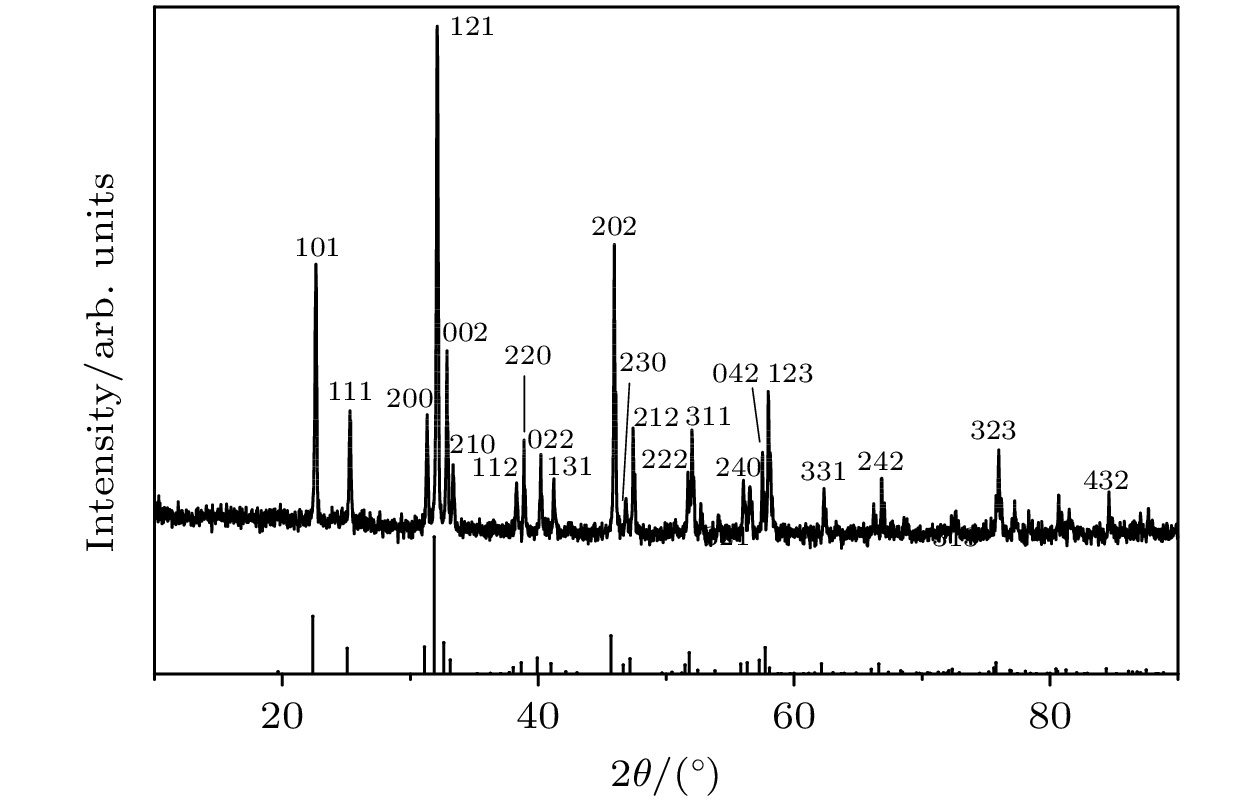

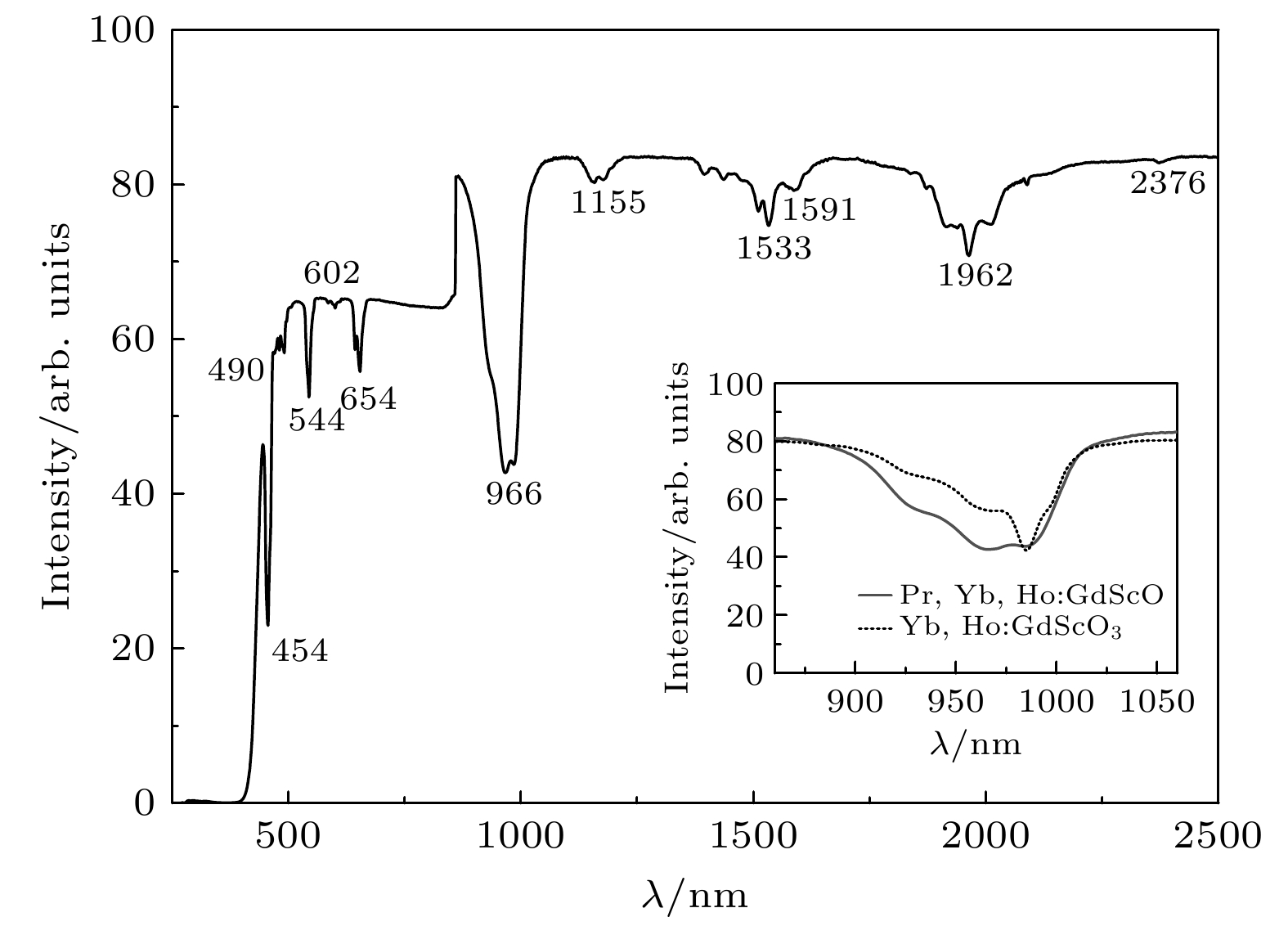

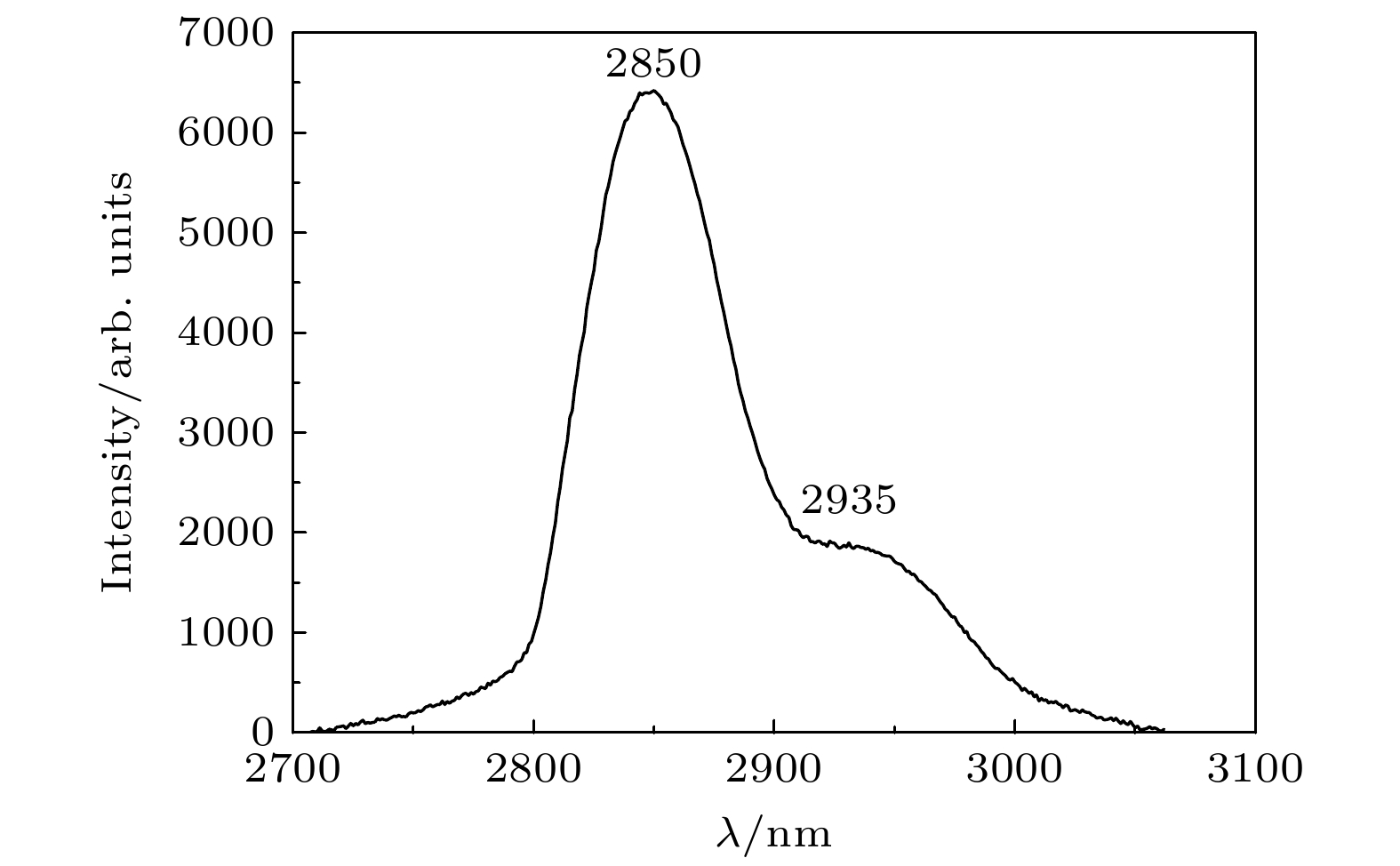

2.7—3.0 μm波段激光在很多领域具有重要应用, 为探索和发展该波段新型晶体材料, 本文采用提拉法生长出Pr, Yb, Ho:GdScO3晶体, 通过共掺入Pr3+离子以达到衰减Ho3+:5I7能级寿命的目的. 采用X射线衍射测试得到了晶体的粉末衍射数据, 测量了拉曼光谱, 并对晶体的拉曼振动峰进行指认, 对Pr, Yb, Ho:GdScO3晶体的透过光谱、发射光谱和荧光寿命进行表征. Yb3+的最强吸收峰在966 nm, 吸收峰半峰宽为90 nm; 2.7—3.0 μm波段最强发射峰在2850 nm, 半峰宽为70 nm; Ho3+:5I6和5I7能级寿命分别为1094 µs和56 µs. 与Yb, Ho:GdScO3晶体相比, Yb3+的吸收峰和2.7—3.0 μm的发射峰半峰宽明显展宽, 同时下能级寿命显著减小, 计算表明Ho3+:5I7与Pr3+:3F2+3H6能级之间能实现高效的能量传递. 以上结果表明Pr, Yb, Ho:GdScO3晶体是性能更优异的2.7—3.0 μm波段激光材料.

-

关键词:

- 2.7—3.0 μm激光 /

- Pr /

- Yb /

- Ho:GdScO3晶体 /

- 晶体生长 /

- 光谱性能

In order to explore and develop new crystal materials in the 2.7–3.0 μm band, Pr, Yb, Ho:GdScO3 crystal are successfully grown by the Czochralski method for the first time. X-ray diffraction measurement is performed to obtain powder diffraction data. Raman spectra aree measured and the vibration peaks are identified. The transmission spectrum, emission spectrum and fluorescence lifetime of Pr, Yb, Ho:GdScO3 crystal are also characterized. The center of the strongest absorption band is at 966 nm with a half-peak width of 90 nm, which comes from the transition of Yb3+:2F7/2 → 2F5/2. The absorption cross section of Yb3+ is calculated and the values at 966, 973, 985 nm are 0.62×10–20, 0.60×10–20 and 0.58×10–20 cm2 respectively. The maximum emission peak is at 2850 nm and the half-peak width is 70 nm, the lifetimes of Ho3+:5I6 and 5I7 are measured to be 1094 and 56 μs respectively, and the emission cross section at 2850 and 2935 nm are calculated to be 3.6×10–20 cm2 and 1.21×10–20 cm2, respectively. Comparing with Yb, Ho: GdScO3 crystal, the absorption peak of Yb3+ and the emission peak are both broadened, which are related to the increase of crystal disorder. The lifetime of the lower energy level decreases significantly. Furthermore, the energy transfer mechanism between$\rm Ho^{3+} $ and Pr3+ is analyzed, and the energy transfer efficiency between Ho3+:5I7 and Pr3+:3F2+3H6 is calculated to be 99%, which is higher than those in other materials. All the results show that Pr, Yb, Ho:GdScO3 crystal is an excellent 2.7–3 μm laser material, and is easier to achieve laser output than Yb, Ho:GdScO3 crystal.-

Keywords:

- 2.7–3.0 μm laser /

- Pr /

- Yb /

- Ho:GdScO3 crystal /

- crystal growth /

- optical properties

[1] Hu D, Dong J, Tian J, Wang W D, Wang Q G, Xue Y Y, Xu X D, Xu J 2021 J. Lumin. 238 118243

Google Scholar

Google Scholar

[2] Arsrnev P, Binert K, Svirridova R 1972 Phys. Status Solidi 9 103

Google Scholar

Google Scholar

[3] Yamaji A, Kochurikhin V, Fujimoto Y, Futami Y, Yanagida T, Yokota Y, Kurosawa S, Yoshikawa A 2012 Phys. Status Solidi C 9 2267

Google Scholar

Google Scholar

[4] Peng F, Liu W P, Luo J Q, Sun D L, Sun G H, Zhang D M, Wang X 2018 CrystEngComm 20 6291

Google Scholar

Google Scholar

[5] Hou W T, Zhao H Y, Qin Z P, et al. 2020 Opt. Mater. Express 10 2730

[6] Li S M, Fang Q N, Zhang Y H, et al. 2021 Opt. Laser Technol. 143 107345

Google Scholar

Google Scholar

[7] 李加红, 孙贵花, 张庆礼, 王小飞, 张德明, 刘文鹏, 高进云, 郑丽丽, 韩松, 陈照, 殷绍唐 2022 71 164206

Google Scholar

Google Scholar

Li J H, Sun G H, Zhang Q L, Wang X F, Zhang D M, Liu W P, Gao J Y, Zheng L L, Han S, Chen Z, Yin S T 2022 Acta Phys. Sin. 71 164206

Google Scholar

Google Scholar

[8] 孙贵花, 张庆礼, 李加红, 罗建乔, 王小飞, 高进云 2023 人工晶体学报 52 104

Google Scholar

Google Scholar

Sun G H, Zhang Q L, Li J H, Luo J Q, Wang X F, Gao J Y 2023 J. Synth. Cryst. 52 104

Google Scholar

Google Scholar

[9] He Y, Dou R Q, Zhang H T, et al. 2020 Infrared Laser Engineer. 49 20201067

Google Scholar

Google Scholar

[10] Zhang H L, Sun X J, Luo J Q, Fang Z Q, Zhao X Y, Cheng M J, Zhang Q L, Sun D L 2016 J. Alloy. Compod. 672 223

Google Scholar

Google Scholar

[11] Zhang H L, Sun D L, Luo J Q, et al. 2018 J. Lumin. 194 636

Google Scholar

Google Scholar

[12] Peng J T, Xia H P, Wang P Y, Hu H Y, Tang L, Zhang Y P, Jiang H C, Chen B J 2013 Optoelectron. Lett. 9 362

Google Scholar

Google Scholar

[13] 朱军, 戴世勋, 王训四, 沈祥, 徐铁峰, 聂秋华 2010 59 5803

Google Scholar

Google Scholar

Zhu J, Dai S X, Wang X S, Shen X, Xu T F, Nie Q H 2010 Acta Phys. Sin. 59 5803

Google Scholar

Google Scholar

[14] Ronald W S, Thomas R H 2016 Proc. of SPIE 9726 97261O-1

[15] Chaix-Pluchery O, Sauer Dand Kreisel J 2010 J. Phys.: Condens. Mat. 22 165901

[16] Chaix-Pluchery O, Sauer Dand Kreisel J 2010 J. Phys. Condens. Matter 22 165901

Google Scholar

Google Scholar

[17] Wang Y, Li J F, You Z Y, Zhu Z J, Tu C Y 2010 J. Alloy. Compod. 502 184

Google Scholar

Google Scholar

[18] Zhang Y, Huang F F, Liu L W, Liu X Q, Zheng S P, Chen D P 2016 Mater. Lett. 167 1

Google Scholar

Google Scholar

[19] Amanyan S N, Arsen’ev P A, Bagdasarov Kh S 1983 Plenum Publishing Corporation 38 344

[20] Li J H, Zhang Q L, Sun G H, Gao J Y, Wang X F, Dou R Q, Ding S J, Zhang D M, Liu W P, Luo J Q, Sun Y 2022 Chin. J. Lumin. 43 1779 [李加红, 张庆礼, 孙贵花, 高进云, 王小飞, 窦仁勤, 丁守军, 张德明, 刘文鹏, 罗建乔, 孙 彧 2022 发光学报 43 1779]

Google Scholar

Google Scholar

Li J H, Zhang Q L, Sun G H, Gao J Y, Wang X F, Dou R Q, Ding S J, Zhang D M, Liu W P, Luo J Q, Sun Y 2022 Chin. J. Lumin.43 1779  Google Scholar

Google Scholar

[21] Yan W L, Sun Y J, Wang Z Y, Wang W, Fang S S, Huang Y X, Wang Y Q, Tu C Y, Wen H R 2021 J. Lumin. 236 118067

Google Scholar

Google Scholar

-

表 1 不同材料中Ho3+离子与Pr3+离子之间的能量传递效率

Table 1. The energy transfer efficiencies between Ho3+ and Pr3+ in different materials.

材料 能量传递效率/% Ho3+:5I6 → Pr3+:3F4+3F3 Ho3+:5I7 → Pr3+:3F2+3H6 0.2%Pr, 5%Yb, 1%Ho:GdScO3晶体* 18.9 99.0 0.2%Pr, 5%Yb, 1%Ho:GYTO晶体[9] 10.26 87.13 0.2%Pr, 10%Yb, 1%Ho:YAP晶体[10] 7.1 85.8 2%Cr, 0.1%Pr, 50%Yb, 0.42%Ho:GYSGG晶体[11] 13.3 36.3 1.03%Pr, 2.06%Ho:YLF晶体[12] 27.0 92.5 2%Pr, 1%Ho:Ge-Ga-Se玻璃[13] — 82 15%Yb, 2%Ho, 1%Pr:YAG晶体[14] — 86.4 注: *表示本文的结果. 表中材料的各元素含量均为原子分数. -

[1] Hu D, Dong J, Tian J, Wang W D, Wang Q G, Xue Y Y, Xu X D, Xu J 2021 J. Lumin. 238 118243

Google Scholar

Google Scholar

[2] Arsrnev P, Binert K, Svirridova R 1972 Phys. Status Solidi 9 103

Google Scholar

Google Scholar

[3] Yamaji A, Kochurikhin V, Fujimoto Y, Futami Y, Yanagida T, Yokota Y, Kurosawa S, Yoshikawa A 2012 Phys. Status Solidi C 9 2267

Google Scholar

Google Scholar

[4] Peng F, Liu W P, Luo J Q, Sun D L, Sun G H, Zhang D M, Wang X 2018 CrystEngComm 20 6291

Google Scholar

Google Scholar

[5] Hou W T, Zhao H Y, Qin Z P, et al. 2020 Opt. Mater. Express 10 2730

[6] Li S M, Fang Q N, Zhang Y H, et al. 2021 Opt. Laser Technol. 143 107345

Google Scholar

Google Scholar

[7] 李加红, 孙贵花, 张庆礼, 王小飞, 张德明, 刘文鹏, 高进云, 郑丽丽, 韩松, 陈照, 殷绍唐 2022 71 164206

Google Scholar

Google Scholar

Li J H, Sun G H, Zhang Q L, Wang X F, Zhang D M, Liu W P, Gao J Y, Zheng L L, Han S, Chen Z, Yin S T 2022 Acta Phys. Sin. 71 164206

Google Scholar

Google Scholar

[8] 孙贵花, 张庆礼, 李加红, 罗建乔, 王小飞, 高进云 2023 人工晶体学报 52 104

Google Scholar

Google Scholar

Sun G H, Zhang Q L, Li J H, Luo J Q, Wang X F, Gao J Y 2023 J. Synth. Cryst. 52 104

Google Scholar

Google Scholar

[9] He Y, Dou R Q, Zhang H T, et al. 2020 Infrared Laser Engineer. 49 20201067

Google Scholar

Google Scholar

[10] Zhang H L, Sun X J, Luo J Q, Fang Z Q, Zhao X Y, Cheng M J, Zhang Q L, Sun D L 2016 J. Alloy. Compod. 672 223

Google Scholar

Google Scholar

[11] Zhang H L, Sun D L, Luo J Q, et al. 2018 J. Lumin. 194 636

Google Scholar

Google Scholar

[12] Peng J T, Xia H P, Wang P Y, Hu H Y, Tang L, Zhang Y P, Jiang H C, Chen B J 2013 Optoelectron. Lett. 9 362

Google Scholar

Google Scholar

[13] 朱军, 戴世勋, 王训四, 沈祥, 徐铁峰, 聂秋华 2010 59 5803

Google Scholar

Google Scholar

Zhu J, Dai S X, Wang X S, Shen X, Xu T F, Nie Q H 2010 Acta Phys. Sin. 59 5803

Google Scholar

Google Scholar

[14] Ronald W S, Thomas R H 2016 Proc. of SPIE 9726 97261O-1

[15] Chaix-Pluchery O, Sauer Dand Kreisel J 2010 J. Phys.: Condens. Mat. 22 165901

[16] Chaix-Pluchery O, Sauer Dand Kreisel J 2010 J. Phys. Condens. Matter 22 165901

Google Scholar

Google Scholar

[17] Wang Y, Li J F, You Z Y, Zhu Z J, Tu C Y 2010 J. Alloy. Compod. 502 184

Google Scholar

Google Scholar

[18] Zhang Y, Huang F F, Liu L W, Liu X Q, Zheng S P, Chen D P 2016 Mater. Lett. 167 1

Google Scholar

Google Scholar

[19] Amanyan S N, Arsen’ev P A, Bagdasarov Kh S 1983 Plenum Publishing Corporation 38 344

[20] Li J H, Zhang Q L, Sun G H, Gao J Y, Wang X F, Dou R Q, Ding S J, Zhang D M, Liu W P, Luo J Q, Sun Y 2022 Chin. J. Lumin. 43 1779 [李加红, 张庆礼, 孙贵花, 高进云, 王小飞, 窦仁勤, 丁守军, 张德明, 刘文鹏, 罗建乔, 孙 彧 2022 发光学报 43 1779]

Google Scholar

Google Scholar

Li J H, Zhang Q L, Sun G H, Gao J Y, Wang X F, Dou R Q, Ding S J, Zhang D M, Liu W P, Luo J Q, Sun Y 2022 Chin. J. Lumin.43 1779  Google Scholar

Google Scholar

[21] Yan W L, Sun Y J, Wang Z Y, Wang W, Fang S S, Huang Y X, Wang Y Q, Tu C Y, Wen H R 2021 J. Lumin. 236 118067

Google Scholar

Google Scholar

计量

- 文章访问数: 5668

- PDF下载量: 71

- 被引次数: 0

下载:

下载: