-

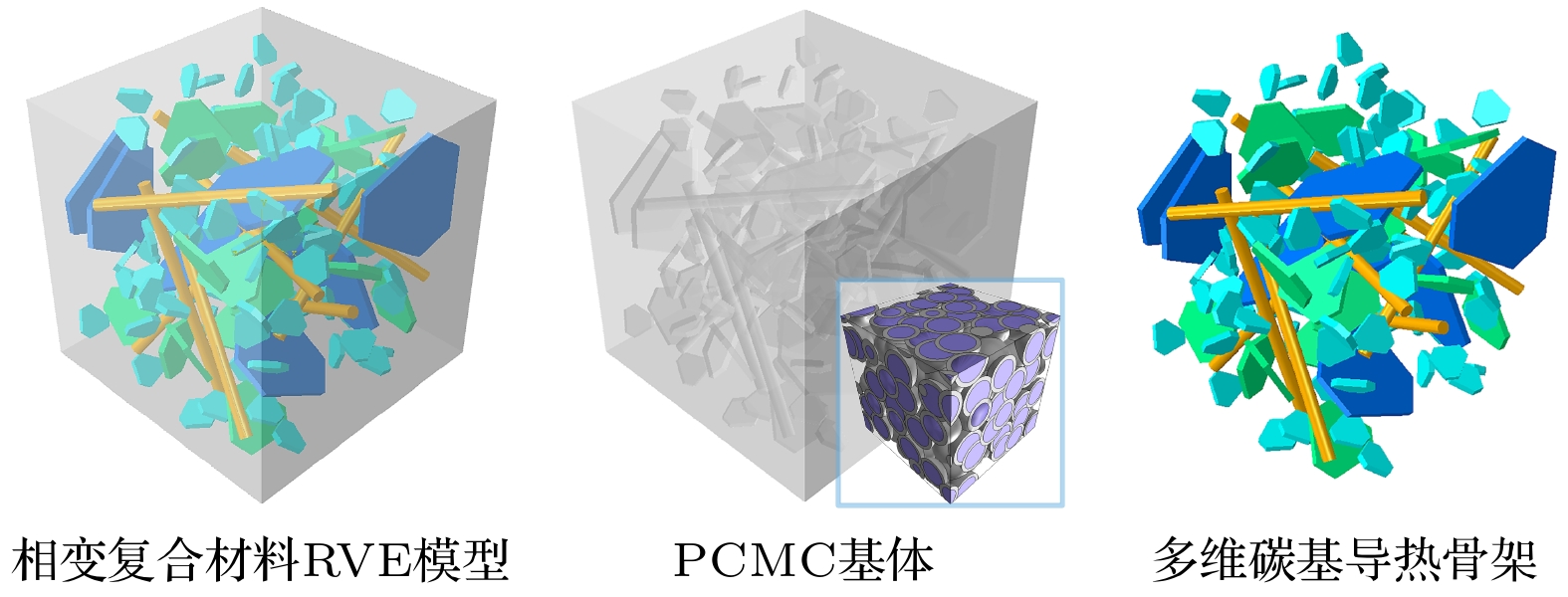

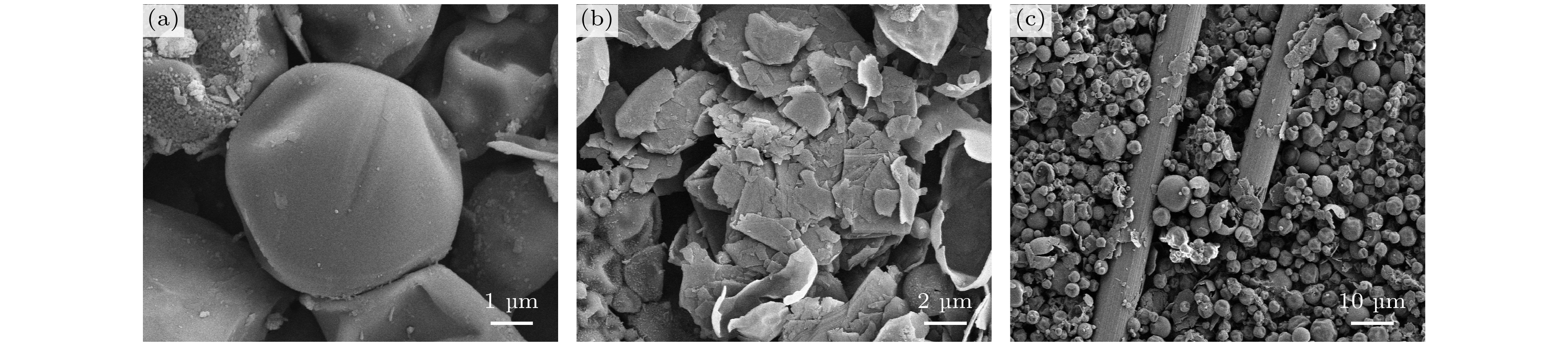

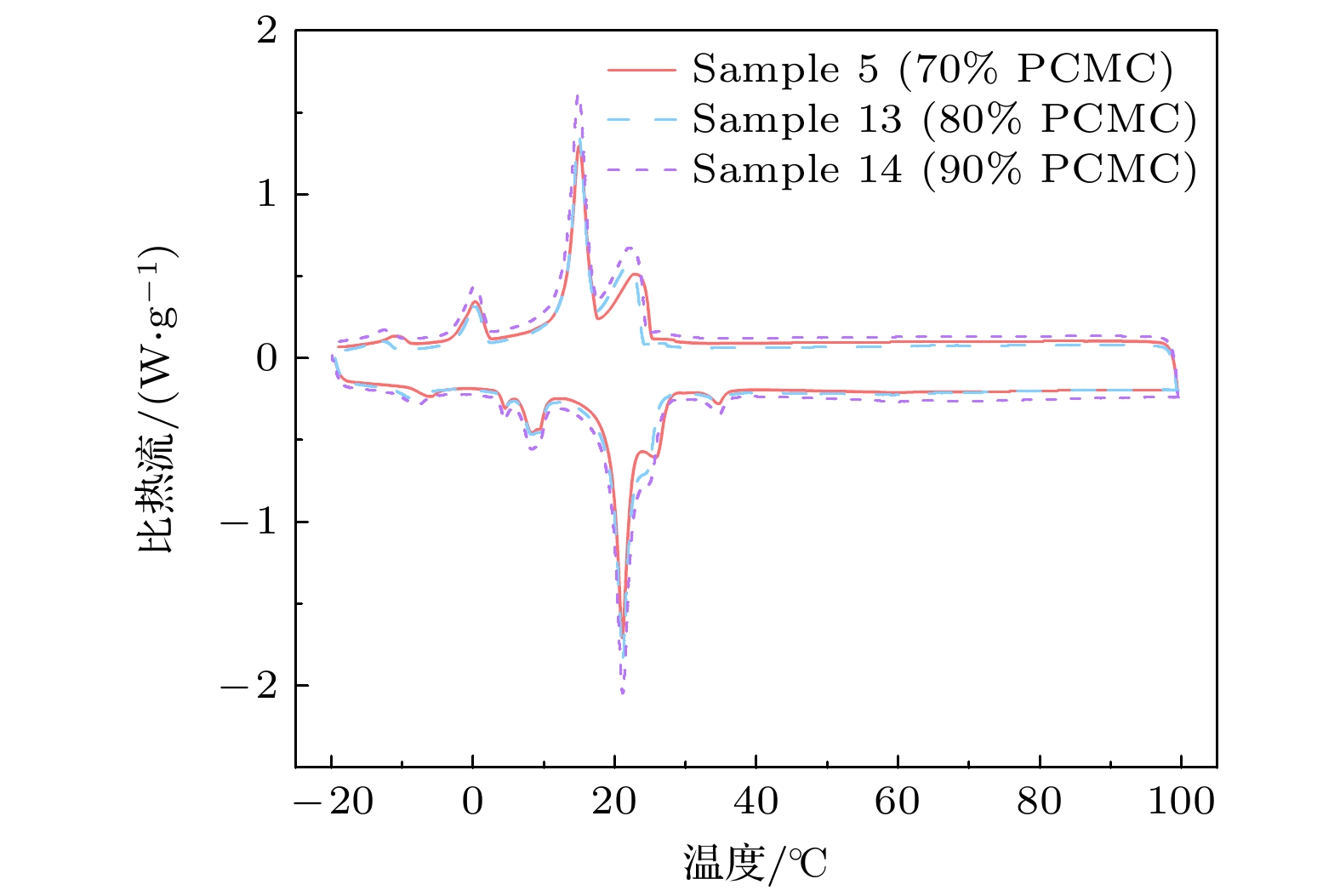

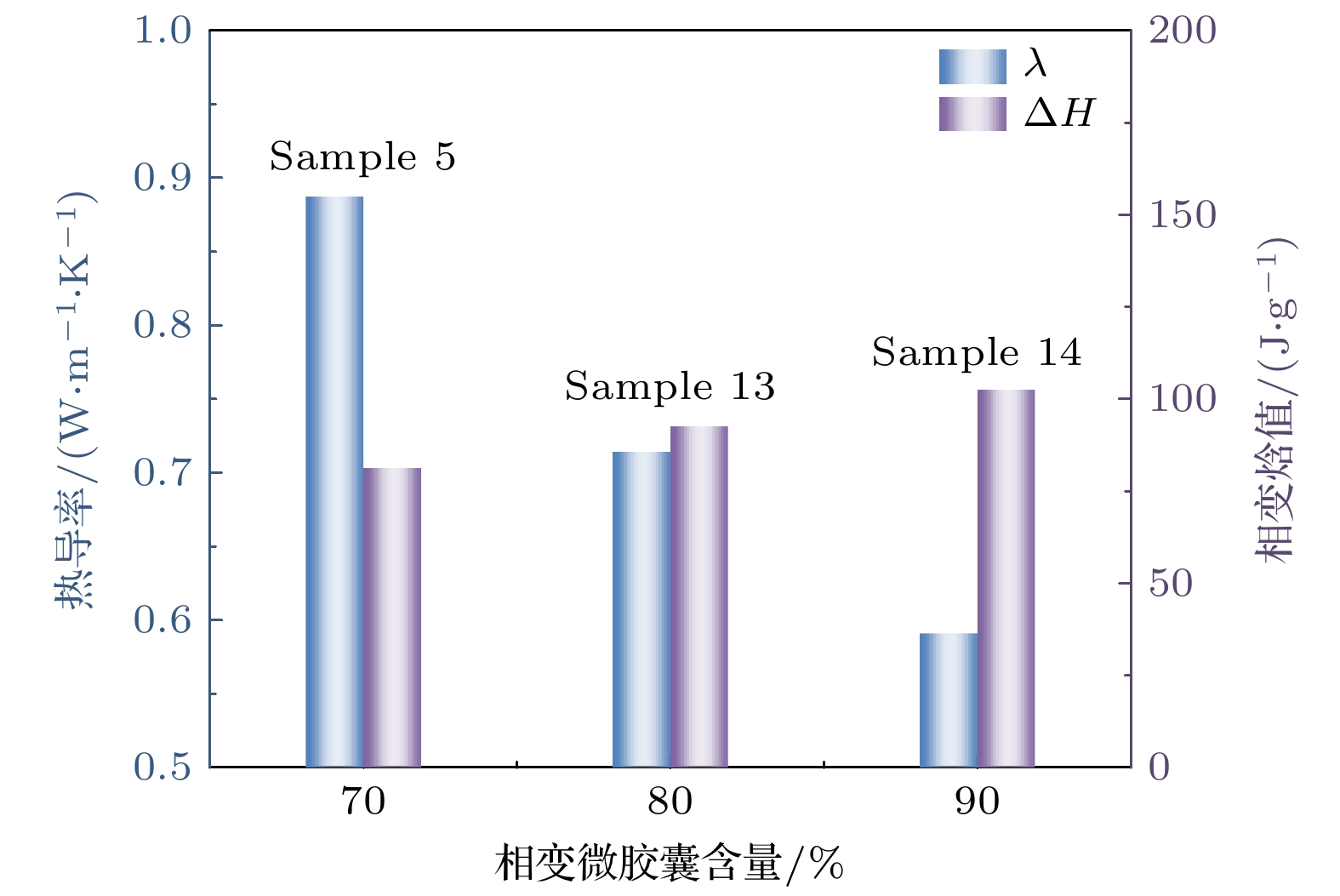

为满足航天器热管理材料对高导热和高储/释热性能的双重需求, 本文采用热压成型工艺制备了一种多维碳基导热增强微胶囊相变复合材料, 以解决传统相变材料热导率低和液态泄漏的问题. 基于实验测试和有限元数值模拟, 系统研究了不同组分的含量与配比对相变复合材料热性能的影响机理, 揭示了材料内部多维导热网络的形成机制. 结果表明, 采用多维导热材料协同掺杂与多尺度鳞片石墨复合填充策略, 构建了兼具连通性和致密性的多维碳基导热网络, 其产生的协同导热增强效应显著提升了微胶囊相变复合材料的热导率(1.021 W/(m·K)), 同时保持了高储热性能(81.540 J/g), 为航天器热管理材料的设计和应用提供了支撑.

In order to meet the requirements for both high thermal conductivity and large latent heat storage and release of thermal management materials for spacecraft, a multidimensional carbon-based, thermally enhanced microencapsulated phase change composite is prepared by using a hot-pressing technique in this work. This method solves the limitations of traditional phase change materials, which suffer from low thermal conductivity and a propensity for liquid leakage. The effects of different content values and ratios of microencapsulated phase change materials, flake graphite, and pitch-based carbon fibers on the composite’s thermal properties, specifically thermal conductivity and latent heat are systematically investigated by integrating experimental assessments with finite element numerical simulations. Furthermore, the mechanism for forming an internal multidimensional heat conduction network is elucidated. These results indicate that introducing multidimensional thermally conductive materials into the microencapsulated phase change system, can establish a continuous and dense multidimensional carbon-based conduction network through optimizing component composition and structure. Using the synergistic effects of these conductive materials and a multi-size flake graphite filling strategy, the overall thermal conductivity of the composite is significantly enhanced, reaching 1.021 W/(m·K), while maintaining a high latent heat of 81.540 J/g. These findings provide theoretical and practical guidance for optimizing and applying advanced thermal management materials to spacecraft. -

Keywords:

- spacecraft thermal management /

- microcapsule phase change composite materials /

- multidimensional carbon-based network /

- synergistic thermal enhancement

[1] 李心泽, 唐桂华, 汪子涵, 冯建朝, 张晓峰 2024 73 184401

Google Scholar

Google Scholar

Li X Z, Tang G H, Wang Z H, Feng J C, Zhang X F 2024 Acta Phys. Sin. 73 184401

Google Scholar

Google Scholar

[2] Wang Z H, He C B, Hu Y, Tang G H 2024 Sci. China Tech. Sci. 67 2387

Google Scholar

Google Scholar

[3] Drissi S, Ling T C, Mo K H 2019 Thermochim Acta 673 198

Google Scholar

Google Scholar

[4] Wu W F, Liu N, Cheng W L, Liu Y 2013 Energy Convers. Manag. 69 174

Google Scholar

Google Scholar

[5] Kong Q Q, Jia H, Xie L J, Tao Z C, Yang X, Liu D, Sun G H, Guo Q G, Lu C X, Chen C M 2021 Compos. Part A 145 106391

Google Scholar

Google Scholar

[6] Velez C, Ortiz de Zarate J M, Khayet M 2015 Int. J. Therm. Sci. 94 139

Google Scholar

Google Scholar

[7] Haddad Z, Buonomo B, Abu-Nada E, Manca O 2024 Renew. Sustain. Energy Rev. 205 114826

Google Scholar

Google Scholar

[8] Chang Z, Wang K, Wu X H, Lei G, Wang Q, Liu H, Wang Y L, Zhang Q 2022 J. Energy Storage 46 103840

Google Scholar

Google Scholar

[9] Xu R, Xia X M, Wang W, Yu D 2020 Colloids Surf. A 591 124519

Google Scholar

Google Scholar

[10] Wang X T, Chen H X, Kuang D L, Huan X, Zeng Z Y, Qi C, Han S J, Li G Y 2024 Compos. Sci. Technol. 257 110836

Google Scholar

Google Scholar

[11] Zhang D F, Cai T Y, Li Y J, Li Y S, He F F, Chen Z G, Zhu L Q, He C D, Yang W B 2022 ChemistrySelect 7 e202202930

Google Scholar

Google Scholar

[12] Wu X H, Gao M T, Wang K, Wang Q W, Cheng C X, Zhu Y J, Zhang F F, Zhang Q 2021 J. Energy Storage 36 102398

Google Scholar

Google Scholar

[13] Lu X T, Qian R D, Xu X Y, Liu M, Liu Y F, Zou D Q 2024 Nano Energy 124 109520

Google Scholar

Google Scholar

[14] 童叶龙, 陶则超, 李一凡, 刘占军, 江利锋, 殷亚州 2022 中国空间科学技术 42 131

Google Scholar

Google Scholar

Tong Y L, Tao Z C, Li Y F, Liu Z J, Jiang L F, Yin Y Z 2022 Chinese Space Sci. Technol. 42 131

Google Scholar

Google Scholar

[15] Dubey A K, Sun J, Choudhary T, Dash M, Rakshit D, Ansari M Z, Ramakrishna S, Liu Y, Nanda H S 2023 Renew. Sustain. Energy Rev. 182 113421

Google Scholar

Google Scholar

[16] Li S Y, Yan T, Pan W G 2024 Cell Rep. Phys. Sci. 5 102046

Google Scholar

Google Scholar

[17] Xia Y P, Zhang H Z, Huang P R, Huang C W, Xu F, Zou Y J, Chu H L, Yan E H, Sun L X 2019 Chem. Eng. J. 362 909

Google Scholar

Google Scholar

[18] Nomura T, Tabuchi K, Zhu C, Sheng N, Wang S, Akiyama T 2015 Appl. Energy 154 678

Google Scholar

Google Scholar

[19] Cheng P, Chen X, Gao H Y, Zhang X W, Tang Z D, Li A, Wang G 2021 Nano Energy 85 105948

Google Scholar

Google Scholar

[20] Yang M S, Li X Y, Chen W Q 2024 Appl. Energy 371 123726

Google Scholar

Google Scholar

[21] Prieto R, Molina J M, Narciso J, Louis E 2011 Compos. Part A 42 1970

Google Scholar

Google Scholar

[22] Zhang H M, Chao M J, Zhang H S, Tang A, Ren B, He X B 2014 Appl. Therm. Eng. 73 739

Google Scholar

Google Scholar

[23] Tian W L, Qi L H, Chao X J, Liang J H, Fu M W 2019 Compos. Part B 162 1

Google Scholar

Google Scholar

[24] Xu J Z, Gao B Z, Du H D, Kang F Y 2016 Int. J. Therm. Sci. 104 348

Google Scholar

Google Scholar

[25] Xu J Z, Gao B Z, Kang F Y 2016 Appl. Therm. Eng. 102 972

Google Scholar

Google Scholar

[26] Zha J W, Wang F, Wan B Q 2025 Prog. Mater. Sci. 148 101362

Google Scholar

Google Scholar

[27] Yan X W, Xie Y, Fang Q Z, Hu Y, Xin Q Q 2024 Int. Commun. Heat Mass Transf. 159 108018

Google Scholar

Google Scholar

[28] Cernuschi F, Kulczyk-Malecka J, Zhang X, Nozahic F, Estournès C, Sloof W G 2023 J. Eur. Ceram. Soc. 43 6296

Google Scholar

Google Scholar

-

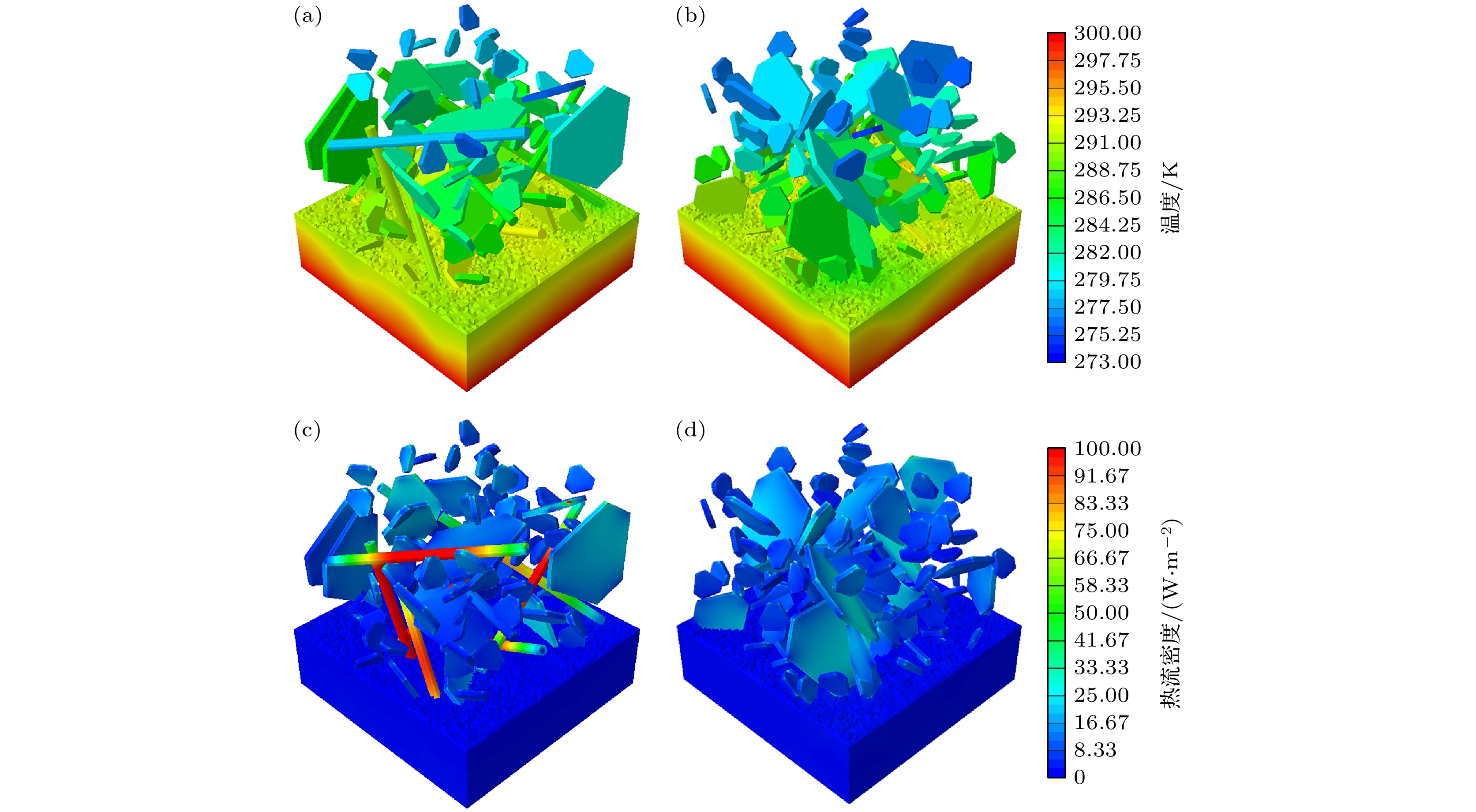

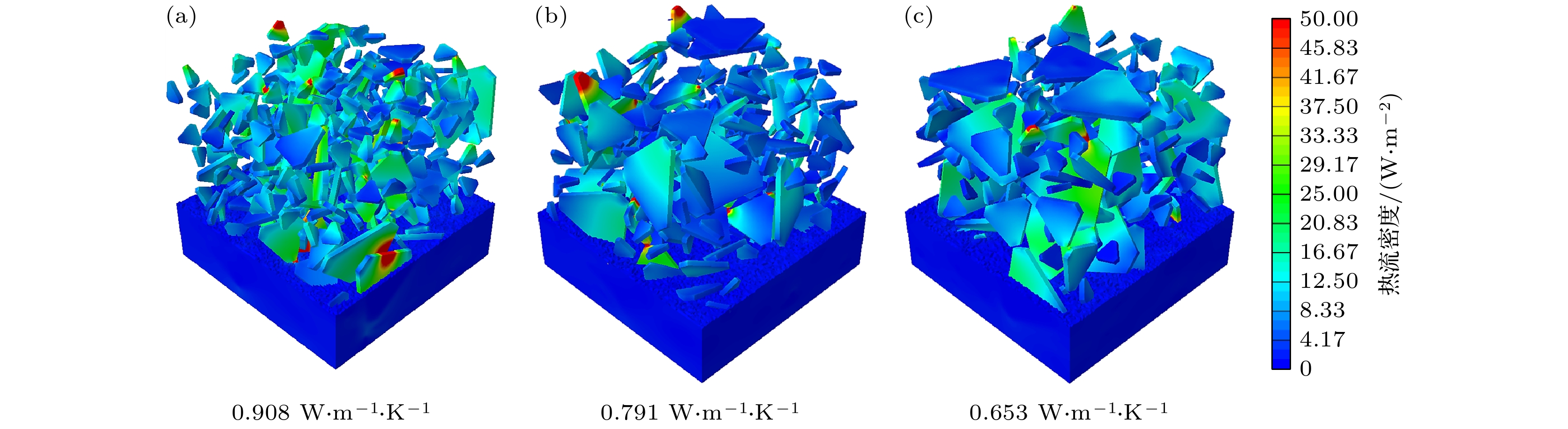

图 6 多维碳基导热增强微胶囊相变复合材料的热传导有限元分析 (a)含PCF的RVE温度分布; (b)未含PCF的RVE温度分布; (c)含PCF的RVE热流密度分布; (d)未含PCF的RVE热流密度分布

Fig. 6. Finite element analysis of thermal conductivity for multidimensional carbon-based thermally enhanced microcapsule phase change composites: (a) Temperature distribution of RVE with PCF; (b) temperature distribution of RVE without PCF; (c) heat flux distribution of RVE with PCF; (d) heat flux distribution of RVE without PCF.

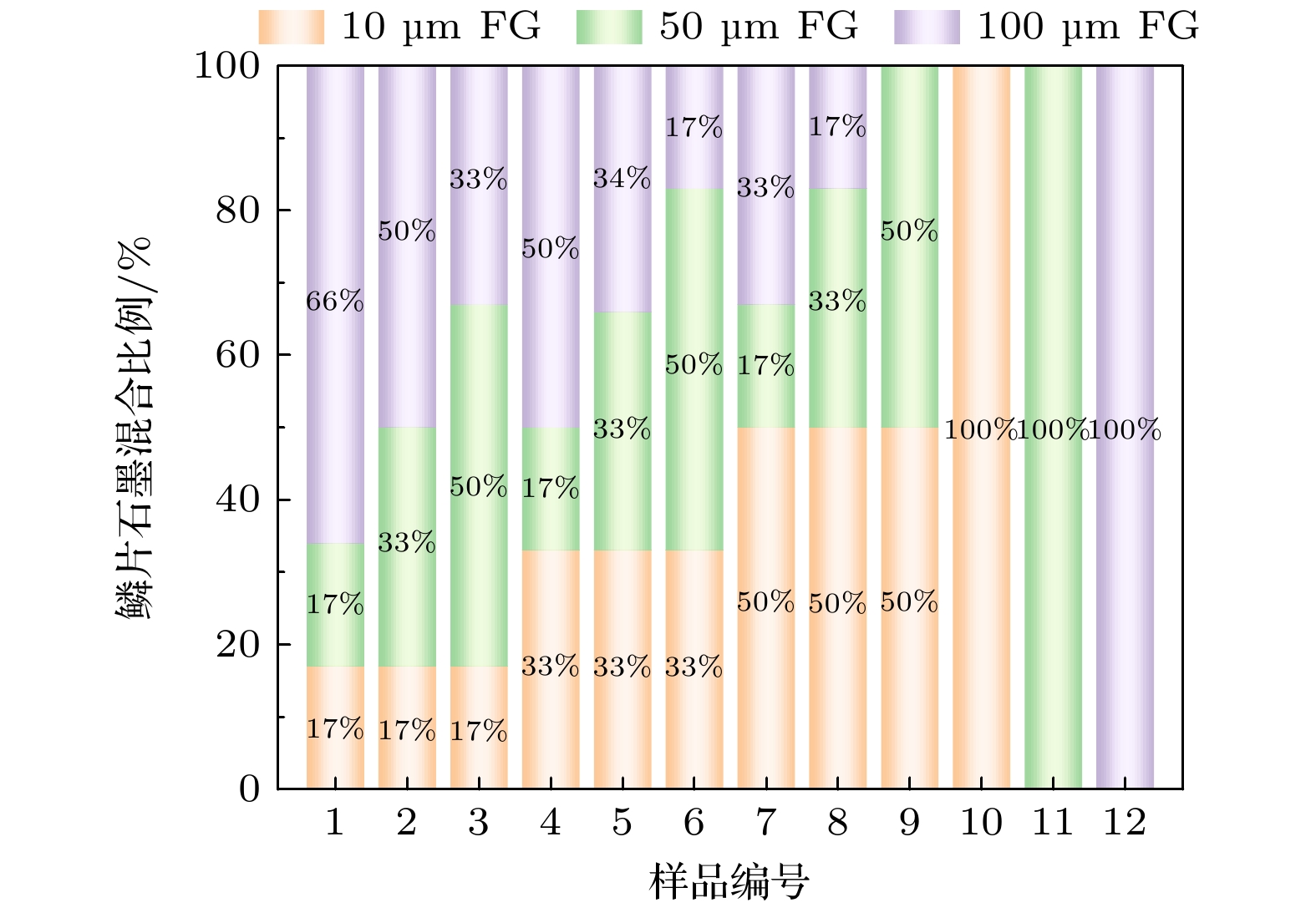

表 1 相变复合材料各组分材料的质量分数

Table 1. Mass fractions of each component in the phase change composites.

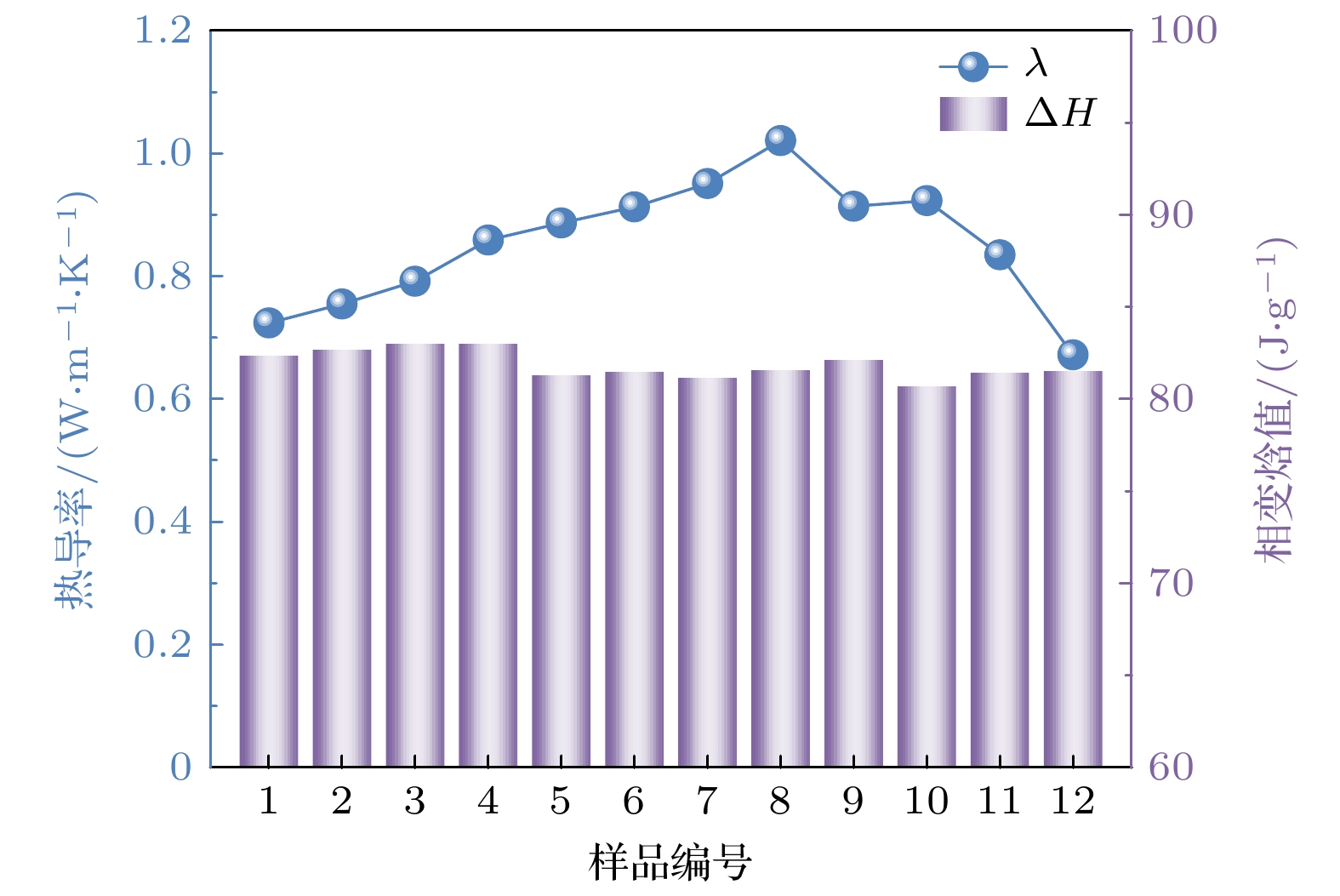

Sample 10 μm FG/% 50 μm FG/% 100 μm FG/% PCMC/% PCF/% 1 4.25 4.25 16.50 70.00 5.00 2 4.25 8.25 12.50 70.00 5.00 3 4.25 12.50 8.25 70.00 5.00 4 8.25 4.25 12.50 70.00 5.00 5 8.25 8.25 8.50 70.00 5.00 6 8.25 12.50 4.25 70.00 5.00 7 12.50 4.25 8.25 70.00 5.00 8 12.50 8.25 4.25 70.00 5.00 9 12.50 12.50 0.00 70.00 5.00 10 25.00 0.00 0.00 70.00 5.00 11 0.00 25.00 0.00 70.00 5.00 12 0.00 0.00 25.00 70.00 5.00 13 4.95 4.95 5.10 80.00 5.00 14 1.65 1.65 1.70 90.00 5.00 15 9.90 9.90 10.20 70.00 0.00 表 2 含PCF与未含PCF相变复合材料的热性能比较

Table 2. Comparison of thermal performance between PCF-containing and PCF-free phase change composites.

Sample PCF/% λ/(W·m–1·K–1) ΔH/(J·g–1) 5 5 0.887 81.282 15 0 0.350 80.241 -

[1] 李心泽, 唐桂华, 汪子涵, 冯建朝, 张晓峰 2024 73 184401

Google Scholar

Google Scholar

Li X Z, Tang G H, Wang Z H, Feng J C, Zhang X F 2024 Acta Phys. Sin. 73 184401

Google Scholar

Google Scholar

[2] Wang Z H, He C B, Hu Y, Tang G H 2024 Sci. China Tech. Sci. 67 2387

Google Scholar

Google Scholar

[3] Drissi S, Ling T C, Mo K H 2019 Thermochim Acta 673 198

Google Scholar

Google Scholar

[4] Wu W F, Liu N, Cheng W L, Liu Y 2013 Energy Convers. Manag. 69 174

Google Scholar

Google Scholar

[5] Kong Q Q, Jia H, Xie L J, Tao Z C, Yang X, Liu D, Sun G H, Guo Q G, Lu C X, Chen C M 2021 Compos. Part A 145 106391

Google Scholar

Google Scholar

[6] Velez C, Ortiz de Zarate J M, Khayet M 2015 Int. J. Therm. Sci. 94 139

Google Scholar

Google Scholar

[7] Haddad Z, Buonomo B, Abu-Nada E, Manca O 2024 Renew. Sustain. Energy Rev. 205 114826

Google Scholar

Google Scholar

[8] Chang Z, Wang K, Wu X H, Lei G, Wang Q, Liu H, Wang Y L, Zhang Q 2022 J. Energy Storage 46 103840

Google Scholar

Google Scholar

[9] Xu R, Xia X M, Wang W, Yu D 2020 Colloids Surf. A 591 124519

Google Scholar

Google Scholar

[10] Wang X T, Chen H X, Kuang D L, Huan X, Zeng Z Y, Qi C, Han S J, Li G Y 2024 Compos. Sci. Technol. 257 110836

Google Scholar

Google Scholar

[11] Zhang D F, Cai T Y, Li Y J, Li Y S, He F F, Chen Z G, Zhu L Q, He C D, Yang W B 2022 ChemistrySelect 7 e202202930

Google Scholar

Google Scholar

[12] Wu X H, Gao M T, Wang K, Wang Q W, Cheng C X, Zhu Y J, Zhang F F, Zhang Q 2021 J. Energy Storage 36 102398

Google Scholar

Google Scholar

[13] Lu X T, Qian R D, Xu X Y, Liu M, Liu Y F, Zou D Q 2024 Nano Energy 124 109520

Google Scholar

Google Scholar

[14] 童叶龙, 陶则超, 李一凡, 刘占军, 江利锋, 殷亚州 2022 中国空间科学技术 42 131

Google Scholar

Google Scholar

Tong Y L, Tao Z C, Li Y F, Liu Z J, Jiang L F, Yin Y Z 2022 Chinese Space Sci. Technol. 42 131

Google Scholar

Google Scholar

[15] Dubey A K, Sun J, Choudhary T, Dash M, Rakshit D, Ansari M Z, Ramakrishna S, Liu Y, Nanda H S 2023 Renew. Sustain. Energy Rev. 182 113421

Google Scholar

Google Scholar

[16] Li S Y, Yan T, Pan W G 2024 Cell Rep. Phys. Sci. 5 102046

Google Scholar

Google Scholar

[17] Xia Y P, Zhang H Z, Huang P R, Huang C W, Xu F, Zou Y J, Chu H L, Yan E H, Sun L X 2019 Chem. Eng. J. 362 909

Google Scholar

Google Scholar

[18] Nomura T, Tabuchi K, Zhu C, Sheng N, Wang S, Akiyama T 2015 Appl. Energy 154 678

Google Scholar

Google Scholar

[19] Cheng P, Chen X, Gao H Y, Zhang X W, Tang Z D, Li A, Wang G 2021 Nano Energy 85 105948

Google Scholar

Google Scholar

[20] Yang M S, Li X Y, Chen W Q 2024 Appl. Energy 371 123726

Google Scholar

Google Scholar

[21] Prieto R, Molina J M, Narciso J, Louis E 2011 Compos. Part A 42 1970

Google Scholar

Google Scholar

[22] Zhang H M, Chao M J, Zhang H S, Tang A, Ren B, He X B 2014 Appl. Therm. Eng. 73 739

Google Scholar

Google Scholar

[23] Tian W L, Qi L H, Chao X J, Liang J H, Fu M W 2019 Compos. Part B 162 1

Google Scholar

Google Scholar

[24] Xu J Z, Gao B Z, Du H D, Kang F Y 2016 Int. J. Therm. Sci. 104 348

Google Scholar

Google Scholar

[25] Xu J Z, Gao B Z, Kang F Y 2016 Appl. Therm. Eng. 102 972

Google Scholar

Google Scholar

[26] Zha J W, Wang F, Wan B Q 2025 Prog. Mater. Sci. 148 101362

Google Scholar

Google Scholar

[27] Yan X W, Xie Y, Fang Q Z, Hu Y, Xin Q Q 2024 Int. Commun. Heat Mass Transf. 159 108018

Google Scholar

Google Scholar

[28] Cernuschi F, Kulczyk-Malecka J, Zhang X, Nozahic F, Estournès C, Sloof W G 2023 J. Eur. Ceram. Soc. 43 6296

Google Scholar

Google Scholar

计量

- 文章访问数: 1203

- PDF下载量: 44

- 被引次数: 0

下载:

下载: