-

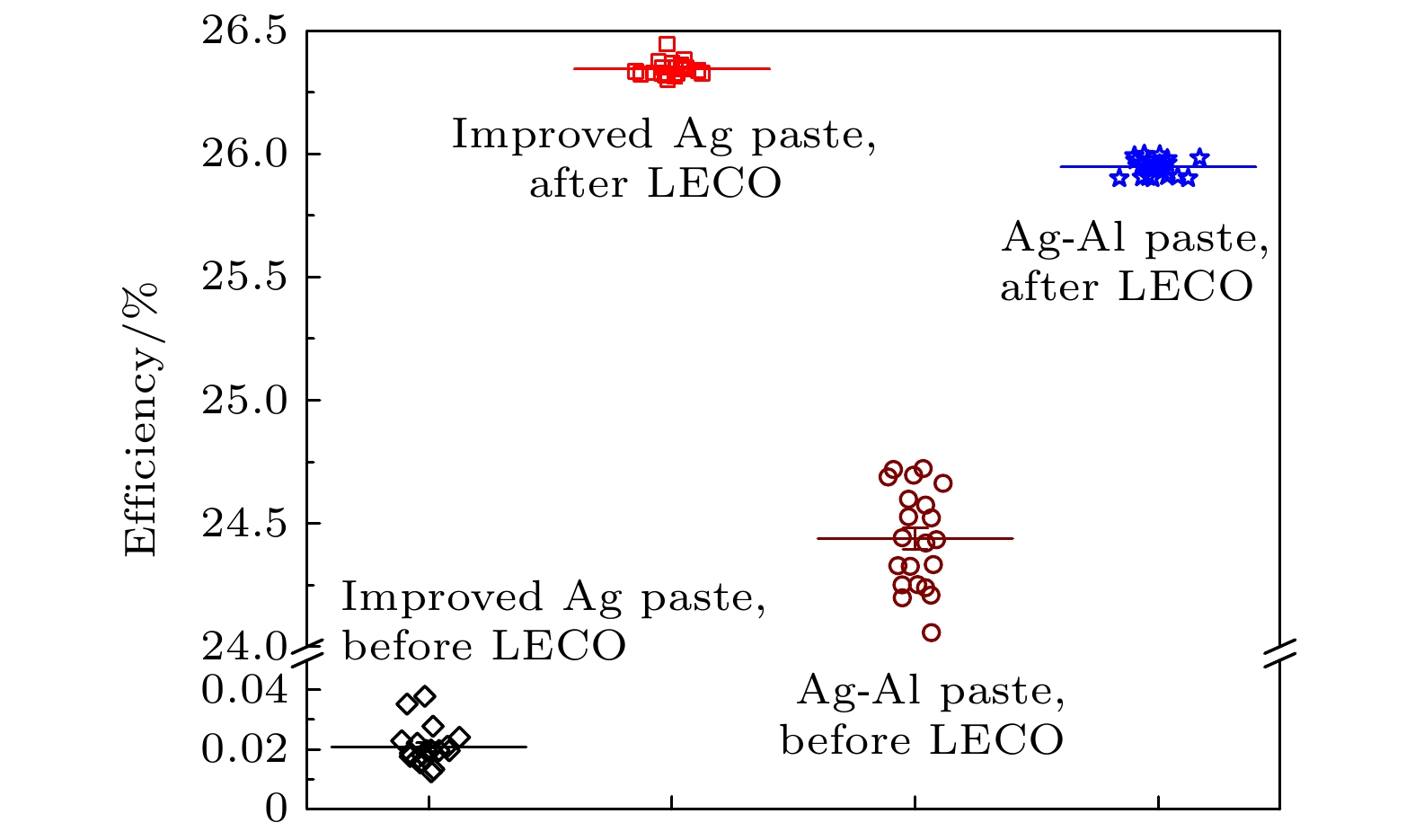

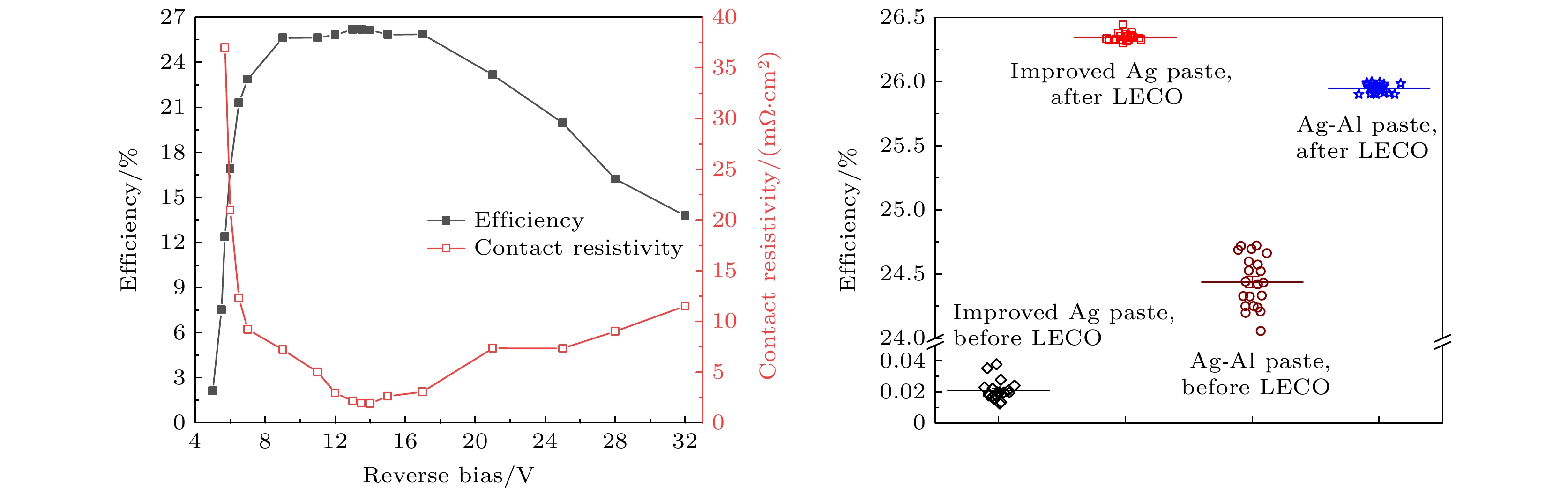

激光诱导烧结又称为激光增强接触优化(LECO), 可以显著降低TOPCon太阳电池金属电极与硅之间的接触电阻, 提高电池效率. 首先, 本文研究了反向偏压、激光强度等LECO工艺参数对TOPCon电池性能的影响, 并对其影响机理进行了详细的讨论与分析. 其次, 研究了二次高温烧结与二次LECO工艺对电池性能的影响. 当二次烧结温度从280 ℃升高至680 ℃时, 电池效率从26.35%急剧下降至1.3%. 但是, 对经过二次高温烧结的电池片再进行二次LECO处理, 电池效率可以恢复到二次高温烧结前的水平. 采用改良后的纯银浆料制备的TOPCon电池, 在没有经过LECO处理之前, 由于银电极与硅没有形成有效的金属半导体接触, 电池平均效率只有0.02%. 经过LECO处理后, 使用纯银浆料的电池效率提升至26.35%, 比使用传统银铝浆料的参考电池提高了0.41%. 最后提出了LECO工艺诱导银-硅接触形成的物理模型, 对二次高温烧结及二次LECO处理如何影响电池性能给出了合理的解释, 这对于进一步理解和优化LECO工艺在TOPCon太阳电池中的应用具有重要意义.

-

关键词:

- 激光诱导烧结 /

- TOPCon太阳电池 /

- 接触形成 /

- 二次高温烧结

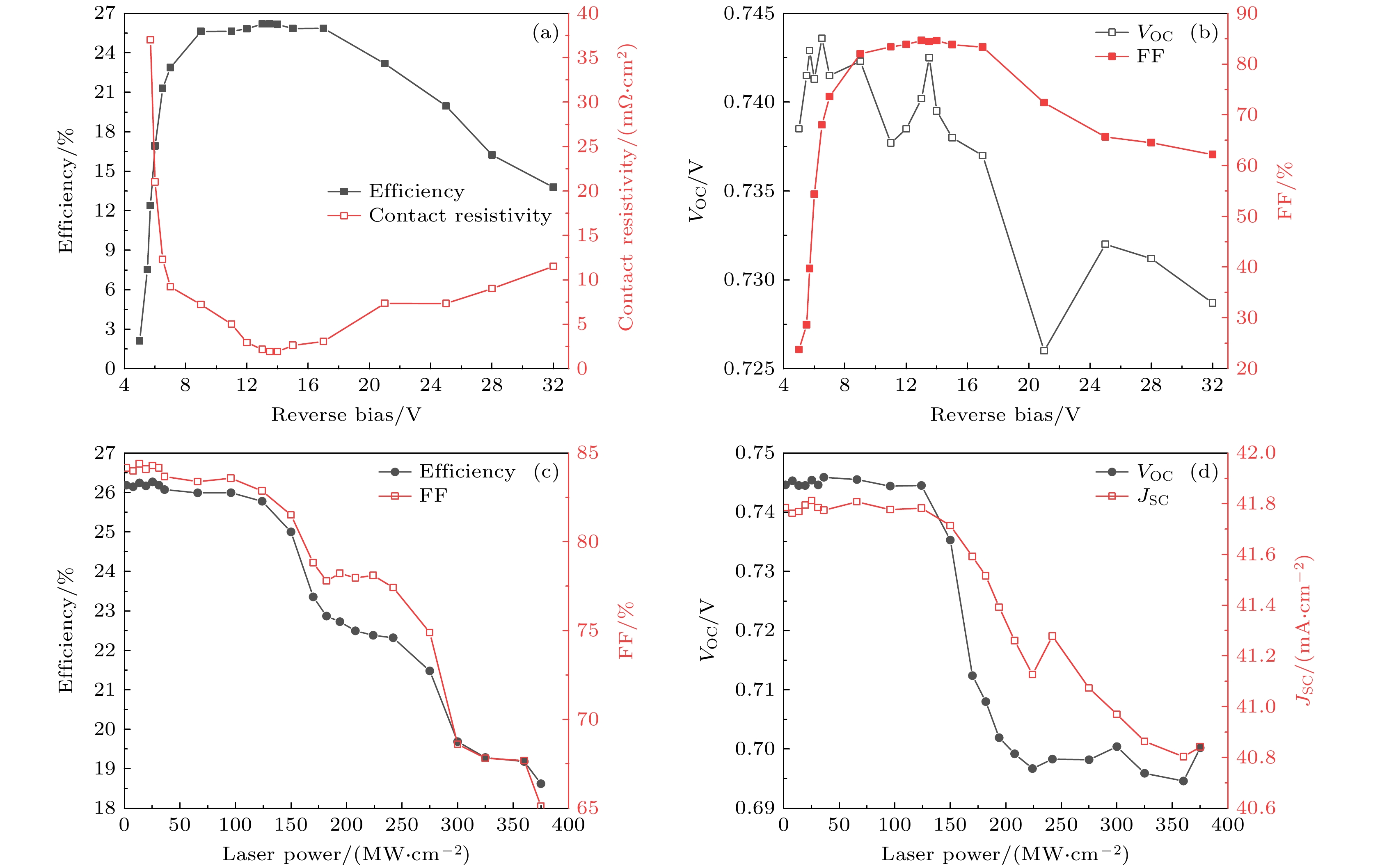

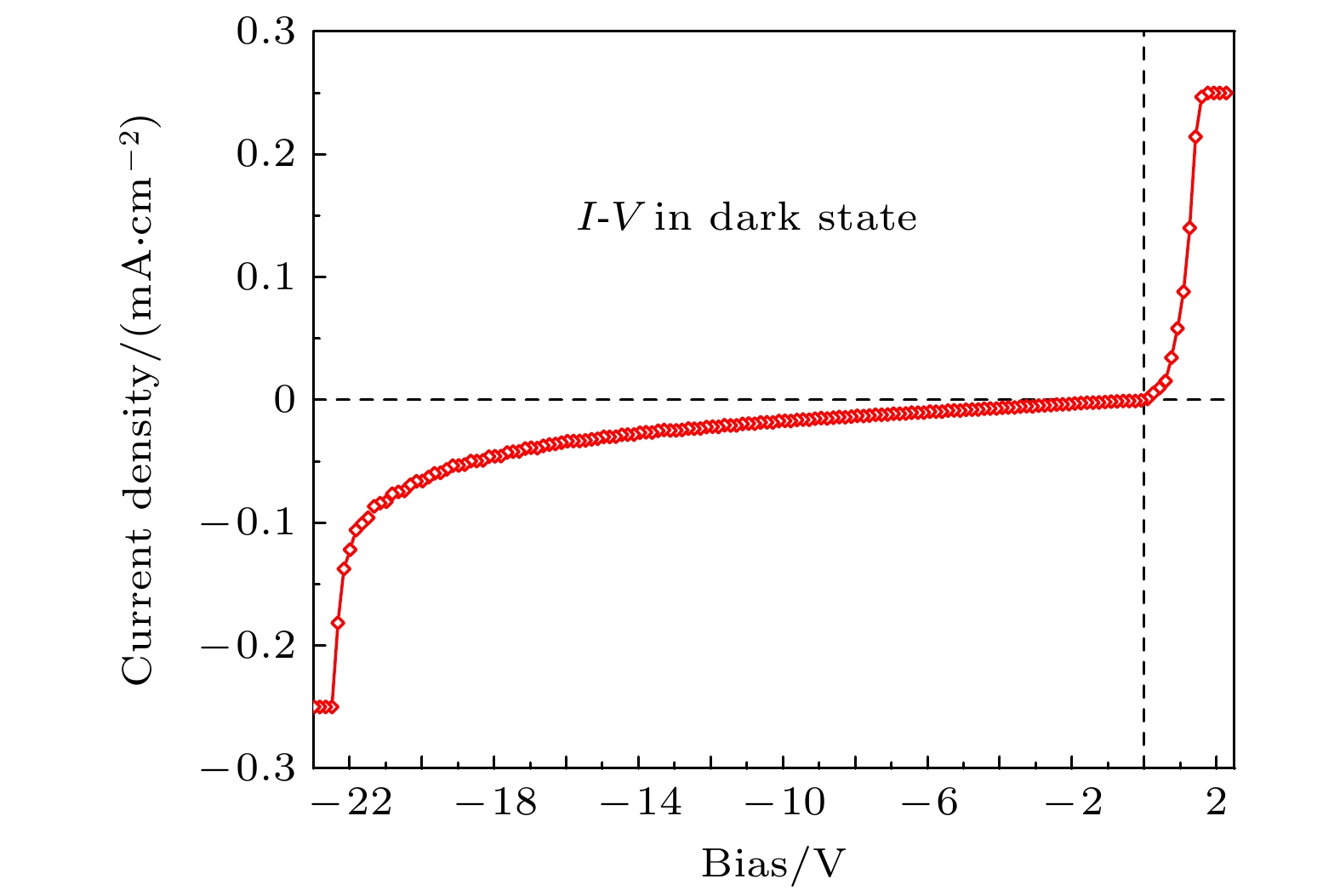

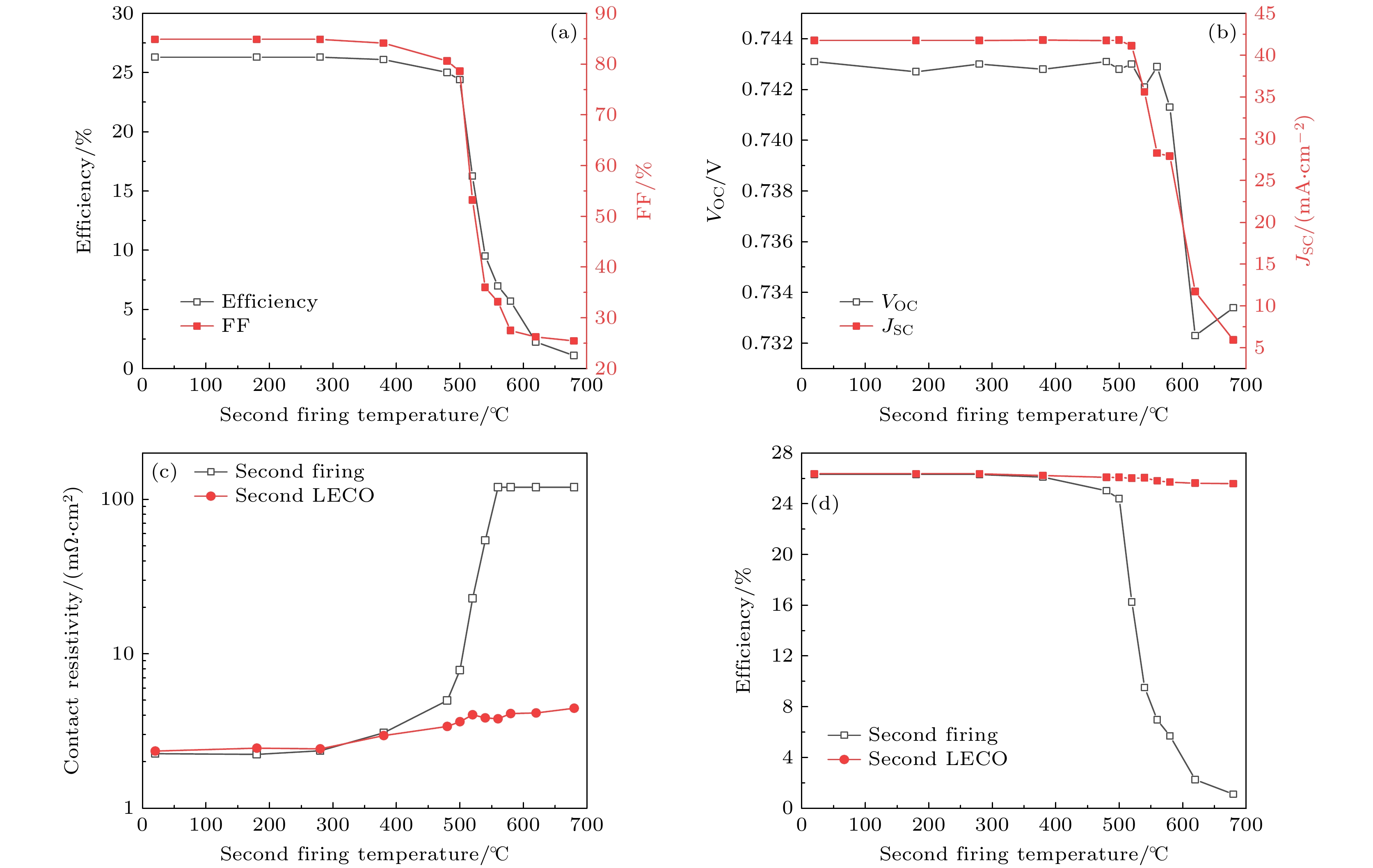

Laser induced sintering, also known as laser enhanced contact optimization (LECO), can significantly reduce the contact resistance between metal electrodes and silicon in TOPCon solar cells, thereby improving its efficiency. In this work, the effects of LECO process parameters such as reverse bias and laser intensity on the performance of TOPCon solar cells are investigated and their influencing mechanisms are analyzed in detail. In the LECO process, as the reverse bias voltage increases, the efficiency of the solar cell first increases and then decreases, while the contact resistivity first decreases and then increases. When the reverse bias voltage is high, the solar cell may experience reverse breakdown. Once the solar cell experiences reverse breakdown, both the illuminated and non-illuminated areas become conducting. Due to the current diversion effect, the local conducting current density in the illuminated area is much lower than the current density without reverse breakdown of the solar cell, Therefore, the Joule heating caused by this is also much smaller, and the contact resistance between the metal and silicon increases, resulting in a decrease in the efficiency of the solar cell. Secondly, the influence of secondary high-temperature sintering and secondary LECO on the performance of TOPCon is studied. When the secondary sintering temperature increases from 280 ℃ to 680 ℃, the efficiency of TOPCon sharply decreases from 26.35% to 1.3%. However, by subjecting the solar cells that have undergone secondary high-temperature sintering to secondary LECO treatment, the efficiency can be restored to the level before the secondary high-temperature sintering. Thirdly, TOPCon solar cells prepared using improved pure silver paste does not form effective metal-semiconductor contact between the silver electrode and silicon before LECO treatment, resulting in an average efficiency of only 0.02%. However, after LECO treatment, the efficiency of solar cells using pure silver paste increases to 26.35%, which is 0.41% higher than the reference solar cells using traditional silver aluminum paste. Fourthly, a physical model of LECO induced silver-silicon contact formation is proposed, providing a reasonable explanation for how secondary high-temperature sintering and secondary LECO treatment affect the performance of TOPCon. This is of great significance for further understanding and optimizing the application of LECO technology in TOPCon solar cells. -

Keywords:

- laser-induced sintering /

- TOPCon solar cell /

- contact formation /

- secondary high-temperature sintering

[1] Feldmann F, Bivour M, Reichel C, Hermle M, Glunz S W 2014 Sol. Energy Mater. Sol. Cells 120 270

Google Scholar

Google Scholar

[2] Richter A, Müller R, Benick J 2021 Nat. Energy 6 429

Google Scholar

Google Scholar

[3] Anderson C L, Nemeth W, Guthrey H 2023 Adv. Energy Mater. 13 2203579

Google Scholar

Google Scholar

[4] Römer U, Peibst R, Ohrdes T, Lim B, Krügener J, Bugiel E, Wietler T, Brendel R 2014 Sol. Energy Mater. Sol. Cells 131 85

Google Scholar

Google Scholar

[5] Haase F, Hollemann C, Schäfer S, Merkle A, Rienäcker M, Krügener J, Brendel R, Peibst R 2018 Sol. Energy Mater. Sol. Cells 186 184

Google Scholar

Google Scholar

[6] Hermle M, Feldmann F, Bivour M, Goldschmidt J C, Glunz S W 2020 Appl. Phys. Rev. 7 021305

Google Scholar

Google Scholar

[7] 肖友鹏, 高超, 王涛, 周浪 2017 66 66 158801

Google Scholar

Google Scholar

Xiao Y P, Gao C, Wang T, Zhou L 2017 Acta Phys. Sin. 66 2017 Acta Phys. Sin. 66 158801

Google Scholar

Google Scholar

[8] 任程超, 周佳凯, 刘璋, 赵颖, 张晓丹, 侯国付 2021 70 178401

Google Scholar

Google Scholar

Ren C C, Zhou J K, Zhang B Y, Liu Z, Zhao Y, Zhang X D, Hou G F 2021 Acta Phys. Sin. 70 178401

Google Scholar

Google Scholar

[9] Yan D, Cuevas A, Michel J, Zhang C, Wan Y M, Zhang X Y, Bullock J 2021 Joule 5 811

Google Scholar

Google Scholar

[10] Glunz S W, Steinhauser B, Polzin J, Luderer C, Grübel B, Niewelt T, Okasha A, Bories M, Nagel H, Krieg K, Feldmann F, Richter A, Bivour M, Hermle M 2021 Prog. Photovolt. Res. Appl 31 341

Google Scholar

Google Scholar

[11] Richter A, Benick J, Feldmann F, Fell A, Hermle M, Glunz S W 2017 Sol. Energy Mater. Sol. Cells 173 96

Google Scholar

Google Scholar

[12] Steinkemper H, Hermle M, Glunz S W 2014 Sol. Energy Mater. Sol. Cells 131 46

Google Scholar

Google Scholar

[13] Schmidt J, Peibst R, Brendel R. 2018 Sol. Energy Mater. Sol. Cells 187 39

Google Scholar

Google Scholar

[14] Zhang X Y, Dumbrell R, Li W Q, Xu M Y, Yan D, Jin J S, Wang Z, Zheng P T, Liu C M, Yang J 2023 Prog. Photovolt.: Res. Appl. 31 369

Google Scholar

Google Scholar

[15] VDMA 2023 International Technology Roadmap for Photovoltaic p60

[16] https://ir.jinkosolar.com/news-releases/news-release-details/jinkosolars-high-efficiency-n-type-monocrystalline-silicon-3 [2023-10-23]

[17] Wang Q Q, Guo K Y, Yuan L, Li L Z, Peng H, Li B R, Wang A L, Zhang L Z, Wu W P, Ding J N, Yuan N Y 2023 Sol. Energy Mater. Sol. Cells 253 112231

Google Scholar

Google Scholar

[18] Allen T G, Bullock J, Yang X, Javey A, Wolf S D 2019 Nat. Energy 4 914

Google Scholar

Google Scholar

[19] Cuevas A, Wan Y M, Yan D, Samundsett C, Allen T, Zhang X, Cui J, Bullock J 2018 Sol. Energy Mater. Sol. Cells 184 38

Google Scholar

Google Scholar

[20] Riegel S, Mutter F, Lauermann T, Terheiden B, Hahn G 2012 Energy Proc. 21 14

Google Scholar

Google Scholar

[21] Fritz S, Konig M, Riegel S, Herguth A, Horteis M, Hahn G 2015 IEEE J. Photovoltaics 5 145

Google Scholar

Google Scholar

[22] Kumar P, Pfeffer M, Willsch B, Eibl O, Koduvelikulathu L J, Mihailetchi L J, Kopecek R 2016 Sol. Energy Mater. Sol. Cells 157 200

Google Scholar

Google Scholar

[23] Urban T, Heimann M, Schmid A, Mette A, Heitmann J 2015 Energy Proc. 77 420

Google Scholar

Google Scholar

[24] Aoyama T, Aoki M, Sumita I, Yoshino Y, Ogura A 2016 Energy Proc. 98 106

Google Scholar

Google Scholar

[25] Fritz S, Emre E, Engelhardt J, Ebert S, Nowak N, Booth J, Hahn G 2016 Energy Proc. 92 925

Google Scholar

Google Scholar

[26] Mack S, Schube J, Fellmeth T, Feldmann F, Lenes M, Luchies J 2017 Phys. Rapid Res. Lett. 11 1700334

Google Scholar

Google Scholar

[27] Kiefer F, Krugener J, Heinemeyer F, Osten H J, Brendel R, Peibst R 2016 IEEE J. Photovoltaics 6 1175

Google Scholar

Google Scholar

[28] Liang L, Li Z G, Cheng L K, Takeda N, Carroll A F 2015 J. Appl. Phys. 117 215102

Google Scholar

Google Scholar

[29] Fritz S, Engelhardt J, Ebert S, Hahn G 2016 Phys. Status Solidi RRL 10 305

Google Scholar

Google Scholar

[30] Mayberry R, Myers K, Chandrasekaran V, Henning A, Zhao H, Hofmüller E 2019 36th European Photovoltaic Solar Energy Conference and Exhibition Marseille, France, September 9–13, 2019

[31] Krassowski E, Großer S, Turek M, Henning A, Zhao H 2021 AIP Conf. Proc. 2367 020005

Google Scholar

Google Scholar

[32] Fellmeth T, Höffler H, Mack S, Krassowski E, Krieg K, Kafle B, Greulich J 2022 Prog. Photovolt. Res. Appl. 30 1393

Google Scholar

Google Scholar

[33] Fan Y, Zou S, Zeng Y L, Dai L F, Wang Z P, Lu Z, Sun H, Zhou X S, Liao B C, Su X D 2024 Solar RRL 8 2400268

Google Scholar

Google Scholar

[34] Dasgupta S, Ok Y W, Upadhyaya V D, Choi W J, Huang Y Y, Duttagupta Y, Rohatgi A 2022 IEEE J. Photovoltaics 12 1282

Google Scholar

Google Scholar

[35] Kuruganti V V, Isabella O, Mihailetchi V D 2024 Phys. Status Solidi A 221 2300820

Google Scholar

Google Scholar

[36] Höffler H, Fellmeth T, Maischner F, Greulich J, Krassowski E, Henning A 2022 AIP Conf. Proc. 2487 110001

Google Scholar

Google Scholar

[37] Großer S, Krassowski E, Swatek S, Zhao H, Hagendorf C 2022 IEEE J. Photovolt. 12 26

Google Scholar

Google Scholar

[38] Höffler H, Simon F, Krassowski E, Greulich J 2022 AIP Conference Proceedings 2826 040002

Google Scholar

Google Scholar

-

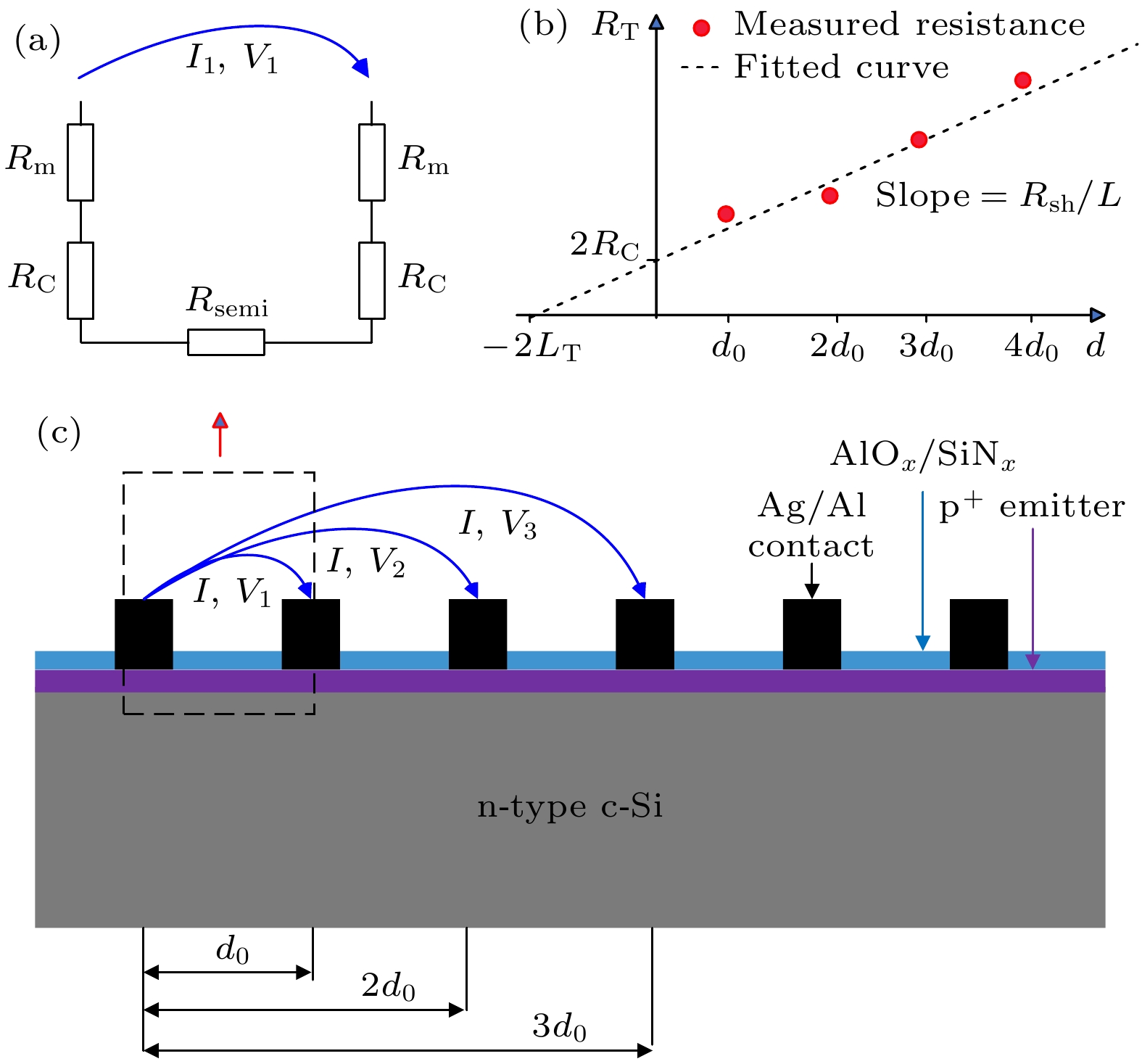

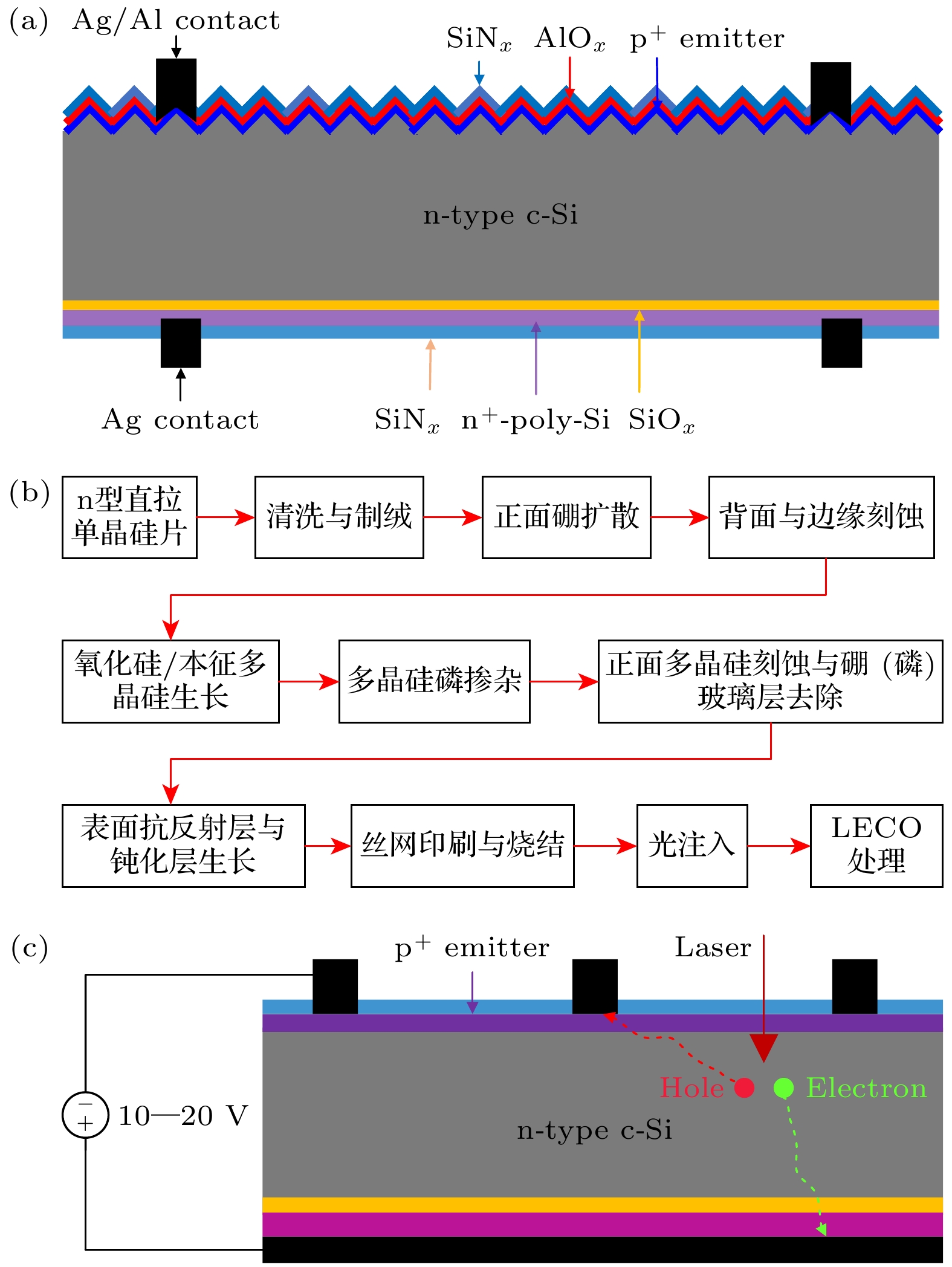

图 1 (a) TOPCon电池的结构示意图; (b) TOPCon电池制备工艺流程示意图; (c) LECO工艺原理示意图, 激光在电池片局部诱导产生的高密度光生载流子(电子和空穴), 在反向偏压下向电池金属电极接触点迁移, 并在接触界面处产生大的电流密度

Fig. 1. (a) Schematic diagram of TOPCon solar cells; (b) schematic diagram of preparation process for TOPCon solar cells; (c) schematic diagram of LECO process principle. The high-density photogenerated carriers (electrons and holes) induced by laser in the local area of the solar cells migrate towards the contact point of the metal electrode under reverse bias, and generate a large current density at the contact interface.

图 3 (a) 反向偏压对电池效率与接触电阻率的影响; (b) 反向偏压对开路电压与填充因子的影响; (c) 激光光强对电池效率与填充因子的影响; (d) 激光光强对开路电压与短路电流的影响

Fig. 3. (a) Influence of reverse bias on cell efficiency and contact resistivity; (b) influence of reverse bias on open circuit voltage and fill factor; (c) influence of laser intensity on efficiency and fill factor; (d) influence of laser intensity open-circuit voltage and short-circuit current.

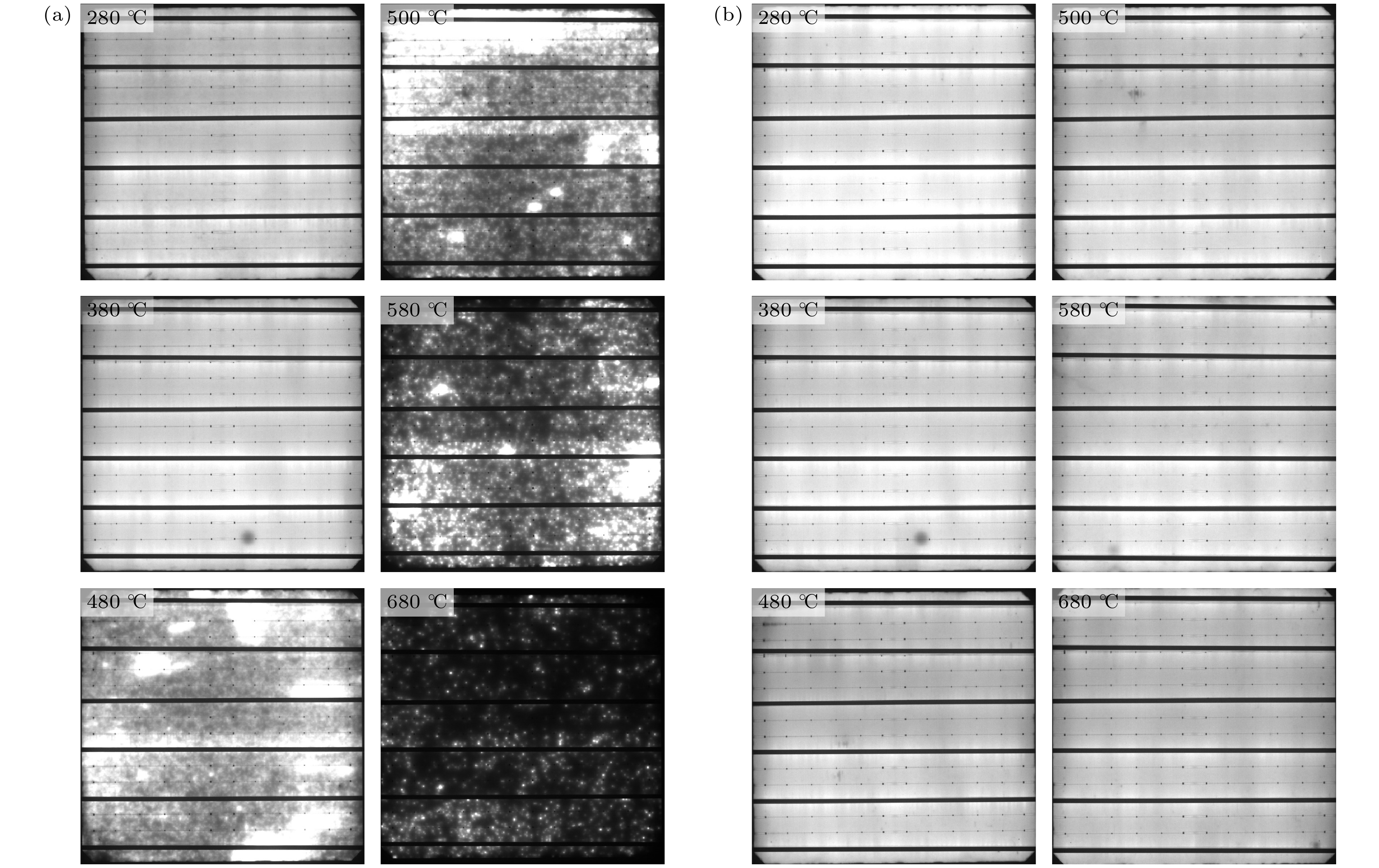

图 5 (a), (b)二次烧结温度对电池效率与填充因子、开路电压与短路电流的影响; (c), (d) 二次烧结温度以及随后的二次LECO工艺对接触电阻、电池效率的影响

Fig. 5. (a), (b) Influence of secondary sintering temperature on efficiency and filling factor, open circuit voltage and short circuit current; (c), (d) influences of secondary firing temperature and subsequent secondary LECO process on contact resistivity, efficiency of solar cells

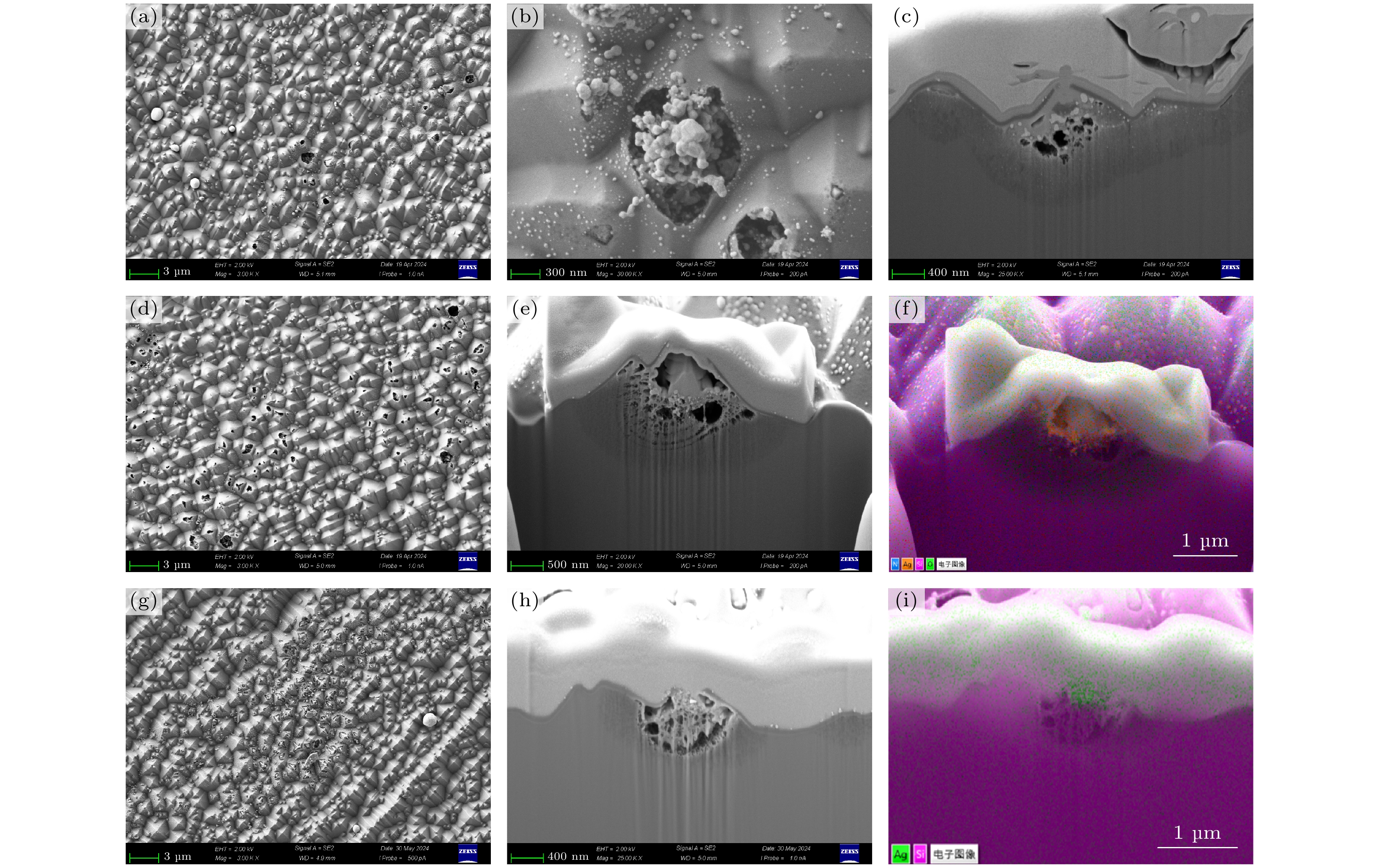

图 8 样品A, B, C的微观结构 (a) 样品A的SEM图像; (b) 样品A的局部SEM图像; (c)图(b)的FIB-SEM截面图; (d)样品B的SEM图像; (e) 样品B的FIB-SEM截面图; (f)图(e)的EDS图谱; (g)样品C的SEM图像; (h) 样品C的FIB-SEM截面图; (i)图(h)的EDS图谱

Fig. 8. Microstructure of samples A, B, C: (a) SEM image of sample A; (b) FIB-SEM cross-section of sample A; (c) EDS pattern of panel (b); (d) SEM image of sample B; (e) FIB-SEM cross-section of sample B; (f) EDS pattern of panel (e); (g) SEM image of sample C; (h) FIB-SEM cross-section; (i) EDS pattern of panel (h).

表 1 不同浆料在经过LECO工艺后对电池性能的影响

Table 1. Influence of different slurries on the performance of solar cells after LECO process.

VOC/mV JSC/(mA·cm–2) FF Eff/% 传统银铝浆料 740 42.03 0.834 25.94 改良后纯银浆料 743 42.05 0.844 26.35 -

[1] Feldmann F, Bivour M, Reichel C, Hermle M, Glunz S W 2014 Sol. Energy Mater. Sol. Cells 120 270

Google Scholar

Google Scholar

[2] Richter A, Müller R, Benick J 2021 Nat. Energy 6 429

Google Scholar

Google Scholar

[3] Anderson C L, Nemeth W, Guthrey H 2023 Adv. Energy Mater. 13 2203579

Google Scholar

Google Scholar

[4] Römer U, Peibst R, Ohrdes T, Lim B, Krügener J, Bugiel E, Wietler T, Brendel R 2014 Sol. Energy Mater. Sol. Cells 131 85

Google Scholar

Google Scholar

[5] Haase F, Hollemann C, Schäfer S, Merkle A, Rienäcker M, Krügener J, Brendel R, Peibst R 2018 Sol. Energy Mater. Sol. Cells 186 184

Google Scholar

Google Scholar

[6] Hermle M, Feldmann F, Bivour M, Goldschmidt J C, Glunz S W 2020 Appl. Phys. Rev. 7 021305

Google Scholar

Google Scholar

[7] 肖友鹏, 高超, 王涛, 周浪 2017 66 66 158801

Google Scholar

Google Scholar

Xiao Y P, Gao C, Wang T, Zhou L 2017 Acta Phys. Sin. 66 2017 Acta Phys. Sin. 66 158801

Google Scholar

Google Scholar

[8] 任程超, 周佳凯, 刘璋, 赵颖, 张晓丹, 侯国付 2021 70 178401

Google Scholar

Google Scholar

Ren C C, Zhou J K, Zhang B Y, Liu Z, Zhao Y, Zhang X D, Hou G F 2021 Acta Phys. Sin. 70 178401

Google Scholar

Google Scholar

[9] Yan D, Cuevas A, Michel J, Zhang C, Wan Y M, Zhang X Y, Bullock J 2021 Joule 5 811

Google Scholar

Google Scholar

[10] Glunz S W, Steinhauser B, Polzin J, Luderer C, Grübel B, Niewelt T, Okasha A, Bories M, Nagel H, Krieg K, Feldmann F, Richter A, Bivour M, Hermle M 2021 Prog. Photovolt. Res. Appl 31 341

Google Scholar

Google Scholar

[11] Richter A, Benick J, Feldmann F, Fell A, Hermle M, Glunz S W 2017 Sol. Energy Mater. Sol. Cells 173 96

Google Scholar

Google Scholar

[12] Steinkemper H, Hermle M, Glunz S W 2014 Sol. Energy Mater. Sol. Cells 131 46

Google Scholar

Google Scholar

[13] Schmidt J, Peibst R, Brendel R. 2018 Sol. Energy Mater. Sol. Cells 187 39

Google Scholar

Google Scholar

[14] Zhang X Y, Dumbrell R, Li W Q, Xu M Y, Yan D, Jin J S, Wang Z, Zheng P T, Liu C M, Yang J 2023 Prog. Photovolt.: Res. Appl. 31 369

Google Scholar

Google Scholar

[15] VDMA 2023 International Technology Roadmap for Photovoltaic p60

[16] https://ir.jinkosolar.com/news-releases/news-release-details/jinkosolars-high-efficiency-n-type-monocrystalline-silicon-3 [2023-10-23]

[17] Wang Q Q, Guo K Y, Yuan L, Li L Z, Peng H, Li B R, Wang A L, Zhang L Z, Wu W P, Ding J N, Yuan N Y 2023 Sol. Energy Mater. Sol. Cells 253 112231

Google Scholar

Google Scholar

[18] Allen T G, Bullock J, Yang X, Javey A, Wolf S D 2019 Nat. Energy 4 914

Google Scholar

Google Scholar

[19] Cuevas A, Wan Y M, Yan D, Samundsett C, Allen T, Zhang X, Cui J, Bullock J 2018 Sol. Energy Mater. Sol. Cells 184 38

Google Scholar

Google Scholar

[20] Riegel S, Mutter F, Lauermann T, Terheiden B, Hahn G 2012 Energy Proc. 21 14

Google Scholar

Google Scholar

[21] Fritz S, Konig M, Riegel S, Herguth A, Horteis M, Hahn G 2015 IEEE J. Photovoltaics 5 145

Google Scholar

Google Scholar

[22] Kumar P, Pfeffer M, Willsch B, Eibl O, Koduvelikulathu L J, Mihailetchi L J, Kopecek R 2016 Sol. Energy Mater. Sol. Cells 157 200

Google Scholar

Google Scholar

[23] Urban T, Heimann M, Schmid A, Mette A, Heitmann J 2015 Energy Proc. 77 420

Google Scholar

Google Scholar

[24] Aoyama T, Aoki M, Sumita I, Yoshino Y, Ogura A 2016 Energy Proc. 98 106

Google Scholar

Google Scholar

[25] Fritz S, Emre E, Engelhardt J, Ebert S, Nowak N, Booth J, Hahn G 2016 Energy Proc. 92 925

Google Scholar

Google Scholar

[26] Mack S, Schube J, Fellmeth T, Feldmann F, Lenes M, Luchies J 2017 Phys. Rapid Res. Lett. 11 1700334

Google Scholar

Google Scholar

[27] Kiefer F, Krugener J, Heinemeyer F, Osten H J, Brendel R, Peibst R 2016 IEEE J. Photovoltaics 6 1175

Google Scholar

Google Scholar

[28] Liang L, Li Z G, Cheng L K, Takeda N, Carroll A F 2015 J. Appl. Phys. 117 215102

Google Scholar

Google Scholar

[29] Fritz S, Engelhardt J, Ebert S, Hahn G 2016 Phys. Status Solidi RRL 10 305

Google Scholar

Google Scholar

[30] Mayberry R, Myers K, Chandrasekaran V, Henning A, Zhao H, Hofmüller E 2019 36th European Photovoltaic Solar Energy Conference and Exhibition Marseille, France, September 9–13, 2019

[31] Krassowski E, Großer S, Turek M, Henning A, Zhao H 2021 AIP Conf. Proc. 2367 020005

Google Scholar

Google Scholar

[32] Fellmeth T, Höffler H, Mack S, Krassowski E, Krieg K, Kafle B, Greulich J 2022 Prog. Photovolt. Res. Appl. 30 1393

Google Scholar

Google Scholar

[33] Fan Y, Zou S, Zeng Y L, Dai L F, Wang Z P, Lu Z, Sun H, Zhou X S, Liao B C, Su X D 2024 Solar RRL 8 2400268

Google Scholar

Google Scholar

[34] Dasgupta S, Ok Y W, Upadhyaya V D, Choi W J, Huang Y Y, Duttagupta Y, Rohatgi A 2022 IEEE J. Photovoltaics 12 1282

Google Scholar

Google Scholar

[35] Kuruganti V V, Isabella O, Mihailetchi V D 2024 Phys. Status Solidi A 221 2300820

Google Scholar

Google Scholar

[36] Höffler H, Fellmeth T, Maischner F, Greulich J, Krassowski E, Henning A 2022 AIP Conf. Proc. 2487 110001

Google Scholar

Google Scholar

[37] Großer S, Krassowski E, Swatek S, Zhao H, Hagendorf C 2022 IEEE J. Photovolt. 12 26

Google Scholar

Google Scholar

[38] Höffler H, Simon F, Krassowski E, Greulich J 2022 AIP Conference Proceedings 2826 040002

Google Scholar

Google Scholar

计量

- 文章访问数: 6066

- PDF下载量: 380

- 被引次数: 0

下载:

下载: