-

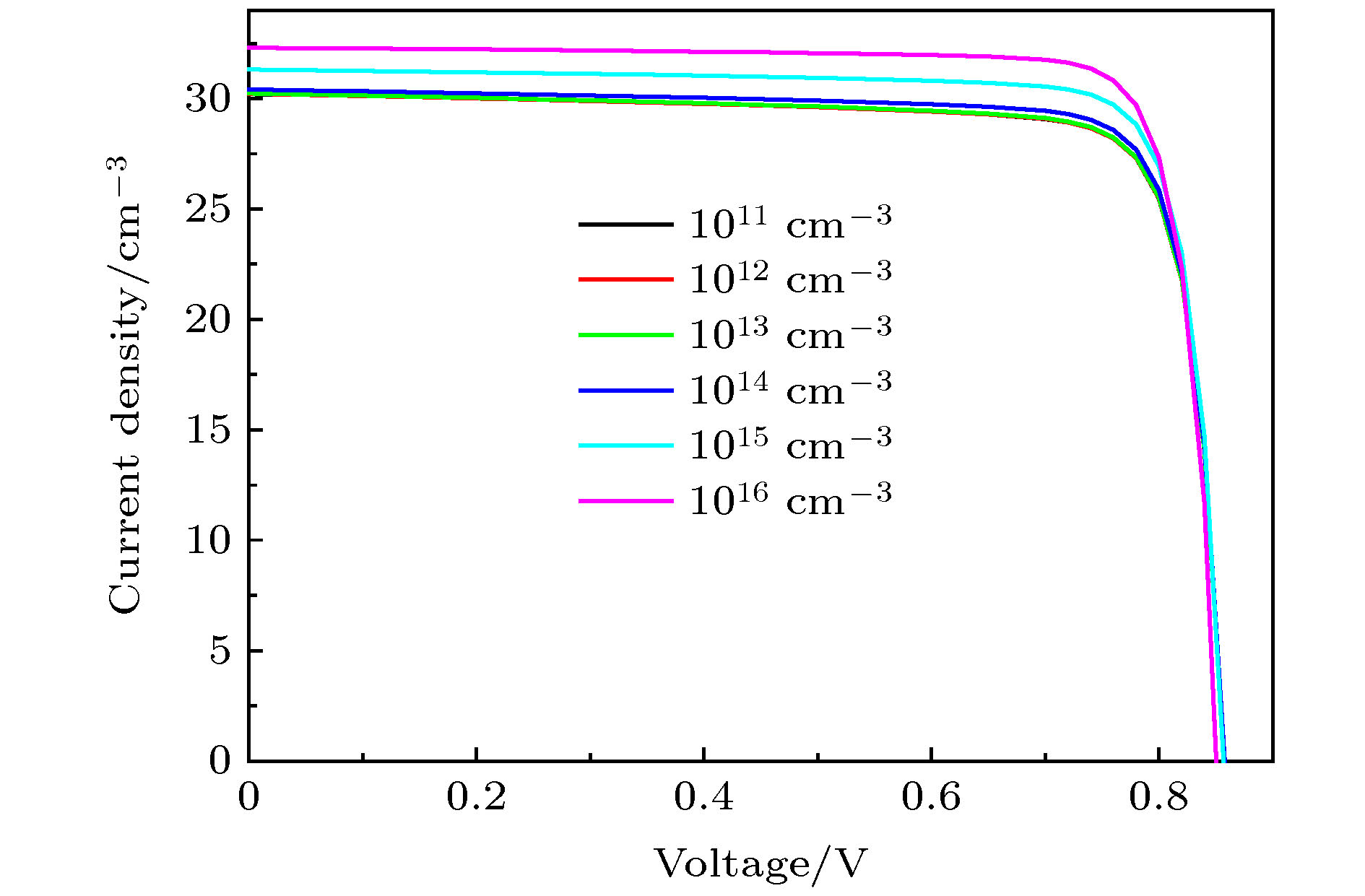

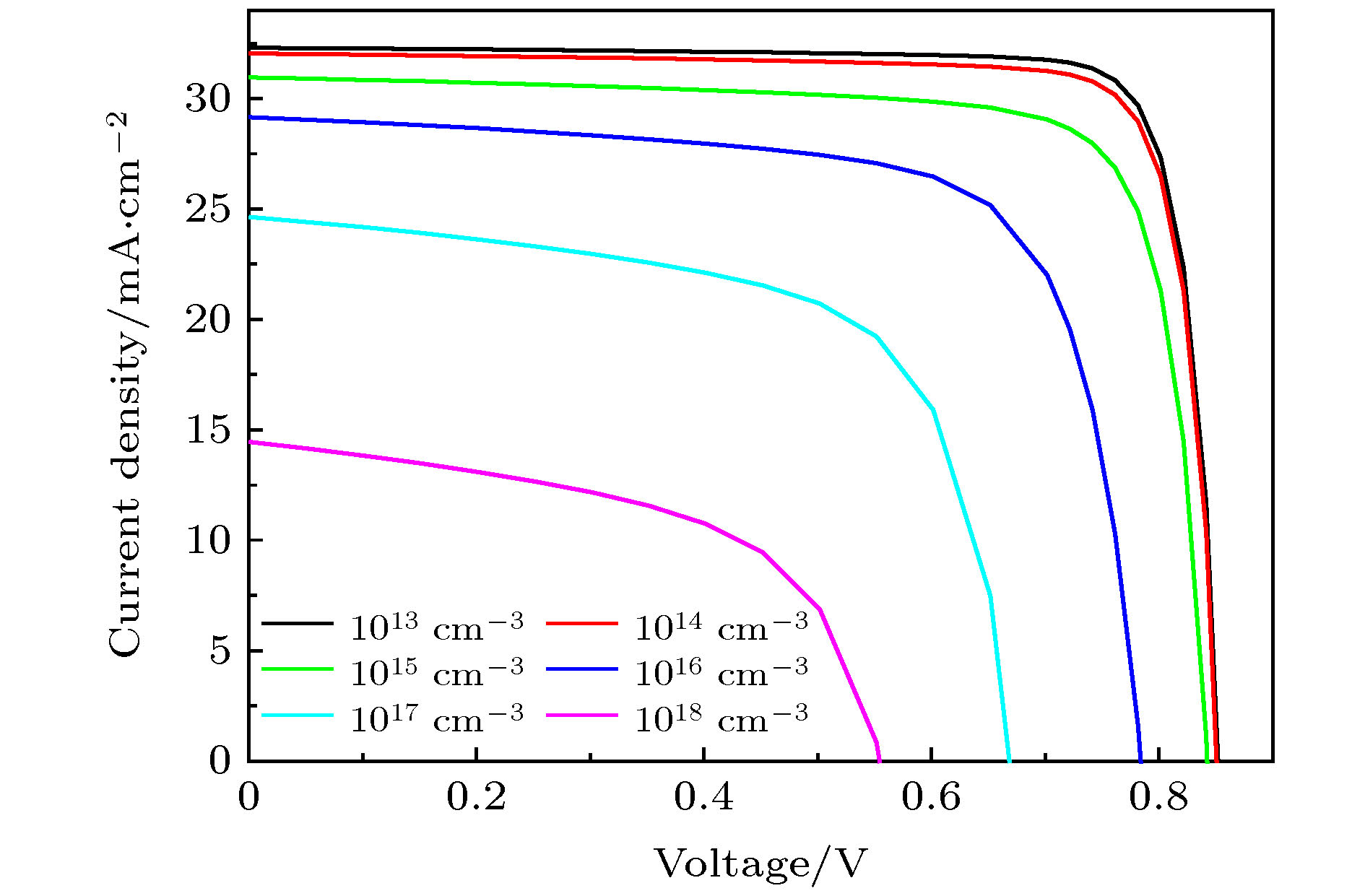

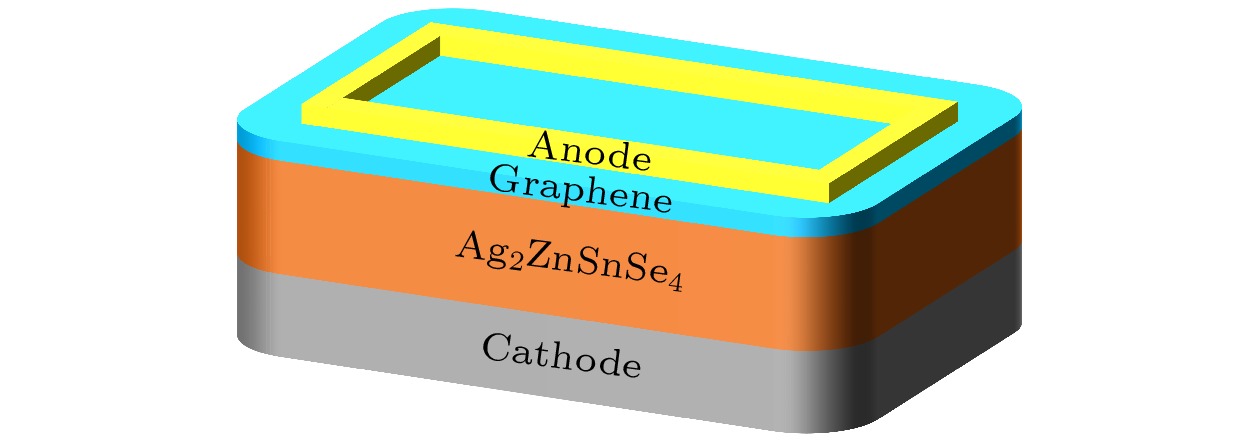

银锌锡硒 (Ag2ZnSnSe4)是一种禁带宽度为1.4 eV的 n型半导体材料. 本文提出一种由n型Ag2ZnSnSe4与石墨烯 (Graphene) 组成的Graphene/Ag2ZnSnSe4诱导p-n结薄膜太阳电池, 并借助wxAMPS软件对电池的物理机理和性能影响因素进行模拟研究. 模拟结果表明, 高功函数的石墨烯与n型Ag2ZnSnSe4半导体接触时, Ag2ZnSnSe4吸收层的前端能带向上弯曲, 在n型Ag2ZnSnSe4吸收层表面诱导形成p型Ag2ZnSnSe4反型层, p型Ag2ZnSnSe4和n型Ag2ZnSnSe4组成p-n同质结. 模拟发现石墨烯和背接触的功函数会影响载流子的分离、输运和收集, 严重影响器件性能, 石墨烯功函数达到5.5 eV, 背接触功函数不高于4.4 eV, 都有利于提高器件性能. Ag2ZnSnSe4吸收层的掺杂浓度主要影响器件的短路电流, 而Ag2ZnSnSe4吸收层的体内缺陷对器件整体性能产生影响. 在石墨烯和背接触功函数分别为5.5和3.8 eV, Ag2ZnSnSe4吸收层的掺杂浓度和缺陷密度分别为1016和1014 cm–3时, Graphene/Ag2ZnSnSe4诱导p-n结薄膜太阳电池能够取得高达23.42%的效率. 这些模拟结果为设计新型高效低成本太阳电池提供了思路和物理阐释.Ag2ZnSnSe4 is an n-type semiconductor with a suitable bandgap of 1.4 eV. In the present study, a graphene/Ag2ZnSnSe4 induced p-n junction thin film solar cell is proposed and the physical mechanism and performance influencing factors of the solar cell are simulated and analyzed by using the wxAMPS software. The simulation results show that when a high work function graphene contacts an n-type Ag2ZnSnSe4 semiconductor, the energy band of the Ag2ZnSnSe4 absorber layer bends upward, meanwhile a p-type Ag2ZnSnSe4 inversion layer is induced on the surface of n-type Ag2ZnSnSe4, therefore the p-type Ag2ZnSnSe4 and n-type Ag2ZnSnSe4 form an induced p-n homojunction. It is found that the work function of graphene and back contact significantly influence the photogenerated carrier separation, transportation and collection. The graphene work function should be 5.5 eV and the work function of back contact should not be greater than 4.4 eV, which is beneficial to the improving of the device performance. The doping concentration of Ag2ZnSnSe4 absorber mainly affects the short-circuit current of the device, however, the defect density of Ag2ZnSnSe4 absorber affects the whole device performance. When the work function of graphene and back contact are 5.5 eV and 3.8 eV, the doping concentration and defect density of Ag2ZnSnSe4 absorber are 1016 cm–3 and 1014 cm–33, respectively, the conversion efficiency of the graphene/Ag2ZnSnSe4 induced p-n junction thin film solar cell can reach 23.42%. These simulation results provide the idea and physical explanation for designing a novel type of solar cell with high efficiency and low cost.

-

Keywords:

- graphene /

- Ag2ZnSnSe4 /

- induced p-n junction /

- thin film solar cell

[1] Repins I, Beall C, Vora N, DeHart C, Kuciauskas D, Dippo P, To B, Mann J, Hsu W C, Goodrich A, Noufi R 2012 Sol. Energy Mater. Sol.Cells 101 154

Google Scholar

Google Scholar

[2] Liu F, Sun K, Li W, Yan C, Cui H, Jiang L, Hao X, Green M A 2014 Appl. Phys. Lett. 104 051105

Google Scholar

Google Scholar

[3] Zeng X, Tai K F, Zhang T, Ho C W J, Chen X, Huan A, Sum T C, Wong L H 2014 Sol. Energy Mater. Sol. Cells 124 55

Google Scholar

Google Scholar

[4] Chen S, Gong X G, Walsh A, Wei S H 2010 Appl. Phys. Lett. 96 021902

Google Scholar

Google Scholar

[5] Gokmen T, Gunawan O, Todorov T K, Mitzi D B 2013 Appl. Phys. Lett. 103 103506

Google Scholar

Google Scholar

[6] Chen S, Walsh A, Gong X G, Wei S H 2013 Adv. Mater. 25 1522

Google Scholar

Google Scholar

[7] Yeh L Y, Cheng K W 2014 Thin Solid Films 558 289

Google Scholar

Google Scholar

[8] Patil R M, Nagapure D R, Chandra G H, Subbaiah Y P V, Gupta M, Rao R P 2020 Phys. Status Solidi 217 1900752

Google Scholar

Google Scholar

[9] Yuan Z K, Chen S, Xiang H, Gong X G, Walsh A, Park J S, Repins I, Wei S H 2015 Adv. Funct. Mater. 25 6733

Google Scholar

Google Scholar

[10] Chagarov E, Sardashti K, Kummel A C, Lee Y S, Haight R, Gershon T S 2016 J. Chem. Phys. 144 104704

Google Scholar

Google Scholar

[11] Gershon T, Sardashti K, Gunawan O, Mankad R, Singh S, Lee Y S, Ott J A, Kummel A, Haight R 2016 Adv. Energy Mater. 6 1601182

Google Scholar

Google Scholar

[12] 肖友鹏, 高超, 王涛, 周浪 2017 66 158801

Google Scholar

Google Scholar

Xiao Y P, Gao C, Wang T, Zhou L 2017 Acta Phys. Sin. 66 158801

Google Scholar

Google Scholar

[13] 曹宇, 祝新运, 陈瀚博, 王长刚, 张鑫童, 候秉东, 申明仁, 周静 2018 67 247301

Google Scholar

Google Scholar

Cao Y, Zhu X Y, Chen H B, Wang C G, Zhang X T, Hou B D, Shen M R, Zhou J 2018 Acta Phys. Sin. 67 247301

Google Scholar

Google Scholar

[14] 梁晓娟, 曹宇, 蔡宏琨, 苏健, 倪牮, 李娟, 张建军 2020 69 057901

Google Scholar

Google Scholar

Liang X J, Cao Y, Cai H K, Su J, Ni J, Li J, Zhang J J 2020 Acta Phys. Sin. 69 057901

Google Scholar

Google Scholar

[15] 张翱, 张春秀, 陈云林, 张春梅, 孟涛 2020 69 118801

Google Scholar

Google Scholar

Zhang A, Zhang C X, Chen Y L, Zhang C M, Meng T 2020 Acta Phys. Sin. 69 118801

Google Scholar

Google Scholar

[16] Gershon T, Sardashti K, Lee Y S, Gunawan O, Singh S, Bishop D, Kummel A C, Haight R 2017 Acta Mater. 126 383

Google Scholar

Google Scholar

[17] Gershon T, Gunawan O, Gokmen T, Brew K W, Singh S, Hopstaken M, Poindester J R, Barnard E S, Buonassisi T, Haight R 2017 J. Appl. Phys. 121 174501

Google Scholar

Google Scholar

[18] Jia J, Li Y, Yao B, Ding Z, Deng R, Jiang Y, Sui Y 2017 J. Appl. Phys. 121 215305

Google Scholar

Google Scholar

[19] Jiang Y, Yao B, Jia J, Ding Z, Deng R, Liu D, Sui Y, Wang H, Li Y 2019 J. Appl. Phys. 125 025703

Google Scholar

Google Scholar

[20] Hibino H, Kageshima H, Kotsugi M, Maeda F, Guo F Z, Watanabe Y 2009 Phys. Rev. B 79 125437

Google Scholar

Google Scholar

[21] Garg R, Dutta N K, Choudhury N R 2014 Nanomaterials 4 267

Google Scholar

Google Scholar

[22] Kim J H, Hwang J H, Suh J, Tongay S, Kwon S, Hwang C C, Wu J, Park J Y 2013 Appl. Phys. Lett. 103 171604

Google Scholar

Google Scholar

[23] Seo J, Bong J, Cha J, Lim T, Son J, Park S H, Hwang J, Hong S, Ju S 2014 J. Appl. Phys. 116 084312

Google Scholar

Google Scholar

[24] Bivour M, Temmler J, Steinkemper H, Hermle M 2015 Sol. Energy Mater. Sol. Cells 142 34

Google Scholar

Google Scholar

[25] Gerling L G, Voz C, Alcubilla R, Puigdollers J 2017 J. Mater. Res. 32 260

Google Scholar

Google Scholar

[26] Dréon J, Jeangros Q, Cattin J, Haschke J, Antognini L, Ballif C, Boccard M 2020 Nano Energy 70 104495

Google Scholar

Google Scholar

-

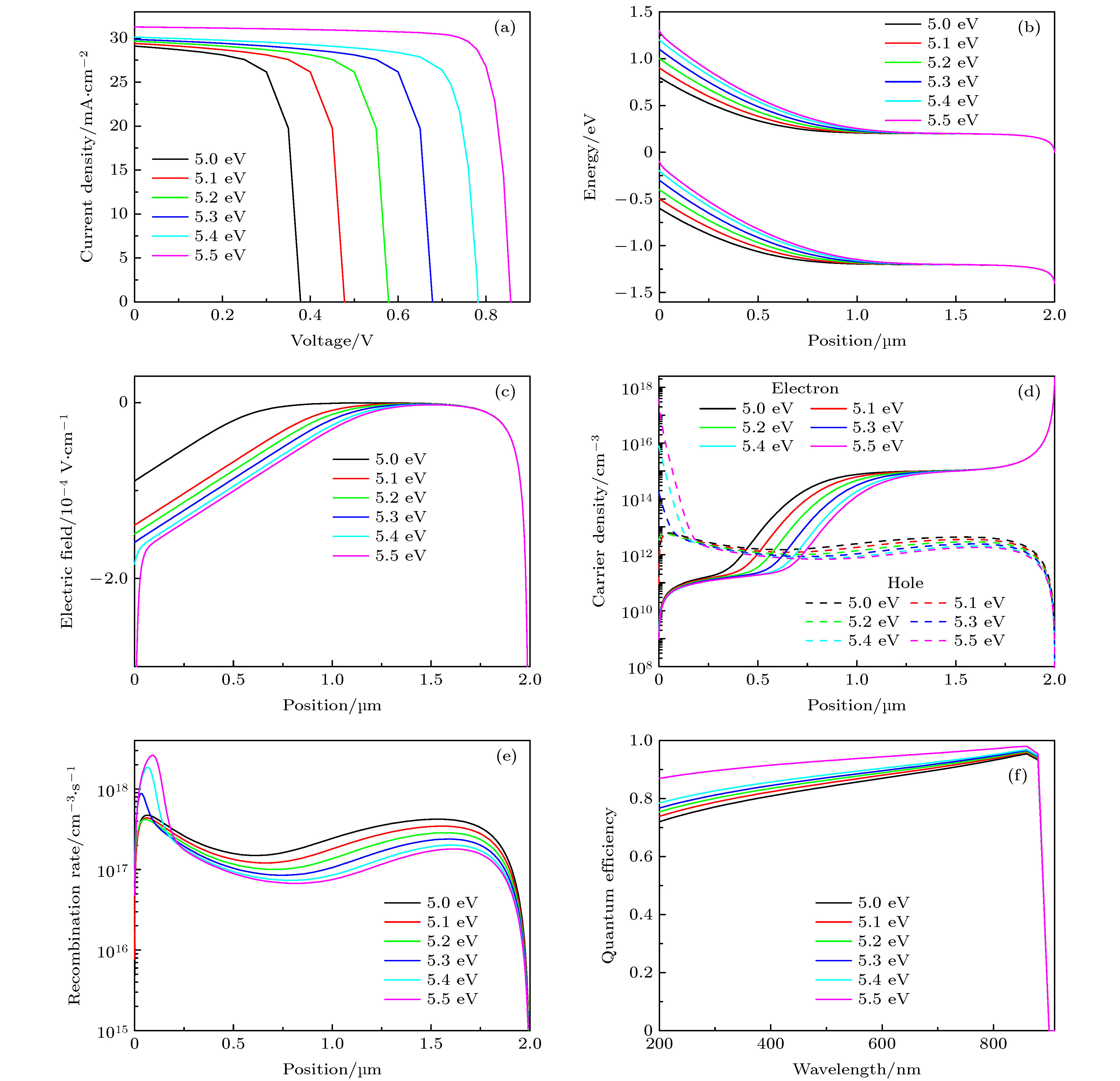

图 2 不同石墨烯功函数情况下电池的 (a)电流密度-电压特性曲线, (b)能带结构, (c)电场分布, (d)载流子浓度, (e)载流子复合率分布, (f)量子效率

Fig. 2. Graphene/AZTSe induced p-n junction thin film solar cell with different values of graphene work function (a) current density-voltage curves, (b) energy band structure, (c) electric field, (d) carrier concentration, (e) carrier recombination rate profile, (f) quantum efficiency.

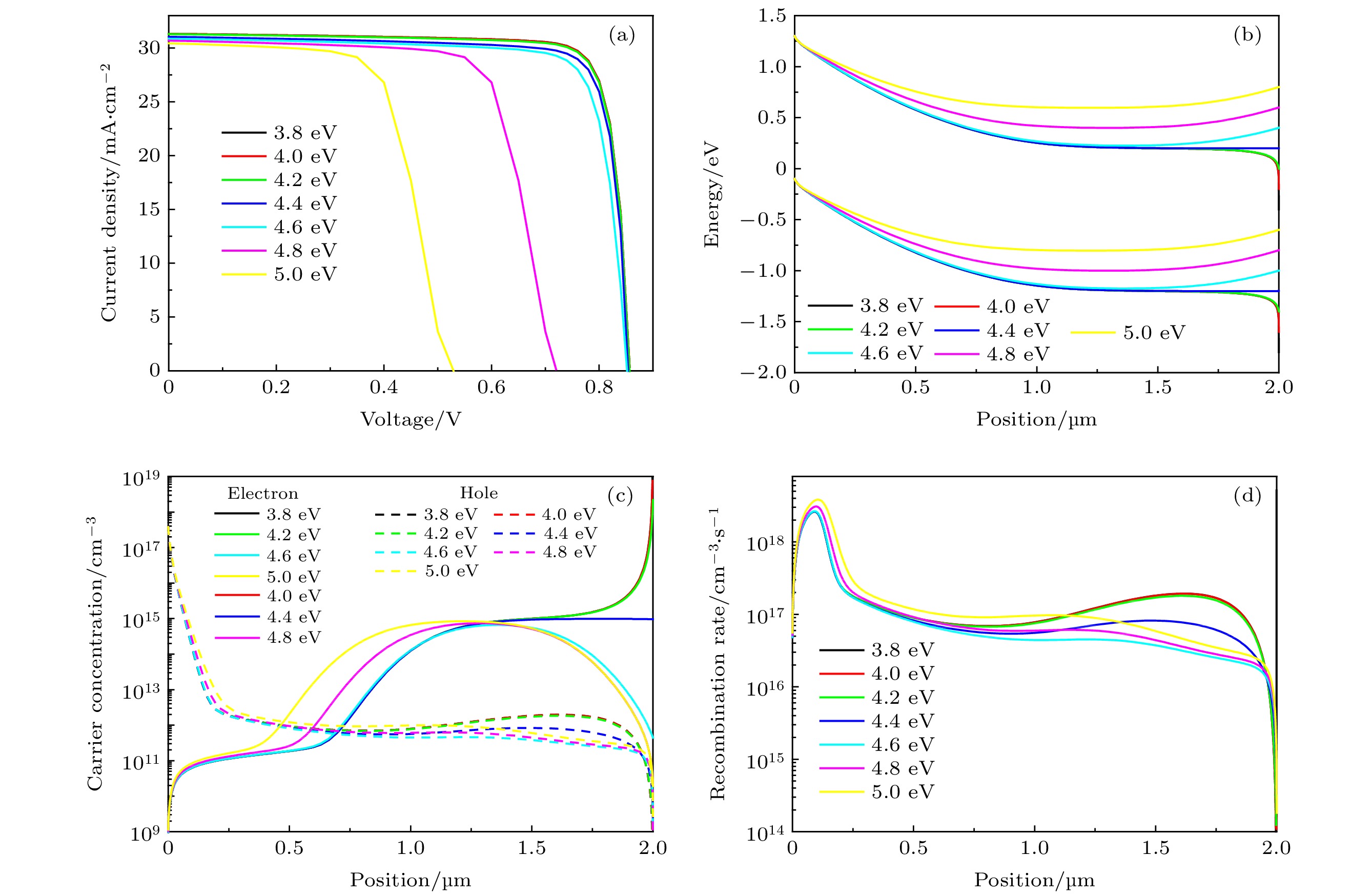

图 3 不同背接触功函数时电池的 (a)电流密度-电压特性曲线, (b)能带结构, (c)电子浓度, (d)载流子复合率分布

Fig. 3. Graphene/AZTSe induced p-n junction thin film solar cell with different values of back contact work function (a) current density-voltage curves, (b) energy band structure, (c) carrier concentration, (d) carrier recombination rate profile.

表 1 模拟使用的主要材料参数

Table 1. Main material parameters used in the numerical simulation.

参数 AZTSe 厚度/µm 2 相对介电常数 εr 12.6 电子亲和能 χe/eV 4.2 禁带宽度 Eg/eV 1.4 施主掺杂浓度 ND/cm–3 1011—1016 导带有效态密度 Nc /cm–3 2.2 × 1018 价带有效态密度Nv /cm–3 1.8 × 1019 电子迁移率 µn/cm2·V–1·s–1 100 空穴迁移率 µp/cm2·V-1·s–1 2 缺陷密度 Nt/cm–3 1013—1018 -

[1] Repins I, Beall C, Vora N, DeHart C, Kuciauskas D, Dippo P, To B, Mann J, Hsu W C, Goodrich A, Noufi R 2012 Sol. Energy Mater. Sol.Cells 101 154

Google Scholar

Google Scholar

[2] Liu F, Sun K, Li W, Yan C, Cui H, Jiang L, Hao X, Green M A 2014 Appl. Phys. Lett. 104 051105

Google Scholar

Google Scholar

[3] Zeng X, Tai K F, Zhang T, Ho C W J, Chen X, Huan A, Sum T C, Wong L H 2014 Sol. Energy Mater. Sol. Cells 124 55

Google Scholar

Google Scholar

[4] Chen S, Gong X G, Walsh A, Wei S H 2010 Appl. Phys. Lett. 96 021902

Google Scholar

Google Scholar

[5] Gokmen T, Gunawan O, Todorov T K, Mitzi D B 2013 Appl. Phys. Lett. 103 103506

Google Scholar

Google Scholar

[6] Chen S, Walsh A, Gong X G, Wei S H 2013 Adv. Mater. 25 1522

Google Scholar

Google Scholar

[7] Yeh L Y, Cheng K W 2014 Thin Solid Films 558 289

Google Scholar

Google Scholar

[8] Patil R M, Nagapure D R, Chandra G H, Subbaiah Y P V, Gupta M, Rao R P 2020 Phys. Status Solidi 217 1900752

Google Scholar

Google Scholar

[9] Yuan Z K, Chen S, Xiang H, Gong X G, Walsh A, Park J S, Repins I, Wei S H 2015 Adv. Funct. Mater. 25 6733

Google Scholar

Google Scholar

[10] Chagarov E, Sardashti K, Kummel A C, Lee Y S, Haight R, Gershon T S 2016 J. Chem. Phys. 144 104704

Google Scholar

Google Scholar

[11] Gershon T, Sardashti K, Gunawan O, Mankad R, Singh S, Lee Y S, Ott J A, Kummel A, Haight R 2016 Adv. Energy Mater. 6 1601182

Google Scholar

Google Scholar

[12] 肖友鹏, 高超, 王涛, 周浪 2017 66 158801

Google Scholar

Google Scholar

Xiao Y P, Gao C, Wang T, Zhou L 2017 Acta Phys. Sin. 66 158801

Google Scholar

Google Scholar

[13] 曹宇, 祝新运, 陈瀚博, 王长刚, 张鑫童, 候秉东, 申明仁, 周静 2018 67 247301

Google Scholar

Google Scholar

Cao Y, Zhu X Y, Chen H B, Wang C G, Zhang X T, Hou B D, Shen M R, Zhou J 2018 Acta Phys. Sin. 67 247301

Google Scholar

Google Scholar

[14] 梁晓娟, 曹宇, 蔡宏琨, 苏健, 倪牮, 李娟, 张建军 2020 69 057901

Google Scholar

Google Scholar

Liang X J, Cao Y, Cai H K, Su J, Ni J, Li J, Zhang J J 2020 Acta Phys. Sin. 69 057901

Google Scholar

Google Scholar

[15] 张翱, 张春秀, 陈云林, 张春梅, 孟涛 2020 69 118801

Google Scholar

Google Scholar

Zhang A, Zhang C X, Chen Y L, Zhang C M, Meng T 2020 Acta Phys. Sin. 69 118801

Google Scholar

Google Scholar

[16] Gershon T, Sardashti K, Lee Y S, Gunawan O, Singh S, Bishop D, Kummel A C, Haight R 2017 Acta Mater. 126 383

Google Scholar

Google Scholar

[17] Gershon T, Gunawan O, Gokmen T, Brew K W, Singh S, Hopstaken M, Poindester J R, Barnard E S, Buonassisi T, Haight R 2017 J. Appl. Phys. 121 174501

Google Scholar

Google Scholar

[18] Jia J, Li Y, Yao B, Ding Z, Deng R, Jiang Y, Sui Y 2017 J. Appl. Phys. 121 215305

Google Scholar

Google Scholar

[19] Jiang Y, Yao B, Jia J, Ding Z, Deng R, Liu D, Sui Y, Wang H, Li Y 2019 J. Appl. Phys. 125 025703

Google Scholar

Google Scholar

[20] Hibino H, Kageshima H, Kotsugi M, Maeda F, Guo F Z, Watanabe Y 2009 Phys. Rev. B 79 125437

Google Scholar

Google Scholar

[21] Garg R, Dutta N K, Choudhury N R 2014 Nanomaterials 4 267

Google Scholar

Google Scholar

[22] Kim J H, Hwang J H, Suh J, Tongay S, Kwon S, Hwang C C, Wu J, Park J Y 2013 Appl. Phys. Lett. 103 171604

Google Scholar

Google Scholar

[23] Seo J, Bong J, Cha J, Lim T, Son J, Park S H, Hwang J, Hong S, Ju S 2014 J. Appl. Phys. 116 084312

Google Scholar

Google Scholar

[24] Bivour M, Temmler J, Steinkemper H, Hermle M 2015 Sol. Energy Mater. Sol. Cells 142 34

Google Scholar

Google Scholar

[25] Gerling L G, Voz C, Alcubilla R, Puigdollers J 2017 J. Mater. Res. 32 260

Google Scholar

Google Scholar

[26] Dréon J, Jeangros Q, Cattin J, Haschke J, Antognini L, Ballif C, Boccard M 2020 Nano Energy 70 104495

Google Scholar

Google Scholar

计量

- 文章访问数: 8774

- PDF下载量: 143

- 被引次数: 0

下载:

下载: