-

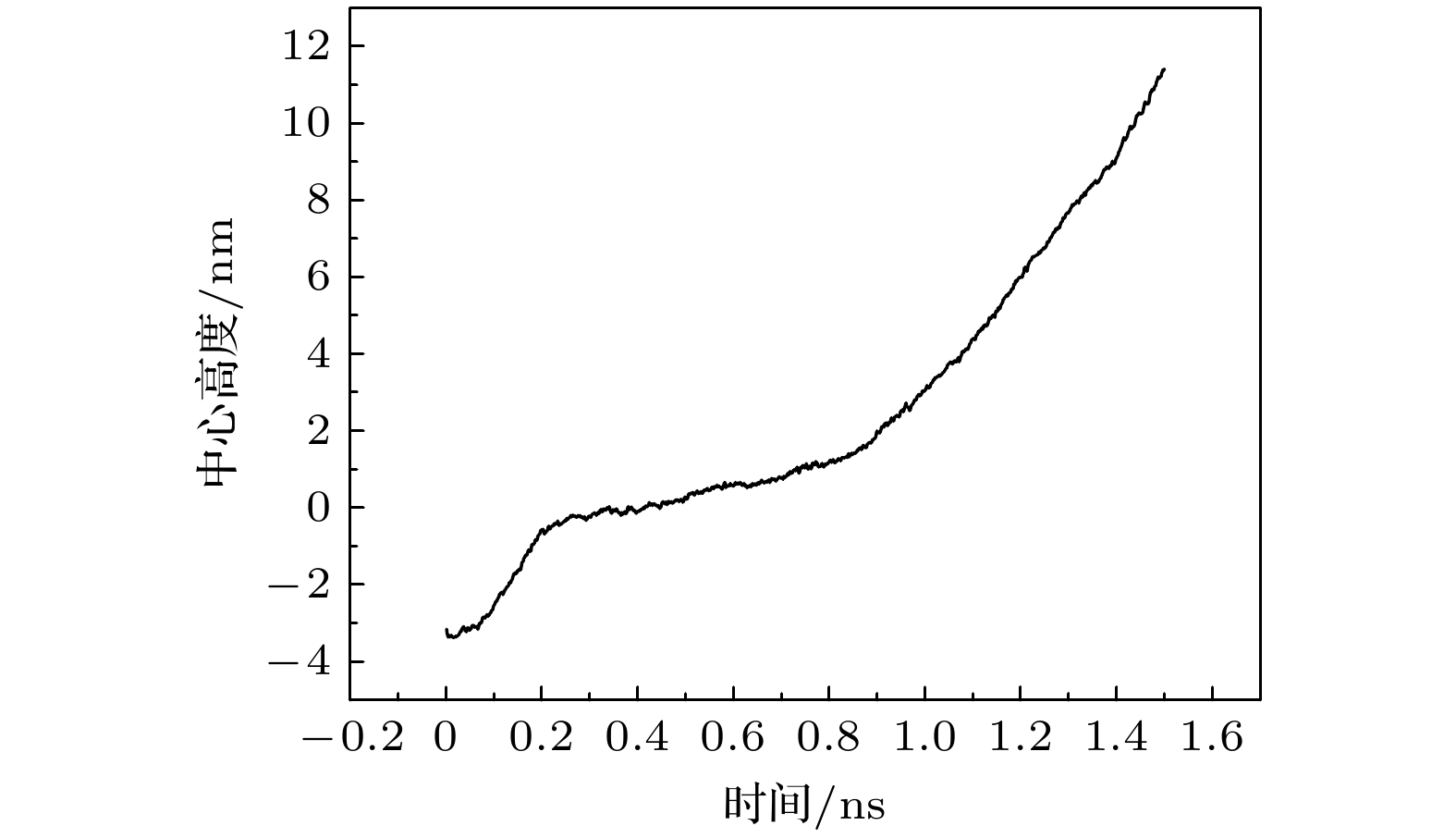

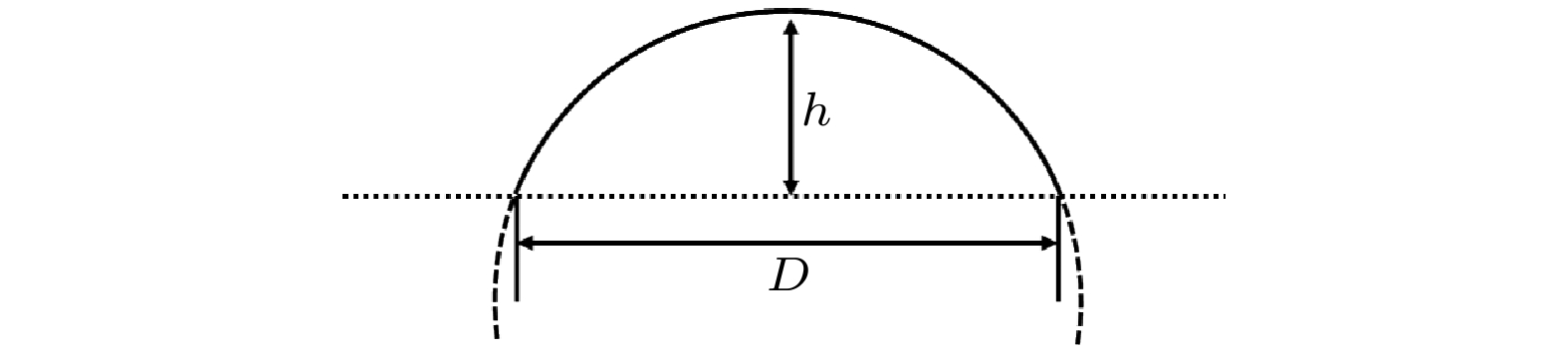

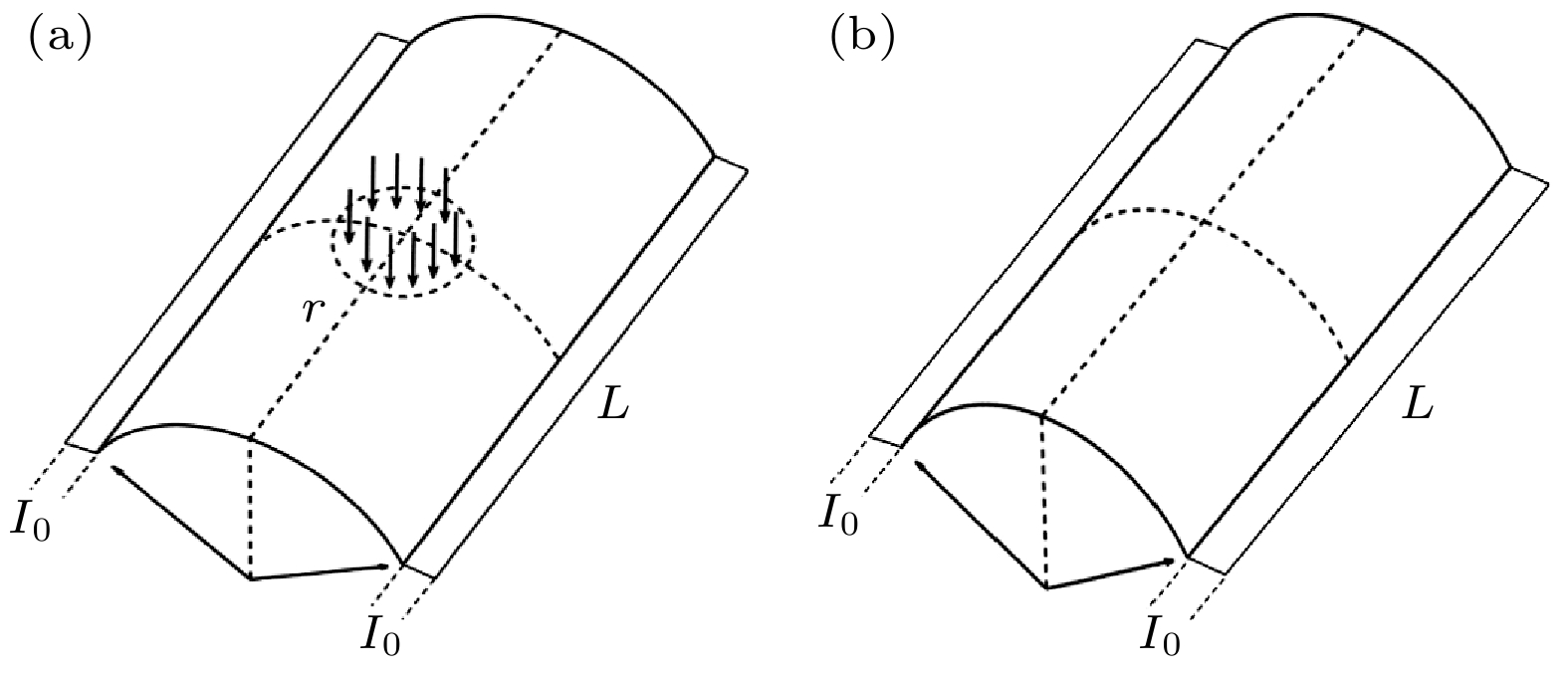

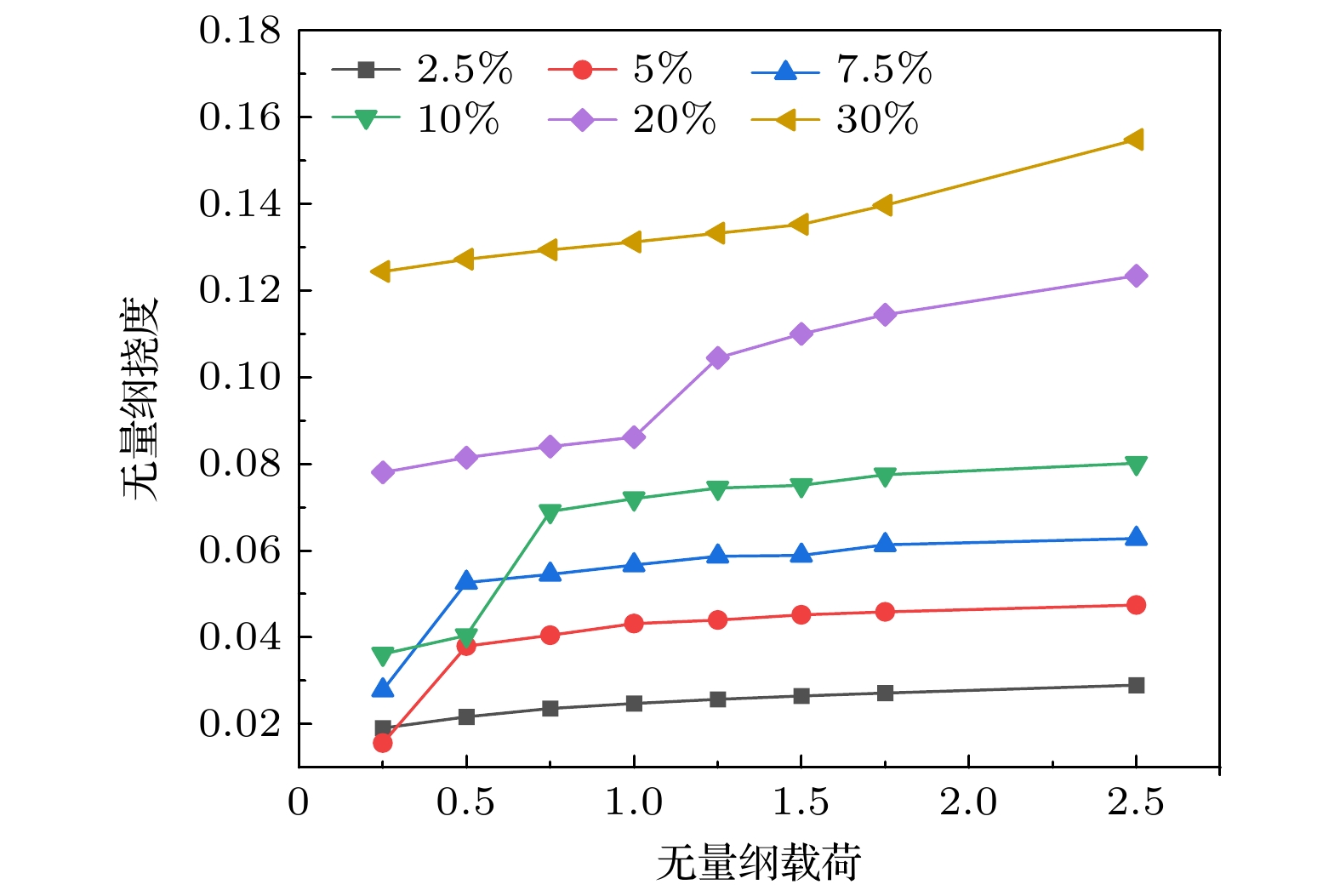

在扫描隧道显微镜的观测中发现了自支撑石墨烯膜镜面屈曲这一独特现象, 目前尚少有研究人员对其进行系统性的研究. 对于这种面外变形行为, 不论是在实验观测, 还是在能量收集系统这种潜在的应用形式中, 石墨烯的尺寸都需要达到微米级. 先前的研究表明, 传统分子动力学适用于纳米尺度石墨烯的计算与分析, 由于其计算方法的限制, 在处理微米级模型时容易出现计算效率低、耗时长等问题. 为了研究微米级尺寸石墨烯膜镜面屈曲现象, 本文使用粗粒化分子动力学方法, 首先验证该方法的适用性, 然后分别施加不同大小的机械载荷和温度载荷在扇形截面不同高跨比的石墨烯膜上以分析各因素带来的影响. 计算结果表明机械载荷作用下各个高跨比石墨烯均可以发生镜面屈曲现象, 且临界载荷随高跨比的增大而增大; 温度载荷作用下, 高跨比较小的石墨烯能够发生完全翻转现象, 大高跨比情况下温度升高使中心高度下降, 但完全翻转较难发生. 研究分析各因素对于石墨烯镜面屈曲现象的影响, 可以加深对这一特殊现象了解的同时, 为能量收集系统的设计提供理论指导.Up to now, the analysis has rarely been conducted of thermal-mechanical mirror buckling behavior of freestanding graphene membranes discovered in scan tunneling microscope experiments. One of the potential applications of the out-of-plane deformational behavior of graphene membranes is energy harvesting system. Whether in the experiments or for energy harvesting systems, the size of graphene membrane needs to be down to micron scale. According to previous researches, traditional molecular dynamics method is a suitable method to characterize nano-scale mirror buckling. However, owing to the limit of algorithm, when dealing with micro size model by molecular dynamics method, two problems arise: low computational efficiency and too long calculation time. Therefore, for analyzing the mirror buckling of micro size graphene membranes, the coarse-grained molecular dynamics method is utilized in this work. Graphene membranes with a fan-shaped cross section and various depth-span ratios are under mechanical or thermal loads. Effects of each factor on the mirror buckling are investigated. The calculations indicate that for graphene membranes with various depth-span ratios under mechanical load mirror buckling can be observed. And the critical loading increases with the depth-span ratio increasing. Under thermal load graphene membranes only with low depth-span ratios can undergo complete flipping phenomenon. For high depth-span ratio graphene, the center height decreases with temperature rising. However, it is hard to flip over completely. The understanding of the effects of various factors on the mirror buckling phenomenon of graphene membranes can provide theoretical guidance for designing the energy harvesting systems.

-

Keywords:

- coarse-grained molecular dynamics /

- mirror buckling /

- graphene

[1] Novoselov K S, Geim A K, Morozov S V, Jiang D, Zhang Y, Dubonos S V, Grigorieva I V, Firsov A A 2004 Science 306 666

Google Scholar

Google Scholar

[2] Lee C, Wei X, Kysar J W, Hone J 2008 Science 321 385

Google Scholar

Google Scholar

[3] Ma T, Li B, Chang T 2011 Appl. Phys. Lett. 99 201901

Google Scholar

Google Scholar

[4] Zhang Y, Pan C 2012 Diamond Relat. Mater. 24 1

Google Scholar

Google Scholar

[5] Galiotis C, Frank O, Koukaras E N, Sfyris D 2015 Annu. Rev. Chem. Biomol. 6 121

Google Scholar

Google Scholar

[6] 李亮亮, 孟凡伟, 邹鲲, 黄瑶, 彭倚天 2021 70 086801

Google Scholar

Google Scholar

Li L L, Meng F W, Zou K, Huang Y, Peng Y T 2021 Acta Phys. Sin. 70 086801

Google Scholar

Google Scholar

[7] Faugeras C, Faugeras B, Orlita M, Potemski M, Nair R R, Geim A K 2010 ACS Nano 4 1889

Google Scholar

Google Scholar

[8] Chen L, Kumar S 2012 J. Appl. Phys. 112 043502

Google Scholar

Google Scholar

[9] Nan H Y, Ni Z H, Wang J, Zafar Z, Shi Z X, Wang Y Y 2013 J. Raman Spectrosc. 44 1018

Google Scholar

Google Scholar

[10] Renteria J D, Nika D L, Balandin A A 2014 Appl. Sci. 4 525

Google Scholar

Google Scholar

[11] Graf D, Molitor F, Ensslin K, Stampfer C, Jungen A, Hierold C, Wirtz L 2007 Nano Lett. 7 238

Google Scholar

Google Scholar

[12] Ferrari A C, Meyer J C, Scardaci V, Casiraghi C, Lazzeri M, Mauri F, Piscanec S, Jiang D, Novoselov K S, Roth S, Geim A K 2006 Phys. Rev. Lett. 97 187401

Google Scholar

Google Scholar

[13] Zhang Y, Tan Y W, Stormer H L, Kim P 2005 Nature 438 201

Google Scholar

Google Scholar

[14] Bolotin K I, Sikes K J, Jiang Z, Klima M, Fudenberg G, Hone J, Kim P, Stormer H L 2008 Solid State Commun. 146 351

Google Scholar

Google Scholar

[15] Peres N M R 2009 Vacuum 83 1248

Google Scholar

Google Scholar

[16] Mogi M, Okamura Y, Kawamura M, Yoshimi R, Yasuda K, Tsukazaki A, Takahashi K S, Morimoto T, Nagaosa N, Kawasaki M, Takahashi Y, Tokura Y 2022 Nat. Phys. 18 390

Google Scholar

Google Scholar

[17] Xin N, Lourembam J, Kumaravadivel P, Kazantsev A E, Wu Z, Mullan C, Barrier J, Geim A A, Grigorieva I V, Mishchenko A, Principi A, Fal’ko V I, Ponomarenko L A, Geim A K, Berdyugin A I 2023 Nature 616 270

Google Scholar

Google Scholar

[18] López-Suárez M, Rurali R, Abadal G 2013 Microelectron. Eng. 111 122

Google Scholar

Google Scholar

[19] López-Suárez M, Rurali R, Gammaitoni L, Abadal G 2011 Phys. Rev. B 84 161401

Google Scholar

Google Scholar

[20] 廖天军, 杨智敏, 林比宏 2021 70 227901

Google Scholar

Google Scholar

Liao T J, Yang Z M, Lin B H 2021 Acta Phys. Sin. 70 227901

Google Scholar

Google Scholar

[21] 万震, 李成, 刘宇健, 宋学锋, 樊尚春 2022 71 126801

Google Scholar

Google Scholar

Wan Z, Li C, Liu Y J, Song X F, Fan S X 2022 Acta Phys. Sin. 71 126801

Google Scholar

Google Scholar

[22] Neek-Amal M, Xu P, Schoelz J K, Ackerman M L, Barber S D, Thibado P M, Sadeghi A, Peeters F M 2014 Nat. Commun. 5 4962

Google Scholar

Google Scholar

[23] Schoelz J K, Xu P, Meunier V, Kumar P, Neek-Amal M, Thibado P M, Peeters F M 2015 Phys. Rev. B 91 045413

Google Scholar

Google Scholar

[24] Ruiz-García M, Bonilla L L, Prados A 2016 Phys. Rev. B 94 205404

Google Scholar

Google Scholar

[25] Xu W, Kai Y, Zhang K, Zheng B 2022 Mater. Today Commun. 33 104230

Google Scholar

Google Scholar

[26] Lindahl N, Midtvedt D, Svensson J, Nerushev O A, Lindvall N, Isacsson A, Campbell E E 2012 Nano Lett. 12 3526

Google Scholar

Google Scholar

[27] Garaj S, Hubbard W, Reina A, Kong J, Branton D, Golovchenko J A 2010 Nature 467 190

Google Scholar

Google Scholar

[28] Chu Y, Ragab T, Basaran C 2014 Comput. Mater. Sci. 81 269

Google Scholar

Google Scholar

[29] Xu C, Xue T, Qiu W, Kang Y 2016 ACS Appl. Mater. Interfaces 8 27099

Google Scholar

Google Scholar

[30] Deng W, Li L, Hu Y, Wang X, Li X 2018 J. Therm. Stresses 41 1182

Google Scholar

Google Scholar

[31] Su R, Zhang X 2018 Appl. Therm. Eng. 144 488

Google Scholar

Google Scholar

[32] Ruiz L, Xia W, Meng Z, Keten S 2015 Carbon 82 103

Google Scholar

Google Scholar

[33] Li H, Zhang H, Cheng X 2017 Physica E 85 97

Google Scholar

Google Scholar

[34] Liu S, Duan K, Li L, Wang X, Hu Y 2021 Carbon 178 528

Google Scholar

Google Scholar

[35] Zhao Y, Zhao Y, Wu F, Zhao Y, Wang Y, Sui C, He X, Wang C, Tan H, Wang C 2021 Carbon 173 600

Google Scholar

Google Scholar

[36] Mangum J M, Harerimana F, Gikunda M N, Thibado P M 2021 Membranes 11 516

Google Scholar

Google Scholar

[37] Timoshenko S P 1936 Theory of Elastic Stability (New York: Dover Publication) pp320–324

[38] Wang W D, Shen C L, Li S, Min J J, Yi C L 2014 AIP Adv. 4 200207

Google Scholar

Google Scholar

[39] https://www.lammps.org/[2023-7-9

[40] https://www.ks.uiuc.edu/Research/vmd/ [2023-7-9

-

图 1 热镜面屈曲现象的实验观测——不同隧穿电流下石墨烯面外高度随电压变化曲线, 其中黑色曲线对应镜面屈曲现象[22]

Fig. 1. Experimental observation of thermal mirror buckling. Constant-current feedback-on, Z(V ) data sets on suspended graphene acquired using the labeled setpoint currents. The 4.0-nA curve (black) shows the mirror buckling phenomenon[22].

图 2 CGMD模型示意图. 黑色圆点表示全粒子模型中的碳原子, 蓝色圆点表示CGMD模型中的珠子. 红色虚线区域表示碳原子与珠子的典型等效方式

Fig. 2. Schematics of the CGMD model. The black dots indicate carbon atoms in the all-atom model. The blue dots indicate beads in the CGMD model. The region marked with rad dotted lines express a typical equivalent mode with carbon atoms and beads.

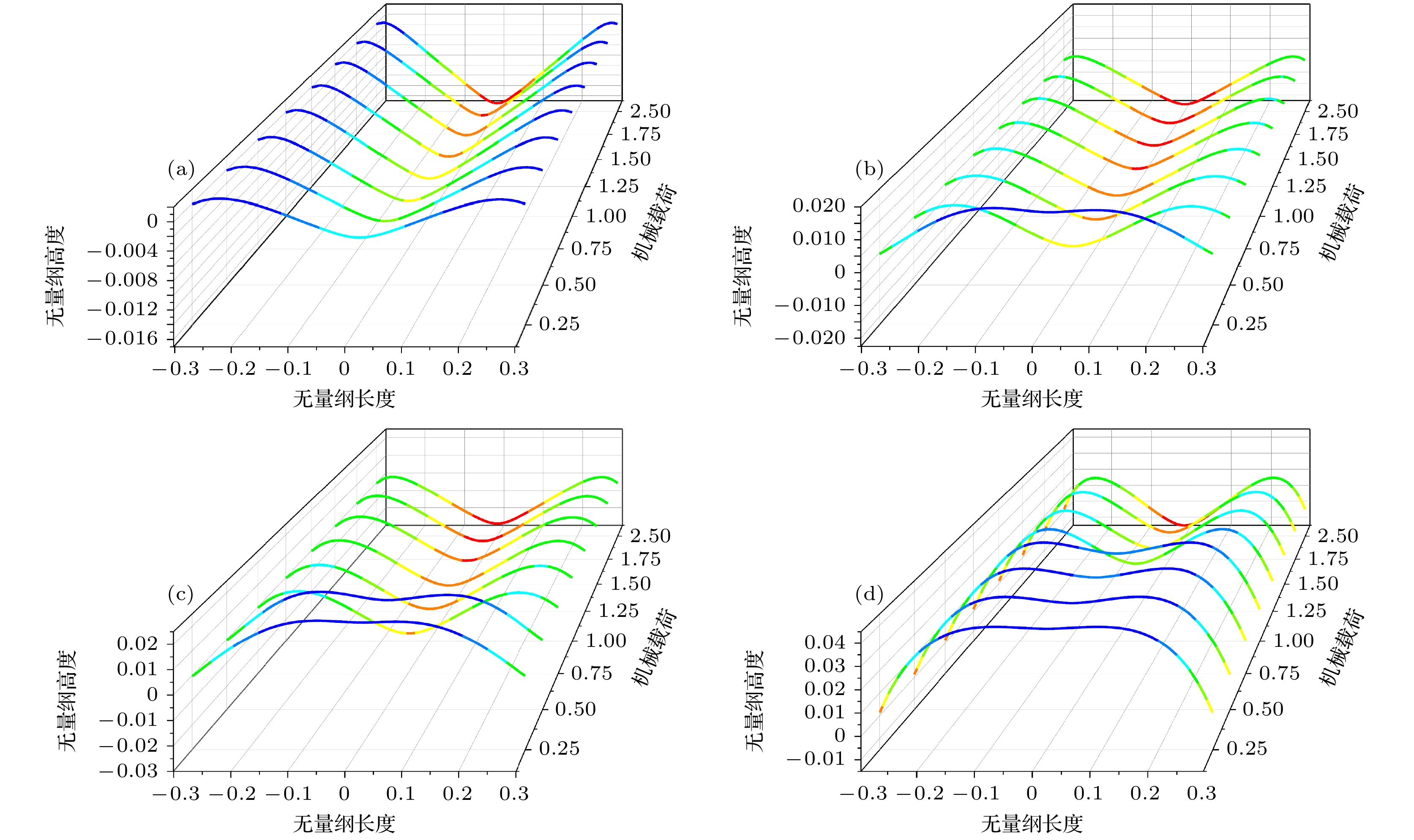

图 8 四种典型高跨比扇形截面石墨烯膜在不同机械载荷作用下, 最大挠度截面轮廓图 (a) λ = 2.5%; (b) λ = 5%; (c) λ = 10%; (d) λ = 20%

Fig. 8. Cross-sectional profiles of maximum dimensionless deflections for the fan-shaped cross-sections of graphene membranes with the four typical depth-span ratio under different mechanical force: (a) λ = 2.5%; (b) λ = 5%; (c) λ = 10%; (d) λ = 20%.

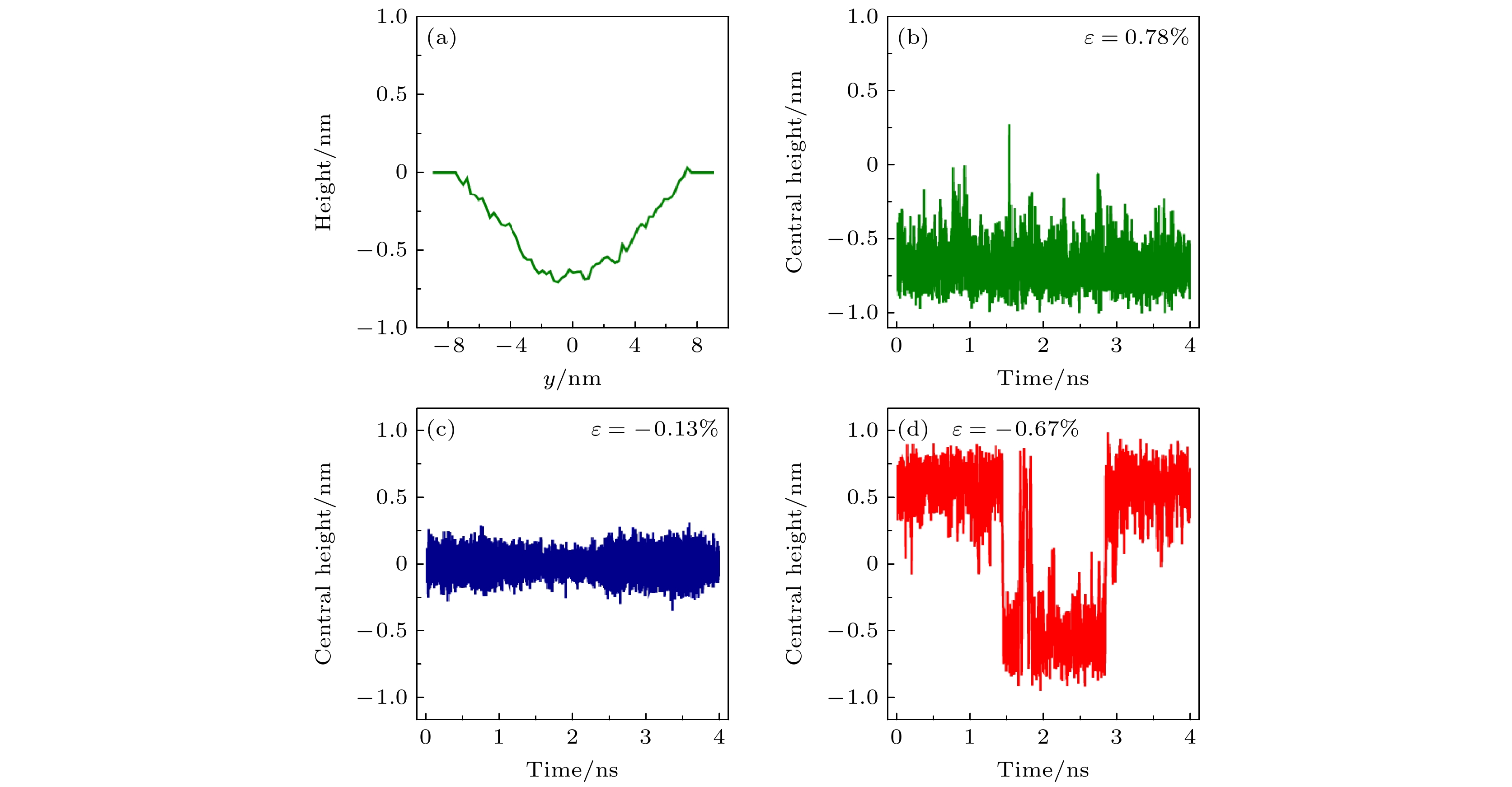

图 10 四种典型高跨比扇形截面石墨烯膜在不同温度载荷作用下, 最大挠度截面轮廓图 (a) λ = 2.5%; (b) λ = 5%; (c) λ = 10%; (d) λ = 20%

Fig. 10. Cross-sectional profiles of maximum dimensionless deflections for the fan-shaped cross-sections of graphene membranes with the four typical depth-span ratio at different temperature: (a) λ = 2.5%; (b) λ = 5%; (c) λ = 10%; (d) λ = 20%.

表 1 CGMD化模型力场参数

Table 1. Parameters of the CGMD model force field

原子间相互作用形式 物理参数 数值 键长 $ {D_0} $/(kcal·mol–1) 196.38 $ \alpha $/Å–1 1.55 $ {k_{\text{b}}} $/(kcal·mol–1·Å–2) 470 键角 $ {k_\theta } $/(kcal·mol–1·Å–2) 409.4 $ {\theta _0} $/(º) 120 二面角 $ {k_\phi } $/(kcal·mol–1) 4.15 非成键 $ {\varepsilon}_{\text{LJ}} $/(kcal·mol–1) 0.82 $ {\sigma _{{\text{LJ}}}} $/Å 3.46 表 2 高跨比及机械载荷和热载荷数据表

Table 2. Depth-span ratios and the magnitudes of mechanical and thermal loadings.

高跨比λ/% 机械载荷大小/(10–3 nN) 热载荷大小/K 1 2.5 –1.086 3 2 5 –2.171 50 3 7.5 –3.256 100 4 10 –4.341 150 5 20 –5.427 200 6 30 –6.512 250 7 — –7.599 300 8 — –10.86 350 9 — — 400 10 — — 450 11 — — 500 -

[1] Novoselov K S, Geim A K, Morozov S V, Jiang D, Zhang Y, Dubonos S V, Grigorieva I V, Firsov A A 2004 Science 306 666

Google Scholar

Google Scholar

[2] Lee C, Wei X, Kysar J W, Hone J 2008 Science 321 385

Google Scholar

Google Scholar

[3] Ma T, Li B, Chang T 2011 Appl. Phys. Lett. 99 201901

Google Scholar

Google Scholar

[4] Zhang Y, Pan C 2012 Diamond Relat. Mater. 24 1

Google Scholar

Google Scholar

[5] Galiotis C, Frank O, Koukaras E N, Sfyris D 2015 Annu. Rev. Chem. Biomol. 6 121

Google Scholar

Google Scholar

[6] 李亮亮, 孟凡伟, 邹鲲, 黄瑶, 彭倚天 2021 70 086801

Google Scholar

Google Scholar

Li L L, Meng F W, Zou K, Huang Y, Peng Y T 2021 Acta Phys. Sin. 70 086801

Google Scholar

Google Scholar

[7] Faugeras C, Faugeras B, Orlita M, Potemski M, Nair R R, Geim A K 2010 ACS Nano 4 1889

Google Scholar

Google Scholar

[8] Chen L, Kumar S 2012 J. Appl. Phys. 112 043502

Google Scholar

Google Scholar

[9] Nan H Y, Ni Z H, Wang J, Zafar Z, Shi Z X, Wang Y Y 2013 J. Raman Spectrosc. 44 1018

Google Scholar

Google Scholar

[10] Renteria J D, Nika D L, Balandin A A 2014 Appl. Sci. 4 525

Google Scholar

Google Scholar

[11] Graf D, Molitor F, Ensslin K, Stampfer C, Jungen A, Hierold C, Wirtz L 2007 Nano Lett. 7 238

Google Scholar

Google Scholar

[12] Ferrari A C, Meyer J C, Scardaci V, Casiraghi C, Lazzeri M, Mauri F, Piscanec S, Jiang D, Novoselov K S, Roth S, Geim A K 2006 Phys. Rev. Lett. 97 187401

Google Scholar

Google Scholar

[13] Zhang Y, Tan Y W, Stormer H L, Kim P 2005 Nature 438 201

Google Scholar

Google Scholar

[14] Bolotin K I, Sikes K J, Jiang Z, Klima M, Fudenberg G, Hone J, Kim P, Stormer H L 2008 Solid State Commun. 146 351

Google Scholar

Google Scholar

[15] Peres N M R 2009 Vacuum 83 1248

Google Scholar

Google Scholar

[16] Mogi M, Okamura Y, Kawamura M, Yoshimi R, Yasuda K, Tsukazaki A, Takahashi K S, Morimoto T, Nagaosa N, Kawasaki M, Takahashi Y, Tokura Y 2022 Nat. Phys. 18 390

Google Scholar

Google Scholar

[17] Xin N, Lourembam J, Kumaravadivel P, Kazantsev A E, Wu Z, Mullan C, Barrier J, Geim A A, Grigorieva I V, Mishchenko A, Principi A, Fal’ko V I, Ponomarenko L A, Geim A K, Berdyugin A I 2023 Nature 616 270

Google Scholar

Google Scholar

[18] López-Suárez M, Rurali R, Abadal G 2013 Microelectron. Eng. 111 122

Google Scholar

Google Scholar

[19] López-Suárez M, Rurali R, Gammaitoni L, Abadal G 2011 Phys. Rev. B 84 161401

Google Scholar

Google Scholar

[20] 廖天军, 杨智敏, 林比宏 2021 70 227901

Google Scholar

Google Scholar

Liao T J, Yang Z M, Lin B H 2021 Acta Phys. Sin. 70 227901

Google Scholar

Google Scholar

[21] 万震, 李成, 刘宇健, 宋学锋, 樊尚春 2022 71 126801

Google Scholar

Google Scholar

Wan Z, Li C, Liu Y J, Song X F, Fan S X 2022 Acta Phys. Sin. 71 126801

Google Scholar

Google Scholar

[22] Neek-Amal M, Xu P, Schoelz J K, Ackerman M L, Barber S D, Thibado P M, Sadeghi A, Peeters F M 2014 Nat. Commun. 5 4962

Google Scholar

Google Scholar

[23] Schoelz J K, Xu P, Meunier V, Kumar P, Neek-Amal M, Thibado P M, Peeters F M 2015 Phys. Rev. B 91 045413

Google Scholar

Google Scholar

[24] Ruiz-García M, Bonilla L L, Prados A 2016 Phys. Rev. B 94 205404

Google Scholar

Google Scholar

[25] Xu W, Kai Y, Zhang K, Zheng B 2022 Mater. Today Commun. 33 104230

Google Scholar

Google Scholar

[26] Lindahl N, Midtvedt D, Svensson J, Nerushev O A, Lindvall N, Isacsson A, Campbell E E 2012 Nano Lett. 12 3526

Google Scholar

Google Scholar

[27] Garaj S, Hubbard W, Reina A, Kong J, Branton D, Golovchenko J A 2010 Nature 467 190

Google Scholar

Google Scholar

[28] Chu Y, Ragab T, Basaran C 2014 Comput. Mater. Sci. 81 269

Google Scholar

Google Scholar

[29] Xu C, Xue T, Qiu W, Kang Y 2016 ACS Appl. Mater. Interfaces 8 27099

Google Scholar

Google Scholar

[30] Deng W, Li L, Hu Y, Wang X, Li X 2018 J. Therm. Stresses 41 1182

Google Scholar

Google Scholar

[31] Su R, Zhang X 2018 Appl. Therm. Eng. 144 488

Google Scholar

Google Scholar

[32] Ruiz L, Xia W, Meng Z, Keten S 2015 Carbon 82 103

Google Scholar

Google Scholar

[33] Li H, Zhang H, Cheng X 2017 Physica E 85 97

Google Scholar

Google Scholar

[34] Liu S, Duan K, Li L, Wang X, Hu Y 2021 Carbon 178 528

Google Scholar

Google Scholar

[35] Zhao Y, Zhao Y, Wu F, Zhao Y, Wang Y, Sui C, He X, Wang C, Tan H, Wang C 2021 Carbon 173 600

Google Scholar

Google Scholar

[36] Mangum J M, Harerimana F, Gikunda M N, Thibado P M 2021 Membranes 11 516

Google Scholar

Google Scholar

[37] Timoshenko S P 1936 Theory of Elastic Stability (New York: Dover Publication) pp320–324

[38] Wang W D, Shen C L, Li S, Min J J, Yi C L 2014 AIP Adv. 4 200207

Google Scholar

Google Scholar

[39] https://www.lammps.org/[2023-7-9

[40] https://www.ks.uiuc.edu/Research/vmd/ [2023-7-9

计量

- 文章访问数: 3185

- PDF下载量: 67

- 被引次数: 0

下载:

下载: