-

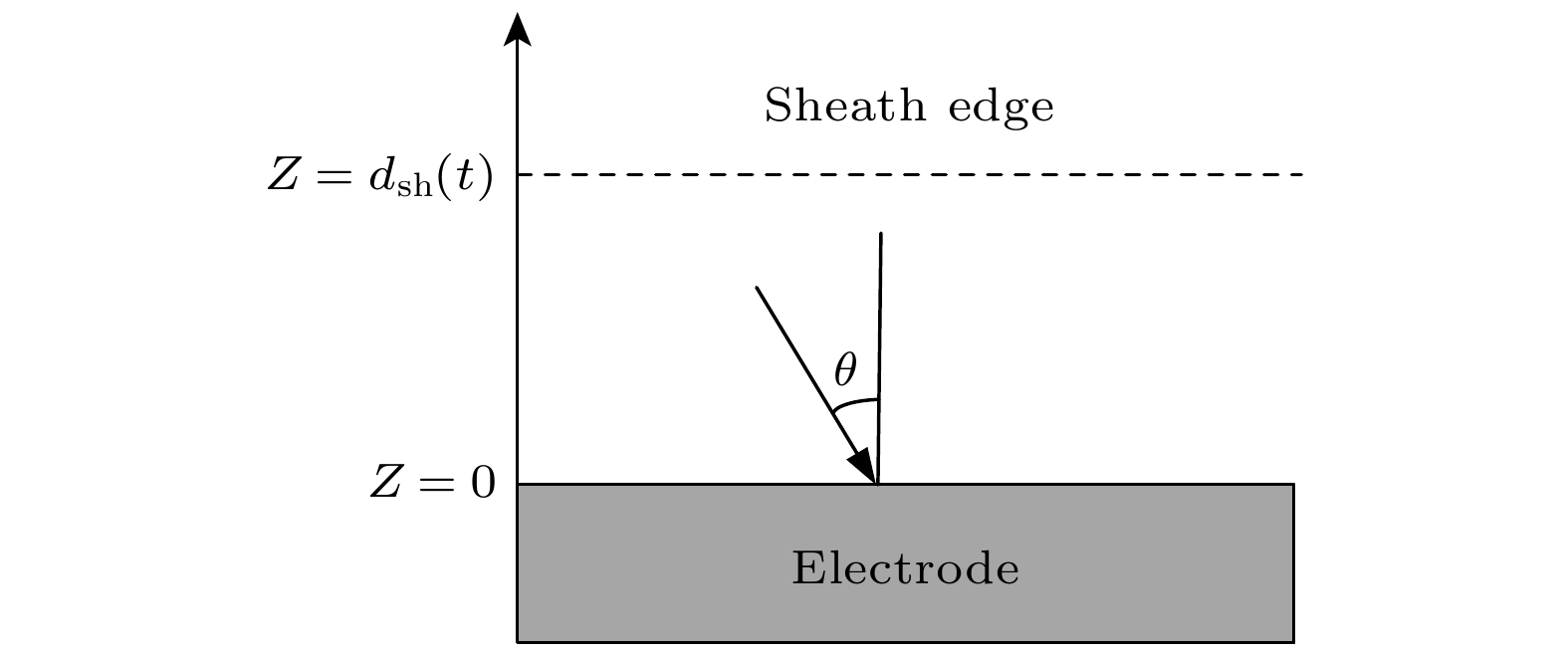

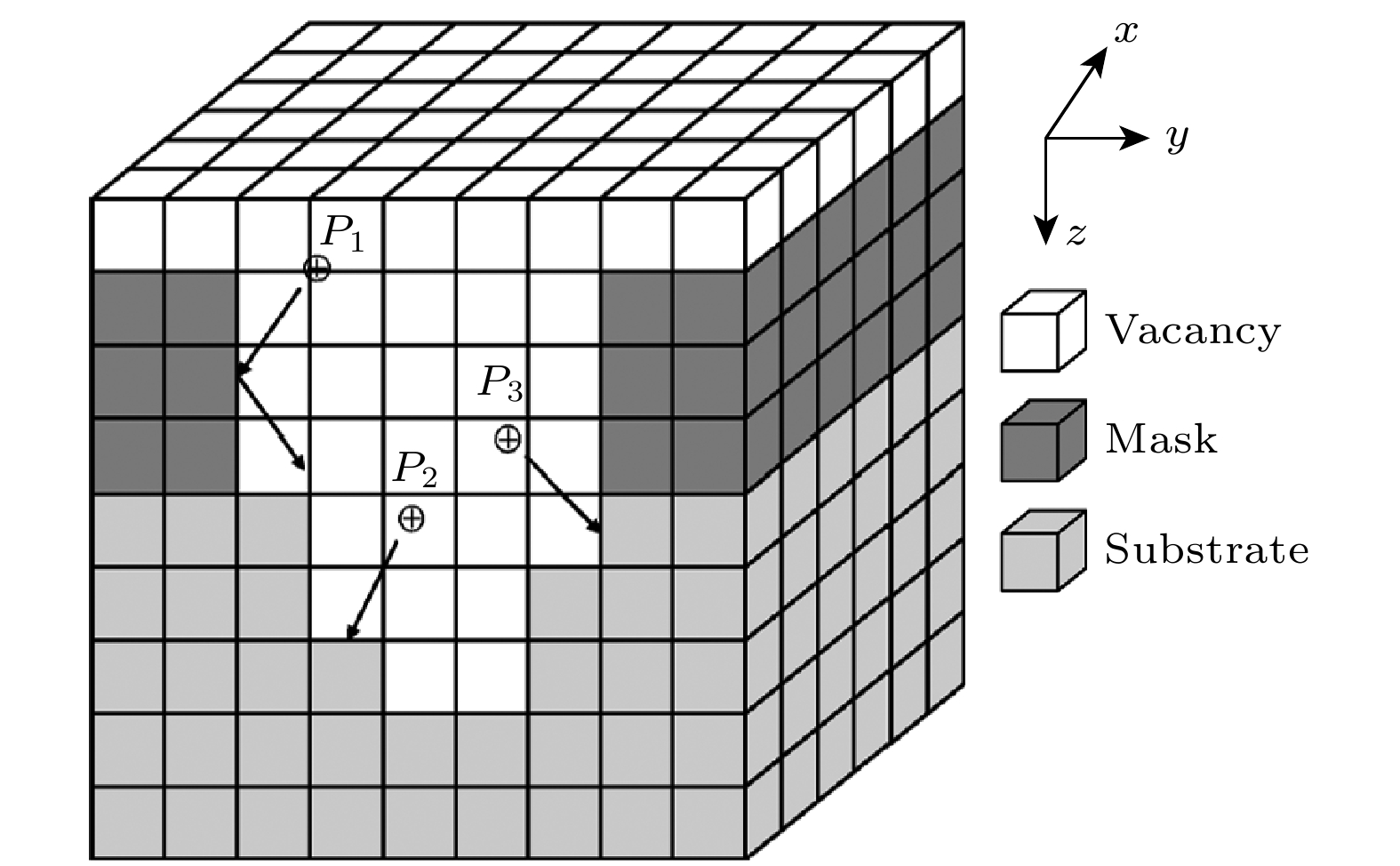

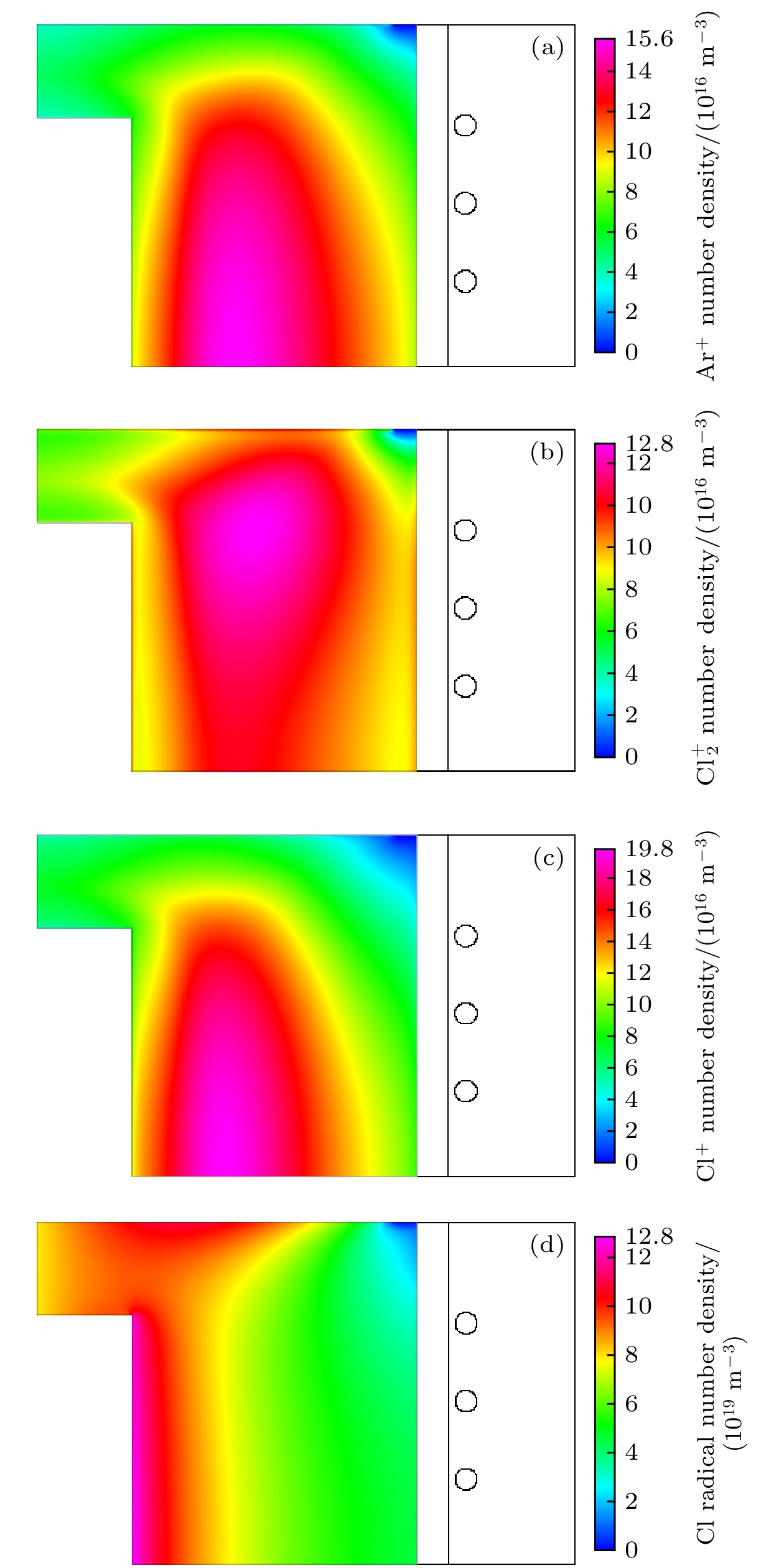

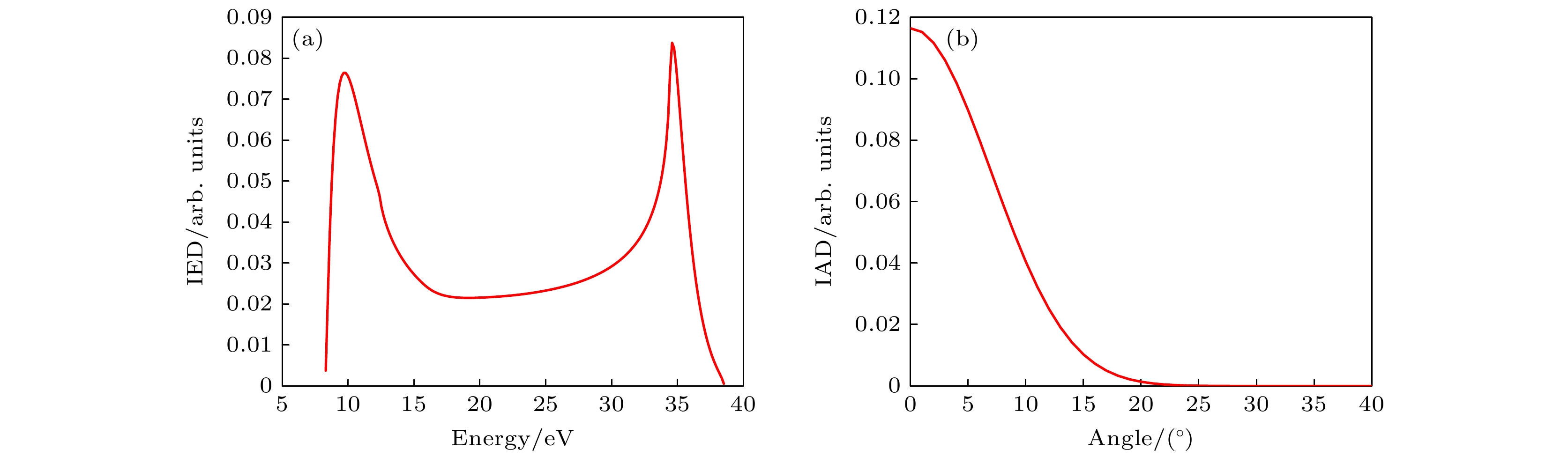

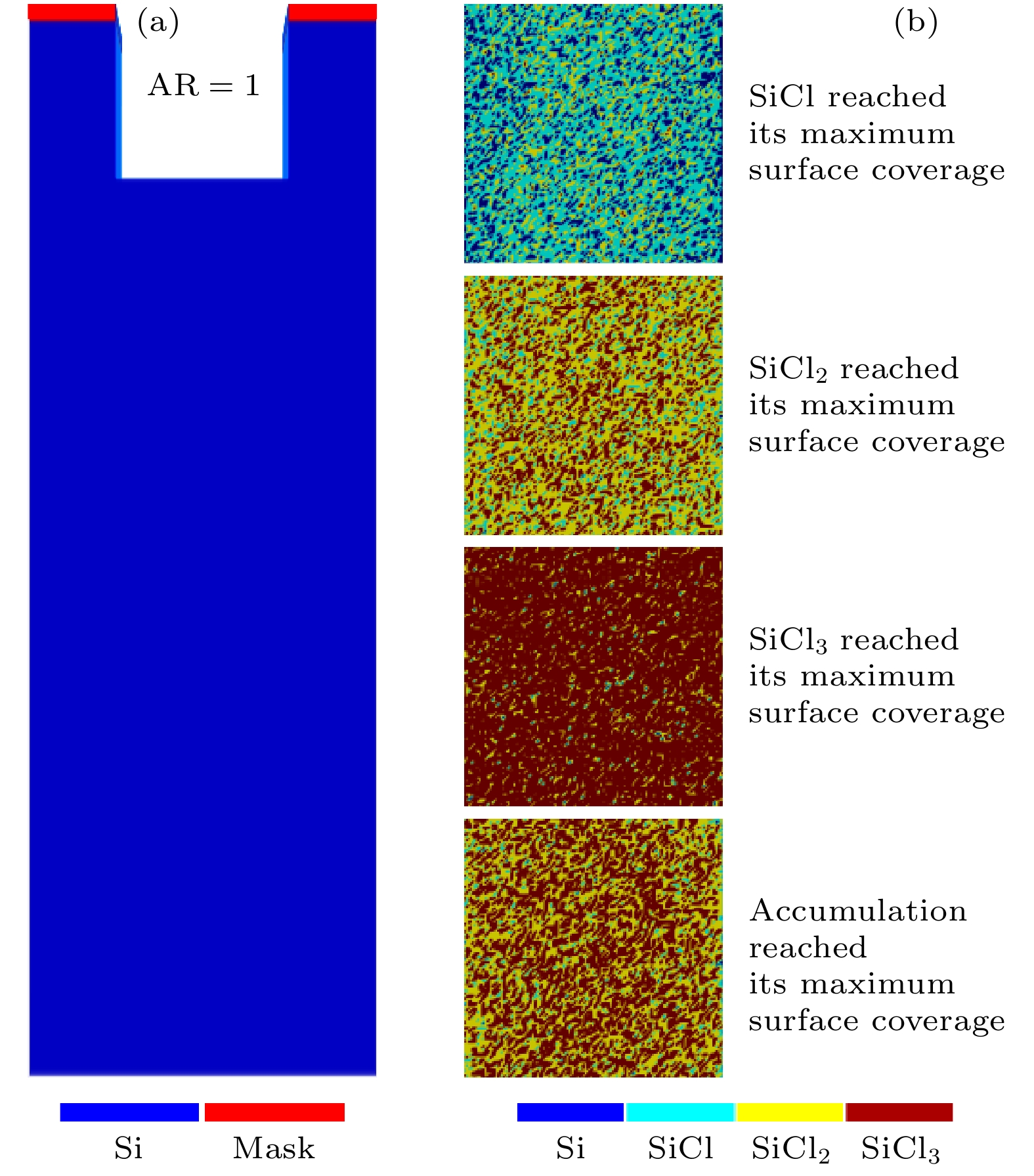

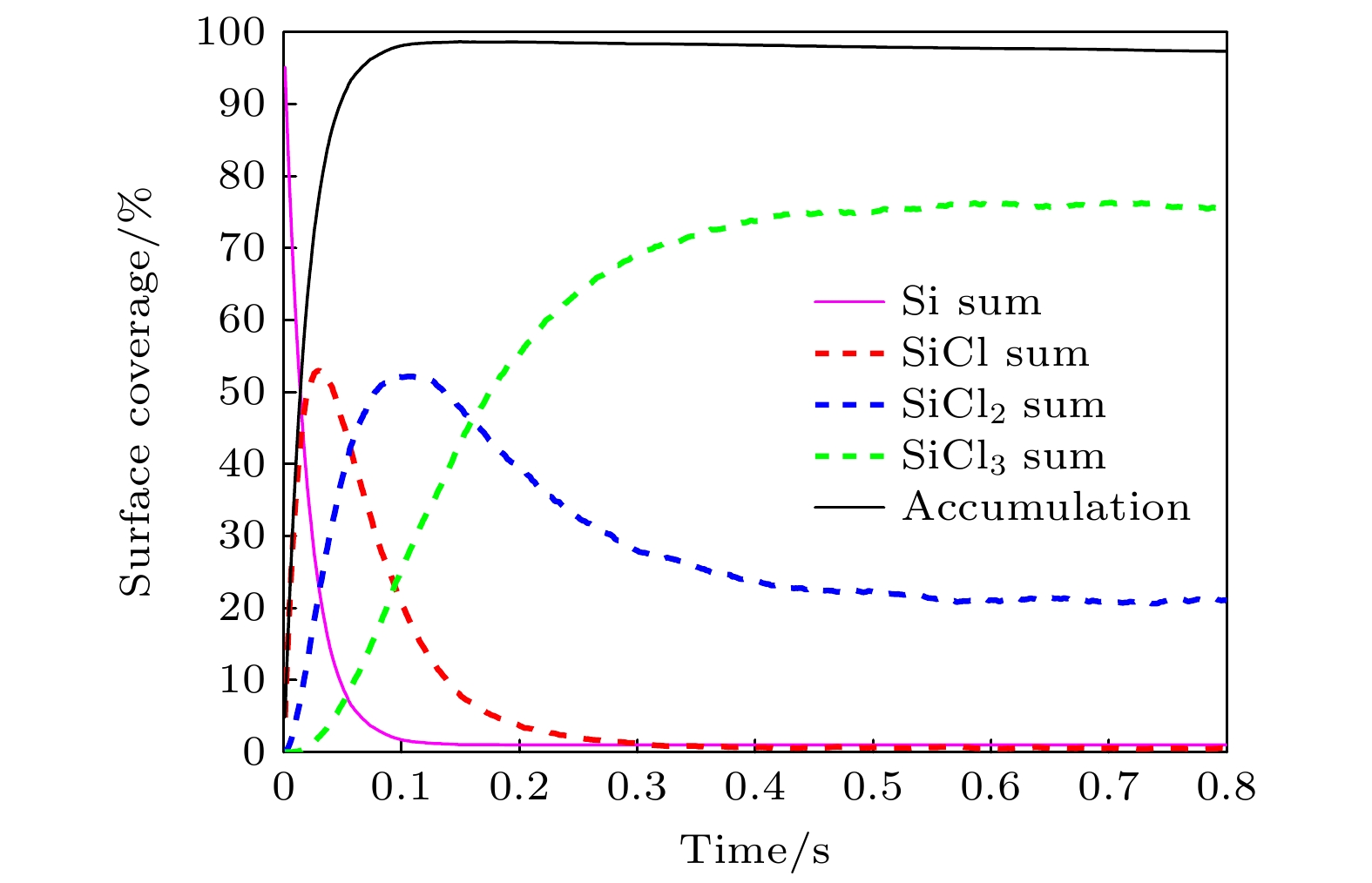

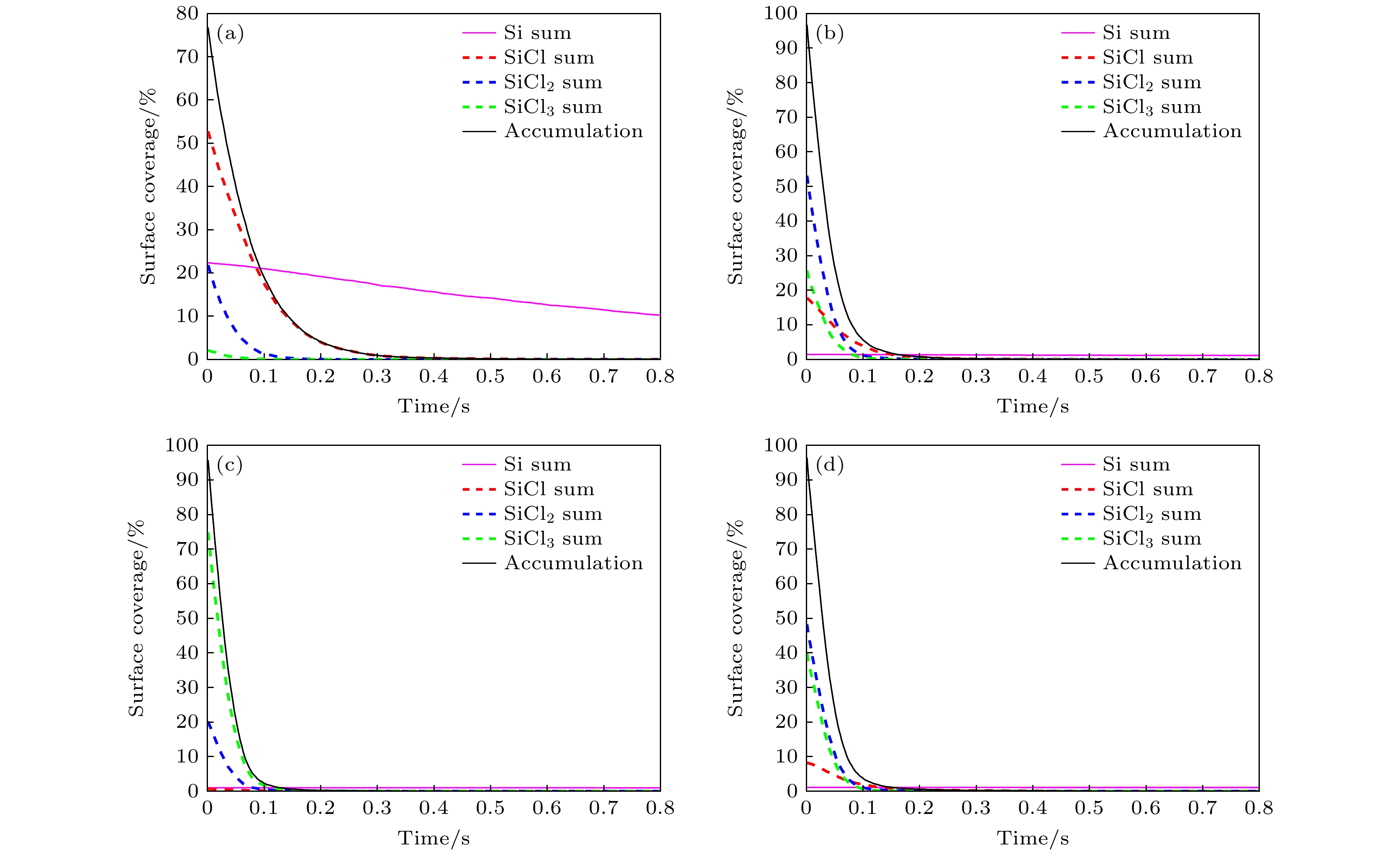

随着半导体器件的关键尺寸缩减至纳米尺度, 原子层刻蚀成为实现单原子分辨率的重要技术. 由于原子层刻蚀通过解耦钝化与刻蚀两个自限性反应流程来实现对刻蚀材料的单层去除, 存在刻蚀速率低的问题. 基于此, 本文通过耦合感性耦合等离子体放电腔室模型、鞘层模型和刻蚀槽模型, 研究了在Ar/Cl2气体和Ar感性耦合等离子体放电条件下, 硅的单次原子层刻蚀流程的最优时间, 并与传统固定时间的原子层刻蚀沟槽进行了对比, 还研究了不同深宽比下原子层刻蚀循环的时间变化规律. 结果表明, 当钝化过程为表面SiCl2的比例最高时, 单次原子层刻蚀循环的时间最短, 且表面质量较好, 多原子层刻蚀循环的刻蚀效率有较大提升; 此外, 随着深宽比的增加, 原子层刻蚀中的钝化和刻蚀时间随之增加, 理想条件下呈线性关系.With the shrink of critical dimensions of semiconductor devices to a few nanometers, atomic layer etching (ALE) has become an important technique to achieve single-atom resolution. The ALE can divide plasma etching into two self-limiting reaction processes: passivation process and etching process, allowing for the sequential removal of material atomic layer by layer. Therefore, it encounters the problem of low etch rate. In this work, the variation in surface substance coverage during the passivation process and the etching process are investigated numerically to optimize both the passivation duration and the etching duration. A coupled model integrating a two-dimensional inductively coupled plasma discharge chamber model, a one-dimensional sheath model, and a three-dimensional etching trench model is developed and used to investigate the optimal time for one single cycle ALE of silicon through the use of Ar/Cl2 gases under the condition of Ar inductively coupled plasma discharge. The results indicate that during the passivation stage, the surface coverage of SiCl and SiCl2 initially increase with time going by and then decrease, while the surface coverage of SiCl3 continuously increases, and eventually, the surface coverage of these three species stabilize. When the surface is predominantly covered by SiCl2, it is the optimal time to trigger the etching process, which induces a relatively favorable surface state and a relatively short etching time. Comparing with typical ALE etching techniques, the time of our optimal ALE single cycle is shortened by about 33.89%. The ALE cycle time (etching rate) exhibits a linear relationship with the aspect ratio. Additionally, the duration of the passivation process and etching process increase linearly with the aspect ratio or etch depth increasing. Moreover, as the etch depth increases, the effect of the passivation process on the ALE rate becomes more significant than that of the etching process.

-

Keywords:

- atomic layer etching /

- passivation and etching time /

- the component of passivated layer /

- aspect ratio

[1] Jung J, Kim K 2023 Materials 16 3611

Google Scholar

Google Scholar

[2] Hao Q, Kim P, Nam S K, Kang S Y, Donnelly V M 2023 J. Vac. Sci. Technol., A 41 032605

Google Scholar

Google Scholar

[3] Eliceiri M, Rho Y, Li R, Grigoropoulos C P 2023 J. Vac. Sci. Technol., A 41 022602

Google Scholar

Google Scholar

[4] Ma X, Zhang S, Dai Z, Wang Y 2017 Plasma Sci. Technol. 19 085502

Google Scholar

Google Scholar

[5] Huard C M, Zhang Y, Sriraman S, Paterson A, Kanarik K J, Kushner M J 2017 J. Vac. Sci. Technol., A 35 031306

Google Scholar

Google Scholar

[6] Horiike Y, Tanaka T, Nakano M, Iseda S, Sakaue H, Nagata A, Shindo H, Miyazaki S, Hirose M 1990 J. Vac. Sci. Technol. , A 8 1844

Google Scholar

Google Scholar

[7] Matsuura T, Murota J, Sawada Y, Ohmi T 1993 Appl. Phys. Lett. 63 2803

Google Scholar

Google Scholar

[8] Imai S, Haga T, Matsuzaki O, Hattori T, Matsumura M 1995 Jpn. J. Appl. Phys., Part 1 34 5049

Google Scholar

Google Scholar

[9] Kim J K, Cho S I, Lee S H, Kim C K, Min K S, Kang S H, Yeom G Y 2013 J. Vac. Sci. Technol., A 31 061310

Google Scholar

Google Scholar

[10] Song E J, Kim J H, Kwon J D, Kwon S H, Ahn J H 2018 Jpn. J. Appl. Phys. 57 106505

Google Scholar

Google Scholar

[11] Goodyear A, Cooke M 2017 J. Vac. Sci. Technol., A 35 01A105

Google Scholar

Google Scholar

[12] Yoon M Y, Yeom H J, Kim J H, Chegal W, Cho Y J, Kwon D C, Jeong J R, Lee H C 2021 Phys. Plasmas 28 063504

Google Scholar

Google Scholar

[13] Nakamura S, Tanide A, Kimura T, Nadahara S, Ishikawa K, Oda O, Hori M 2023 J. Appl. Phys. 133 043302

Google Scholar

Google Scholar

[14] Ranjan A, Wang M, Sherpa S D, Rastogi V, Koshiishi A, Ventzek P L G 2016 J. Vac. Sci. Technol., A 34 031304

Google Scholar

Google Scholar

[15] Agarwal A, Kushner M J 2009 J. Vac. Sci. Technol., A 27 37

Google Scholar

Google Scholar

[16] Huard C M, Lanham S J, Kushner M J 2018 J. Phys. D: Appl. Phys. 51 155201

Google Scholar

Google Scholar

[17] 贺平逆, 宁建平, 秦尤敏, 赵成利, 苟富均 2011 60 045209

Google Scholar

Google Scholar

He P N, Ning J P, Qin Y M, Zhao C L, Gou F J 2011 Acta Phys. 60 045209

Google Scholar

Google Scholar

[18] Vella J R, Humbird D, Graves D B 2022 J. Vac. Sci. Technol., B 40 023205

Google Scholar

Google Scholar

[19] Sui J, Zhang S, Liu Z, Yan J, Dai Z 2016 Plasma Sci. Technol. 18 666

Google Scholar

Google Scholar

[20] 葛婕 2014 硕士学位论文 (北京: 清华大学)

Ge J 2014 M. S. Thesis (Beijing: Tsinghua University

[21] Brezmes A O, Breitkopf C 2015 Vacuum 116 65

Google Scholar

Google Scholar

[22] Liu Z L, Jing X B, Yao K L 2005 J. Phys. D: Appl. Phys. 38 1899

Google Scholar

Google Scholar

[23] 杨宏军, 宋亦旭, 郑树琳, 贾培发 2013 62 208201

Google Scholar

Google Scholar

Yang H J, Song Y X, Zheng S L, Jia P F 2013 Acta Phys. Sin. 62 208201

Google Scholar

Google Scholar

[24] 高扬福, 宋亦旭, 孙晓民 2014 63 048201

Google Scholar

Google Scholar

Gao Y F, Song Y X, Sun X M 2014 Acta Phys. Sin. 63 048201

Google Scholar

Google Scholar

[25] 郑树琳, 宋亦旭, 孙晓民 2013 62 108201

Google Scholar

Google Scholar

Zheng S L, Song Y X, Sun X M 2013 Acta Phys. Sin. 62 108201

Google Scholar

Google Scholar

[26] Huard C M, Zhang Y, Sriraman S, Paterson A, Kushner M J 2017 J. Vac. Sci. Technol. , A 35 05C301

Google Scholar

Google Scholar

[27] Han J, Pribyl P, Gekelman W, Paterson A, Lanham S J, Qu C, Kushner M J 2019 Phys. Plasmas 26 103503

Google Scholar

Google Scholar

[28] Kushner M J 2009 J. Phys. D: Appl. Phys. 42 194013

Google Scholar

Google Scholar

-

图 11 AR为1状态下, 不同条件下启动刻蚀后的表面物质占比随时间的变化曲线 (a) SiCl最多时启动; (b) SiCl2最多时启动; (c) SiCl3最多时启动; (d) 钝化物总和最多时启动

Fig. 11. Time evolution of surface composition during etching initiation under different conditions with AR of 1: (a) Initiation with maximum SiCl percentage; (b) initiation with maximum SiCl2 percentage; (c) initiation with maximum SiCl3 percentage; (d) initiation with maximum accumulated passivation species percentage.

表 1 Si原子层刻蚀多尺度仿真模型对比

Table 1. Summary of Si ALE multi-scale simulation.

ICP

计算模型IEADs

计算模型ALE刻蚀

计算模型研究目标 重点指标 国外 Huard等[5,16] 采用HPEM(2D), 主要包括电磁模块、电子蒙特卡罗模块、流体动力学模块和辐射传输模块 PCMCM

(1D)粒子网格算法元胞法耦合蒙特卡罗法(3D) 统计表面物质占比; 计算ALE协同率和每循环刻蚀深度 非理想的通量和IEADs对ALE的影响; 离子分布不均匀性对ALE的影响 Agarwal和Kushner[15] 元胞法耦合蒙特卡罗法(2D) 分析二维刻蚀剖面形貌 传统的等离子体刻蚀设备即非理想的离子通量对ALE形貌的影响 国内 Ma等[4] 采用商业求解器CFD-ACE+耦合了流体、传热、化学、等离子体和电磁场, 通过有限元方法求解 1D流体模型、蒙特卡罗法 元胞法耦合蒙特卡罗法(2D) 对比IEADs和刻蚀样貌 定制偏压波形对IEADs和刻蚀槽轮廓的影响 本文 元胞法耦合蒙特卡罗法(3D) 统计表面物质占比 ALE最优的钝化和刻蚀时间以及该最优时间随AR的变化规律 表 2 钝化过程和刻蚀过程中离子和中性基的通量

Table 2. Ion and neutral fluxes during passivation and etching processes.

Ion Flux/(1020 ${{\text{m}}^{ - 2}}{\cdot}{{\text{s}}^{ - 1}}$) Passivation Ar+ 1.762 ${\text{Cl}}_2^ + $ 1.614 Cl+ 1.890 Cl Radical 69.210 Etching Ar+ 21.710 表 3 AR为1状态下, 刻蚀启动条件不同时完成ALE单循环所需时间以及Si残留占比

Table 3. Time required for completing a single ALE cycle and Si residual ratio under different etching initiation conditions with AR of 1.

Etching initiation

condition (the

largest percentage)SiCl SiCl2 SiCl3 Accumluation Passivation time/s 0.030 0.106 0.550 0.148 Etching time/s 0.296 0.182 0.128 0.155 Total time/s 0.326 0.288 0.678 0.303 Si residual

percent/%17.34 1.35 1.00 1.09 表 4 ALE刻蚀相同深度的沟槽时间对比

Table 4. Comparison of ALE time for trenches with the same depth.

Total passivation time/s Total etching time/s Number

of ALE

cyclesTotal

ALE

time/sThis paper 2.388 24.520 100 26.908 Ranjan

et al.[14]2.200 38.500 55 40.700 表 5 AR与原子层刻蚀时间线性拟合的均方根误差(root mean square error, RMSE)和决定系数

Table 5. Root mean square error (RMSE) and coefficient of determination for linear fitting of AR with atomic layer etching time.

Time Passivation time Etching time Total time RMSE 0.018079 0.0052829 0.019098 R2 0.99271 0.99007 0.99478 -

[1] Jung J, Kim K 2023 Materials 16 3611

Google Scholar

Google Scholar

[2] Hao Q, Kim P, Nam S K, Kang S Y, Donnelly V M 2023 J. Vac. Sci. Technol., A 41 032605

Google Scholar

Google Scholar

[3] Eliceiri M, Rho Y, Li R, Grigoropoulos C P 2023 J. Vac. Sci. Technol., A 41 022602

Google Scholar

Google Scholar

[4] Ma X, Zhang S, Dai Z, Wang Y 2017 Plasma Sci. Technol. 19 085502

Google Scholar

Google Scholar

[5] Huard C M, Zhang Y, Sriraman S, Paterson A, Kanarik K J, Kushner M J 2017 J. Vac. Sci. Technol., A 35 031306

Google Scholar

Google Scholar

[6] Horiike Y, Tanaka T, Nakano M, Iseda S, Sakaue H, Nagata A, Shindo H, Miyazaki S, Hirose M 1990 J. Vac. Sci. Technol. , A 8 1844

Google Scholar

Google Scholar

[7] Matsuura T, Murota J, Sawada Y, Ohmi T 1993 Appl. Phys. Lett. 63 2803

Google Scholar

Google Scholar

[8] Imai S, Haga T, Matsuzaki O, Hattori T, Matsumura M 1995 Jpn. J. Appl. Phys., Part 1 34 5049

Google Scholar

Google Scholar

[9] Kim J K, Cho S I, Lee S H, Kim C K, Min K S, Kang S H, Yeom G Y 2013 J. Vac. Sci. Technol., A 31 061310

Google Scholar

Google Scholar

[10] Song E J, Kim J H, Kwon J D, Kwon S H, Ahn J H 2018 Jpn. J. Appl. Phys. 57 106505

Google Scholar

Google Scholar

[11] Goodyear A, Cooke M 2017 J. Vac. Sci. Technol., A 35 01A105

Google Scholar

Google Scholar

[12] Yoon M Y, Yeom H J, Kim J H, Chegal W, Cho Y J, Kwon D C, Jeong J R, Lee H C 2021 Phys. Plasmas 28 063504

Google Scholar

Google Scholar

[13] Nakamura S, Tanide A, Kimura T, Nadahara S, Ishikawa K, Oda O, Hori M 2023 J. Appl. Phys. 133 043302

Google Scholar

Google Scholar

[14] Ranjan A, Wang M, Sherpa S D, Rastogi V, Koshiishi A, Ventzek P L G 2016 J. Vac. Sci. Technol., A 34 031304

Google Scholar

Google Scholar

[15] Agarwal A, Kushner M J 2009 J. Vac. Sci. Technol., A 27 37

Google Scholar

Google Scholar

[16] Huard C M, Lanham S J, Kushner M J 2018 J. Phys. D: Appl. Phys. 51 155201

Google Scholar

Google Scholar

[17] 贺平逆, 宁建平, 秦尤敏, 赵成利, 苟富均 2011 60 045209

Google Scholar

Google Scholar

He P N, Ning J P, Qin Y M, Zhao C L, Gou F J 2011 Acta Phys. 60 045209

Google Scholar

Google Scholar

[18] Vella J R, Humbird D, Graves D B 2022 J. Vac. Sci. Technol., B 40 023205

Google Scholar

Google Scholar

[19] Sui J, Zhang S, Liu Z, Yan J, Dai Z 2016 Plasma Sci. Technol. 18 666

Google Scholar

Google Scholar

[20] 葛婕 2014 硕士学位论文 (北京: 清华大学)

Ge J 2014 M. S. Thesis (Beijing: Tsinghua University

[21] Brezmes A O, Breitkopf C 2015 Vacuum 116 65

Google Scholar

Google Scholar

[22] Liu Z L, Jing X B, Yao K L 2005 J. Phys. D: Appl. Phys. 38 1899

Google Scholar

Google Scholar

[23] 杨宏军, 宋亦旭, 郑树琳, 贾培发 2013 62 208201

Google Scholar

Google Scholar

Yang H J, Song Y X, Zheng S L, Jia P F 2013 Acta Phys. Sin. 62 208201

Google Scholar

Google Scholar

[24] 高扬福, 宋亦旭, 孙晓民 2014 63 048201

Google Scholar

Google Scholar

Gao Y F, Song Y X, Sun X M 2014 Acta Phys. Sin. 63 048201

Google Scholar

Google Scholar

[25] 郑树琳, 宋亦旭, 孙晓民 2013 62 108201

Google Scholar

Google Scholar

Zheng S L, Song Y X, Sun X M 2013 Acta Phys. Sin. 62 108201

Google Scholar

Google Scholar

[26] Huard C M, Zhang Y, Sriraman S, Paterson A, Kushner M J 2017 J. Vac. Sci. Technol. , A 35 05C301

Google Scholar

Google Scholar

[27] Han J, Pribyl P, Gekelman W, Paterson A, Lanham S J, Qu C, Kushner M J 2019 Phys. Plasmas 26 103503

Google Scholar

Google Scholar

[28] Kushner M J 2009 J. Phys. D: Appl. Phys. 42 194013

Google Scholar

Google Scholar

计量

- 文章访问数: 6343

- PDF下载量: 179

- 被引次数: 0

下载:

下载: