-

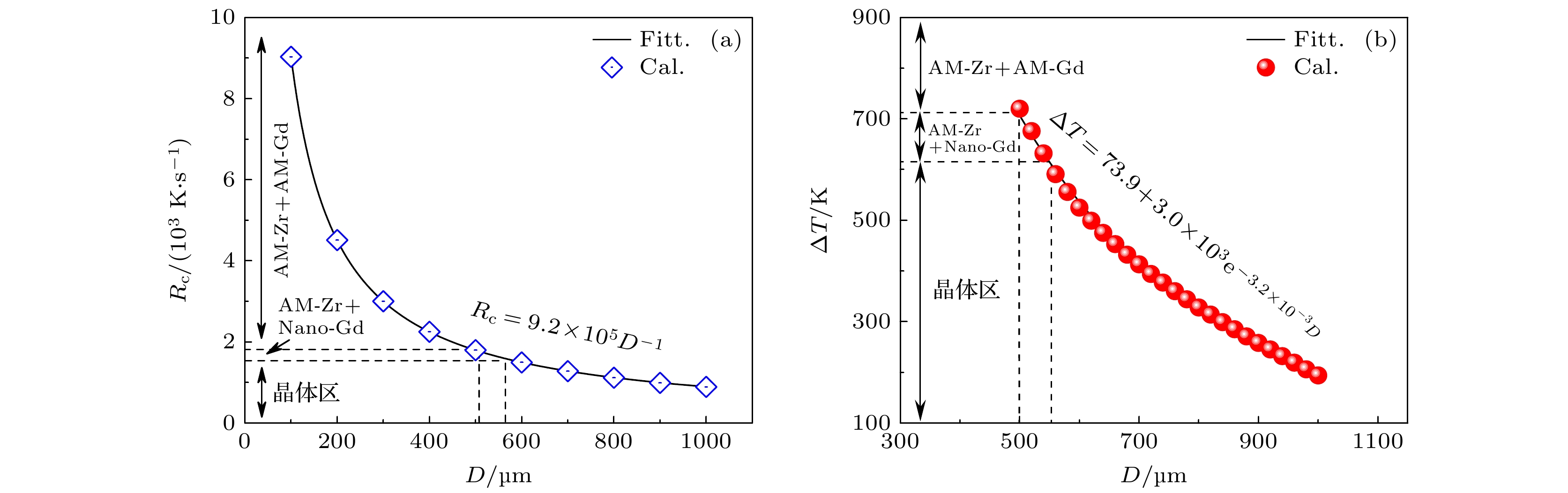

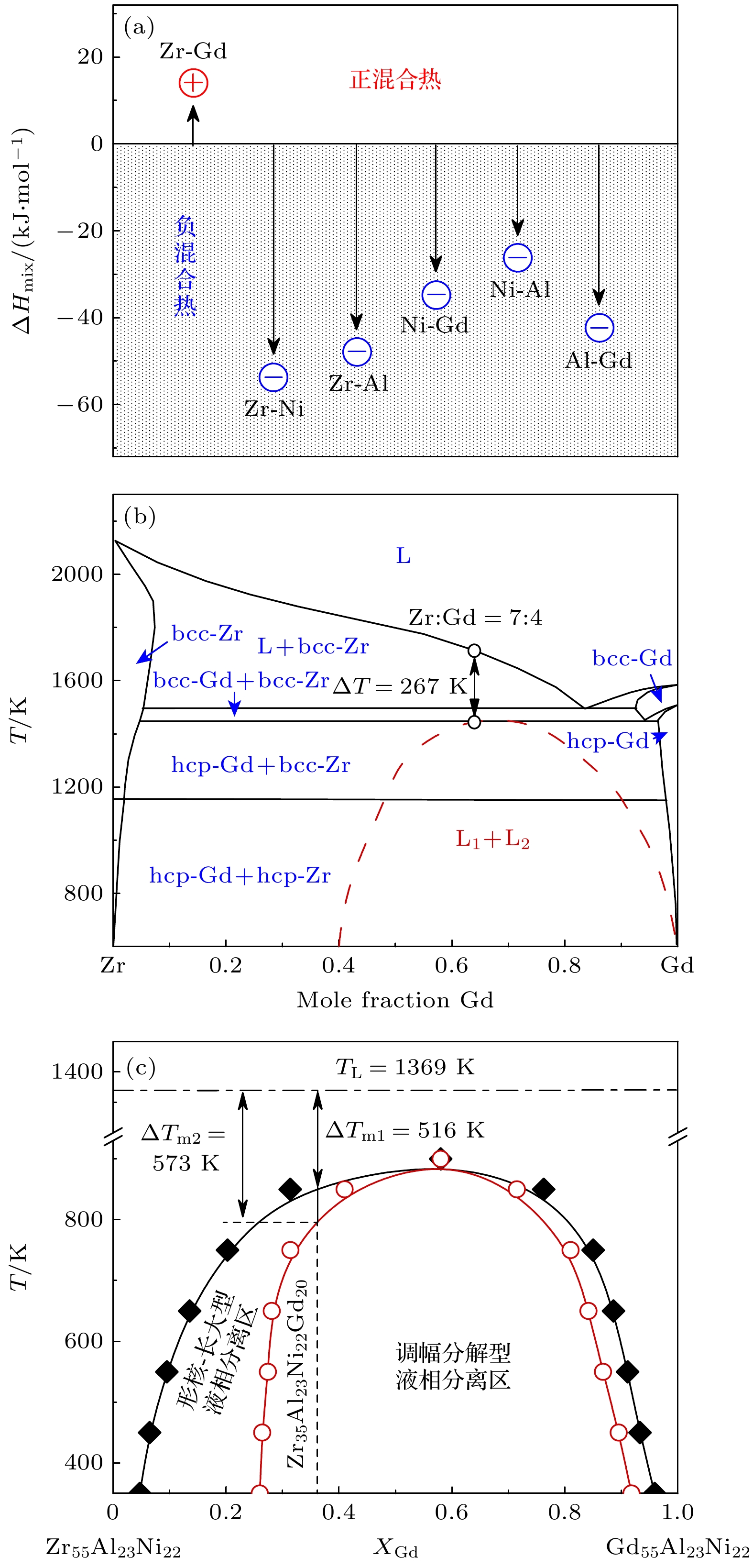

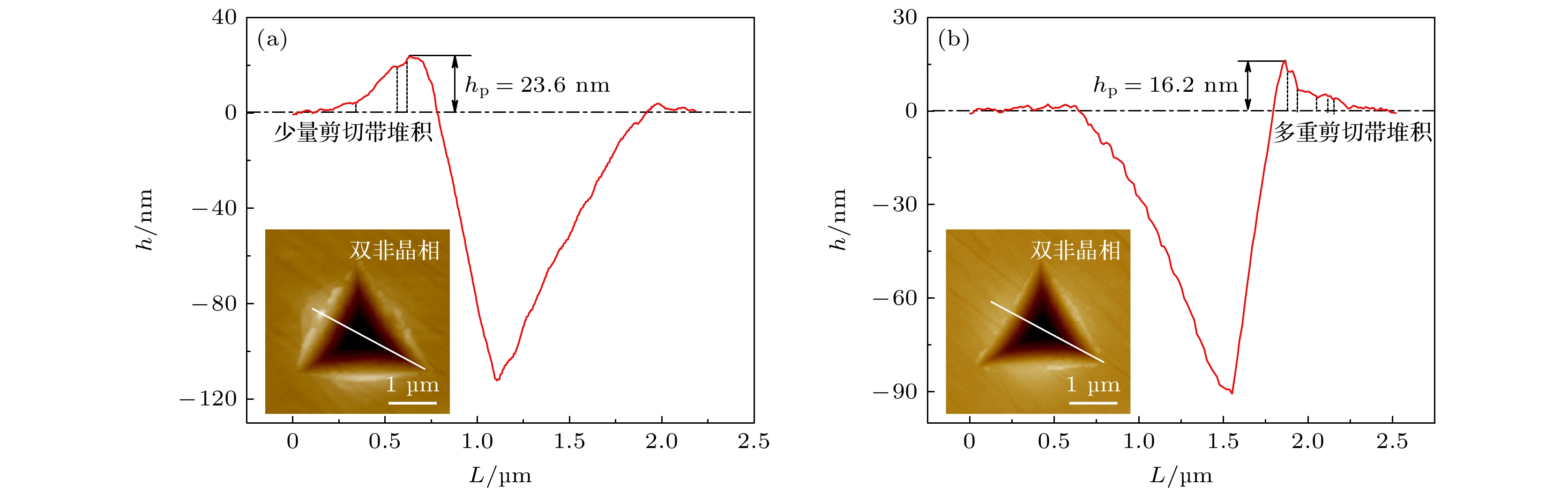

研究了液态Zr35Al23Ni22Gd20合金在深过冷快速凝固条件下的亚稳相分离和双非晶相形成机理. 实验发现, 在平衡条件下其凝固组织由3种晶体相构成, 诱发亚稳相分离的临界过冷度约为516 K (0.37TL). 当过冷度达到624 K (0.45TL)时, 分离后的富Zr液相发生非晶转变, 形成非晶AM-Zr相; 当过冷度进一步增大到714 K(0.52TL)时, 富Gd液相发生非晶转变形成非晶AM-Gd相. 同时, 过冷度和冷却速率的增大导致亚稳相分离机制由形核长大型转变为调幅分解型, 双非晶相的组织形貌由球状向网状转变. 双相非晶合金的平均硬度和杨氏模量由自由体积、相体积分数和双非晶相结构共同支配, 呈现出先减小后增大的变化规律. 双非晶相的形成有利于合金应力加载过程中的能量耗散, 促进了多重剪切带的产生, 提高了非晶合金的塑性.Duplex metallic glass with two amorphous phases has been extensively investigated for desirable strength and plasticity. In this paper, the metastable phase separation and dual amorphous phase formation of liquid Zr35Al23Ni22Gd20 alloy under substantial undercooling condition and rapid cooling condition are studied by drop tube technology. The equilibrium solidification structure consists of three crystalline phases, while the critical undercooling temperature of metastable phase separation is determined to be 516 K (0.37TL). The separated Zr-rich liquid phase undergoes amorphous transition and becomes amorphous AM-Zr phase with the composition of Zr45Ni23Al23Gd9 when alloy undercooling is increased to 624 K (0.45TL). After that, the Gd-rich liquid phase forms amorphous AM-Gd phase with the composition of Gd39Al22Ni20Zr19 at larger undercooling of 714 K (0.52TL). With the increase of liquid undercooling and cooling rate, the kinetic mechanism of metastable phase separation changes from nucleation and growth type to spinodal decomposition type, and consequently the microstructure of dual amorphous phases transforms from a spherical morphology to a reticular structure. The average hardness and Young’s modulus, which are influenced by free volume, phase volume fraction and structure of dual amorphous phases, exhibit a complex variation of first increasing and then decreasing with the decrease of alloy droplet size. The formation of dual amorphous phases is in favor of the energy dissipation and the generation of multiple shear bands during mechanical compression, which improves the plasticity for this kind of amorphous alloy.

-

Keywords:

- liquid undercooling /

- rapid solidification /

- metastable phase separation /

- duplex amorphous alloy

[1] Johnson W L, Samwer K 2005 Phys. Rev. Lett. 95 195501

Google Scholar

Google Scholar

[2] Schroers J 2013 Phys. Today 66 32

Google Scholar

Google Scholar

[3] Wisitsorasak A, Wolynes P G 2012 Proc. Natl. Acad. Sci. U. S. A. 109 16068

Google Scholar

Google Scholar

[4] Li H Q, Tao K X, Fan C, Liaw P K, Choo H 2006 Appl. Phys. Lett. 89 041921

Google Scholar

Google Scholar

[5] Xing L Q, Li Y, Ramesh K T, Li J, Hufnagel T C 2001 Phys. Rev. B. 64 180201

Google Scholar

Google Scholar

[6] Liu Y H, Wang G, Wang R J, Zhao D Q, Pan M X, Wang W H 2007 Science 315 1385

Google Scholar

Google Scholar

[7] Zong H T, Ma M Z, Zhang X Y, Qi L, Li G, Jing Q, Liu R P 2011 Chin. Phys. Lett. 28 036103

Google Scholar

Google Scholar

[8] Kim D H, Kim W T, Park E S, Mattern N, Eckert J 2013 Prog. Mater Sci. 58 1103

Google Scholar

Google Scholar

[9] Chen HS, Turnbull D 1969 Acta Metall. Mater. 17 1021

Google Scholar

Google Scholar

[10] Kündig AA, Ohnuma M, Ping D H, Ohkubo T, Hono K 2004 Acta Mater. 52 2441

Google Scholar

Google Scholar

[11] Du X H , Huang J C, Hsieh K C, Lai Y H, Chen H M, Jang J S C, Liaw P K 2007 Appl. Phys. Lett. 91 131901

Google Scholar

Google Scholar

[12] Baumer R E, Demkowicz M J 2013 Phys. Rev. Lett. 110 145502

Google Scholar

Google Scholar

[13] Banerjee R, Puthucode A, Bose S, Ayyub P 2007 Appl. Phys. Lett. 90 021904

Google Scholar

Google Scholar

[14] Chang H J, Yook W, Park E S, Kyeong J S, Kim D H 2010 Acta Mater. 58 2483

Google Scholar

Google Scholar

[15] Park B J, Chang H J, Kim D H, et al. 2006 Phys. Rev. Lett. 96 245503

Google Scholar

Google Scholar

[16] 沙莎, 王伟丽, 吴宇昊, 魏炳波 2018 67 046402

Google Scholar

Google Scholar

Sha S, Wang W L, Wu Y H, Wei B B 2018 Acta Phys. Sin. 67 046402

Google Scholar

Google Scholar

[17] Ruan Y, Wang Q Q, Chang S Y, Wei B 2017 Acta Mater. 141 456

Google Scholar

Google Scholar

[18] Luo B C, Liu X R, Wei B 2009 J. Appl. Phys. 106 053523

Google Scholar

Google Scholar

[19] 徐山森, 常健, 吴宇昊, 沙莎, 魏炳波 2019 68 196401

Google Scholar

Google Scholar

Xu S S, Chang J, Wu Y H, Sha S, Wei B B 2019 Acta Phys. Sin. 68 196401

Google Scholar

Google Scholar

[20] Levi C G, Mehrabian R 1982 Metall. Trans. A 13 221

Google Scholar

Google Scholar

[21] 陈克萍, 吕鹏, 王海鹏 2017 66 068101

Google Scholar

Google Scholar

Chen K P, Lü P, Wang H P 2017 Acta Phys. Sin. 66 068101

Google Scholar

Google Scholar

[22] Sohn S W, Yook W, Kim W T, Kim D H 2012 Intermetallics 23 57

Google Scholar

Google Scholar

[23] Bo H, Liu L B, Hu J L, et al. 2014 Thermochim. Acta 591 51

Google Scholar

Google Scholar

[24] Fischer E, Colinet C 2015 J. Phase Equilib. Diffus. 36 5

Google Scholar

Google Scholar

[25] Mattern N, Han J H, Zinkevich M, et al. 2012 Calphad 39 27

Google Scholar

Google Scholar

[26] Spaepen F 1977 Acta Metall. Mater. 23 407

Google Scholar

Google Scholar

[27] Liu Y, Bei H, Liu C T, George E P 2007 Appl. Phys. Lett. 90 513

Google Scholar

Google Scholar

[28] Bian X L, Wang G, Chan K C, Ren J L, Gao Y L, Zhai Q J 2013 Appl. Phys. Lett. 103 101907

Google Scholar

Google Scholar

[29] Dai L H, Liu L F, Yan M, Xie X, Wei B C, Jurgen E 2004 Chin. Phys. Lett. 21 1593

Google Scholar

Google Scholar

[30] Yan P X, Wang W L , Yan N, Sha S, Wei B B 2020 Sci. Sin. Technol. 50 1402

Google Scholar

Google Scholar

-

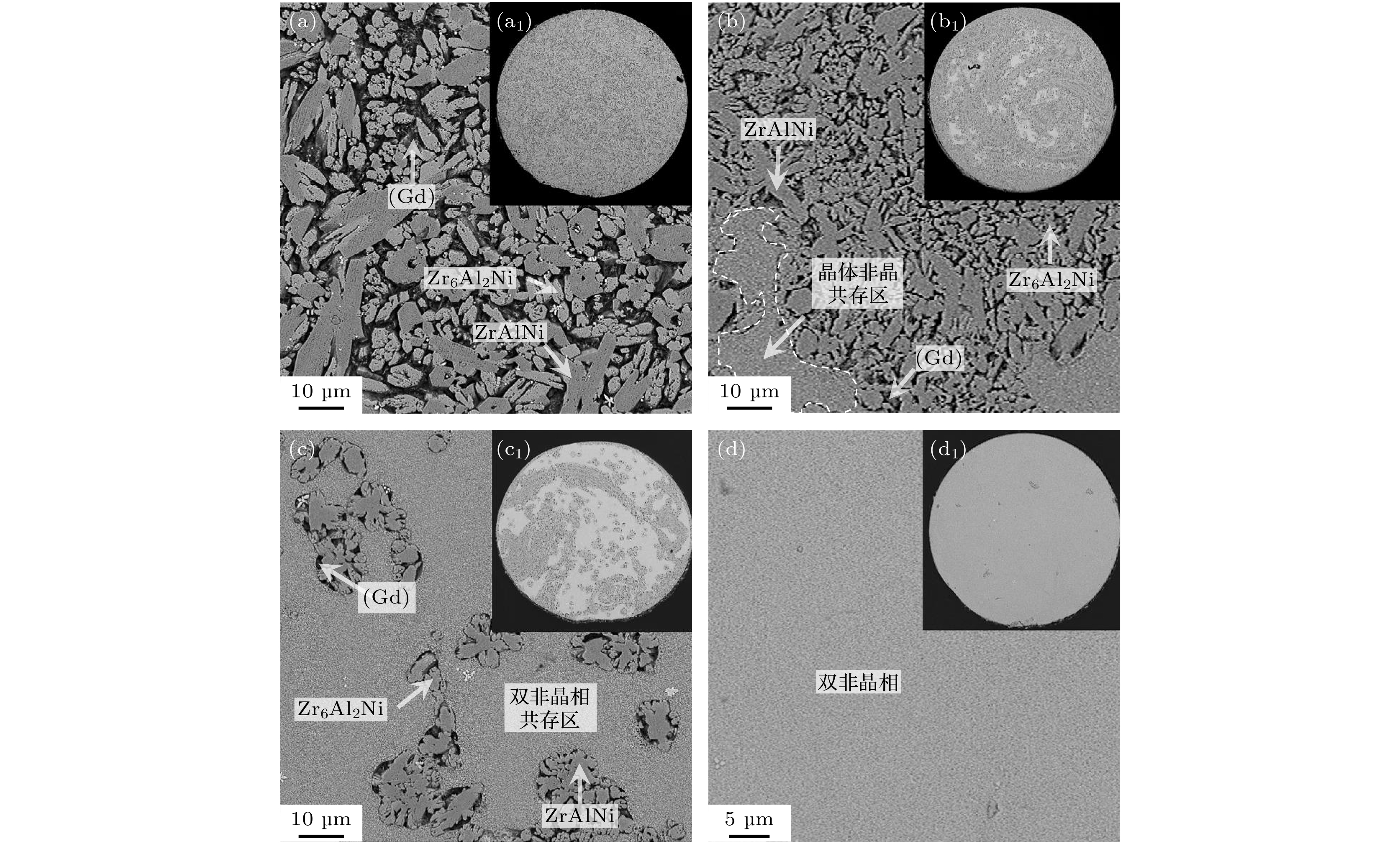

图 3 Zr35Al23Ni22Gd20合金的双相共存区凝固组织与液滴直径关系 (a) D = 520 μm, 晶体非晶共存区; (b)晶体非晶共存区HRTEM放大图; (c) D = 390 μm, 双非晶相共存区; (d) D = 90 μm, 双非晶相; (a1), (c1), (d1)选区电子衍射; (c2), (d2) Gd元素EDS图谱

Fig. 3. Duplex phases microstructure of Zr35Al23Ni22Gd20 alloy with different droplet diameters: (a) Crystalline and amorphous phases coexistence zone with 520 μm droplet diameter; (b) HRTEM micrograph of (a); (c) duplex amorphous phases coexistence zone with 390 μm droplet diameter; (d) duplex amorphous phases with 90 μm droplet diameter; (a1), (c1), (d1) selected area electron diffraction, (c2) and (d2) EDS-mapping of Gd.

图 6 四元Zr35Al23Ni22Gd20合金的热力学性质 (a)四组元之间的混合焓[23,24]; (b)二元Zr-Gd合金中的亚稳相分离区[25]; (c) Zr55(1–X)Al23Ni22Gd55X合金中Zr-Gd组元亚稳相分离曲线

Fig. 6. Thermodynamic properties of quaternary Zr35Al23Ni22Gd20 alloy: (a) Mixing enthalpy between elements[23,24]; (b) metastable phase separation zone in binary Zr-Gd phase diagram[25]; (c) Zr-Gd metastable miscibility gap of Zr55(1–X)Al23Ni22Gd55X alloy.

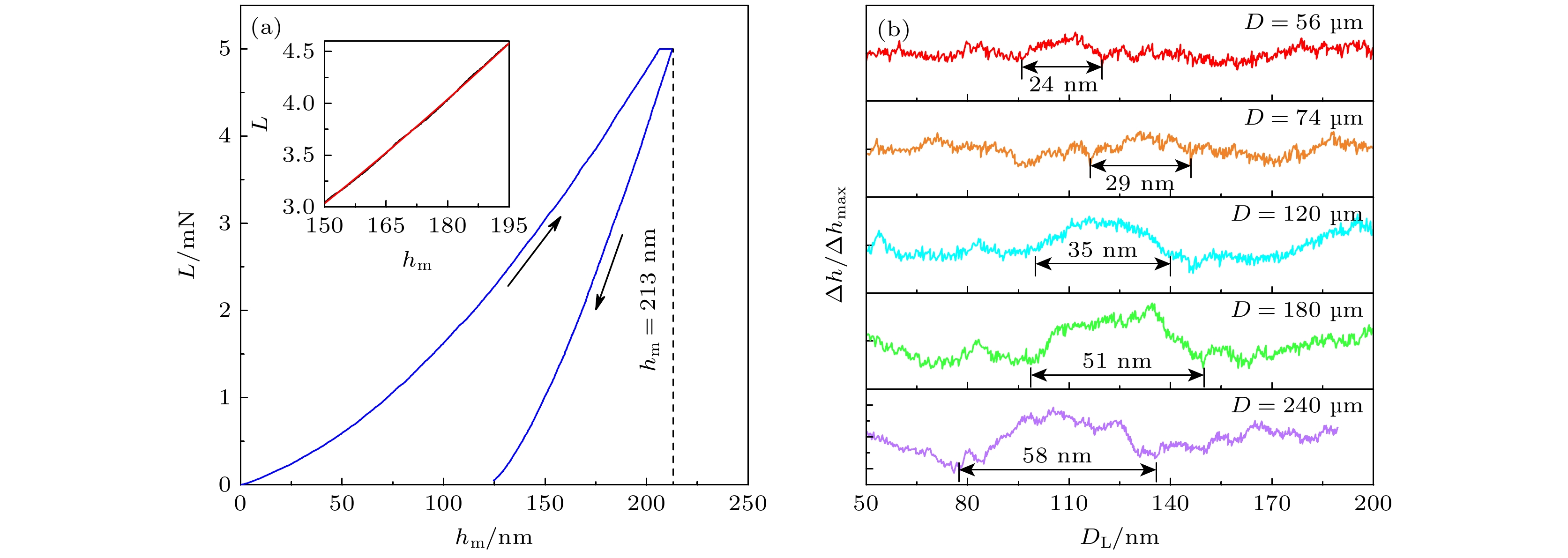

图 10 双相非晶Zr35Al23Ni22Gd20合金流变行为 (a) 240 μm合金颗粒载荷-位移关系; 插图为(a)图的局部放大图; (b) 合金颗粒锯齿流变行为的归一化结果

Fig. 10. Serration features of duplex amorphous phases Zr35Al23Ni22Gd20 alloy: (a) Load-displacement curves of solidified 240 μm droplet, where the inset is enlarged view of (a); (b) normalization results for serration properties of solidified alloy droplets.

-

[1] Johnson W L, Samwer K 2005 Phys. Rev. Lett. 95 195501

Google Scholar

Google Scholar

[2] Schroers J 2013 Phys. Today 66 32

Google Scholar

Google Scholar

[3] Wisitsorasak A, Wolynes P G 2012 Proc. Natl. Acad. Sci. U. S. A. 109 16068

Google Scholar

Google Scholar

[4] Li H Q, Tao K X, Fan C, Liaw P K, Choo H 2006 Appl. Phys. Lett. 89 041921

Google Scholar

Google Scholar

[5] Xing L Q, Li Y, Ramesh K T, Li J, Hufnagel T C 2001 Phys. Rev. B. 64 180201

Google Scholar

Google Scholar

[6] Liu Y H, Wang G, Wang R J, Zhao D Q, Pan M X, Wang W H 2007 Science 315 1385

Google Scholar

Google Scholar

[7] Zong H T, Ma M Z, Zhang X Y, Qi L, Li G, Jing Q, Liu R P 2011 Chin. Phys. Lett. 28 036103

Google Scholar

Google Scholar

[8] Kim D H, Kim W T, Park E S, Mattern N, Eckert J 2013 Prog. Mater Sci. 58 1103

Google Scholar

Google Scholar

[9] Chen HS, Turnbull D 1969 Acta Metall. Mater. 17 1021

Google Scholar

Google Scholar

[10] Kündig AA, Ohnuma M, Ping D H, Ohkubo T, Hono K 2004 Acta Mater. 52 2441

Google Scholar

Google Scholar

[11] Du X H , Huang J C, Hsieh K C, Lai Y H, Chen H M, Jang J S C, Liaw P K 2007 Appl. Phys. Lett. 91 131901

Google Scholar

Google Scholar

[12] Baumer R E, Demkowicz M J 2013 Phys. Rev. Lett. 110 145502

Google Scholar

Google Scholar

[13] Banerjee R, Puthucode A, Bose S, Ayyub P 2007 Appl. Phys. Lett. 90 021904

Google Scholar

Google Scholar

[14] Chang H J, Yook W, Park E S, Kyeong J S, Kim D H 2010 Acta Mater. 58 2483

Google Scholar

Google Scholar

[15] Park B J, Chang H J, Kim D H, et al. 2006 Phys. Rev. Lett. 96 245503

Google Scholar

Google Scholar

[16] 沙莎, 王伟丽, 吴宇昊, 魏炳波 2018 67 046402

Google Scholar

Google Scholar

Sha S, Wang W L, Wu Y H, Wei B B 2018 Acta Phys. Sin. 67 046402

Google Scholar

Google Scholar

[17] Ruan Y, Wang Q Q, Chang S Y, Wei B 2017 Acta Mater. 141 456

Google Scholar

Google Scholar

[18] Luo B C, Liu X R, Wei B 2009 J. Appl. Phys. 106 053523

Google Scholar

Google Scholar

[19] 徐山森, 常健, 吴宇昊, 沙莎, 魏炳波 2019 68 196401

Google Scholar

Google Scholar

Xu S S, Chang J, Wu Y H, Sha S, Wei B B 2019 Acta Phys. Sin. 68 196401

Google Scholar

Google Scholar

[20] Levi C G, Mehrabian R 1982 Metall. Trans. A 13 221

Google Scholar

Google Scholar

[21] 陈克萍, 吕鹏, 王海鹏 2017 66 068101

Google Scholar

Google Scholar

Chen K P, Lü P, Wang H P 2017 Acta Phys. Sin. 66 068101

Google Scholar

Google Scholar

[22] Sohn S W, Yook W, Kim W T, Kim D H 2012 Intermetallics 23 57

Google Scholar

Google Scholar

[23] Bo H, Liu L B, Hu J L, et al. 2014 Thermochim. Acta 591 51

Google Scholar

Google Scholar

[24] Fischer E, Colinet C 2015 J. Phase Equilib. Diffus. 36 5

Google Scholar

Google Scholar

[25] Mattern N, Han J H, Zinkevich M, et al. 2012 Calphad 39 27

Google Scholar

Google Scholar

[26] Spaepen F 1977 Acta Metall. Mater. 23 407

Google Scholar

Google Scholar

[27] Liu Y, Bei H, Liu C T, George E P 2007 Appl. Phys. Lett. 90 513

Google Scholar

Google Scholar

[28] Bian X L, Wang G, Chan K C, Ren J L, Gao Y L, Zhai Q J 2013 Appl. Phys. Lett. 103 101907

Google Scholar

Google Scholar

[29] Dai L H, Liu L F, Yan M, Xie X, Wei B C, Jurgen E 2004 Chin. Phys. Lett. 21 1593

Google Scholar

Google Scholar

[30] Yan P X, Wang W L , Yan N, Sha S, Wei B B 2020 Sci. Sin. Technol. 50 1402

Google Scholar

Google Scholar

计量

- 文章访问数: 5322

- PDF下载量: 135

- 被引次数: 0

下载:

下载: