-

Ni-Mn-Ti基全d族Heusler合金因具有良好的力学性能和弹热效应而成为金属功能材料领域的研究热点, 然而此类合金具有临界应力和滞后较大的问题限制了其实际应用. 有研究学者发现Ni-Mn基合金掺杂Fe不仅可以降低相变滞后, 还可以大幅提高合金力学性能. 鉴于此, 本文采用第一性原理计算系统地研究了Fe掺杂对Ni50–xMn37.5Ti12.5Fex(x = 3.125, 6.25, 9.375)全d族Heusler合金的相稳定性、马氏体相变和磁性能的影响. 结果表明随着Fe掺杂量的增多, 奥氏体的晶格常数逐渐减小; 相稳定性随着Fe掺杂量的增加而逐渐降低, 但在不同成分下, 马氏体始终比奥氏体更稳定, 表明合金可以发生马氏体相变. 合金的奥氏体相为铁磁性, 磁矩主要由Mn原子提供, 而马氏体相由于正常占位的Mn(MnMn)原子与占据Ti位的富余Mn(MnTi)原子的磁矩反平行排列而表现为反铁磁性. Fe取代Ni使Ni50–xMn37.5Ti12.5Fex合金系奥氏体和马氏体之间的能量差ΔE、电子浓度e/a和电子密度n都呈现减小趋势, 表明合金的马氏体相变温度随着Fe原子掺杂量的增多而下降. 本文旨在为新型Ni-Mn-Ti-Fe合金的成分设计和性能优化提供指导.

-

关键词:

- Ni-Mn-Ti-Fe合金 /

- 第一性原理计算 /

- 马氏体相变 /

- 磁性能

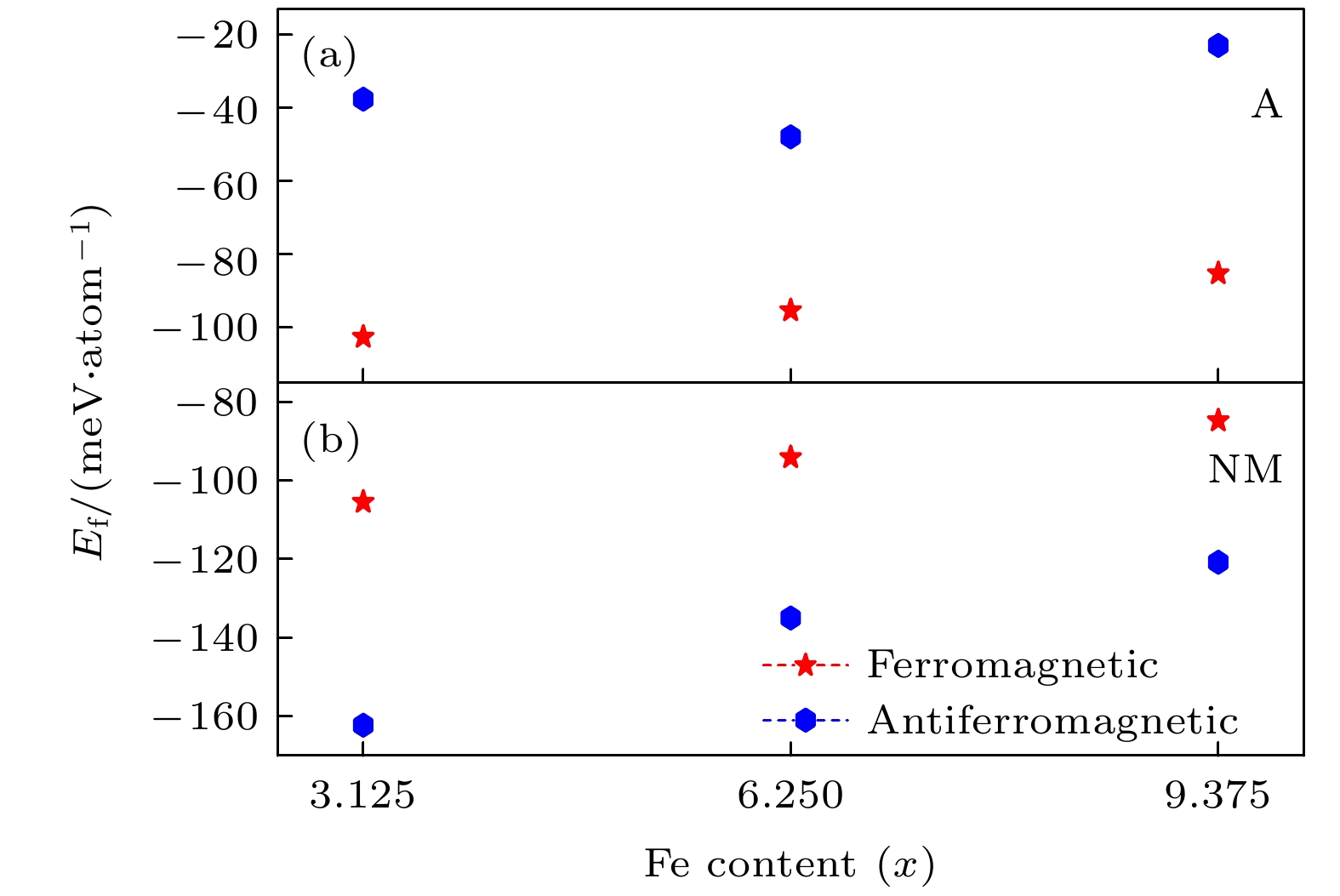

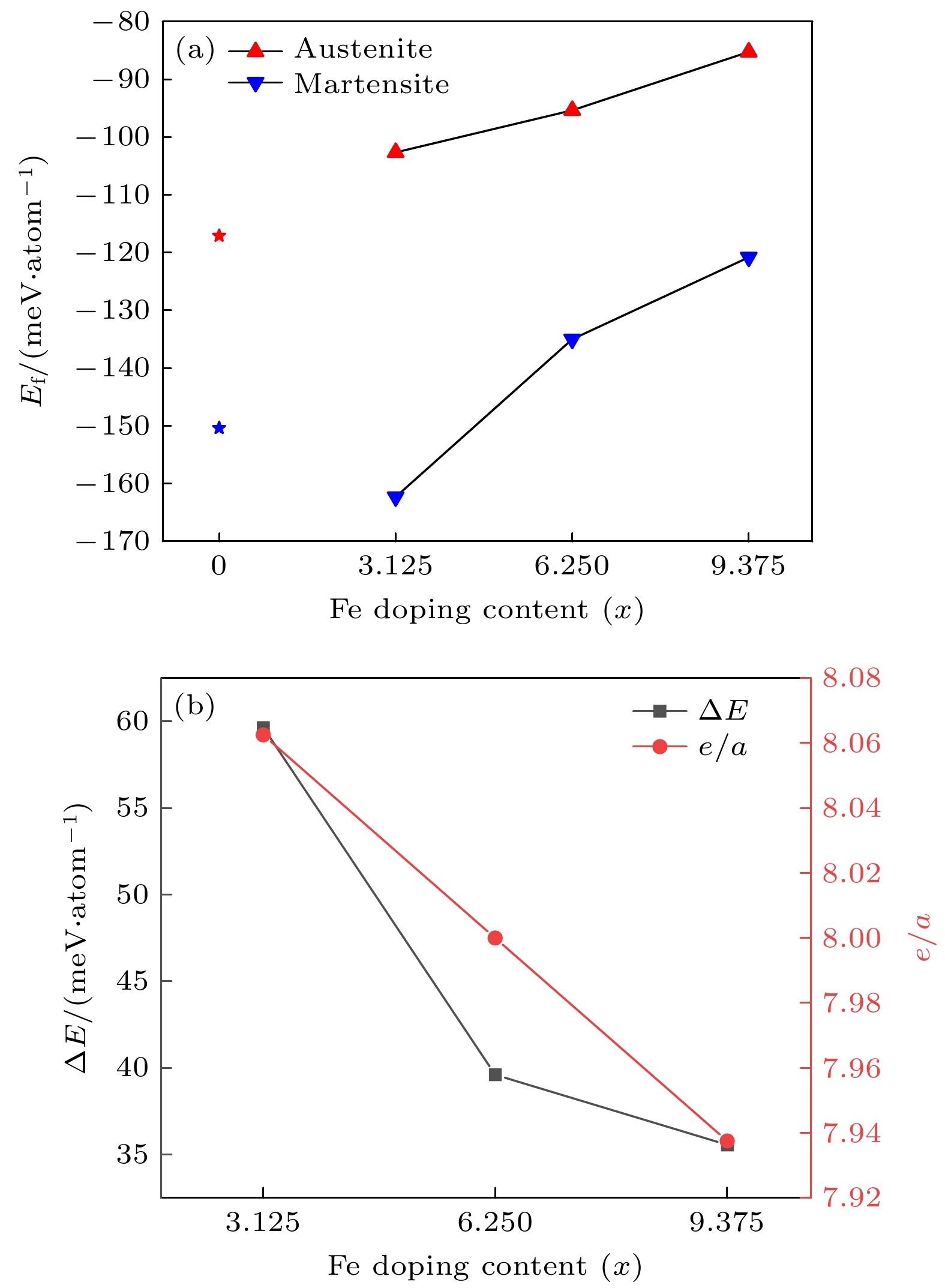

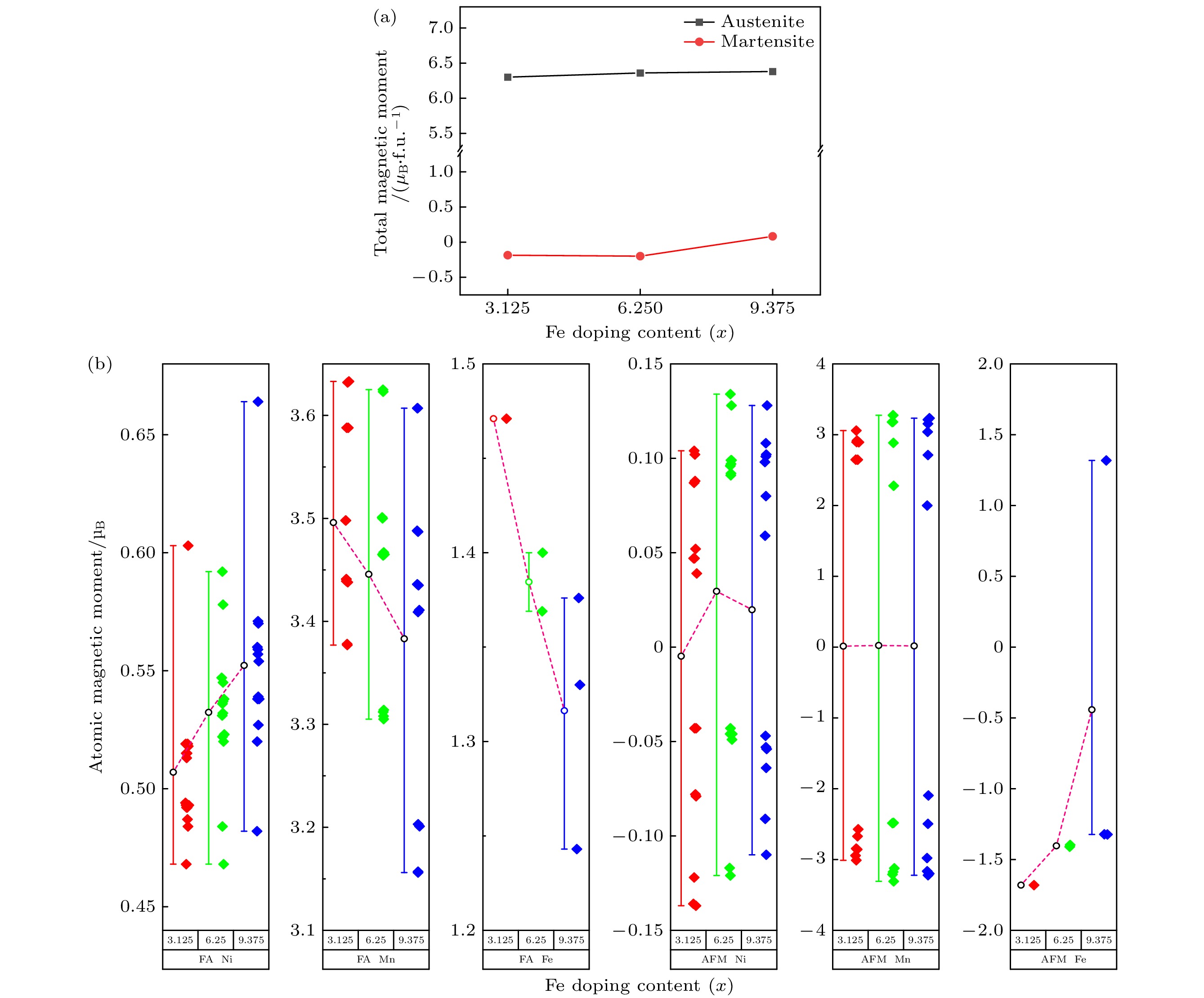

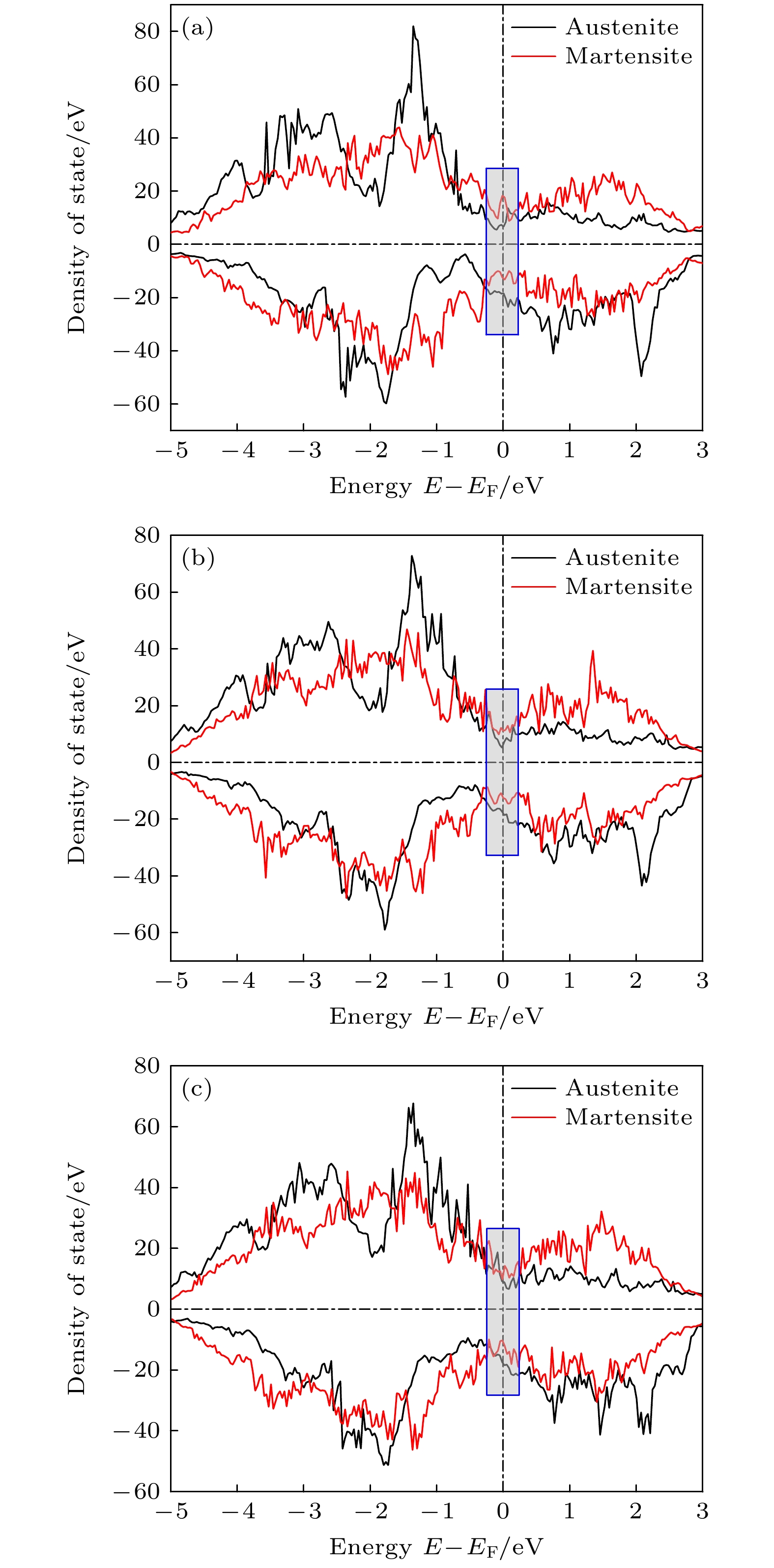

Ni-Mn-Ti-based all-d-metal Heusler alloys have become a hot research topic in the field of metal functional materials due to their excellent mechanical properties and elastocaloric effect. However, the relatively large critical stress and transition hysteresis limit its practical applications. Some researchers have found that doping Fe in Ni-Mn-based alloys can not only reduce hysteresis, but also greatly improve the mechanical properties of alloys. Based on this, the effects of Fe doping on phase stability, martensitic transformation and magnetic properties of Ni50–xMn37.5Ti12.5Fex (x = 3.125, 6.25, 9.375) Heusler alloys are systematically studied by first principles calculation. The corresponding magnetic states of the austenite and martensite of the alloy systems are determined according to the results of the formation energy. The variations of the lattice constants and the phase stability of the austenite and martensite with the increase of Fe content in the alloy systems are revealed, and the associated mechanism is elucidated. The atomic and total magnetic moments of the austenite and martensite in the Ni50–xMn37.5Ti12.5Fex (x = 3.125, 6.25, 9.375) systems are calculated. Based on the results of electronic structure, the essential reasons for the magnetic state changes of the alloys are further explained. In the Ni50–xMn37.5Ti12.5Fex alloy system, the lattice constant of austenite decreases gradually with the increase of Fe doping amount. The stability of austenite phase and martensite phase decrease with the increase of Fe doping amount. Under the different compositions, the formation energy of martensite is always lower than that of austenite, indicating that the alloy can undergo martensite transformation. The energy difference ΔE, electron concentration e/a and density of electrons n of the alloy show a decreasing trend, indicating that the driving force of martensitic transformation decreases, and the corresponding martensitic transformation temperature decreases with the increase of Fe atom doping. The austenite of the alloy is ferromagnetic and the martensite is antiferromagnetic. After the martensitic transformation, the distance between Mn-Mn atoms decreases, and the magnetic moments of MnMn and MnTi atoms are arranged in antiparallel manner, resulting in the total magnetic moments being almost zero. The magnetic properties of the two phases are little affected by the amount of Fe atom doping. The peak density of electronic states in the Fermi surface of martensite phase is lower than that of austenite phase, indicating that martensite phase has a more stable electronic structure than austenite phase. During the transition from austenite to martensite, there is a Jahn-Teller splitting effect at the peak of the down-spin density of states near the Fermi surface. The aim of this paper is to provide guidance for designing the composition design and optimizing the property of the Ni-Mn-Ti-Fe alloy. -

Keywords:

- Ni-Mn-Ti-Fe alloys /

- first principles calculations /

- martensitic transformation /

- magnetic properties

[1] Kainuma R, Oikawa K, Ito W, Sutou Y, Kanomata T, Ishida K 2008 J. Mater. Chem. 18 1837

Google Scholar

Google Scholar

[2] Kainuma R, Imano Y, Ito W, Sutou Y, Morito H, Okamoto S, Kitakami O, Oikawa K, Fujita A, Kanomata T, Ishida K 2006 Nature 439 7079

[3] Oikawa K, Ito W, Imano Y, Sutou Y, Kainuma R, Ishida K, Okamoto S, Kitakami O, Kanomata T 2006 Appl. Phys. Lett. 88 122507

Google Scholar

Google Scholar

[4] Otsuka K, Shimizu K, Cornelis I, Wayman C M 1972 Scr. Metall. 6 5

[5] Liu J, Gottschall T, Skokov K P, Moore J D, Gutfleisch O 2012 Nat. Mater. 11 620

Google Scholar

Google Scholar

[6] Pathak A K, Khan M, Dubenko I, Stadler S, Ali N 2007 Appl. Phys. Lett. 90 262504

Google Scholar

Google Scholar

[7] Mañosa L, González-Alonso D, Planes A, Bonnot E, Barrio M, Tamarit J, Aksoy S, Acet M 2010 Nat. Mater. 9 478

Google Scholar

Google Scholar

[8] Huang Y J, Hu Q D, Bruno N M, Chen J, Karaman I, Ross Jr J H, Li J G 2015 Scr. Mater. 105 42

Google Scholar

Google Scholar

[9] Xiao F, Fukuda T, Jin X, Liu J, Kakeshita T 2018 Phys. Status Solidi B 255 1700246

Google Scholar

Google Scholar

[10] Cong D, Xiong W, Planes A, Ren Y, Mañosa L, Cao P, Nie Z, Sun X, Yang Z, Hong X, Wang Y 2019 Phys. Rev. Lett. 122 255703

Google Scholar

Google Scholar

[11] Liu K, Han X, Yu K, Ma C, Zhang Z, Song Y, Ma S, Zeng H, Chen C, Luo X 2019 Intermetallics 110 106472

Google Scholar

Google Scholar

[12] Sarawate N, Dapino M 2006 Appl. Phys. Lett. 88 121923

Google Scholar

Google Scholar

[13] Karaman I, Basaran B, Karaca H E, Karsilayan A I, Chumlyakov Y I 2007 Appl. Phys. Lett. 90 172505

Google Scholar

Google Scholar

[14] Huang L, Cong D Y, Suo H L, Wang Y D 2014 Appl. Phys. Lett. 104 132407

Google Scholar

Google Scholar

[15] Wei Z Y, Liu E K, Chen J H, Li Y, Liu G D, Luo H Z, Xi X K, Zhang H W, Wang W H, Wu G H 2015 Appl. Phys. Lett. 107 022406

Google Scholar

Google Scholar

[16] Li G J, Liu E K, Wu G H 2022 J. Alloys Compd. 923 166369

Google Scholar

Google Scholar

[17] Wu M X, Zhou F, Khenata R, Kuang M Q, Wang X T 2021 Front. Chem. 8 546947

[18] Wei Z Y, Liu E K, Li Y, Han X L, Du Z W, Luo H Z, Liu G D, Xi X K, Zhang H W, Wang W H, Wu G H 2016 Appl. Phys. Lett. 109 071904

Google Scholar

Google Scholar

[19] Zeng Q Q, Shen J L, Zhang H N, Chen J, Ding B, Xi X X, Liu E K, Wang W H, Wu G H 2019 J. Phys. Condens. Matter 31 425401

Google Scholar

Google Scholar

[20] Guan Z Q, Bai J, Gu J L, Liang X Z, Liu D, Jiang X J, Huang R K, Zhang Y D, Esling L D, Zhao X, Zuo L 2021 J. Mater. Sci. Technol. 68 103

Google Scholar

Google Scholar

[21] Liu S, Xuan H, Cao T, Wang L, Xie Z, Liang X, Li H, Feng L, Chen F, Han P 2019 Phys. Status Solidi A 216 1900563

Google Scholar

Google Scholar

[22] Taubel A, Beckmann B, Pfeuffer L, Fortunato N, Scheibel F, Ener S, Gottschall T, Skokov K P, Zhang H, Gutfleisch O 2020 Acta Mater. 201 425

Google Scholar

Google Scholar

[23] Li S H, Cong D Y, Xiong W X, Chen Z, Zhang X, Nie Z, Li S, Li R, Wang Y, Cao Y 2021 ACS Appl. Mater. Interfaces 13 31870

Google Scholar

Google Scholar

[24] Chang L C, Read T A 1951 J. Met. 1989 3 47

[25] Buehler W J, Gilfrich J V, Wiley R C 1963 J. Appl. Phys. 34 1475

Google Scholar

Google Scholar

[26] Liu X, Bai J, Sun S D, Xu J X, Jiang X J, Guan Z Q, Gu J L, Cong D Y, Zhang Y D, Esling C, Zhao X, Zuo L 2022 J. Appl. Phys. 132 095101

Google Scholar

Google Scholar

[27] Liu K, Ma S C, Ma C C, Han X Q, Yu K, Yang S, Zhang Z S, Song Y, Luo X H, Chen C C, Rehman S U, Zhong Z C 2019 J. Alloys Compd. 790 78

Google Scholar

Google Scholar

[28] Qi H X, Bai J, Xu J X, Sun S D, Liu X, Guan Z Q, Gu J L, Cong D Y, Zhang Y D, Esling C, Zhao X, Zuo L 2022 Mater. Today Commun. 33 104725

Google Scholar

Google Scholar

[29] Kresse G, Furthmuller J 1996 Phys. Rev. B 54 11169

Google Scholar

Google Scholar

[30] Kresse G, Hafner J 1994 J. Phys. Condens. Matter. 6 8245

Google Scholar

Google Scholar

[31] Froyen S 1989 Phys. Rev. B 39 3168

Google Scholar

Google Scholar

[32] Bai J, Raulot J M, Zhang Y D, Esling C, Zhao X, Zuo L 2010 J. Appl. Phys. 108 064904

Google Scholar

Google Scholar

[33] Kaufmann S, Rößler U, Heczko O, Wuttig M, Buschbeck J, Schultz L, Fahler S 2010 Phys. Rev. Lett. 104 145702

Google Scholar

Google Scholar

[34] Zayak A T, Adeagbo W A, Entel P, Rabe K M 2006 Appl. Phys. Lett. 88 111903

Google Scholar

Google Scholar

[35] Chen X Q, Yang F J, Lu X, Qin Z X 2007 Phys. Status Solidi B 244 1047

Google Scholar

Google Scholar

[36] Kundu A, Ghosh S, Ghosh S 2017 Phys. Rev. B 96 174107

Google Scholar

Google Scholar

[37] Biochl P E, Jepsen O, Andersen O K 1994 Phys. Rev. B 49 16223

Google Scholar

Google Scholar

[38] Xiao H B, Yang C P, Wang R L, Marchenkov V V, Bärner K 2012 J. Appl. Phys. 112 123723

Google Scholar

Google Scholar

[39] Tan C L, Huang Y W, Tian X H, Jiang J X, Cai W 2012 Appl. Phys. Lett. 100 132402

Google Scholar

Google Scholar

[40] Ye M, Kimura A, Miura Y, Shirai M, Cui Y T, Shimada K, Namatame H, Taniguchi M, Ueda S, Kobayashi K, Kainuma R, Shishido T, Fukushima K, Kanomata T 2010 Phys. Rev. Lett. 104 176401

Google Scholar

Google Scholar

-

图 1 Ni50–xMn37.5Ti12.5Fex (x = 3.125, 6.25, 9.375)合金系奥氏体相的原子占位方式 (a) x = 3.125; (b1) x = 6.25, 聚集分布; (b2) x = 6.25, 离散分布; (c) x = 9.375

Fig. 1. Atomic occupancy of austenitic phase in Ni50–xMn37.5Ti12.5Fex (x = 3.125, 6.25, 9.375) alloys: (a) x = 3.125; (b1) x = 6.25, aggregated distribution; (b2) x = 6.25, distant distribution; (c) x = 9.375.

图 3 (a) Ni50–xMn37.5Ti12.5Fex (x = 3.125, 6.25, 9.375)合金系的形成能随Fe掺杂含量的变化趋势; (b) Ni50–xMn37.5Ti12.5Fex (x = 3.125, 6.25, 9.375)合金系奥氏体和马氏体的能量差ΔE和电子浓度e/a随Fe掺杂量的变化

Fig. 3. (a) Ef of Ni50–xMn37.5Ti12.5Fex (x = 3.125, 6.25, 9.375) alloys; (b) variation of energy difference ΔE and e/a of Ni50–xMn37.5Ti12.5Fex (x = 3.125, 6.25, 9.375) alloys with Fe doping content.

表 1 Ni50–xMn37.5Ti12.5Fex (x = 3.125, 6.25, 9.375)合金系的电子浓度e/a、晶胞体积Vcell和电子密度n

Table 1. Electron concentration (e/a), the cell volume (Vcell), and density of electrons (n) of Ni50–xMn37.5Ti12.5Fex (x = 3.125, 6.25, 9.375) alloys.

成分 e/a Vcell n x = 3.125 8.06 201.25 0.641 x = 6.25 8 200.31 0.639 x = 9.375 7.94 199.38 0.637 表 2 Ni50–xMn37.5Ti12.5Fex (x = 3.125, 6.25, 9.375)合金系的平衡晶格常数

Table 2. Equilibrium lattice parameters of Ni50–xMn37.5Ti12.5Fex (x = 3.125, 6.25, 9.375) alloys.

相 晶格常数 铁掺杂量 x = 3.125 x = 6.25 x = 9.375 Austenite a = b = c/Å 5.86 5.85 5.84 V/Å3 201.25 200.31 199.38 Martensite a/Å 9.09 7.52 7.51 b/Å 4.14 3.76 3.76 c/Å 5.08 6.83 6.81 V/Å3 190.94 193.41 192.49 -

[1] Kainuma R, Oikawa K, Ito W, Sutou Y, Kanomata T, Ishida K 2008 J. Mater. Chem. 18 1837

Google Scholar

Google Scholar

[2] Kainuma R, Imano Y, Ito W, Sutou Y, Morito H, Okamoto S, Kitakami O, Oikawa K, Fujita A, Kanomata T, Ishida K 2006 Nature 439 7079

[3] Oikawa K, Ito W, Imano Y, Sutou Y, Kainuma R, Ishida K, Okamoto S, Kitakami O, Kanomata T 2006 Appl. Phys. Lett. 88 122507

Google Scholar

Google Scholar

[4] Otsuka K, Shimizu K, Cornelis I, Wayman C M 1972 Scr. Metall. 6 5

[5] Liu J, Gottschall T, Skokov K P, Moore J D, Gutfleisch O 2012 Nat. Mater. 11 620

Google Scholar

Google Scholar

[6] Pathak A K, Khan M, Dubenko I, Stadler S, Ali N 2007 Appl. Phys. Lett. 90 262504

Google Scholar

Google Scholar

[7] Mañosa L, González-Alonso D, Planes A, Bonnot E, Barrio M, Tamarit J, Aksoy S, Acet M 2010 Nat. Mater. 9 478

Google Scholar

Google Scholar

[8] Huang Y J, Hu Q D, Bruno N M, Chen J, Karaman I, Ross Jr J H, Li J G 2015 Scr. Mater. 105 42

Google Scholar

Google Scholar

[9] Xiao F, Fukuda T, Jin X, Liu J, Kakeshita T 2018 Phys. Status Solidi B 255 1700246

Google Scholar

Google Scholar

[10] Cong D, Xiong W, Planes A, Ren Y, Mañosa L, Cao P, Nie Z, Sun X, Yang Z, Hong X, Wang Y 2019 Phys. Rev. Lett. 122 255703

Google Scholar

Google Scholar

[11] Liu K, Han X, Yu K, Ma C, Zhang Z, Song Y, Ma S, Zeng H, Chen C, Luo X 2019 Intermetallics 110 106472

Google Scholar

Google Scholar

[12] Sarawate N, Dapino M 2006 Appl. Phys. Lett. 88 121923

Google Scholar

Google Scholar

[13] Karaman I, Basaran B, Karaca H E, Karsilayan A I, Chumlyakov Y I 2007 Appl. Phys. Lett. 90 172505

Google Scholar

Google Scholar

[14] Huang L, Cong D Y, Suo H L, Wang Y D 2014 Appl. Phys. Lett. 104 132407

Google Scholar

Google Scholar

[15] Wei Z Y, Liu E K, Chen J H, Li Y, Liu G D, Luo H Z, Xi X K, Zhang H W, Wang W H, Wu G H 2015 Appl. Phys. Lett. 107 022406

Google Scholar

Google Scholar

[16] Li G J, Liu E K, Wu G H 2022 J. Alloys Compd. 923 166369

Google Scholar

Google Scholar

[17] Wu M X, Zhou F, Khenata R, Kuang M Q, Wang X T 2021 Front. Chem. 8 546947

[18] Wei Z Y, Liu E K, Li Y, Han X L, Du Z W, Luo H Z, Liu G D, Xi X K, Zhang H W, Wang W H, Wu G H 2016 Appl. Phys. Lett. 109 071904

Google Scholar

Google Scholar

[19] Zeng Q Q, Shen J L, Zhang H N, Chen J, Ding B, Xi X X, Liu E K, Wang W H, Wu G H 2019 J. Phys. Condens. Matter 31 425401

Google Scholar

Google Scholar

[20] Guan Z Q, Bai J, Gu J L, Liang X Z, Liu D, Jiang X J, Huang R K, Zhang Y D, Esling L D, Zhao X, Zuo L 2021 J. Mater. Sci. Technol. 68 103

Google Scholar

Google Scholar

[21] Liu S, Xuan H, Cao T, Wang L, Xie Z, Liang X, Li H, Feng L, Chen F, Han P 2019 Phys. Status Solidi A 216 1900563

Google Scholar

Google Scholar

[22] Taubel A, Beckmann B, Pfeuffer L, Fortunato N, Scheibel F, Ener S, Gottschall T, Skokov K P, Zhang H, Gutfleisch O 2020 Acta Mater. 201 425

Google Scholar

Google Scholar

[23] Li S H, Cong D Y, Xiong W X, Chen Z, Zhang X, Nie Z, Li S, Li R, Wang Y, Cao Y 2021 ACS Appl. Mater. Interfaces 13 31870

Google Scholar

Google Scholar

[24] Chang L C, Read T A 1951 J. Met. 1989 3 47

[25] Buehler W J, Gilfrich J V, Wiley R C 1963 J. Appl. Phys. 34 1475

Google Scholar

Google Scholar

[26] Liu X, Bai J, Sun S D, Xu J X, Jiang X J, Guan Z Q, Gu J L, Cong D Y, Zhang Y D, Esling C, Zhao X, Zuo L 2022 J. Appl. Phys. 132 095101

Google Scholar

Google Scholar

[27] Liu K, Ma S C, Ma C C, Han X Q, Yu K, Yang S, Zhang Z S, Song Y, Luo X H, Chen C C, Rehman S U, Zhong Z C 2019 J. Alloys Compd. 790 78

Google Scholar

Google Scholar

[28] Qi H X, Bai J, Xu J X, Sun S D, Liu X, Guan Z Q, Gu J L, Cong D Y, Zhang Y D, Esling C, Zhao X, Zuo L 2022 Mater. Today Commun. 33 104725

Google Scholar

Google Scholar

[29] Kresse G, Furthmuller J 1996 Phys. Rev. B 54 11169

Google Scholar

Google Scholar

[30] Kresse G, Hafner J 1994 J. Phys. Condens. Matter. 6 8245

Google Scholar

Google Scholar

[31] Froyen S 1989 Phys. Rev. B 39 3168

Google Scholar

Google Scholar

[32] Bai J, Raulot J M, Zhang Y D, Esling C, Zhao X, Zuo L 2010 J. Appl. Phys. 108 064904

Google Scholar

Google Scholar

[33] Kaufmann S, Rößler U, Heczko O, Wuttig M, Buschbeck J, Schultz L, Fahler S 2010 Phys. Rev. Lett. 104 145702

Google Scholar

Google Scholar

[34] Zayak A T, Adeagbo W A, Entel P, Rabe K M 2006 Appl. Phys. Lett. 88 111903

Google Scholar

Google Scholar

[35] Chen X Q, Yang F J, Lu X, Qin Z X 2007 Phys. Status Solidi B 244 1047

Google Scholar

Google Scholar

[36] Kundu A, Ghosh S, Ghosh S 2017 Phys. Rev. B 96 174107

Google Scholar

Google Scholar

[37] Biochl P E, Jepsen O, Andersen O K 1994 Phys. Rev. B 49 16223

Google Scholar

Google Scholar

[38] Xiao H B, Yang C P, Wang R L, Marchenkov V V, Bärner K 2012 J. Appl. Phys. 112 123723

Google Scholar

Google Scholar

[39] Tan C L, Huang Y W, Tian X H, Jiang J X, Cai W 2012 Appl. Phys. Lett. 100 132402

Google Scholar

Google Scholar

[40] Ye M, Kimura A, Miura Y, Shirai M, Cui Y T, Shimada K, Namatame H, Taniguchi M, Ueda S, Kobayashi K, Kainuma R, Shishido T, Fukushima K, Kanomata T 2010 Phys. Rev. Lett. 104 176401

Google Scholar

Google Scholar

计量

- 文章访问数: 5623

- PDF下载量: 108

- 被引次数: 0

下载:

下载: