-

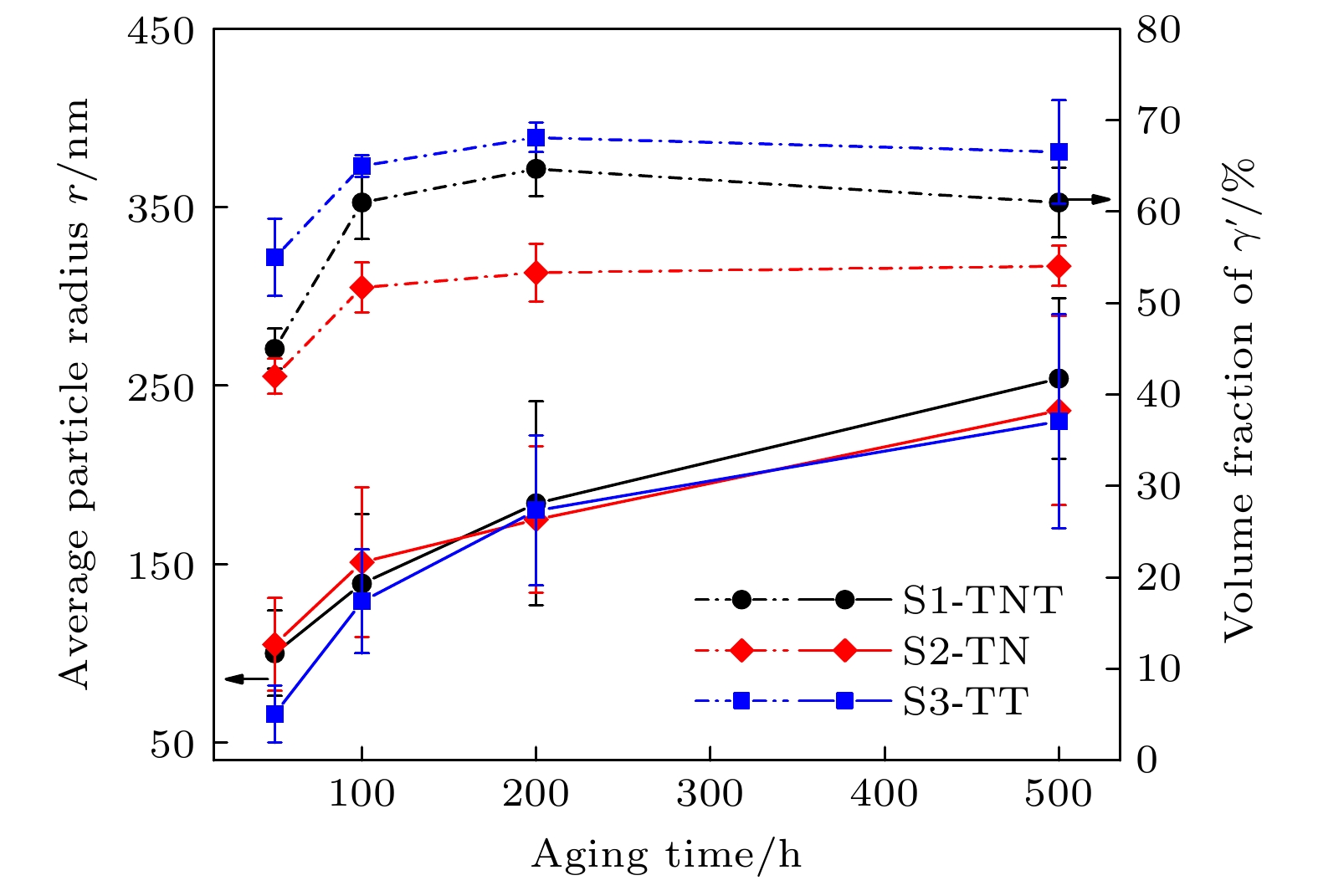

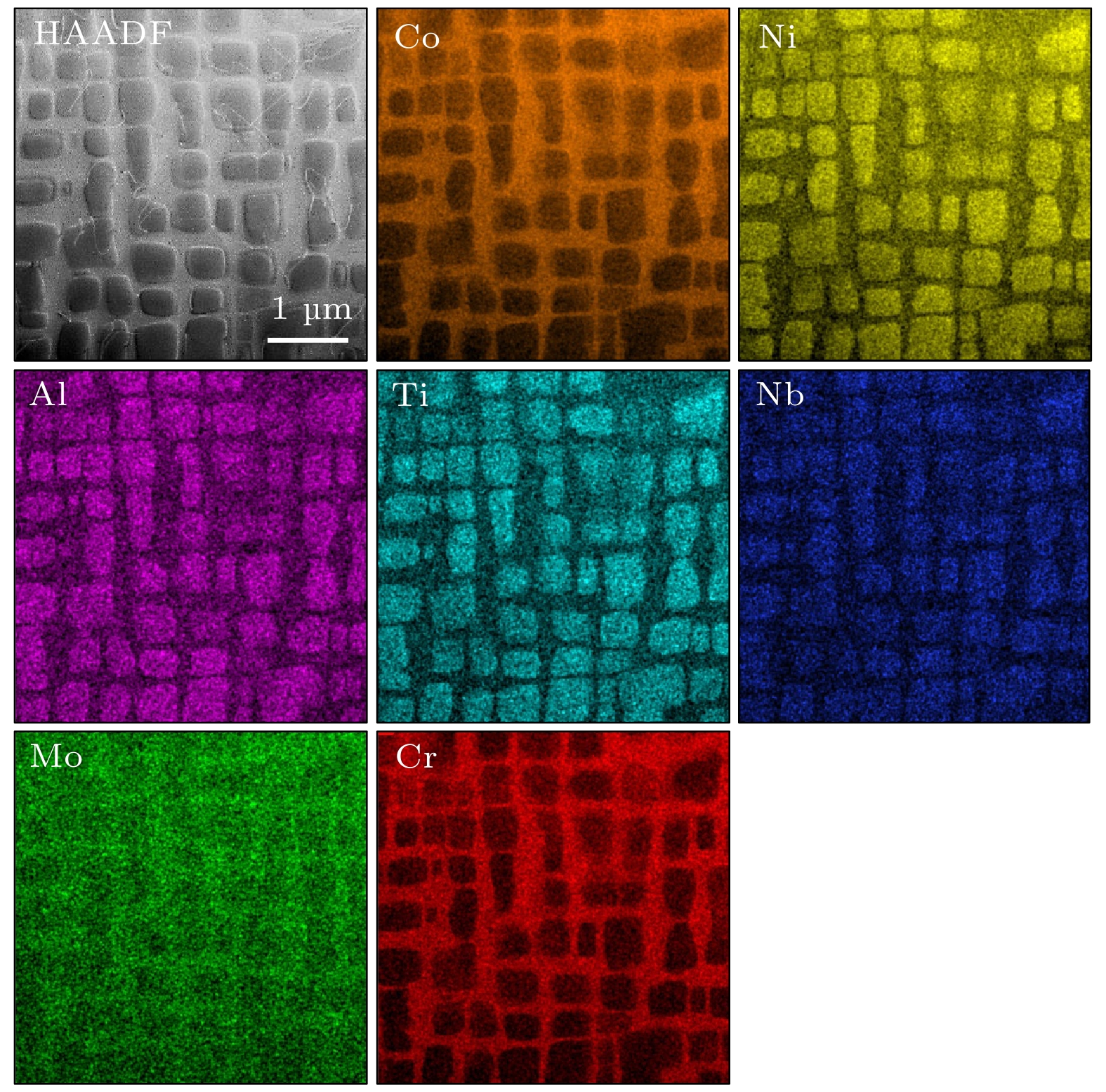

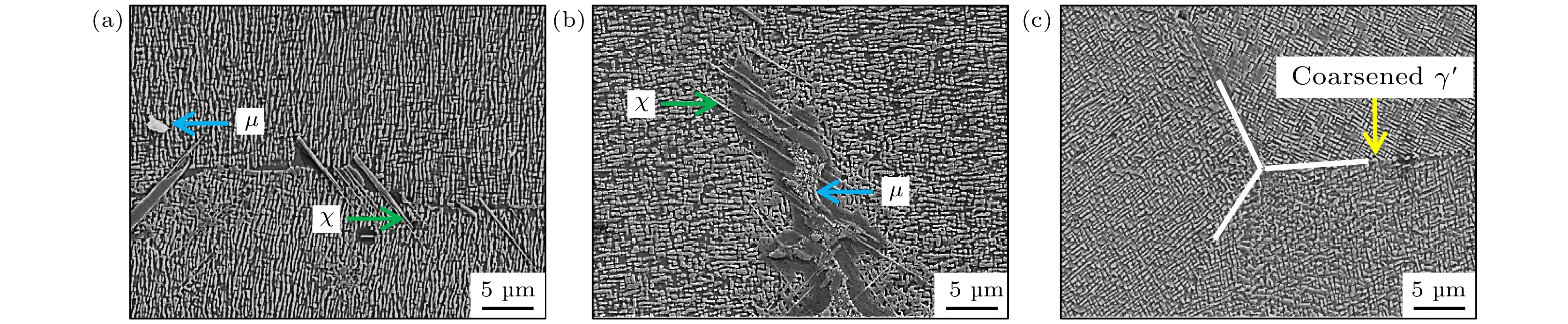

利用团簇成分式方法设计系列低密度Co基高温合金[Al-(Co8Ni4)]((Al0.5(Ti/Nb/Ta)0.5Mo0.5) (Mo0.5Cr0.5Co0.5))(=Co8.5Ni4Al1.5Mo1.0Cr0.5(Ti/Nb/Ta)0.5), 采用真空非自耗电弧炉制备合金铸锭, 并对其在1300 ℃固溶15 h , 在900 ℃下进行长期时效处理, 进而对时效态样品进行微观组织表征和力学性能测试. 结果表明, 当Ti/Nb/Ta, Ti/Nb和Ti/Ta以等物质的量比匹配时, 3种合金的微观组织均表现为立方形γ′相均匀地分布在γ基体中, 这取决于合金适中的γ/γ′点阵错配度(0.27%—0.34%). 在900 ℃长期时效过程中, 3种合金中的γ′相均具有较小的粗化速率, 且合金的显微硬度随时效时间基本不发生变化(275—296 HV); 尤其(Ti/Ta)0.5合金具有最高的γ/γ′共格组织稳定性, 时效500 h后γ′相粗化最慢, 并在晶界处无其他第二相粒子析出, 而在其他合金的晶界附近均析出针状和颗粒状的第二相粒子.Co-base superalloys generally have high strengths, good oxidation- and corrosion-resistances, as well as excellent creep-resistant properties at high temperatures (HTs), which are ascribed to the coherent precipitation of cuboidal γ′ phase into face-centered-cubic (FCC) γ matrix induced by co-alloying of multiple elements. However, the cuboidal γ/γ′ coherent microstructure is liable to be destabilized after a long-time aging at HTs in Co-base superalloys. In the present work, the cluster formula is used to design a series of low-density Co-base superalloys with the composition of [Al-(Co8Ni4)]((Al0.5(Ti/Nb/Ta)0.5Mo0.5)(Mo0.5Cr0.5Co0.5)) (=Co8.5Ni4Al1.5Mo1.0Cr0.5(Ti/Nb/Ta)0.5). Alloy ingots are prepared by arc melting under an argon atmosphere, and are solid-solutionized at 1300 ℃ for 15 h and then aged at 900 ℃ for up to 500 h. Microstructural characterizations and mechanical properties of these alloys in different aged states are obtained by using XRD, SEM, EPMA, TEM, and HV. It is found that all these alloys with Ti/Nb/Ta, Ti/Nb, and Ti/Ta in an equi-molar mixing have a special coherent microstructure with cuboidal γ′ phase uniformly-precipitated into the γ matrix, which is contributed to the moderate lattice misfit of γ/γ′ (0.27%–0.34%). Moreover, these cuboidal γ′ phase are coarsened slowly during aging, in which the microhardness does not vary obviously with aging time (275 HV–296 HV). Especially, the alloy with (Ti/Ta)0.5 exhibits the highest γ/γ′ microstructural stability with a slow coarsening rate after aging 500 h, and no other second phases appear near the grain boundaries. While needle and bulk particles would precipitate on grain boundaries in other alloys after 500 h-aging.

-

Keywords:

- Co-base superalloys /

- coherent microstructure /

- γ′ phase coarsening /

- the second precipitated phases

[1] Meyers M A, Chawla K K 2008 Mechanical Behavior of Materials (2nd Ed.) (New York: Cambridge University Press) p1

[2] Gleiter H, Hornbogen E 1968 Mater. Sci. Eng. 2 285

Google Scholar

Google Scholar

[3] Reed R C 2006 The Superalloys: Fundamentals and Applications (Cambridge: Cambridge University Press) p19

[4] Kobayashi S, Tsukamoto Y, Takasugi T, Chinen H, Omori T, Ishida K, Zaefferer S 2009 Intermetallics 17 1085

Google Scholar

Google Scholar

[5] Tsukamoto Y, Kobayashi S, Takasugi T 2010 Mater. Sci. Forum. 654 448

[6] Lass E A, Williams M E, Campbell C E, Moon K W, Kattner U R 2014 J. Phase Equilib. Diffus. 35 711

Google Scholar

Google Scholar

[7] Lass E A, Grist R D, Williams M E 2016 J. Phase equilib. Diffus. 37 387

Google Scholar

Google Scholar

[8] Bauer A, Neumeier S, Pyczak F, Göken M 2010 Intermetallics 63 1197

[9] Chen Y, Wang C, Ruan J, Omori T, Kainuma R, Ishida K, Liu X 2019 Acta Mater. 170 62

Google Scholar

Google Scholar

[10] Ng D S, Chung D W, Toinin J P, Seidman D N, Dunand D C, Lass E A 2020 Mater. Sci. Eng. A 778 139108

Google Scholar

Google Scholar

[11] Pandey P, Makineni S K, Samanta A, Sharma A, Das S M, Nithin B, Srivastava C, Singh A K, Raabe D, Gault B, Chattopadhyay K 2019 Acta Mater. 163 140

Google Scholar

Google Scholar

[12] Pyczak F, Bauer A, Göken M, Lorenz U, Neumeier S, Oehring M, Paul J, Schell N, Schreyer A, Stark A, Symanzik F 2015 J. Alloy. Compd. 632 110

Google Scholar

Google Scholar

[13] Feng G, Li H, Li S S, Sha J B 2012 Scr. Mater. 67 499

Google Scholar

Google Scholar

[14] Liu X, Chen Z, Chen Y, Yang S, Pan Y, Lu Y, Qu S, Li Y J, Yang Y S, Wang C 2021 Mater. Lett. 284 128910

Google Scholar

Google Scholar

[15] Vorontsov V A, Barnard J S, Rahman K M, Yan H Y, Midgley P A, Dye D 2016 Acta Mater. 120 14

Google Scholar

Google Scholar

[16] Tian L Y, Lizárraga R, Larsson H, Holmström E, Vitos L 2017 Acta Mater. 136 215

Google Scholar

Google Scholar

[17] Naghavi S S, Hegde V I, Wolverton C 2017 Acta Mater. 132 467

Google Scholar

Google Scholar

[18] Neumeier S, Rehman H U, Neuner J, Zenk C H, Michel S, Schuwalow S, Rogal J, Drautz R, Göken M 2016 Acta Mater. 106 304

Google Scholar

Google Scholar

[19] Liu X J, Yu Y, Liu Y H, Huang W L, Lu Y, Guo Y H, Wang C P 2017 J. Phase Equilib. Diffus. 38 733

Google Scholar

Google Scholar

[20] Wang C, Zhao C, Lu Y, Li T, Peng D, Shi J, Liu X 2015 Mater. Chem. Phys. 162 555

Google Scholar

Google Scholar

[21] Ruan J J, Wang C P, Yang S Y, Omori T, Yang T, Kimura Y, Liu X J, Kainuma R, Ishida K 2016 J. Alloy. Compd. 664 141

Google Scholar

Google Scholar

[22] Wang C P, Yang S, Yang S Y, Wang D, Ruan J J, Li J, Liu X J 2015 J. Phase Equilib. Diffus. 36 592

Google Scholar

Google Scholar

[23] Ruan J, Xu W, Yang T, Yu J, Yang S, Luan J, Omori T, Wang C, Kainuma R, Ishida K, Liu C T, Liu X 2020 Acta Mater. 186 425

Google Scholar

Google Scholar

[24] 宿彦京, 付华栋, 白洋, 姜雪, 谢建新 2020 金属学报 56 1313

Google Scholar

Google Scholar

Su Y J, Fu H D, Bai Y, Jiang X, Xie J X 2020 Acta. Metall. Sin. 56 1313

Google Scholar

Google Scholar

[25] Li W, Li L, Wei C, Zhao J C, Feng Q 2021 J. Mater. Sci. Technol. 80 139

Google Scholar

Google Scholar

[26] 王清, 查钱锋, 刘恩雪, 董闯, 王学军, 谭朝鑫, 冀春俊 2012 金属学报 48 1201

Google Scholar

Google Scholar

Wang Q, Zha Q F, Liu E X, Dong C, Wang X J, Tan C X, Ji C J 2012 Acta. Metall. Sin. 48 1201

Google Scholar

Google Scholar

[27] 马仁涛, 郝传璞, 王清, 任明法, 王英敏, 董闯 2010 金属学报 46 1034

Google Scholar

Google Scholar

Ma R T, Hao C P, Wang Q, Ren M F, Wang Y M, Dong C 2010 Acta. Metall. Sin. 46 1034

Google Scholar

Google Scholar

[28] Zhang Y, Wang Q, Dong H G, Dong C, Zhang H Y, Sun X F 2018 Acta Metall. Sin. -Engl. Lett. 31 127

Google Scholar

Google Scholar

[29] Chen C, Wang Q, Dong C, Zhang Y, Dong H 2020 Sci. Rep. 10 1

Google Scholar

Google Scholar

[30] Makineni S K, Samanta A, Rojhirunsakool T, Alam T, Nithin B, Singh A K, Banerjee R, Chattopadhyay K 2015 Acta Mater. 97 29

Google Scholar

Google Scholar

[31] Zhang J, Huang T, Cao K, Chen J, Zong H, Wang D, Zhang J, Zhang J, Liu L 2021 J. Mater. Sci. Technol. 75 68

Google Scholar

Google Scholar

[32] Yang T, Zhao Y L, Tong Y, Jiao Z B, Wei J, Cai J X, Han X D, Chen D, Hu A, Liu C T 2018 Science 362 933

Google Scholar

Google Scholar

[33] Kim K, Voorhees P W 2018 Acta Materi. 152 327

Google Scholar

Google Scholar

[34] Orthacker A, Haberfehlner G, Taendl J, Poletti M C, Sonderegger B, Kothleitner G 2018 Nat. Mater. 17 1101

Google Scholar

Google Scholar

[35] Sims C T, S Stoloff N S, Hagel W C 1987 Superalloy II (New York: John Wiley & Sons Inc) p1

[36] Nithin B, Samanta A, Makineni S K, Alam T, Pandey P, Singh A K, Banerjee R, Chattopadhyay K 2017 J. Mater. Sci. 52 11036

Google Scholar

Google Scholar

[37] Wang Q, Li Z, Pang S, Li X, Dong C, Liaw P K 2018 Entropy 20 878

Google Scholar

Google Scholar

[38] Yoo Y S, Yoon D Y, Henry M F 1995 Met. Mater. 1 47

Google Scholar

Google Scholar

[39] Zenk C H, Neumeier S, Stone H J, Göken M 2014 Intermetallics 55 28

Google Scholar

Google Scholar

[40] Philippe T, Voorhees P W 2013 Acta Mater. 61 4237

Google Scholar

Google Scholar

[41] Zhou H J, Xue F, Chang H, Feng Q 2018 J. Mater. Sci. Technol. 34 799

Google Scholar

Google Scholar

-

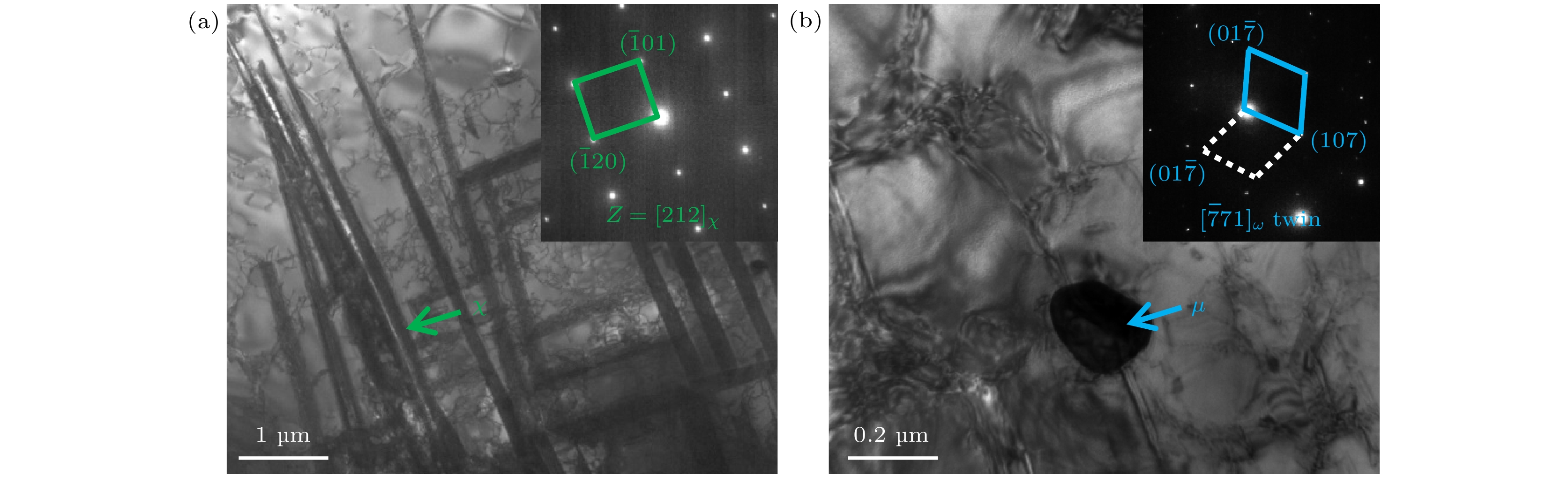

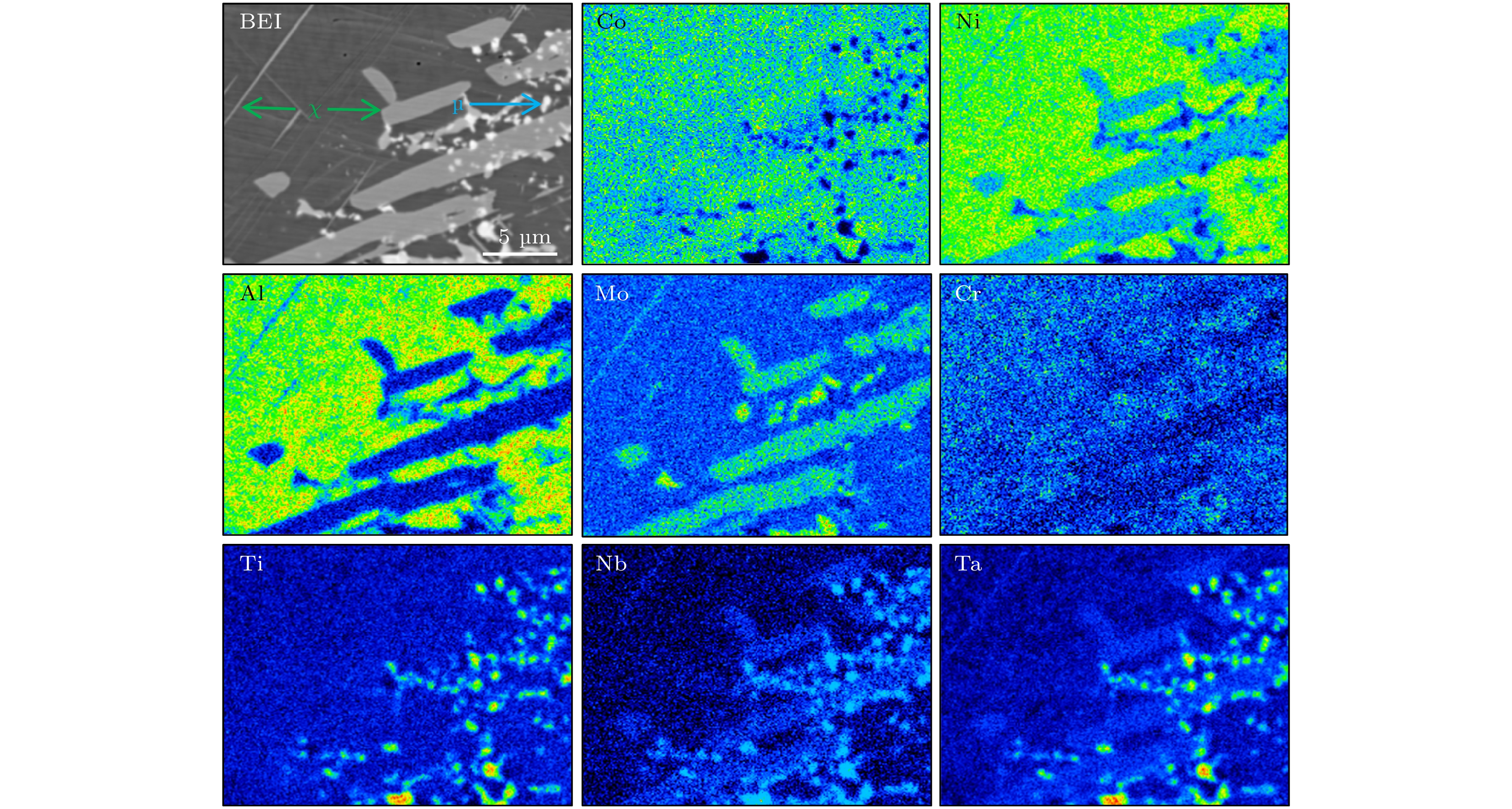

图 3 Co8.5Ni4Al1.5Mo1.0Cr0.5(Ti/Ta)0.5合金(S3-TT)时效50 h后的TEM结果 (a) TEM明场(BF)像; (b) TEM暗场(DF)像; (c)TEM高分辨(HRTEM)像及其对应的FFT图谱

Fig. 3. TEM characterization of 50 h aged Co8.5Ni4Al1.5Mo1.0Cr0.5(Ti/Ta)0.5 alloy (S3-TT): (a) The bright-field (BF) image; (b) the corresponding dark-field (DF) image; (c) the HRTEM image and FFT patterns.

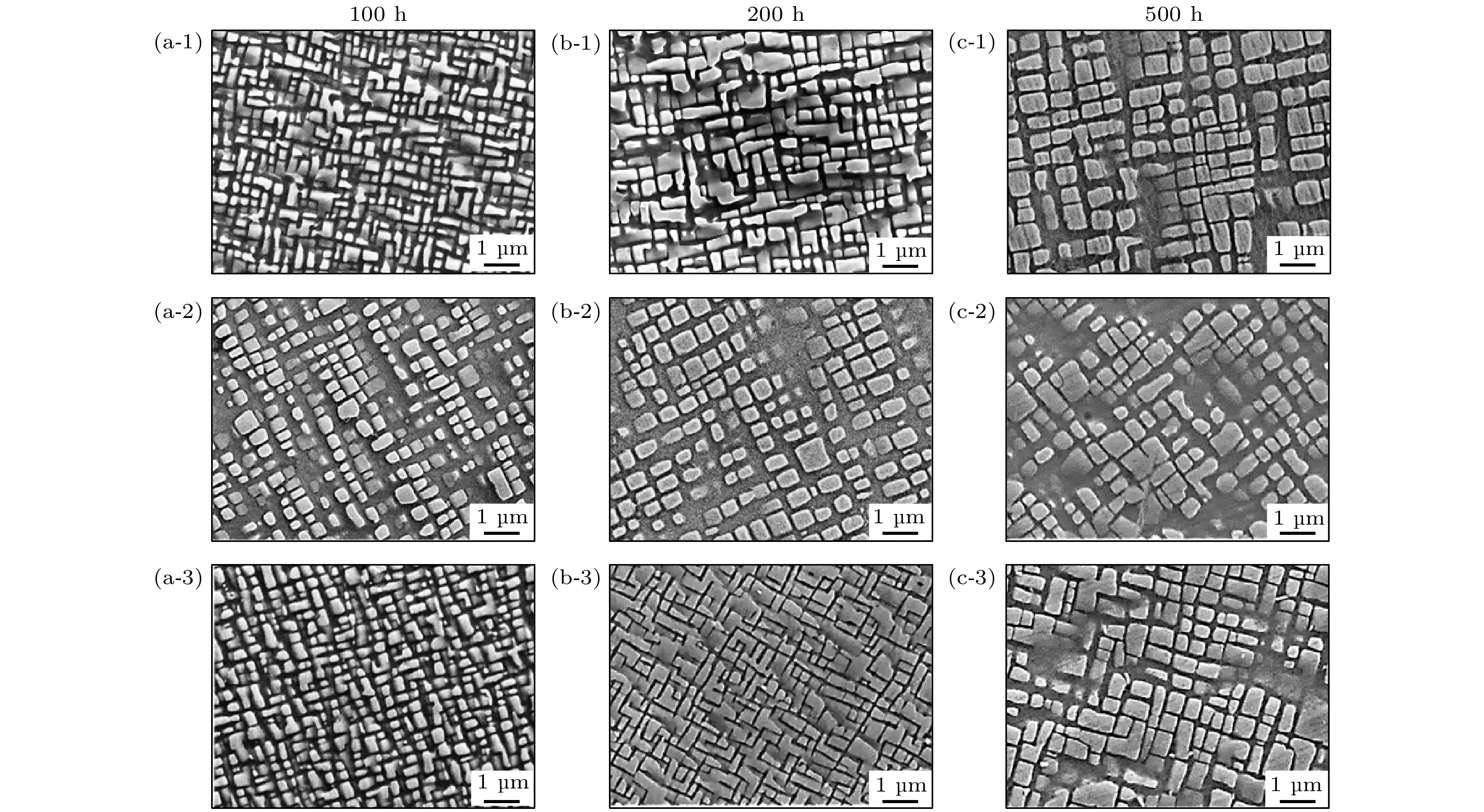

图 4 设计的3种合金在900 ℃长期时效过程中γ/γ′共格组织形貌演变 (a-1)—(c-1) S1-TNT时效100, 200, 500 h; (a-2)—(c-2) S2-TN时效100, 200, 500 h; (a-3)—(c-3) S3-TT时效100, 200, 500 h

Fig. 4. Microstructural evolutions with the aging time at 900 ℃ of the three alloys: (a-1)−(c-1) Aged S1-TNT for 100, 200, and 500 h, respectively; (a-2)−(c-2) aged S2-TN for 100, 200, and 500 h, respectively; (a-3)−(c-3) aged S3-TT for 100, 200, and 500 h, respectively.

表 1 设计的3种合金的成分(团簇式和原子百分比)、以及900 ℃/50 h时效后γ和γ′两相的晶格常数(aγ, aγ′)和点阵错配度(ε)

Table 1. Related data of the designed series of alloys, including cluster formulas, alloy composition, lattice constant (a), lattice misfit (ε) between γ and γ′ phases after aging at 900 ℃ for 50 h.

Alloy Cluster formulas Alloy composition/% a/nm ε/% S1-TNT [Al-(Co8Ni4)]((Al0.5(Ti, Nb, Ta)0.5Mo0.5)(Mo0.5Cr0.5Co0.5)) Co53.13Ni25.00Al9.38Ti1.04Nb1.04Ta1.04Cr3.12Mo6.25 aγ = 0.3570 ± 0.0003

aγ′ = 0.3583 ± 0.00020.34 ± 0.05 S2-TN [Al-(Co8Ni4)]((Al0.5(Ti, Nb)0.5Mo0.5)(Mo0.5Cr0.5Co0.5)) Co53.13Ni25.00Al9.38Ti1.56Nb1.56Cr3.12Mo6.25 aγ = 0.3575 ± 0.0004

aγ′ = 0.3584 ± 0.00020.27 ± 0.05 S3-TT [Al-(Co8Ni4)]((Al0.5(Ti, Ta)0.5Mo0.5)(Mo0.5Cr0.5Co0.5)) Co53.13Ni25.00Al9.38Ti1.56Ta1.56Cr3.12Mo6.25 aγ = 0.3575 ± 0.0004

aγ′= 0.3586 ± 0.00030.29 ± 0.07 -

[1] Meyers M A, Chawla K K 2008 Mechanical Behavior of Materials (2nd Ed.) (New York: Cambridge University Press) p1

[2] Gleiter H, Hornbogen E 1968 Mater. Sci. Eng. 2 285

Google Scholar

Google Scholar

[3] Reed R C 2006 The Superalloys: Fundamentals and Applications (Cambridge: Cambridge University Press) p19

[4] Kobayashi S, Tsukamoto Y, Takasugi T, Chinen H, Omori T, Ishida K, Zaefferer S 2009 Intermetallics 17 1085

Google Scholar

Google Scholar

[5] Tsukamoto Y, Kobayashi S, Takasugi T 2010 Mater. Sci. Forum. 654 448

[6] Lass E A, Williams M E, Campbell C E, Moon K W, Kattner U R 2014 J. Phase Equilib. Diffus. 35 711

Google Scholar

Google Scholar

[7] Lass E A, Grist R D, Williams M E 2016 J. Phase equilib. Diffus. 37 387

Google Scholar

Google Scholar

[8] Bauer A, Neumeier S, Pyczak F, Göken M 2010 Intermetallics 63 1197

[9] Chen Y, Wang C, Ruan J, Omori T, Kainuma R, Ishida K, Liu X 2019 Acta Mater. 170 62

Google Scholar

Google Scholar

[10] Ng D S, Chung D W, Toinin J P, Seidman D N, Dunand D C, Lass E A 2020 Mater. Sci. Eng. A 778 139108

Google Scholar

Google Scholar

[11] Pandey P, Makineni S K, Samanta A, Sharma A, Das S M, Nithin B, Srivastava C, Singh A K, Raabe D, Gault B, Chattopadhyay K 2019 Acta Mater. 163 140

Google Scholar

Google Scholar

[12] Pyczak F, Bauer A, Göken M, Lorenz U, Neumeier S, Oehring M, Paul J, Schell N, Schreyer A, Stark A, Symanzik F 2015 J. Alloy. Compd. 632 110

Google Scholar

Google Scholar

[13] Feng G, Li H, Li S S, Sha J B 2012 Scr. Mater. 67 499

Google Scholar

Google Scholar

[14] Liu X, Chen Z, Chen Y, Yang S, Pan Y, Lu Y, Qu S, Li Y J, Yang Y S, Wang C 2021 Mater. Lett. 284 128910

Google Scholar

Google Scholar

[15] Vorontsov V A, Barnard J S, Rahman K M, Yan H Y, Midgley P A, Dye D 2016 Acta Mater. 120 14

Google Scholar

Google Scholar

[16] Tian L Y, Lizárraga R, Larsson H, Holmström E, Vitos L 2017 Acta Mater. 136 215

Google Scholar

Google Scholar

[17] Naghavi S S, Hegde V I, Wolverton C 2017 Acta Mater. 132 467

Google Scholar

Google Scholar

[18] Neumeier S, Rehman H U, Neuner J, Zenk C H, Michel S, Schuwalow S, Rogal J, Drautz R, Göken M 2016 Acta Mater. 106 304

Google Scholar

Google Scholar

[19] Liu X J, Yu Y, Liu Y H, Huang W L, Lu Y, Guo Y H, Wang C P 2017 J. Phase Equilib. Diffus. 38 733

Google Scholar

Google Scholar

[20] Wang C, Zhao C, Lu Y, Li T, Peng D, Shi J, Liu X 2015 Mater. Chem. Phys. 162 555

Google Scholar

Google Scholar

[21] Ruan J J, Wang C P, Yang S Y, Omori T, Yang T, Kimura Y, Liu X J, Kainuma R, Ishida K 2016 J. Alloy. Compd. 664 141

Google Scholar

Google Scholar

[22] Wang C P, Yang S, Yang S Y, Wang D, Ruan J J, Li J, Liu X J 2015 J. Phase Equilib. Diffus. 36 592

Google Scholar

Google Scholar

[23] Ruan J, Xu W, Yang T, Yu J, Yang S, Luan J, Omori T, Wang C, Kainuma R, Ishida K, Liu C T, Liu X 2020 Acta Mater. 186 425

Google Scholar

Google Scholar

[24] 宿彦京, 付华栋, 白洋, 姜雪, 谢建新 2020 金属学报 56 1313

Google Scholar

Google Scholar

Su Y J, Fu H D, Bai Y, Jiang X, Xie J X 2020 Acta. Metall. Sin. 56 1313

Google Scholar

Google Scholar

[25] Li W, Li L, Wei C, Zhao J C, Feng Q 2021 J. Mater. Sci. Technol. 80 139

Google Scholar

Google Scholar

[26] 王清, 查钱锋, 刘恩雪, 董闯, 王学军, 谭朝鑫, 冀春俊 2012 金属学报 48 1201

Google Scholar

Google Scholar

Wang Q, Zha Q F, Liu E X, Dong C, Wang X J, Tan C X, Ji C J 2012 Acta. Metall. Sin. 48 1201

Google Scholar

Google Scholar

[27] 马仁涛, 郝传璞, 王清, 任明法, 王英敏, 董闯 2010 金属学报 46 1034

Google Scholar

Google Scholar

Ma R T, Hao C P, Wang Q, Ren M F, Wang Y M, Dong C 2010 Acta. Metall. Sin. 46 1034

Google Scholar

Google Scholar

[28] Zhang Y, Wang Q, Dong H G, Dong C, Zhang H Y, Sun X F 2018 Acta Metall. Sin. -Engl. Lett. 31 127

Google Scholar

Google Scholar

[29] Chen C, Wang Q, Dong C, Zhang Y, Dong H 2020 Sci. Rep. 10 1

Google Scholar

Google Scholar

[30] Makineni S K, Samanta A, Rojhirunsakool T, Alam T, Nithin B, Singh A K, Banerjee R, Chattopadhyay K 2015 Acta Mater. 97 29

Google Scholar

Google Scholar

[31] Zhang J, Huang T, Cao K, Chen J, Zong H, Wang D, Zhang J, Zhang J, Liu L 2021 J. Mater. Sci. Technol. 75 68

Google Scholar

Google Scholar

[32] Yang T, Zhao Y L, Tong Y, Jiao Z B, Wei J, Cai J X, Han X D, Chen D, Hu A, Liu C T 2018 Science 362 933

Google Scholar

Google Scholar

[33] Kim K, Voorhees P W 2018 Acta Materi. 152 327

Google Scholar

Google Scholar

[34] Orthacker A, Haberfehlner G, Taendl J, Poletti M C, Sonderegger B, Kothleitner G 2018 Nat. Mater. 17 1101

Google Scholar

Google Scholar

[35] Sims C T, S Stoloff N S, Hagel W C 1987 Superalloy II (New York: John Wiley & Sons Inc) p1

[36] Nithin B, Samanta A, Makineni S K, Alam T, Pandey P, Singh A K, Banerjee R, Chattopadhyay K 2017 J. Mater. Sci. 52 11036

Google Scholar

Google Scholar

[37] Wang Q, Li Z, Pang S, Li X, Dong C, Liaw P K 2018 Entropy 20 878

Google Scholar

Google Scholar

[38] Yoo Y S, Yoon D Y, Henry M F 1995 Met. Mater. 1 47

Google Scholar

Google Scholar

[39] Zenk C H, Neumeier S, Stone H J, Göken M 2014 Intermetallics 55 28

Google Scholar

Google Scholar

[40] Philippe T, Voorhees P W 2013 Acta Mater. 61 4237

Google Scholar

Google Scholar

[41] Zhou H J, Xue F, Chang H, Feng Q 2018 J. Mater. Sci. Technol. 34 799

Google Scholar

Google Scholar

计量

- 文章访问数: 8307

- PDF下载量: 78

- 被引次数: 0

下载:

下载: