-

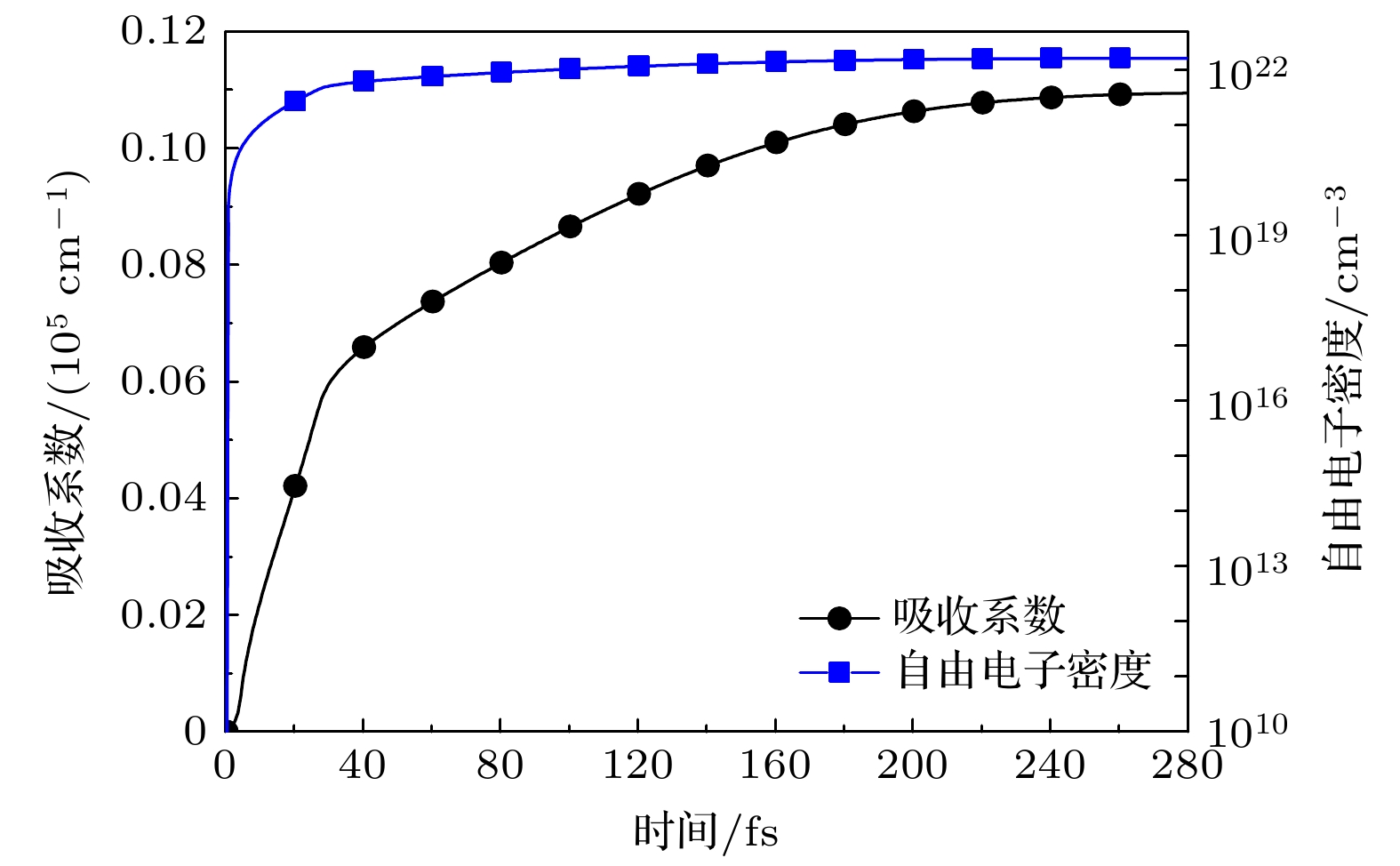

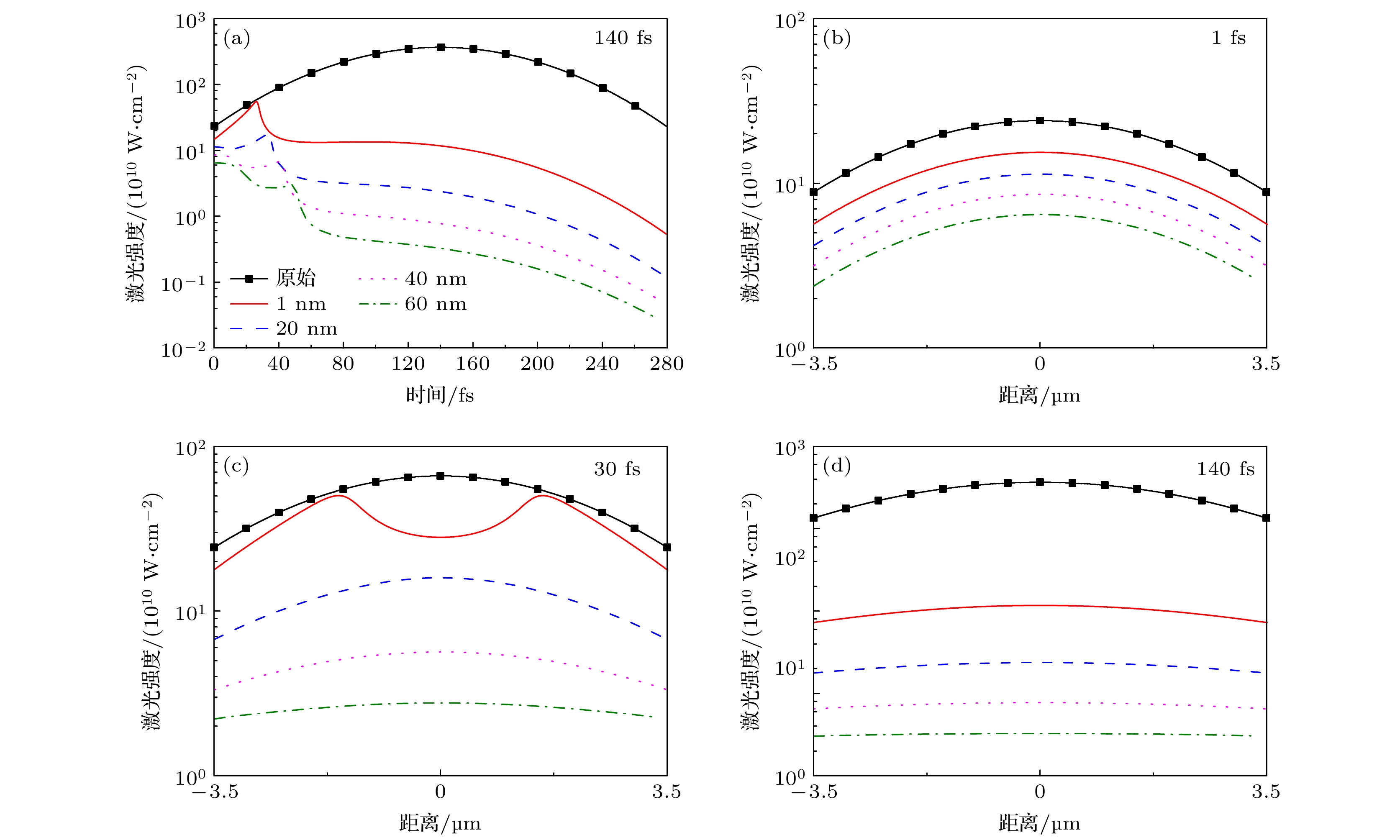

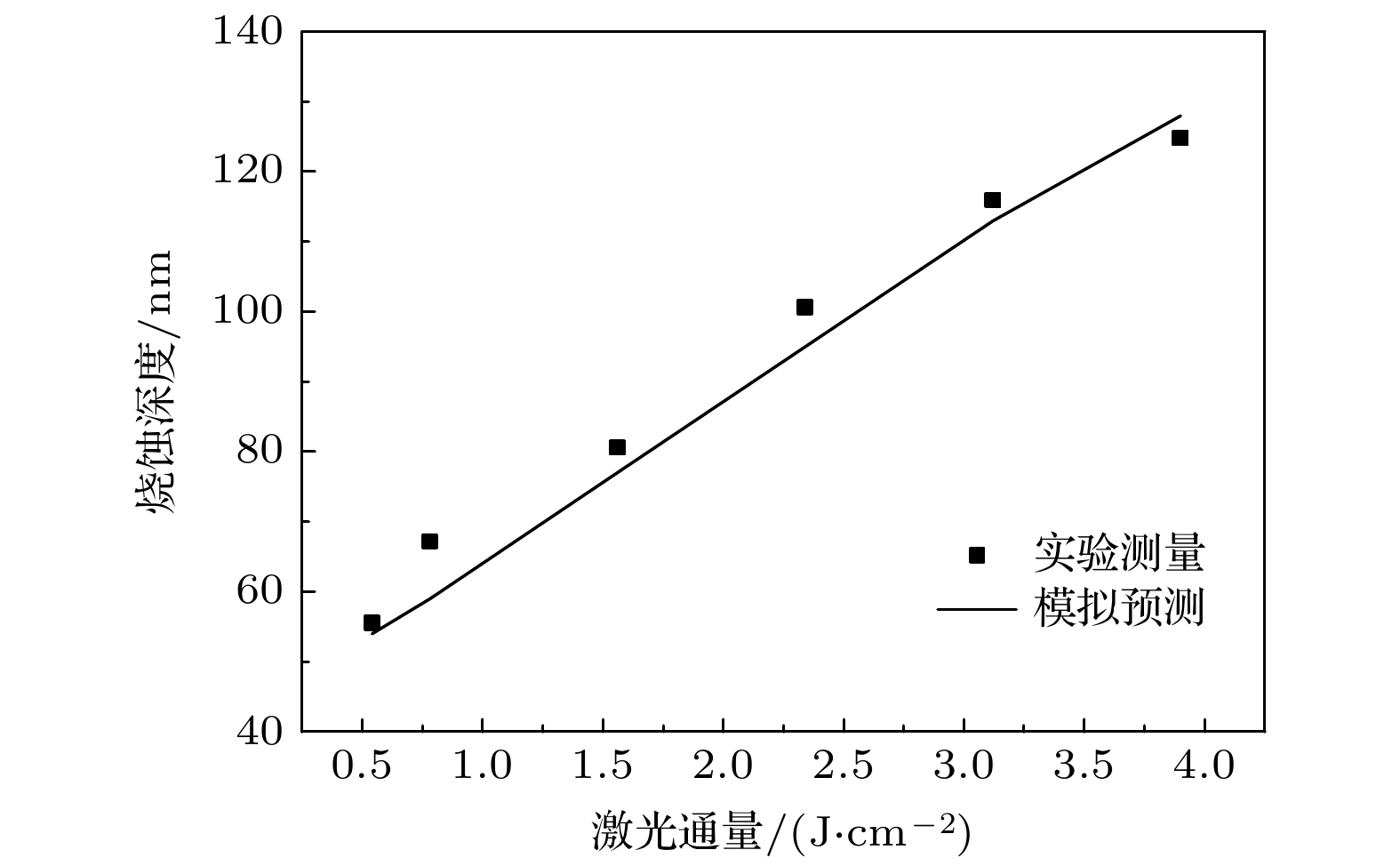

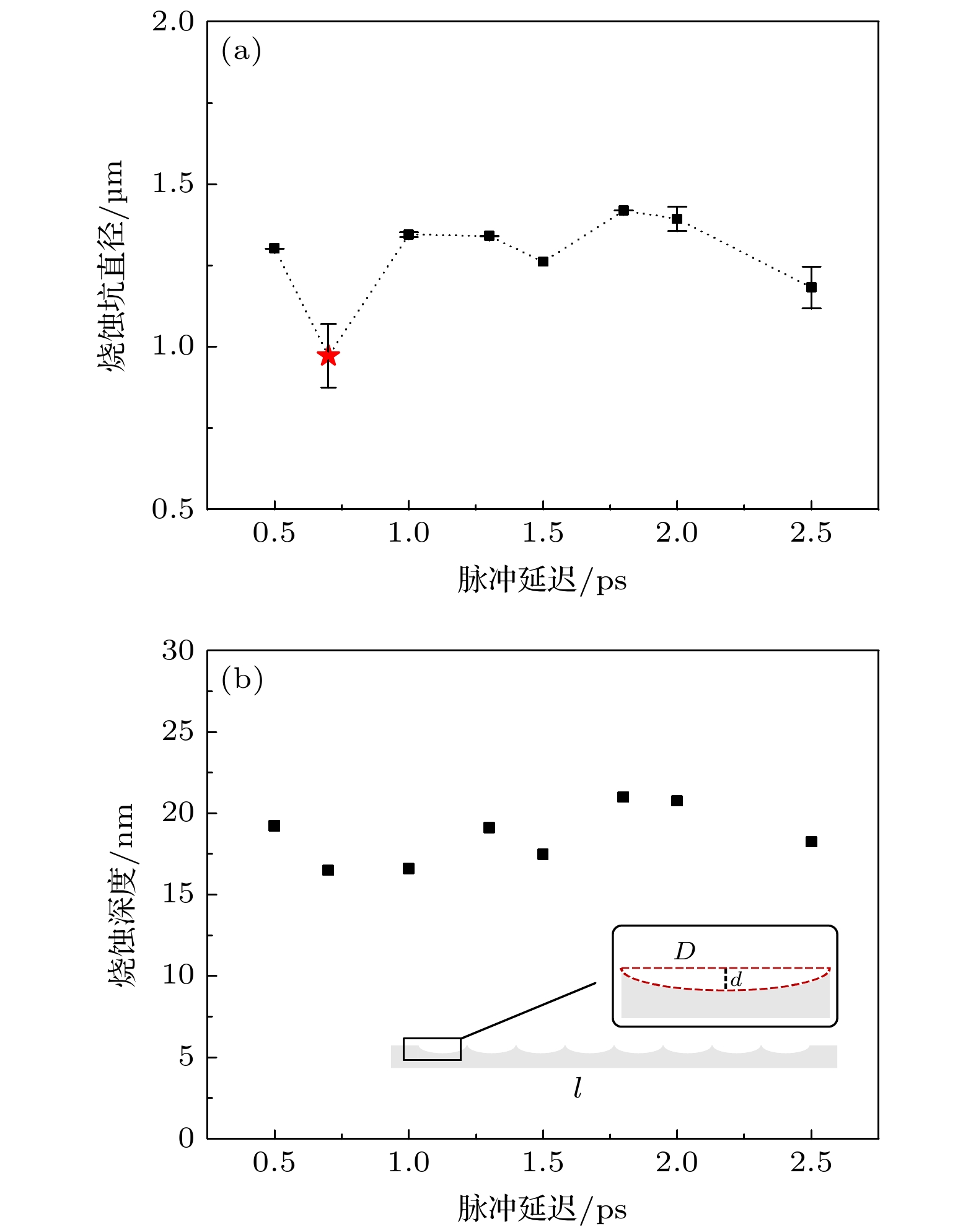

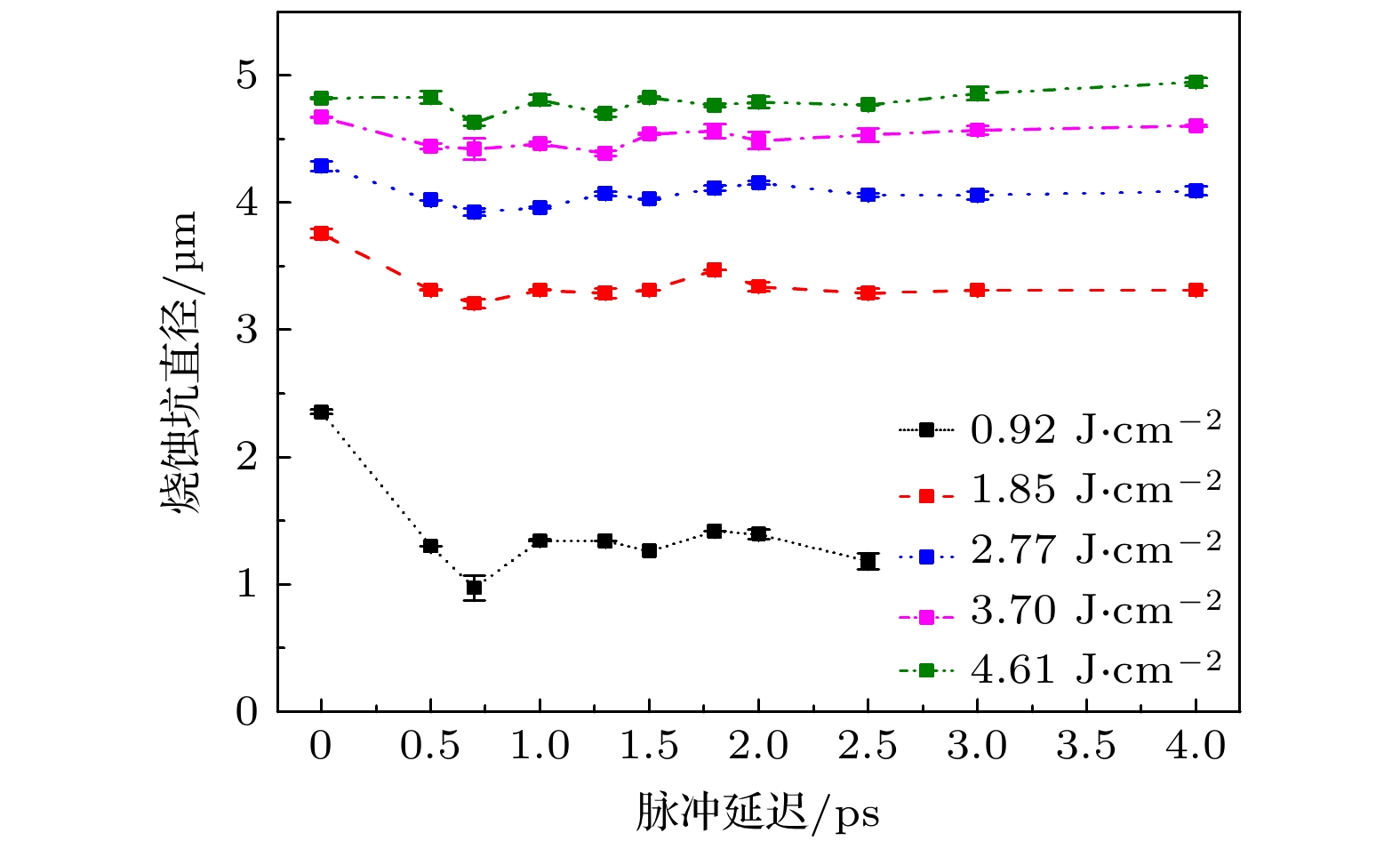

飞秒激光加工作为一种高效可控的调制手段, 其辐照所引起的材料电离可以对激光脉冲在材料内部的能量传递和沉积产生重要影响, 进而调控材料的表面形貌和化学组分. 因此, 本文重点研究了飞秒激光辐照二硫化钨的烧蚀特性并利用等离子体模型对辐照过程中材料的超快响应以及能量的传递、吸收进行计算分析. 研究发现, 烧蚀坑的深度和直径均展现出先快速增长再趋于稳定的变化规律, 并且理论计算与实验结果符合. 揭示了飞秒激光烧蚀二硫化钨的机制, 辐照初期材料内部会产生大量自由电子并形成致密等离子体区域, 导致材料表面反射和内部吸收的显著增加. 两个增强效应共同影响激光能量的注入和沉积, 使得大量入射能量沉积在近表面浅层区域, 并且激光通量增加时烧蚀坑的扩张出现饱和趋势. 此外, 利用时域整形双脉冲序列烧蚀二硫化钨, 通过调节脉冲延迟在保持烧蚀深度不变的情况下, 在双脉冲延时为0.7 ps时得到最优化的最小烧蚀坑直径. 研究结果有助于激光调制二氧化钨在光催化方面的应用研究.Femtosecond laser treatment has been widely used for modulating different kinds of materials as a convenient and efficient approach. In the process of laser modulation, the ionization caused by femtosecond laser irradiation may significantly affect the propagation and energy deposition of laser pulse inside the material, and thus finally influencing the surface morphology and optimizing the material properties. In this work, the ablation of WS2 is conducted in a wide range of laser fluence by single pulse. With the increase of injected energy, the expansion of craters goes through a process from rapid growth to stabilization both in the direction of diameter and in the depth direction. And a plasma model is proposed to track the dynamic response of the excited material and the transfer and deposition of the laser energy in the irradiation of WS2. The calculated results reveal that a great number of free electrons will generate after the incidence of laser pulse and leads the dense plasma zone to form. In this zone, the reflection on the surface and the absorption inside of WS2 are both enhanced due to the rapid increase of free electron density, which affects the injection and deposition of laser energy, thus resulting in the deposition of most energy in the shallow area below the surface. With the increasing of the laser fluence, the majority of laser energy is deposited on the surface of WS2, which leads the ablation crater to reach the saturation state. Meanwhile, a double-pulse train generated by temporal shaping is utilized to modulate the diameter of craters. By adjusting the pulse delay, the smallest diameter of the crater can be obtained at 0.7 ps. The results pave the way for potential applications of the effective method in controlling the material removal and improving the catalytic performance of pristine WS2.

-

Keywords:

- femtosecond laser /

- temporal shaping /

- ablation /

- energy deposition

[1] Afzal A M, Iqbal M Z, Dastgeer G, Nazir G, Mumtaz S, Usman M, Eom J 2020 ACS Appl. Mater. Interfaces 12 39524

Google Scholar

Google Scholar

[2] Sang Y, Zhao Z, Zhao M, Hao P, Leng Y, Liu H 2015 Adv. Mater. 27 363

Google Scholar

Google Scholar

[3] Liu Y, Huang W, Chen W, Wang X, Guo J, Tian H, Zhang H, Wang Y, Yu B, Ren T-L 2019 Appl. Surf. Sci. 481 1127

Google Scholar

Google Scholar

[4] 王聪, 刘杰, 张晗 2019 68 188101

Google Scholar

Google Scholar

Wang C, Liu J, Zhang H 2019 Acta Phys. Sin. 68 188101

Google Scholar

Google Scholar

[5] Rahman M S, Hasan M R, Rikta K A, Anower M 2018 Opt. Mater. 75 567

Google Scholar

Google Scholar

[6] Zhang C, Wang S, Yang L, Liu Y, Xu T, Ning Z, Zak A, Zhang Z, Tenne R, Chen Q 2012 Appl. Phys. Lett. 100 243101

Google Scholar

Google Scholar

[7] Ma S, Zeng L, Tao L, Tang C Y, Yuan H, Long H, Cheng P K, Chai Y, Chen C, Fung K H 2017 Sci. Rep. 7 1

Google Scholar

Google Scholar

[8] Venkatakrishnan A, Chua H, Tan P, Hu Z, Liu H, Liu Y, Carvalho A, Lu J, Sow C H 2017 ACS Nano 11 713

Google Scholar

Google Scholar

[9] Phillips K C, Gandhi H H, Mazur E, Sundaram S 2015 Adv. Opt. Photonics 7 684

Google Scholar

Google Scholar

[10] Jiang L, Wang A, Li B, Cui T, Lu Y 2018 Light Sci. Appl. 7 17134

Google Scholar

Google Scholar

[11] Xu C, Jiang L, Li X, Li C, Shao C, Zuo P, Liang M, Qu L, Cui T 2020 Nano Energy 67 104260

Google Scholar

Google Scholar

[12] Zuo P, Jiang L, Li X, Tian M, Xu C, Yuan Y, Ran P, Li B, Lu Y 2019 ACS Appl. Mater. Interfaces 11 39334

Google Scholar

Google Scholar

[13] Lu J, Lu J H, Liu H, Liu B, Chan K X, Lin J, Chen W, Loh K P, Sow C H 2014 Acs Nano 8 6334

Google Scholar

Google Scholar

[14] Alrasheed A, Gorham J M, Tran Khac B C, Alsaffar F, DelRio F W, Chung K H, Amer M R 2018 ACS Appl. Mater. Interfaces 10 18104

Google Scholar

Google Scholar

[15] Sundaram S, Mazur E 2002 Nature Mater. 1 217

Google Scholar

Google Scholar

[16] Vaidyanathan A, Mitra S, Narducci L, Shatas R 1977 Solid State Commun. 21 405

Google Scholar

Google Scholar

[17] Petrakakis E, Tsibidis G, Stratakis E 2019 Phys. Rev. B 99 195201

Google Scholar

Google Scholar

[18] Jiang L, Tsai H L 2005 Int. J. Heat Mass Transf. 48 487

Google Scholar

Google Scholar

[19] Fox M 2009固体的光学性质(注释版) (北京: 科学出版社) 第155−156页

Fox M 2009 Optical Properties of Solids (Beijing: Science Press) pp155−156 (in Chinese)

[20] Zhao X, Shin Y C 2014 Appl. Phys. Lett. 105 111907

Google Scholar

Google Scholar

[21] Höhm S, Rosenfeld A, Krüger J, Bonse J 2013 Appl. Surf. Sci. 278 7

Google Scholar

Google Scholar

[22] Hernandez-Rueda J, Götte N, Siegel J, Soccio M, Zielinski B, Sarpe C, Wollenhaupt M, Ezquerra T A, Baumert T, Solis J 2015 ACS Appl. Mater. Interfaces 7 6613

Google Scholar

Google Scholar

[23] Zhao M, Hu J, Jiang L, Zhang K, Liu P, Lu Y 2015 Sci. Rep. 5 1

Google Scholar

Google Scholar

-

图 6 辐照后二硫化钨内部激光强度分布(F = 0.54 J/cm2) (a) 辐照中心区域激光强度; (b)−(d) 分别为1, 30, 140 fs时二硫化钨内部的激光强度分布

Fig. 6. Distribution of laser intensity inside the irradiated WS2 (F = 0.54 J/cm2): (a) laser intensity of the central irradiated region as the function of time; (b)−(d) distribution of laser intensity inside WS2 at 1, 30, and 140 fs, respectively.

表 1 模型中用到相关参数

Table 1. Parameters used in the model.

参数 符号 取值 禁带宽度/eV Eg 1.35 正折射率 n 4.0 消光系数 k 0 价带电子数/cm-3 Nev 1.44 × 1023 光斑半径/μm r0 3.5 激光通量/(J·cm-1) F 0.5—4.0 激光脉宽/fs tp 140 激光波长/nm λ 800 -

[1] Afzal A M, Iqbal M Z, Dastgeer G, Nazir G, Mumtaz S, Usman M, Eom J 2020 ACS Appl. Mater. Interfaces 12 39524

Google Scholar

Google Scholar

[2] Sang Y, Zhao Z, Zhao M, Hao P, Leng Y, Liu H 2015 Adv. Mater. 27 363

Google Scholar

Google Scholar

[3] Liu Y, Huang W, Chen W, Wang X, Guo J, Tian H, Zhang H, Wang Y, Yu B, Ren T-L 2019 Appl. Surf. Sci. 481 1127

Google Scholar

Google Scholar

[4] 王聪, 刘杰, 张晗 2019 68 188101

Google Scholar

Google Scholar

Wang C, Liu J, Zhang H 2019 Acta Phys. Sin. 68 188101

Google Scholar

Google Scholar

[5] Rahman M S, Hasan M R, Rikta K A, Anower M 2018 Opt. Mater. 75 567

Google Scholar

Google Scholar

[6] Zhang C, Wang S, Yang L, Liu Y, Xu T, Ning Z, Zak A, Zhang Z, Tenne R, Chen Q 2012 Appl. Phys. Lett. 100 243101

Google Scholar

Google Scholar

[7] Ma S, Zeng L, Tao L, Tang C Y, Yuan H, Long H, Cheng P K, Chai Y, Chen C, Fung K H 2017 Sci. Rep. 7 1

Google Scholar

Google Scholar

[8] Venkatakrishnan A, Chua H, Tan P, Hu Z, Liu H, Liu Y, Carvalho A, Lu J, Sow C H 2017 ACS Nano 11 713

Google Scholar

Google Scholar

[9] Phillips K C, Gandhi H H, Mazur E, Sundaram S 2015 Adv. Opt. Photonics 7 684

Google Scholar

Google Scholar

[10] Jiang L, Wang A, Li B, Cui T, Lu Y 2018 Light Sci. Appl. 7 17134

Google Scholar

Google Scholar

[11] Xu C, Jiang L, Li X, Li C, Shao C, Zuo P, Liang M, Qu L, Cui T 2020 Nano Energy 67 104260

Google Scholar

Google Scholar

[12] Zuo P, Jiang L, Li X, Tian M, Xu C, Yuan Y, Ran P, Li B, Lu Y 2019 ACS Appl. Mater. Interfaces 11 39334

Google Scholar

Google Scholar

[13] Lu J, Lu J H, Liu H, Liu B, Chan K X, Lin J, Chen W, Loh K P, Sow C H 2014 Acs Nano 8 6334

Google Scholar

Google Scholar

[14] Alrasheed A, Gorham J M, Tran Khac B C, Alsaffar F, DelRio F W, Chung K H, Amer M R 2018 ACS Appl. Mater. Interfaces 10 18104

Google Scholar

Google Scholar

[15] Sundaram S, Mazur E 2002 Nature Mater. 1 217

Google Scholar

Google Scholar

[16] Vaidyanathan A, Mitra S, Narducci L, Shatas R 1977 Solid State Commun. 21 405

Google Scholar

Google Scholar

[17] Petrakakis E, Tsibidis G, Stratakis E 2019 Phys. Rev. B 99 195201

Google Scholar

Google Scholar

[18] Jiang L, Tsai H L 2005 Int. J. Heat Mass Transf. 48 487

Google Scholar

Google Scholar

[19] Fox M 2009固体的光学性质(注释版) (北京: 科学出版社) 第155−156页

Fox M 2009 Optical Properties of Solids (Beijing: Science Press) pp155−156 (in Chinese)

[20] Zhao X, Shin Y C 2014 Appl. Phys. Lett. 105 111907

Google Scholar

Google Scholar

[21] Höhm S, Rosenfeld A, Krüger J, Bonse J 2013 Appl. Surf. Sci. 278 7

Google Scholar

Google Scholar

[22] Hernandez-Rueda J, Götte N, Siegel J, Soccio M, Zielinski B, Sarpe C, Wollenhaupt M, Ezquerra T A, Baumert T, Solis J 2015 ACS Appl. Mater. Interfaces 7 6613

Google Scholar

Google Scholar

[23] Zhao M, Hu J, Jiang L, Zhang K, Liu P, Lu Y 2015 Sci. Rep. 5 1

Google Scholar

Google Scholar

计量

- 文章访问数: 5789

- PDF下载量: 79

- 被引次数: 0

下载:

下载: