-

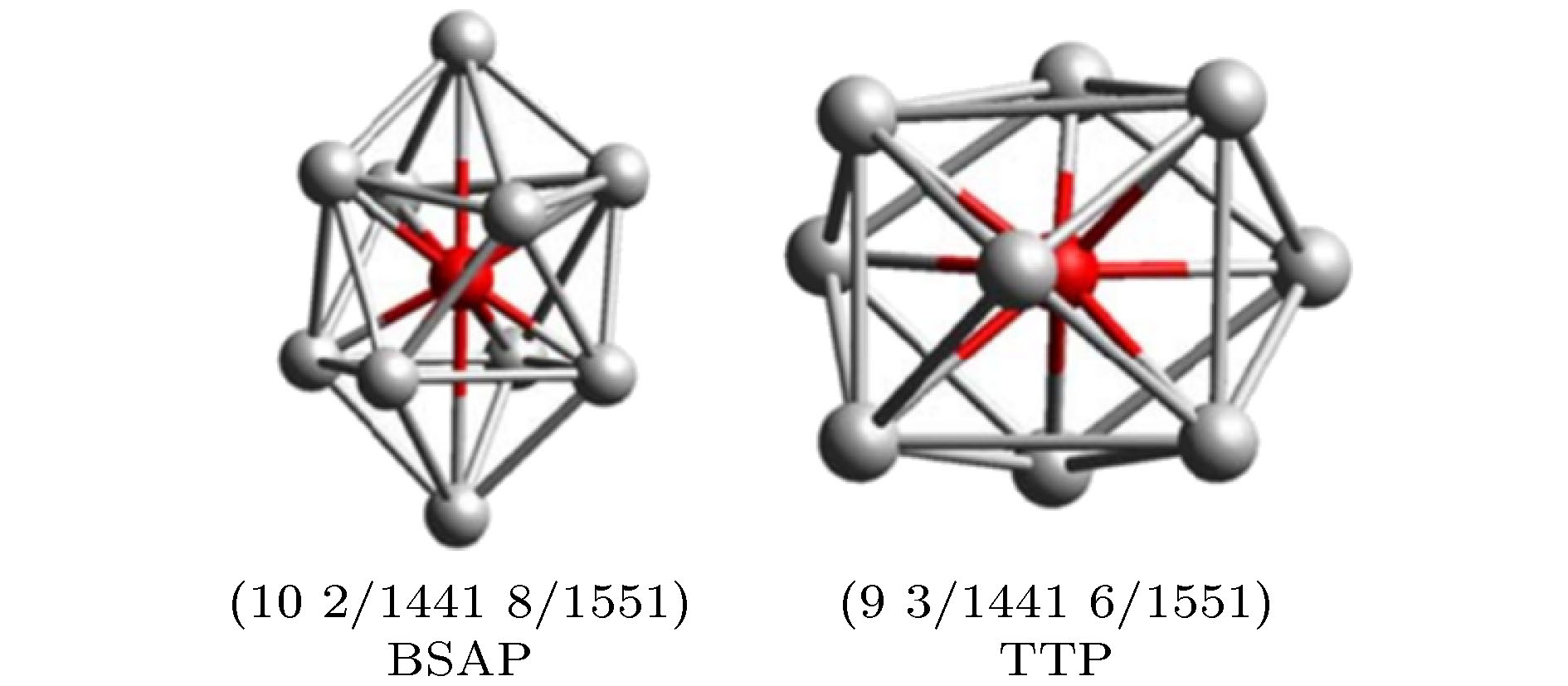

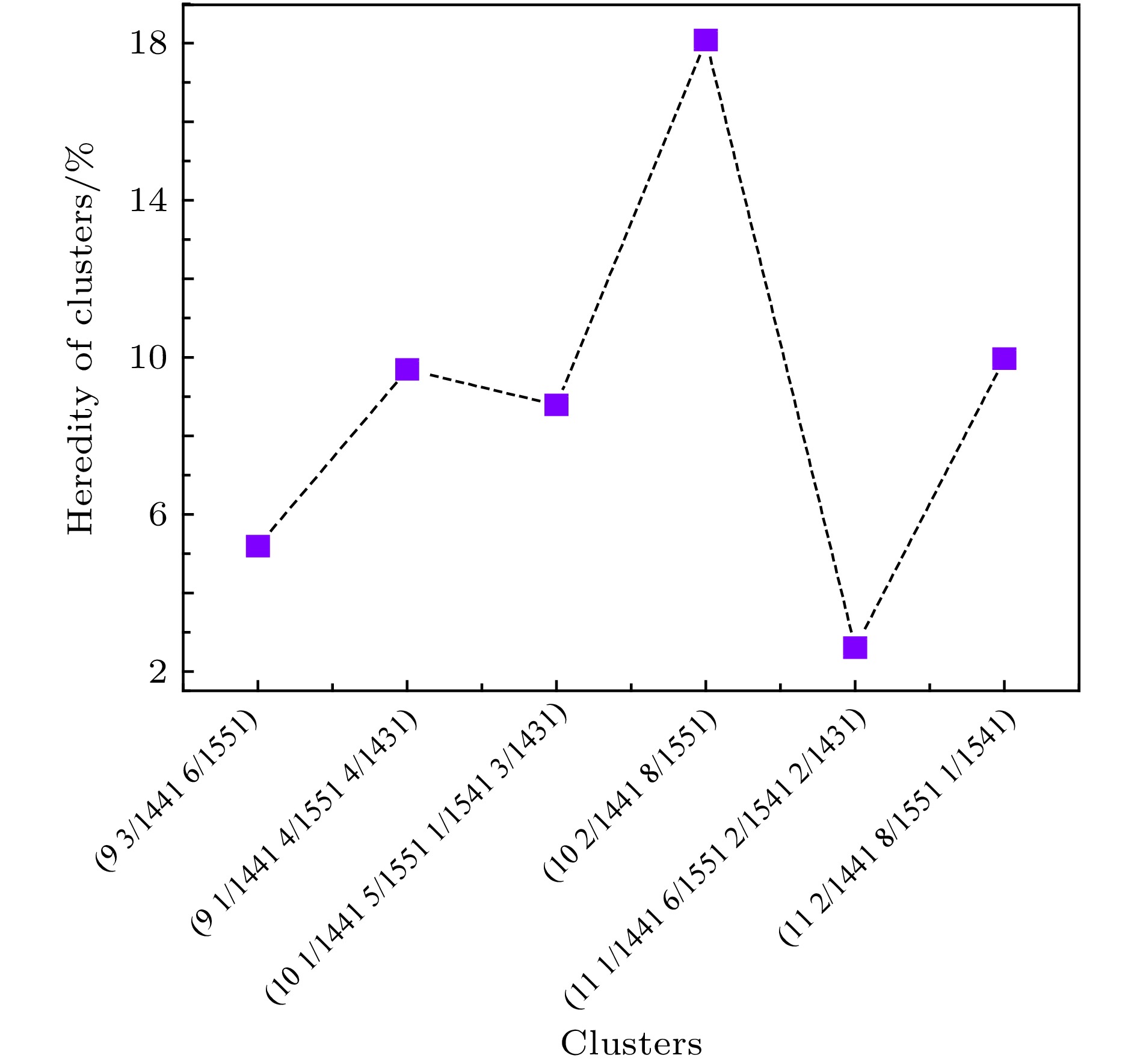

采用分子动力学(MD)模拟计算, 对Pd82Si18合金快凝过程中基本原子团簇的遗传特性、演化趋势和结构稳定性进行了研究. 团簇类型指数法(CTIM)分析表明: 非晶固体中Si原子为中心的(10 2/1441 8/1551)双帽阿基米德反棱柱(BSAP)团簇数目占据优势. 快凝过程中, BSAP结构团簇具有最大的遗传分数, 并且其他以Si原子为中心的Kasper团簇大多都会向BSAP结构团簇转变. 通过对Si原子为中心的Kasper基本团簇电子性质第一性原理计算发现, 体系中BSAP团簇的结合能最低, 结构稳定性较高, 与分子动力学计算结果一致.

-

关键词:

- Pd82Si18合金 /

- 快速凝固 /

- 团簇 /

- 遗传 /

- 电子性质

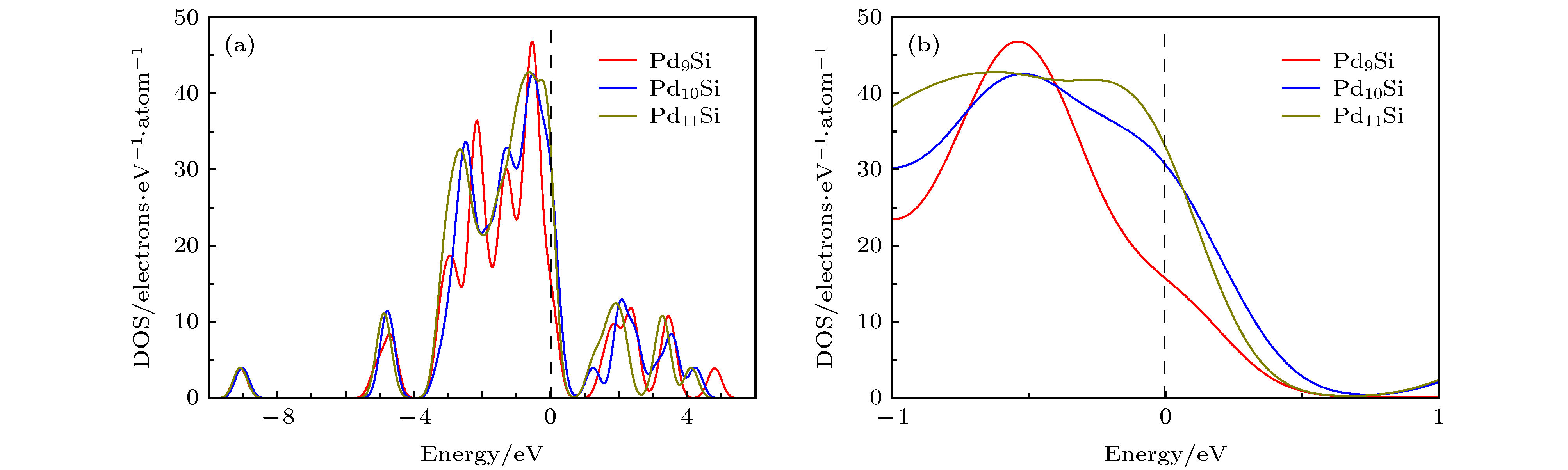

Molecular dynamics (MD) simulation and first-principles calculation were used to study the heredity characteristics, evolution trend and structural stability of basic clusters during the rapid solidification of Pd82Si18 alloy. The local atomic structures were characterized by the pair distribution function g(r) and the extended cluster-type index method (CTIM). The MD simulations reveal that the number of bi-cap Archimedes anti-prism (BSAP) clusters with CTIM index (10 2/1441 8/1551) is dominant in the amorphous solids rather than three-cap triangular prism(TTP) with CTIM index (9 3/1441 6/1551), which is identified be the most popular basic units in Pd82Si18 alloys analyzed by Voronoi index Relative to other basic clusters, the Si-centered BSAP possesses much larger fraction in the glassy state of Pd82Si18 alloys. Different from the findings in Cu-Zr alloys, the Si-centered BSAP instead of icosahedra has a larger hereditary fraction than any other Kasper clusters. During the solidification, it was found that most of the other Si-centered basic clusters are transferred into BSAP. Via the DFT calculations, it is observed that the Si-centered basic clusters with higher fraction of heredity and possesses lower binding energy. Among of them, BSAP always keeps lower binding energy than any other Si-centered Kasper clusters during the rapid solidification, resulting in its highest structural stability and the largest heredity fraction.-

Keywords:

- Pd82Si18alloy /

- rapid solidification /

- cluster /

- heredity /

- electronic property

[1] Kui H W, Greer A L, Turnbull D 1984 Appl. Phys. Lett. 45 615

Google Scholar

Google Scholar

[2] Inoue A 1997 Mater. Sci. Eng. A 226-228 357

[3] Nelson D 1983 Phys. Rev. B 28 5515

Google Scholar

Google Scholar

[4] Sha Z D, Xu B, Shen L, Zhang A H, Feng Y P, Li Y 2010 J. Appl. Phys. 107 063508

Google Scholar

Google Scholar

[5] Wen D D, Peng P, Jiang Y Q, Liu R S 2013 J. Non-Cryst. Solids 378 61

Google Scholar

Google Scholar

[6] 邓永和, 文大东, 彭超, 韦彦丁, 赵瑞, 彭平 2016 65 066401

Google Scholar

Google Scholar

Deng Y H, Wen D D, Peng C, Wei Y D, Zhao R, Peng P 2016 Acta Phys. Sin. 65 066401

Google Scholar

Google Scholar

[7] Wu Z W, Li M Z, Wang W H, Liu K X 2013 Phys. Rev. B 88 054202

Google Scholar

Google Scholar

[8] Cheng Y Q, Sheng H W, Ma E 2008 Phys. Rev. B 78 014207

Google Scholar

Google Scholar

[9] Luo H B, Xiong L H, Ahmad A S, Li A G, Yang K, Glazyrin K, Liermann H P, Franz H, Wang X D, Cao Q P, Zhang D X, Jiang J Z 2014 Acta Mater. 81 420

Google Scholar

Google Scholar

[10] Luo W K, Ma E 2008 J. Non-Cryst. Solids 354 945

Google Scholar

Google Scholar

[11] Sheng H W, Luo W K, Alamgir F M, Bai J M, Ma E 2006 Nature 439 419

Google Scholar

Google Scholar

[12] 彭超, 李媛, 邓永和, 彭平 2017 金属学报 53 1659

Peng C, Li Y, Deng Y H, Peng P 2017 Acta Metal. Sin. 53 1659

[13] Deng Y H, Wen D D, Li Y, Liu J, Peng P 2018 Philos.Mag. 98 2861

Google Scholar

Google Scholar

[14] 姚可夫, 陈娜 2008 中国科学 G 辑 38 387

Yao K F, Chen N 2008 Sci. China Ser. G 38 387

[15] Plimpton S 1995 J. Comput. Phys. 117 1

Google Scholar

Google Scholar

[16] https:\\www.google.com/site/eampotentials/Home/PdSi[2019-6-21]

[17] Delley B 2000 J. Chem. Phys. 113 7756

Google Scholar

Google Scholar

[18] Delley B 1990 J. Chem. Phys. 92 508

Google Scholar

Google Scholar

[19] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[20] Mattern N, Schops A, Kuhn U, Acker J, Eckert J 2008 J. Non-Cryst. Solids 354 1054

Google Scholar

Google Scholar

[21] Honeycutt J D, Andersen H C 1987 J. Phys. Chem. 91 4950

Google Scholar

Google Scholar

[22] 文大东, 彭平, 蒋元祺, 田泽安, 刘让苏 2013 62 196101

Wen D D, Peng P, Jiang Y Q, Tian Z A, Liu R S 2013 Acta Phys. Sin. 62 196101

[23] Tian Z A, Liu R S, Dong K J, Yu A B 2011 Euro. Phys. Lett. 96 36001

Google Scholar

Google Scholar

[24] Wang H, Hu T, Qin J Y, Zhang T 2012 J. Appl. Phys. 112 073520

Google Scholar

Google Scholar

[25] Cheng Y Q, Ding J, Ma E 2013 Mater. Res. Lett. 1 3

Google Scholar

Google Scholar

[26] Jiang Y Q, Peng P, Wen D D, Han S C, Hou Z Y 2015 Comput. Mater. Sci. 99 156

Google Scholar

Google Scholar

[27] Peng P, Li G F, Tian Z A, Dong K J, Liu R S 2009 Comput. Mater. Sci. 44 881

Google Scholar

Google Scholar

-

图 1 Pd82Si18在1300 →300 K快凝过程中体系的双体分布函数(ΔT = 100 K) (a) g(r)tot; (b) g(r)tot的第一峰放大图; (c) g(r)tot第二峰放大图; (d) g(r)Pd-Si和g(r)Pd-Pd第一峰的放大图

Fig. 1. Pair distribution functions g(r) for rapidly solidified of Pd82Si18 from 1300 to 300 K (ΔT =100 K): (a) The g(r)tot curve; (b) first peak zoom of g(r)tot curve; (c) second peak zoom of g(r)tot curve; (d) first peak zoom of g(r)Pd-Si and g(r)Pd-Pd curve.

图 7 非晶合金Pd82Si18在810 K和300 K的几种基本Si为中心的团簇的结合能随团簇的分布 (a) 810 K基本Si为中心的团簇的结合能分布; (b) 300 K基本Si为中心的团簇的结合能分布; (c) 810 与300 K基本Si为中心的团簇的平均结合能分布

Fig. 7. Binding energies of several basic Si-centered clusters of amorphous alloy Pd82Si18 at 810 and 300 K depend on the distribution of clusters: (a) Binding energy distribution of basic Si-centered clusters at 800 K; (B) binding energy distribution of basic Si-centered clusters at 300 K; (c) distribution of average binding energy of basic Si-centered clusters at 800 and 300 K.

图 9 局域电荷密度分布图 (a)Si原子为中心的Pd10Si团簇的局域电荷密度; (b)Si原子为中心的Pd9Si团簇的局域电子密度(图中白色和红色的字体表示切面上的原子)

Fig. 9. Pattern of local charge density distribution: (a) Local charge density of Si-centered Pd10Si cluster; (b) local charge density of Si-centered Pd9Si cluster(White and red fonts in the figure represents atoms on the tangent plane).

表 1 Pd82Si18合金从810 到300 K的几种基本Si原子为中心的团簇的演化分数

Table 1. The evolution fractions of several basic Si-centered clusters in amorphous alloy Pd82Si18 from 810 to 300 K.

810 K 300 K (9 3/1441 6/1551) (9 1/1441 4/1551 4/1431) (10 2/1441 8/1551) (10 1/1441 5/1551 1/1541 3/1431) (11 1/1441 6/1551 2/1541 2/1431) (11 2/1441 8/1551 1/1661) Sum/% (9 3/1441 6/1551) — 6.93 10.39 9.52 2.16 9.96 38.96 (9 1/1441 4/1551 4/1431) 7.75 — 16.67 7.36 3.10 9.69 44.57 (10 2/1441 8/1551) 5.80 6.97 — 10.12 1.49 12.94 37.32 (10 1/1441 5/1551 1/1541 3/1431) 5.71 5.93 14.73 — 2.42 9.67 38.46 (11 1/1441 6/1551 2/1541 2/1431) 6.49 4.55 13.64 10.39 — 11.04 46.11 (11 2/1441 8/1551 1/1661) 4.77 4.56 17.01 10.58 3.11 — 40.03 Sum(%) 30.52 28.94 72.44 47.97 12.28 53.30 — -

[1] Kui H W, Greer A L, Turnbull D 1984 Appl. Phys. Lett. 45 615

Google Scholar

Google Scholar

[2] Inoue A 1997 Mater. Sci. Eng. A 226-228 357

[3] Nelson D 1983 Phys. Rev. B 28 5515

Google Scholar

Google Scholar

[4] Sha Z D, Xu B, Shen L, Zhang A H, Feng Y P, Li Y 2010 J. Appl. Phys. 107 063508

Google Scholar

Google Scholar

[5] Wen D D, Peng P, Jiang Y Q, Liu R S 2013 J. Non-Cryst. Solids 378 61

Google Scholar

Google Scholar

[6] 邓永和, 文大东, 彭超, 韦彦丁, 赵瑞, 彭平 2016 65 066401

Google Scholar

Google Scholar

Deng Y H, Wen D D, Peng C, Wei Y D, Zhao R, Peng P 2016 Acta Phys. Sin. 65 066401

Google Scholar

Google Scholar

[7] Wu Z W, Li M Z, Wang W H, Liu K X 2013 Phys. Rev. B 88 054202

Google Scholar

Google Scholar

[8] Cheng Y Q, Sheng H W, Ma E 2008 Phys. Rev. B 78 014207

Google Scholar

Google Scholar

[9] Luo H B, Xiong L H, Ahmad A S, Li A G, Yang K, Glazyrin K, Liermann H P, Franz H, Wang X D, Cao Q P, Zhang D X, Jiang J Z 2014 Acta Mater. 81 420

Google Scholar

Google Scholar

[10] Luo W K, Ma E 2008 J. Non-Cryst. Solids 354 945

Google Scholar

Google Scholar

[11] Sheng H W, Luo W K, Alamgir F M, Bai J M, Ma E 2006 Nature 439 419

Google Scholar

Google Scholar

[12] 彭超, 李媛, 邓永和, 彭平 2017 金属学报 53 1659

Peng C, Li Y, Deng Y H, Peng P 2017 Acta Metal. Sin. 53 1659

[13] Deng Y H, Wen D D, Li Y, Liu J, Peng P 2018 Philos.Mag. 98 2861

Google Scholar

Google Scholar

[14] 姚可夫, 陈娜 2008 中国科学 G 辑 38 387

Yao K F, Chen N 2008 Sci. China Ser. G 38 387

[15] Plimpton S 1995 J. Comput. Phys. 117 1

Google Scholar

Google Scholar

[16] https:\\www.google.com/site/eampotentials/Home/PdSi[2019-6-21]

[17] Delley B 2000 J. Chem. Phys. 113 7756

Google Scholar

Google Scholar

[18] Delley B 1990 J. Chem. Phys. 92 508

Google Scholar

Google Scholar

[19] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[20] Mattern N, Schops A, Kuhn U, Acker J, Eckert J 2008 J. Non-Cryst. Solids 354 1054

Google Scholar

Google Scholar

[21] Honeycutt J D, Andersen H C 1987 J. Phys. Chem. 91 4950

Google Scholar

Google Scholar

[22] 文大东, 彭平, 蒋元祺, 田泽安, 刘让苏 2013 62 196101

Wen D D, Peng P, Jiang Y Q, Tian Z A, Liu R S 2013 Acta Phys. Sin. 62 196101

[23] Tian Z A, Liu R S, Dong K J, Yu A B 2011 Euro. Phys. Lett. 96 36001

Google Scholar

Google Scholar

[24] Wang H, Hu T, Qin J Y, Zhang T 2012 J. Appl. Phys. 112 073520

Google Scholar

Google Scholar

[25] Cheng Y Q, Ding J, Ma E 2013 Mater. Res. Lett. 1 3

Google Scholar

Google Scholar

[26] Jiang Y Q, Peng P, Wen D D, Han S C, Hou Z Y 2015 Comput. Mater. Sci. 99 156

Google Scholar

Google Scholar

[27] Peng P, Li G F, Tian Z A, Dong K J, Liu R S 2009 Comput. Mater. Sci. 44 881

Google Scholar

Google Scholar

计量

- 文章访问数: 8289

- PDF下载量: 95

- 被引次数: 0

下载:

下载: