-

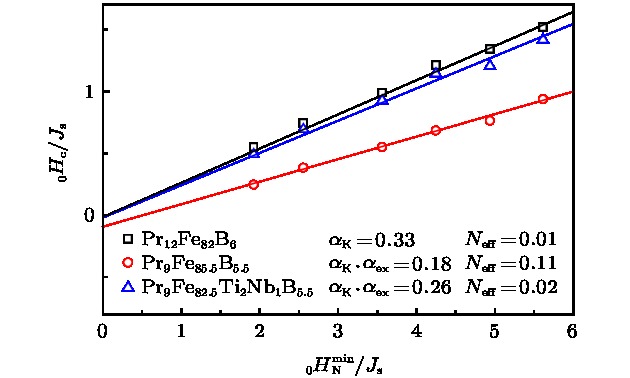

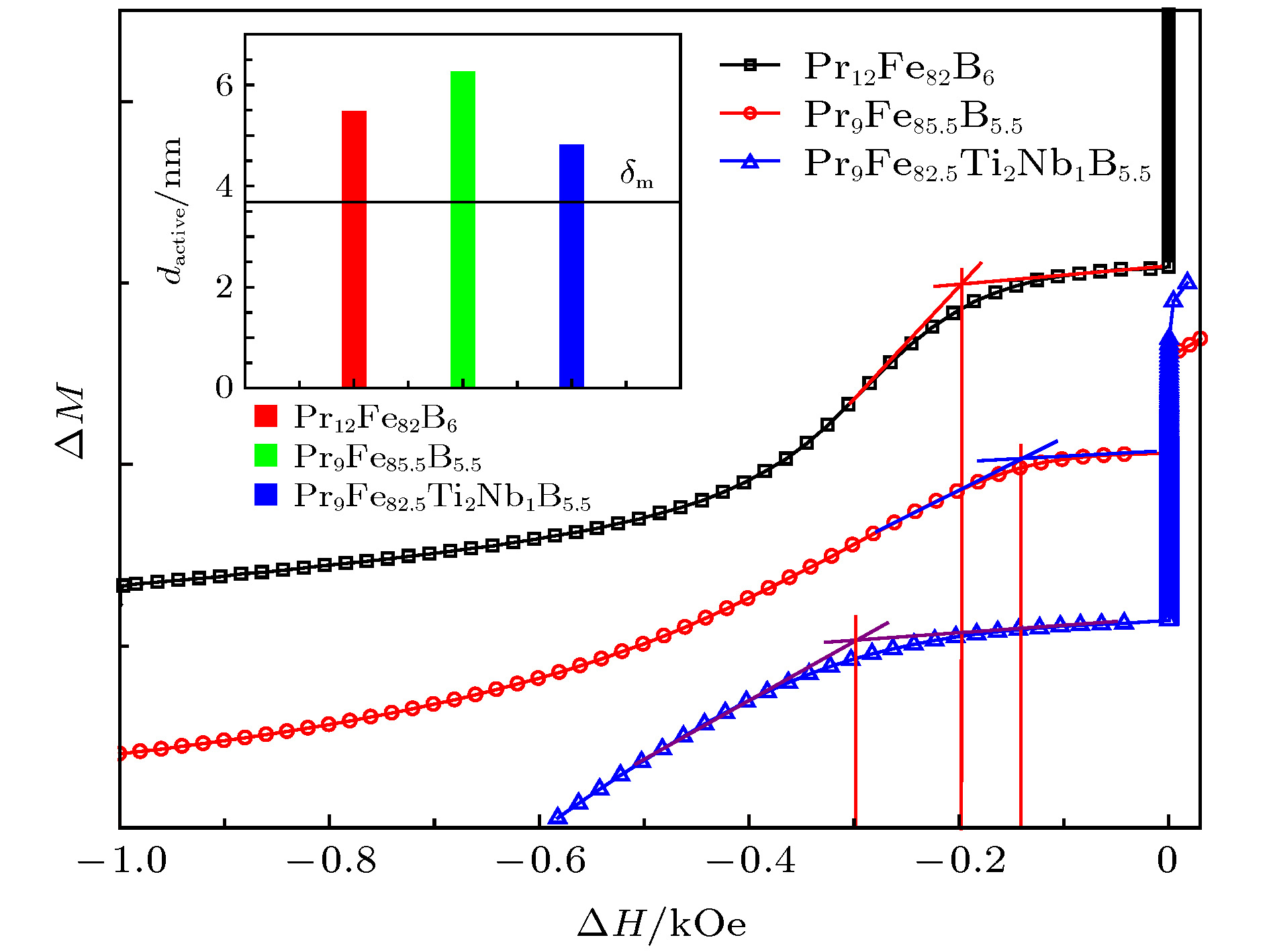

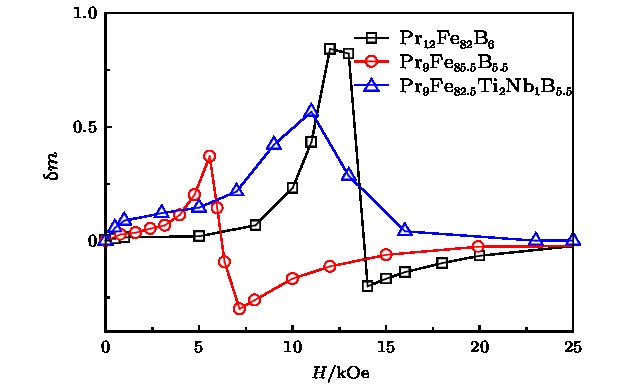

稀土永磁体即使内秉性质相同, 但矫顽力可能相差很大. 本文以Pr-Fe-B磁体为例, 从热激活反磁化即反磁化临界过程探讨决定矫顽力的关键因素. Pr-Fe-B晶粒表层缺陷区与晶粒内部耦合推动反磁化畴形核从而去钉扎, 晶粒表层缺陷区的各向异性对克服晶粒内部势垒具有贡献, 因此反磁化形核场和矫顽力大大降低. 由于晶粒表层缺陷区与晶粒内部耦合, 在反磁化临界过程磁畴壁尺寸稍大于理论尺寸. 具有软、硬磁相结构的Pr-Fe-B复合磁体, 软、硬磁相晶粒之间交换耦合作用也会增大反磁化畴壁尺寸. 软、硬磁交换耦合的能量对克服硬磁相晶粒内部各向异性势垒也会有贡献, 这将进一步降低磁体矫顽力. 添加Ti, Nb高熔点金属, 复合磁体矫顽力显著提高. 分析认为, 这不仅仅是磁体晶粒尺寸减小的缘故. 热激活尺寸减小说明磁畴壁中包含的硬磁相晶粒表层缺陷区尺寸减小, 硬磁相表面和两相界面各向异性对克服硬磁相晶粒内部势垒的贡献减小, 反磁化所需外磁场增大.The coercivities in rare earth permanent magnets even with the same intrinsic properties may differ largely. In this paper, what determines the coercivity is discussed via the investigation of thermal activation in Pr-Fe-B ribbons prepared by melt-spinning method. The thermal activation, resulting from thermal fluctuation overcoming the energy barrier under the applied field, is the critical behavior of magnetization reversal. The activation size is comparable to the theoretical domain wall size, implying that the magnetization reversal undergoes the nucleation of revered domain wall at grain outer-layer in Pr-Fe-B ribbons, and the defects near the grain boundary are critical for the magnetization reversal and coercivity. The exchange coupling between the defect region at grain outer-layer and the perfect region in the inside of grain promotes the nucleation of reversed domain and the depinning of domain wall motion. The reduced anisotropy of the defect region also contributes to the overcoming of energy barrier of magneto crystallie anisotropy in the inside of Pr-Fe-B grains by the coupling effect, so the nucleation field of reversed domain and coercivity decrease largely, and the domain wall size is a little larger than the theoretical value due to the coupling between the defect region at grain outer-layer and the perfect region in the inside of grain in the critical magnetization reversal. In Pr2Fe14B/α-Fe composite magnets, the exchange coupling between the soft and hard magnetic phase leads the domain wall size to increase in the critical magnetization reversal of thermal activation, and so the exchange energy plays a role in overcoming the energy barrier, resulting in the further decrease of coercivity. Via the addition of Ti and Nb element, the coercivity increases significantly. Based on the investigation of thermal activation, the size of defect region involved in the domain wall decreases, and the contribution of the anisotropy in the defect region and interface to the overcoming of energy barrier is weakened, so the applied magnetic field should be increased in the magnetization reversal. The coercivity can be enhanced by reducing the size of defect region at grain outer-layer and by making the anisotropy change abruptly at the interface between the hard and soft magnetic phase.

-

Keywords:

- permanent magnets /

- coercivity /

- domain wall /

- defect

[1] Herbst J F 1991 Rev. Mod. Phys. 63 819

Google Scholar

Google Scholar

[2] Kou X C, Kronmüller H, Givord D, Rossignol M F 1994 Phys. Rev. B 50 3849

Google Scholar

Google Scholar

[3] Zhao G P, Zhao M G, Lim H S, Feng Y P, Ong C K 2005 Appl. Phys. Lett. 87 162513

Google Scholar

Google Scholar

[4] Zhang H W, Rong C B, Zhang J, Zhang S Y, Shen B G 2002 Phys. Rev. B 66 184436

Google Scholar

Google Scholar

[5] Kronmüller H 1987 Phys. Stat. Sol. B 144 385

Google Scholar

Google Scholar

[6] Sepehri-Amin H, Ohkubo T, Shima T, Hono K 2012 Acta Mater. 60 819

Google Scholar

Google Scholar

[7] Chen S L, Liu W, Zhang Z D 2005 Phys. Rev. B 72 224419

Google Scholar

Google Scholar

[8] Yue M, Liu W Q, Zhang D T, Jian Z G, Cao A L, Zhang J X 2009 Appl. Phys. Lett. 94 092501

Google Scholar

Google Scholar

[9] Givord D, Tenaud P, Viadieu T 1988 IEEE Trans. Magn. 24 1921

Google Scholar

Google Scholar

[10] Gao R W, Zhang D H, Li H, Jiang S T, Zhou S Z, Li F B, Zhang L D 1995 J. Appl. Phys. 78 1156

Google Scholar

Google Scholar

[11] Zhao G P, Wang X L, Yang C, Xie L H, Zhou G 2007 J. Appl. Phys. 101 09K102

Google Scholar

Google Scholar

[12] Givord D, Rossignol M, Barthem V M T S 2003 J. Magn. Magn. Mater. 258-259 1

[13] Li Z B, Shen B G, Niu E, Sun J R 2013 Appl. Phys. Lett. 103 062405

Google Scholar

Google Scholar

[14] Kronmüller H, Durst K D, Sagawa M 1988 J. Magn. Magn. Mater. 74 291

Google Scholar

Google Scholar

[15] Wohlfarth E P 1984 J. Phys. F: Met. Phys. 14 L155

Google Scholar

Google Scholar

[16] 张宏伟, 荣传兵, 张健, 张绍英, 沈保根 2003 52 722

Google Scholar

Google Scholar

Zhang H W, Rong C B, Zhang J, Zhang S Y, Shen B G 2003 Acta Phys. Sin. 52 722

Google Scholar

Google Scholar

[17] Li Z B, Shen B G, Niu E, Liu R M, Zhang M, Sun J R 2013 Chin. Phys. B 22 117503

Google Scholar

Google Scholar

[18] Li Z B, Zhang Y, Shen B G, Zhang M, Hu F X, Sun J R 2017 J. Magn. Magn. Mater. 422 249

Google Scholar

Google Scholar

[19] Bauer J, Seeger M, Zern A, Kronmüller H 1996 J. Appl. Phys. 80 1667

Google Scholar

Google Scholar

[20] Zhang H W, Rong C B, Du X B, Zhang S Y, Shen B G 2004 J. Magn. Magn. Mater. 278 127

Google Scholar

Google Scholar

[21] Kronmüller H, Fahnle M 2003 Micromagnetism and the Microstructure of Ferromagnetic Solids (Cambridge: Cambridge University Press) p420

[22] Zhang H W, Zhang S Y, Shen B G, Goll D, Kronmüller H 2001 Chin. Phys. 10 1169

Google Scholar

Google Scholar

[23] Li Z B, Shen B G, Zhang M, Zhang Y, Hu F X, Sun J R 2015 Appl. Phys. Lett. 106 042403

Google Scholar

Google Scholar

[24] 张宏伟, 张文勇, 阎阿儒, 沈保根 1999 48 211

Zhang H W, Zhang W Y, Yan A R, Shen B G 1999 Acta Phys. Sin. 48 211

[25] Li H L, Lou L, Hou F C, Guo D F, Li W, Li X H, Gunderov D V, Sato K, Zhang X Y 2013 Appl. Phys. Lett. 103 142406

Google Scholar

Google Scholar

[26] Seeger M, Köhler D, Kronmüller H 1994 J. Magn. Magn. Mater. 130 165

Google Scholar

Google Scholar

[27] Liu W, Liu X H, Cui W B, Gong W J, Zhang Z D 2013 Chin. Phys. B 22 027104

Google Scholar

Google Scholar

[28] Zhang J, Takahashi Y K, Gopalan R, Hono K 2005 Appl. Phys. Lett. 86 122509

Google Scholar

Google Scholar

[29] Si W J, Zhao G P, Ran N, Peng Y, Morvan F J, Wan X L 2015 Sci. Rep. 5 16212

Google Scholar

Google Scholar

[30] Cui W B, Takahashi Y K, Hono K 2012 Adv. Mater. 24 6530

Google Scholar

Google Scholar

[31] Kelly P E, O’Grady K, Mayo P I, Chantrell R W 1989 IEEE Trans. Magn. 25 3881

Google Scholar

Google Scholar

[32] Choi Y, Jiang J S, Ding Y, Rosenberg R A, Pearson J E, Bader S D, Zambano A, Murakami M, Takeuchi I, Wang Z L, Liu J P 2007 Phys. Rev. B 75 104432

Google Scholar

Google Scholar

-

-

[1] Herbst J F 1991 Rev. Mod. Phys. 63 819

Google Scholar

Google Scholar

[2] Kou X C, Kronmüller H, Givord D, Rossignol M F 1994 Phys. Rev. B 50 3849

Google Scholar

Google Scholar

[3] Zhao G P, Zhao M G, Lim H S, Feng Y P, Ong C K 2005 Appl. Phys. Lett. 87 162513

Google Scholar

Google Scholar

[4] Zhang H W, Rong C B, Zhang J, Zhang S Y, Shen B G 2002 Phys. Rev. B 66 184436

Google Scholar

Google Scholar

[5] Kronmüller H 1987 Phys. Stat. Sol. B 144 385

Google Scholar

Google Scholar

[6] Sepehri-Amin H, Ohkubo T, Shima T, Hono K 2012 Acta Mater. 60 819

Google Scholar

Google Scholar

[7] Chen S L, Liu W, Zhang Z D 2005 Phys. Rev. B 72 224419

Google Scholar

Google Scholar

[8] Yue M, Liu W Q, Zhang D T, Jian Z G, Cao A L, Zhang J X 2009 Appl. Phys. Lett. 94 092501

Google Scholar

Google Scholar

[9] Givord D, Tenaud P, Viadieu T 1988 IEEE Trans. Magn. 24 1921

Google Scholar

Google Scholar

[10] Gao R W, Zhang D H, Li H, Jiang S T, Zhou S Z, Li F B, Zhang L D 1995 J. Appl. Phys. 78 1156

Google Scholar

Google Scholar

[11] Zhao G P, Wang X L, Yang C, Xie L H, Zhou G 2007 J. Appl. Phys. 101 09K102

Google Scholar

Google Scholar

[12] Givord D, Rossignol M, Barthem V M T S 2003 J. Magn. Magn. Mater. 258-259 1

[13] Li Z B, Shen B G, Niu E, Sun J R 2013 Appl. Phys. Lett. 103 062405

Google Scholar

Google Scholar

[14] Kronmüller H, Durst K D, Sagawa M 1988 J. Magn. Magn. Mater. 74 291

Google Scholar

Google Scholar

[15] Wohlfarth E P 1984 J. Phys. F: Met. Phys. 14 L155

Google Scholar

Google Scholar

[16] 张宏伟, 荣传兵, 张健, 张绍英, 沈保根 2003 52 722

Google Scholar

Google Scholar

Zhang H W, Rong C B, Zhang J, Zhang S Y, Shen B G 2003 Acta Phys. Sin. 52 722

Google Scholar

Google Scholar

[17] Li Z B, Shen B G, Niu E, Liu R M, Zhang M, Sun J R 2013 Chin. Phys. B 22 117503

Google Scholar

Google Scholar

[18] Li Z B, Zhang Y, Shen B G, Zhang M, Hu F X, Sun J R 2017 J. Magn. Magn. Mater. 422 249

Google Scholar

Google Scholar

[19] Bauer J, Seeger M, Zern A, Kronmüller H 1996 J. Appl. Phys. 80 1667

Google Scholar

Google Scholar

[20] Zhang H W, Rong C B, Du X B, Zhang S Y, Shen B G 2004 J. Magn. Magn. Mater. 278 127

Google Scholar

Google Scholar

[21] Kronmüller H, Fahnle M 2003 Micromagnetism and the Microstructure of Ferromagnetic Solids (Cambridge: Cambridge University Press) p420

[22] Zhang H W, Zhang S Y, Shen B G, Goll D, Kronmüller H 2001 Chin. Phys. 10 1169

Google Scholar

Google Scholar

[23] Li Z B, Shen B G, Zhang M, Zhang Y, Hu F X, Sun J R 2015 Appl. Phys. Lett. 106 042403

Google Scholar

Google Scholar

[24] 张宏伟, 张文勇, 阎阿儒, 沈保根 1999 48 211

Zhang H W, Zhang W Y, Yan A R, Shen B G 1999 Acta Phys. Sin. 48 211

[25] Li H L, Lou L, Hou F C, Guo D F, Li W, Li X H, Gunderov D V, Sato K, Zhang X Y 2013 Appl. Phys. Lett. 103 142406

Google Scholar

Google Scholar

[26] Seeger M, Köhler D, Kronmüller H 1994 J. Magn. Magn. Mater. 130 165

Google Scholar

Google Scholar

[27] Liu W, Liu X H, Cui W B, Gong W J, Zhang Z D 2013 Chin. Phys. B 22 027104

Google Scholar

Google Scholar

[28] Zhang J, Takahashi Y K, Gopalan R, Hono K 2005 Appl. Phys. Lett. 86 122509

Google Scholar

Google Scholar

[29] Si W J, Zhao G P, Ran N, Peng Y, Morvan F J, Wan X L 2015 Sci. Rep. 5 16212

Google Scholar

Google Scholar

[30] Cui W B, Takahashi Y K, Hono K 2012 Adv. Mater. 24 6530

Google Scholar

Google Scholar

[31] Kelly P E, O’Grady K, Mayo P I, Chantrell R W 1989 IEEE Trans. Magn. 25 3881

Google Scholar

Google Scholar

[32] Choi Y, Jiang J S, Ding Y, Rosenberg R A, Pearson J E, Bader S D, Zambano A, Murakami M, Takeuchi I, Wang Z L, Liu J P 2007 Phys. Rev. B 75 104432

Google Scholar

Google Scholar

计量

- 文章访问数: 19687

- PDF下载量: 173

- 被引次数: 0

下载:

下载: