-

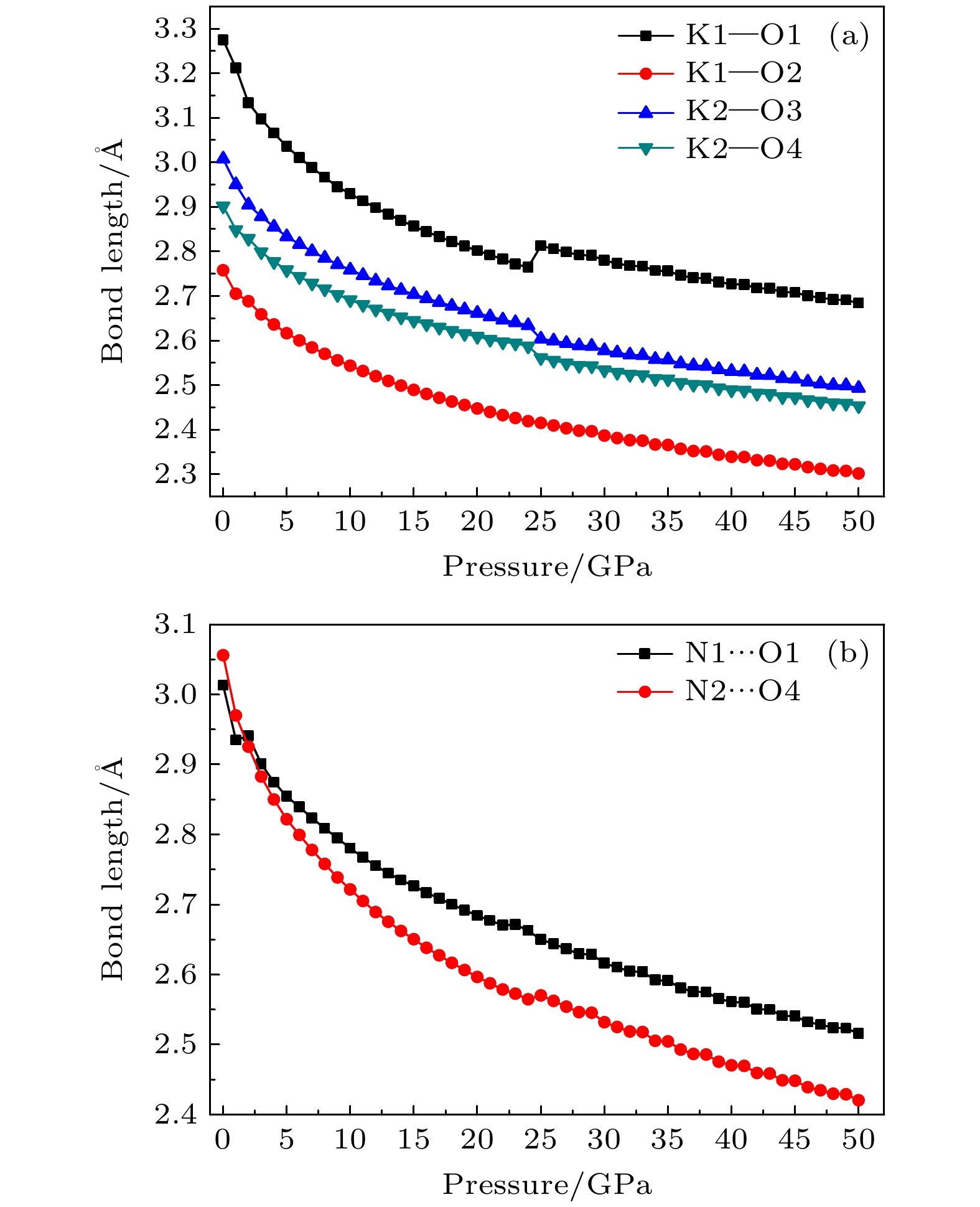

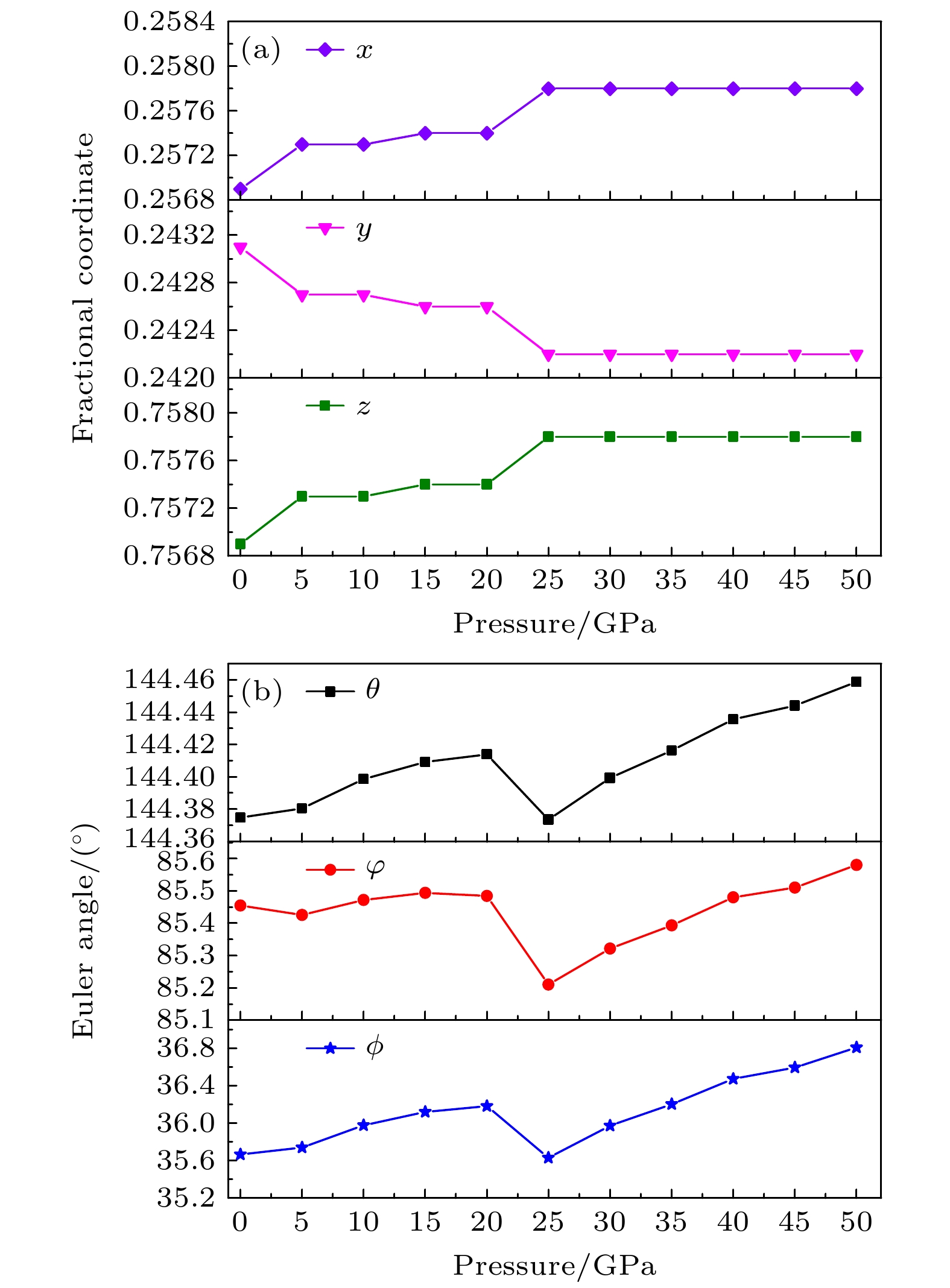

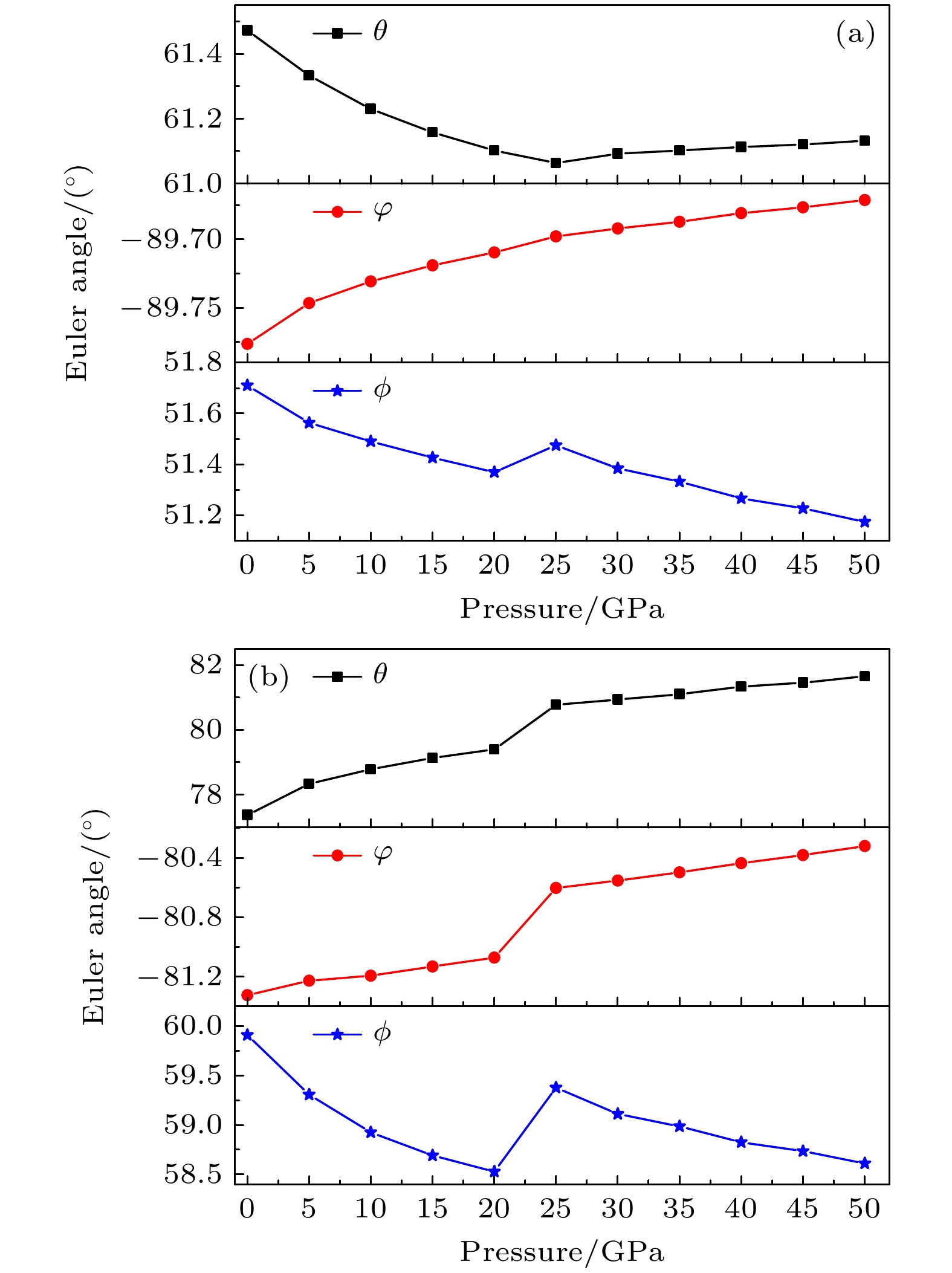

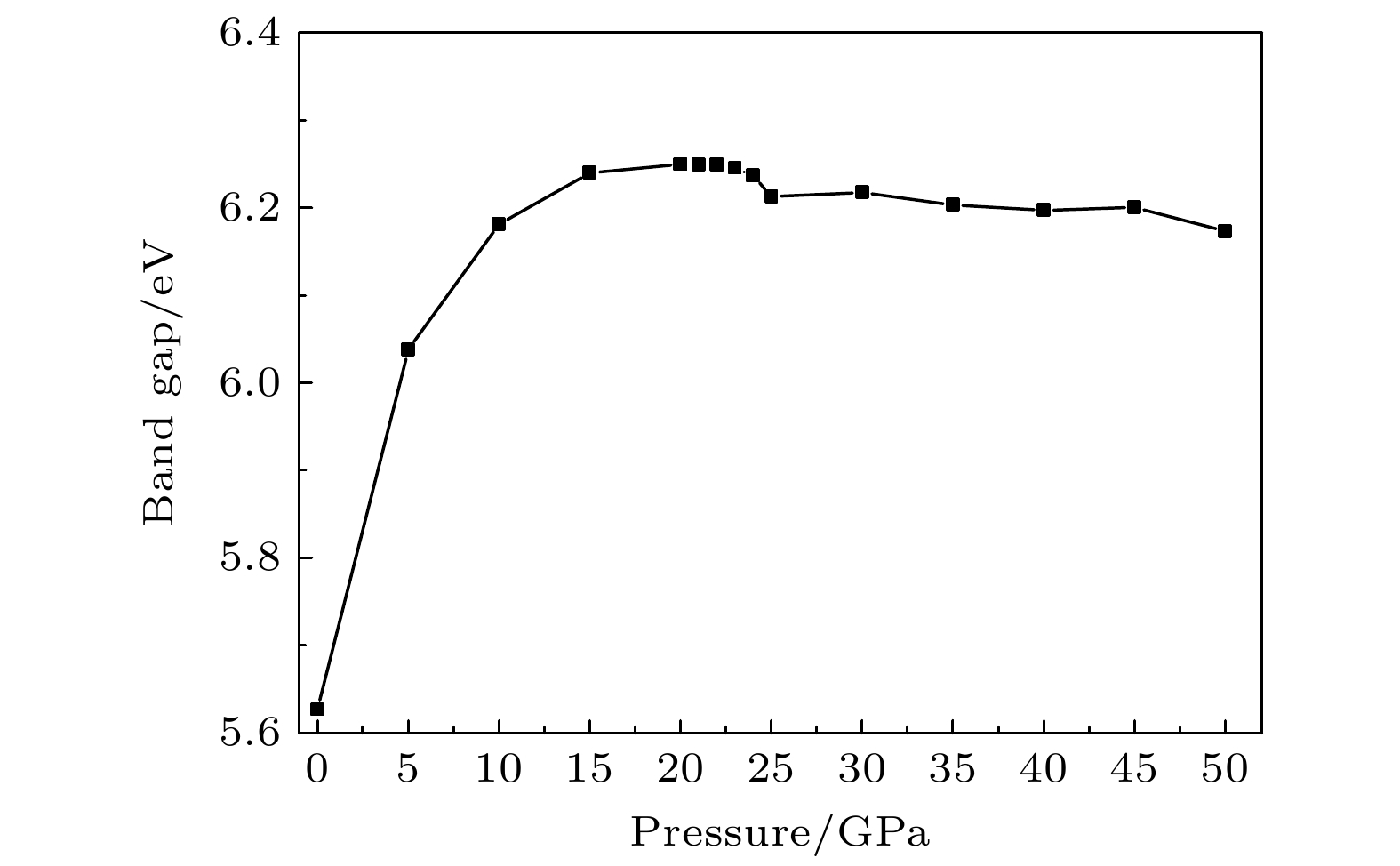

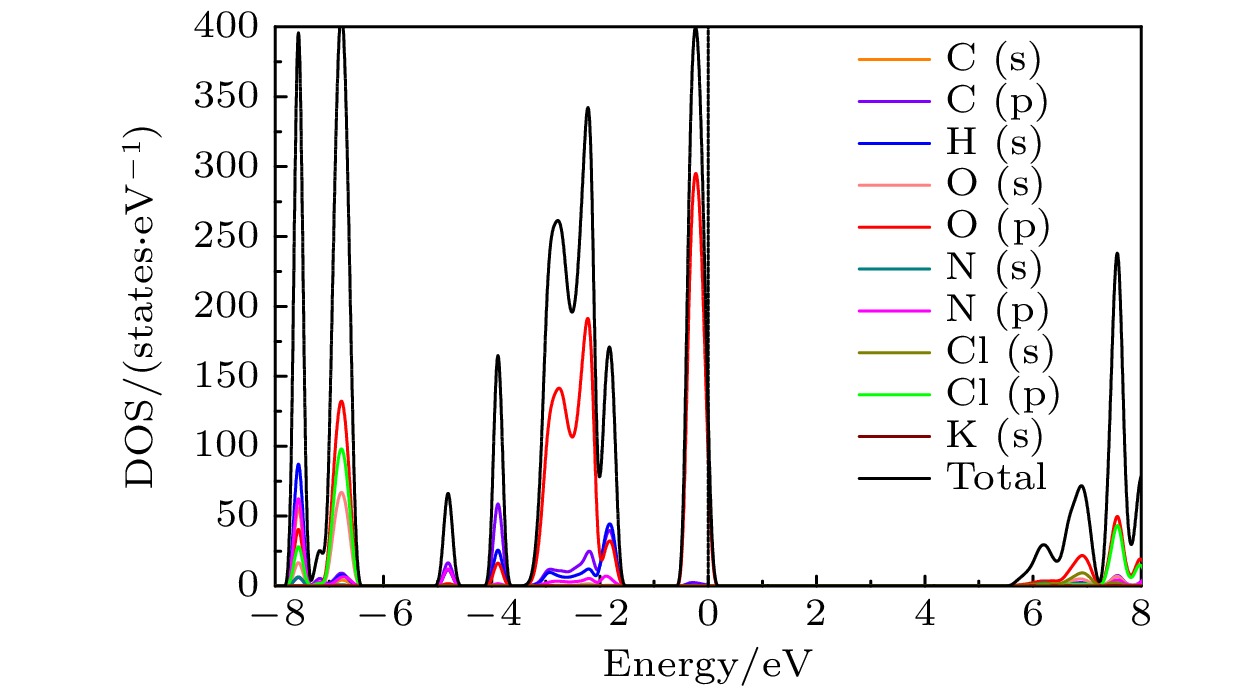

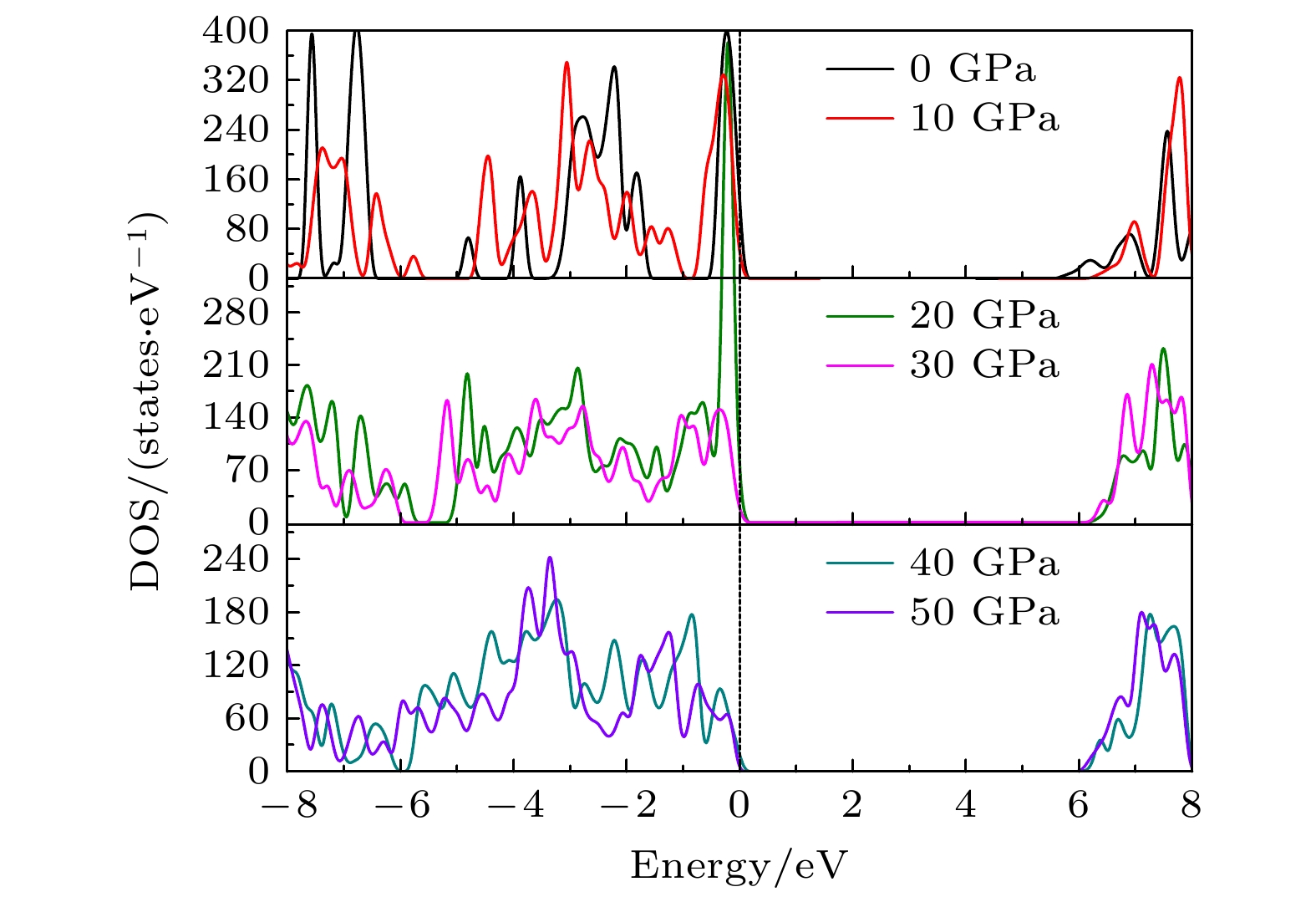

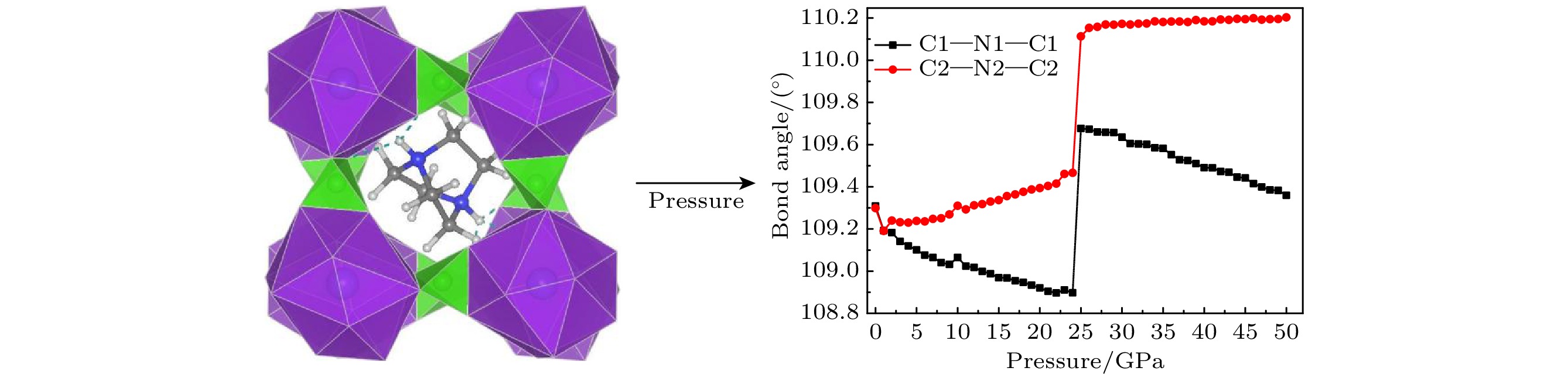

基于第一性原理计算, 深入研究了(H2dabco)[K(ClO4)3](DAP-2)晶体在0—50 GPa压力作用下的晶体结构、分子结构、电子结构和力学性质变化, 并评估了压力对其撞击感度和稳定性的影响. 通过分析晶体内部特征键长和键角发现, 在25 GPa处, 有机阳离子H2dabco2+的笼状结构发生了扭曲. 对H2dabco2+和KO12多面体的质心平均分数坐标和欧拉角的计算结果显示, 整个压力范围内晶体可能保持Pa-3空间群对称性不变. 根据第一性原理带隙判据和不同压力下的带隙变化, 发现在低于20 GPa时, DAP-2的撞击感度随着压力增加而逐渐减小; 而当压力高于20 GPa时, 撞击感度则呈现出随压力增加而缓慢增大的趋势. 此外, 弹性常数Cij、杨氏模量(E)、体积模量(B)、剪切模量(G)以及柯西压(C12–C44)均随着压力的增大而增大, 表明在压力作用下晶体的刚性和延展性得到了显著增强. 根据力学稳定性准则, 该晶体在整个压力范围内保持力学稳定性.The crystal structure, molecular structure, electronic structure and mechanical properties of molecular perovskite high-energetic material (H2dabco)[K(ClO4)3] (DAP-2) under hydrostatic pressure ranging from 0 to 50 GPa are calculated and studied based on density functional theory. And the influences of pressure on its stability and impact sensitivity of DAP-2 are investigated. As the external pressure gradually increases, both the lattice parameters and the volume of DAP-2 crystal exhibit a monotonic decreasing trend. In the entire pressure range, the unit cell volume shrinks by up to 40.20%. By using the Birch Munnaghan equation of state to fit P-V relation, the bulk modulus B0 and its first-order derivative B0’ with respect to pressure are obtained to be 23.4 GPa and 4.9 GPa, respectively. The observations of the characteristic bond length and bond angle within the crystal indicate that the cage-like structure of organic cation H2dabco2+ undergoes distortion at 25 GPa. Further analysis of the average fractional coordinates of the center-of-mass and Euler angles for H2dabco2+ and KO12 polyhedron shows that within a pressure range from 0 to 50 GPa, both the average fractional coordinates of the center-of-mass and the Euler angles exhibit fluctuations at 25 GPa, but the overall amplitude of these fluctuations is very small. Based on this finding, it is speculated that the space group symmetry of the crystal may remain unchanged in the entire pressure range. In terms of electronic structure, with the increase of pressure, the band gap value increases rapidly and reaches a maximum value at about 20 GPa, followed by a slow decreasing trend. Based on the first-principles band gap criterion and the variation of the band gap under different pressures, it is demonstrated that below 20 GPa, the impact sensitivity of DAP-2 gradually decreases with pressure increasing; however, when the pressure exceeds 20 GPa, the impact sensitivity exhibits a slow increasing trend. In addition, the elastic constants Cij, Young’s modulus (E), bulk modulus (B), shear modulus (G), and Cauchy pressure (C12 – C44) all increase with pressure rising, indicating that the rigidity and ductility of the crystal under pressure are significantly strengthened. According to the mechanical stability criterion, the crystal maintains the mechanical stability throughout the pressure range.

-

Keywords:

- energetic perovskite /

- density functional theory /

- crystal structure /

- electronic structure /

- mechanical properties

[1] Agrawal J P, Hodgson R 2007 Organic Chemistry of Explosives (New York: Wiley

[2] Agrawal J P 2005 Propel. Explos. Pyrot. 30 316

Google Scholar

Google Scholar

[3] Yu Q, Yin P, Zhang J H, He C L, Imler G H, Parrish D A, Shreeve J M 2017 J. Am. Chem. Soc. 139 8816

Google Scholar

Google Scholar

[4] Kumar D, Imler G H, Parrish D A 2017 J. Mater. Chem. A 5 16767

Google Scholar

Google Scholar

[5] Bennion J C, Siddiqi Z R, Matzger A J 2017 Chem. Commun. 53 6065

Google Scholar

Google Scholar

[6] Zhang J H, Dharavath S, Mitchell L A, Parrish D A, Shreeve J M 2016 J. Am. Chem. Soc. 138 7500

Google Scholar

Google Scholar

[7] He C, Shreeve J M 2016 Angew. Chem. 128 782

Google Scholar

Google Scholar

[8] Liu W, Liu W L, Pang S P 2017 RSC Adv. 7 3617

Google Scholar

Google Scholar

[9] Xu J G, Sun C, Zhang M J, Liu B W, Li X Z, Lu J, Wang S H, Zheng F K, Guo G C 2017 Chem. Mater. 29 9725

Google Scholar

Google Scholar

[10] Sun C G, Zhang C, Jiang C, Yang C, Du Y, Zhao Y, Hu B C, Zheng Z S, Christe K O 2018 Nat. Commun. 9 1269

Google Scholar

Google Scholar

[11] Wang S, Wang Q Y, Feng X, Wang B, Yang L 2017 Adv. Mater. 29 1701898

Google Scholar

Google Scholar

[12] Shen C, Liu Y, Zhu Z Q, Xu Y G, Lu M 2017 Chem. Commun. 53 7489

Google Scholar

Google Scholar

[13] Lin J D, Li Y H, Xu J G, Zheng F K, Guo G C, Lv R X, He W C, Huang Z N, Liu J F 2018 J. Solid State Chem. 265 42

Google Scholar

Google Scholar

[14] Nielsen A T, Chafin A P, Christian S L, Moore D W, Nadler M P, Nissan R A, Vanderah D J, Gilardi R D, George C F, Flippen-Anderson J L 1998 Tetrahedron 54 11793

Google Scholar

Google Scholar

[15] Liao W Q, Zhao D W, Tang Y Y, Zhang Y, Li P F, Shi P P, Chen X G, You Y M, Xiong R G 2019 Science 363 1206

Google Scholar

Google Scholar

[16] Ye H Y, Tang Y Y, Li P F, Liao W Q, Gao J X, Hua X N, Cai H, Shi P P, You Y M, Xiong R G 2018 Science 361 151

Google Scholar

Google Scholar

[17] 徐豪杰, 韩世国, 孙志华, 罗军华 2021 化学学报 79 23

Google Scholar

Google Scholar

Luo J H, Sun Z H, Han S G, Xu H J 2021 Acta Chim. Sin. 79 23

Google Scholar

Google Scholar

[18] He Y P, Galli G 2014 Chem. Mater. 26 5394

Google Scholar

Google Scholar

[19] Xing G, Mathews N, Lim S S, Yantara N, Liu X F, Sabba D, Grätzel M, Mhaisalkar S, Sum T C 2014 Nat. Mater. 13 476

Google Scholar

Google Scholar

[20] Guo Y L, Liu C, Tanaka H, Nakamura E 2015 J. Phys. Chem. Lett. 6 535

Google Scholar

Google Scholar

[21] Chen S L, Yang Z R, Wang B J, Shang Y, Sun L Y, He C T, Zhou H L, Zhang W X, Chen X M 2018 Sci. China Mater. 61 1123

Google Scholar

Google Scholar

[22] Chen S L, Shang Y, He C T, Sun L Y, Ye Z M, Zhang W X, Chen X M 2018 CrystEngComm 20 7458

Google Scholar

Google Scholar

[23] Shang Y, Huang R K, Chen S L, He C T, Yu Z H, Ye Z M, Zhang W X, Chen X M, Design 2020 Cryst. Growth Des. 20 1891

Google Scholar

Google Scholar

[24] Shang Y, Yu Z H, Huang R K, Chen S L, Liu D X, Chen X X, Zhang W X, Chen X M 2020 Eng. PRC. 6 1013

[25] Shang Y, Chen S L, Yu Z H, Huang R K, He C T, Ye Z M, Zhang W X, Chen X M 2022 Inorg. Chem. 61 4143

Google Scholar

Google Scholar

[26] Feng Y, Zhang J, Cao W, Zhang J, Shreeve J n M 2023 Nat. Commun. 14 7765

Google Scholar

Google Scholar

[27] Chen S, Yi Z, Jia C, Li Y, Chen H, Zhu S, Zhang L 2023 Small 19 2302631

Google Scholar

Google Scholar

[28] Zhou J, Ding L, Bi F, Wang B, Zhang J 2018 J. Anal. Appl. Pyrolysis 129 189

Google Scholar

Google Scholar

[29] An T, He W, Chen S W, Zuo B L, Qi X F, Zhao F Q, Luo Y J, Yan Q L 2018 J. Phys. Chem. C 122 26956

Google Scholar

Google Scholar

[30] Jia Q, Deng P, Li X X, Hu L S, Cao X 2020 Vacuum 175 109257

Google Scholar

Google Scholar

[31] Deng P, Wang H, Yang X, Ren H, Jiao Q J 2020 J. Alloy. Compd. 827 154257

Google Scholar

Google Scholar

[32] Zhou J, Ding L, Zhao F Q, Wang B, Zhang J L 2020 Chin. Chem. Lett. 31 554

Google Scholar

Google Scholar

[33] Li X X, Hu S Q, Cao X, Hu L S, Deng P, Xie Z B 2020 J. Energ. Mater. 38 162

Google Scholar

Google Scholar

[34] Jia Q, Bai X, Zhu S, Cao X, Deng P, Hu L 2019 J. Energ. Mater. 38 377

[35] Kresse G, Hafner J 1993 Phys. Rev. B 47 558

Google Scholar

Google Scholar

[36] Kresse G, Hafner J 1994 Phys. Rev. B 49 14251

Google Scholar

Google Scholar

[37] Kresse G, Furthmüller J 1996 Phys. Rev. B 54 11169

Google Scholar

Google Scholar

[38] Kresse G, Furthmüller J 1996 Comp. Mater. Sci. 6 15

Google Scholar

Google Scholar

[39] Kresse G, Joubert D 1999 Phys. Rev. B 59 1758

[40] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[41] Ganose A M, Savory C N, Scanlon D O 2015 J. Phys. Chem. Lett. 6 4594

Google Scholar

Google Scholar

[42] P J, Ruzsinszky A, Csonka G I, Vydrov O A, Scuseria G E, Constantin L A, Zhou X l, Burke K 2008 Phys. Rev. Lett. 100 136406

Google Scholar

Google Scholar

[43] Le Page Y, Saxe P 2002 Phys. Rev. B 65 104104

Google Scholar

Google Scholar

[44] Alyoubi R Y, Raffah B M, Hamioud F, Mubarak A A 2021 Mod. Phys. Lett. B 35 2150056

[45] Murnaghan F D 1944 P. Natl. Acad. Sci. USA 30 244

Google Scholar

Google Scholar

[46] Feng G Q, Jiang X X, Wei W J, Gong P F, Kang L, Li Z H, Li Y C, Li X D, Wu X S, Lin Z S 2016 Dalton T. 45 4303

Google Scholar

Google Scholar

[47] Agrawal P M, Rice B M, Zheng L Q, Velardez G F, Thompson D L 2006 J. Phys. Chem. B 110 5721

Google Scholar

Google Scholar

[48] Agrawal P M, Rice B M, Zheng L Q, Thompson D L 2006 J. Phys. Chem. B 110 26185

Google Scholar

Google Scholar

[49] Xiao H M, Li Y F 1995 Sci. China Ser. B 5 538

[50] Zhu W H, Xiao J J, Ji G F, Zhao F, Xiao H M 2007 J. Phys. Chem. B 111 12715

Google Scholar

Google Scholar

[51] Xu X J, Zhu W H, Xiao H M 2007 J. Phys. Chem. B 111 2090

Google Scholar

Google Scholar

[52] Zhu W H, Xiao H M 2008 J. Comput. Chem. 29 176

Google Scholar

Google Scholar

[53] Zhu W H, Xiao H M 2010 Struct. Chem. 21 657

Google Scholar

Google Scholar

[54] Fan J Y, Su Y, Zheng Z Y, Zhang Q Y, Zhao J J 2019 J. Raman Spectrosc. 50 889

Google Scholar

Google Scholar

[55] Wu Q, Zhu W, Xiao H 2014 Struct. Chem. 26 477

[56] Xiang F, Wu Q, Zhu W H, Xiao H M 2014 Struct. Chem. 25 1625

Google Scholar

Google Scholar

[57] Wang W P, Liu F S, Liu Q J, Wang Y G, Liu Z T 2016 Comp. Mater. Sci. 121 225

Google Scholar

Google Scholar

[58] Feng J 2014 APL Mater. 2 081801

Google Scholar

Google Scholar

[59] 袁文翎, 姚碧霞, 李喜, 胡顺波, 任伟 2024 73 086104

Google Scholar

Google Scholar

Yuan W L, Yao B X, Li X, Hu S B, Ren W 2024 Acta Phys. Sin. 73 086104

Google Scholar

Google Scholar

[60] Liu Q J, Ran Z, Liu F S, Liu Z T 2015 J. Alloys Compd. 631 192

Google Scholar

Google Scholar

[61] Chen S, Sun Y, Duan Y H, Huang B, Peng M J 2015 J. Alloys Compd. 630 202

Google Scholar

Google Scholar

[62] Pettifor D G 1992 Mater. Sci. Technol. 8 345

Google Scholar

Google Scholar

[63] Jund P, Viennois R, Tao X M, Niedziolka K, Tédenac J C 2012 Phys. Rev. B 85 224105

Google Scholar

Google Scholar

-

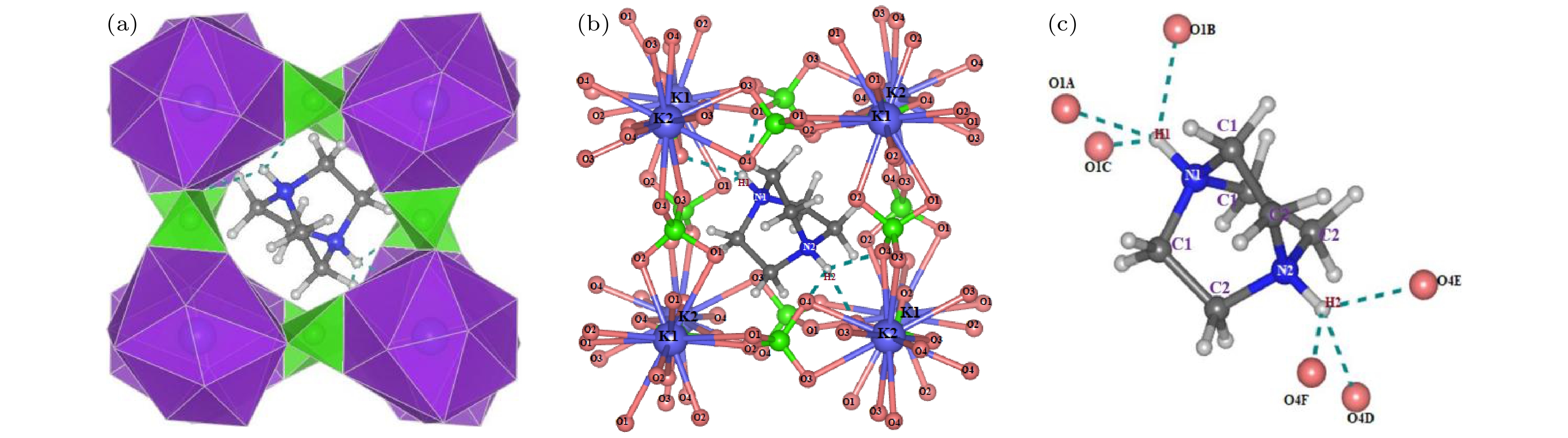

图 1 (a) DAP-2单胞的多面体模型示意图; (b) DAP-2单胞的球棍模型示意图; (c) 有机阳离子H2dabco2+结构, K, O, Cl, C, N和H原子分别用蓝紫色、粉色、绿色、深灰色、蓝色和浅灰色表示, 而N—H…O键用青色虚线表示, 对称性代码: A: –z+1, –x+1, –y+1; B: –y+1/2, z –1/2, x; C: x –1/2, y, –z+3/2; D: z –1/2, –x+1/2, –y+1; E: x, y, z; F: –y+1/2, –z+1, x+1/2

Fig. 1. (a) Schematic diagram of the polyhedral model for the unit cell of DAP-2; (b) schematic diagram of the ball-and-stick model for the unit cell of DAP-2; (c) structure of the organic cation H2dabco2+. The atoms of K, O, Cl, C, N and H are represented by blue purple, pink, green, dark gray, blue, and light gray, respectively, while N—H···O bonds are represented by cyan dashed lines. Symmetry code: A: –z+1, –x+1, –y+1; B: –y+1/2, z –1/2, x; C: x –1/2, y, –z+3/2; D: z –1/2, –x+1/2, –y+1; E: x, y, z; F: –y+1/2, –z+1, x+1/2.

表 1 DAP-2晶胞参数的计算值与实验值

Table 1. The calculated and experimental values of crystal cell parameters for DAP-2.

Method a/Å Δa/% α/(°) V/Å3 ΔV/% Experiment[21] 14.291 — 90 2918.689 — PBE 14.530 +1.67 90 3067.650 +5.10 PBEsol 14.288 –0.02 90 2917.954 –0.03 PBE+D3 14.282 –0.06 90 2913.178 –0.19 -

[1] Agrawal J P, Hodgson R 2007 Organic Chemistry of Explosives (New York: Wiley

[2] Agrawal J P 2005 Propel. Explos. Pyrot. 30 316

Google Scholar

Google Scholar

[3] Yu Q, Yin P, Zhang J H, He C L, Imler G H, Parrish D A, Shreeve J M 2017 J. Am. Chem. Soc. 139 8816

Google Scholar

Google Scholar

[4] Kumar D, Imler G H, Parrish D A 2017 J. Mater. Chem. A 5 16767

Google Scholar

Google Scholar

[5] Bennion J C, Siddiqi Z R, Matzger A J 2017 Chem. Commun. 53 6065

Google Scholar

Google Scholar

[6] Zhang J H, Dharavath S, Mitchell L A, Parrish D A, Shreeve J M 2016 J. Am. Chem. Soc. 138 7500

Google Scholar

Google Scholar

[7] He C, Shreeve J M 2016 Angew. Chem. 128 782

Google Scholar

Google Scholar

[8] Liu W, Liu W L, Pang S P 2017 RSC Adv. 7 3617

Google Scholar

Google Scholar

[9] Xu J G, Sun C, Zhang M J, Liu B W, Li X Z, Lu J, Wang S H, Zheng F K, Guo G C 2017 Chem. Mater. 29 9725

Google Scholar

Google Scholar

[10] Sun C G, Zhang C, Jiang C, Yang C, Du Y, Zhao Y, Hu B C, Zheng Z S, Christe K O 2018 Nat. Commun. 9 1269

Google Scholar

Google Scholar

[11] Wang S, Wang Q Y, Feng X, Wang B, Yang L 2017 Adv. Mater. 29 1701898

Google Scholar

Google Scholar

[12] Shen C, Liu Y, Zhu Z Q, Xu Y G, Lu M 2017 Chem. Commun. 53 7489

Google Scholar

Google Scholar

[13] Lin J D, Li Y H, Xu J G, Zheng F K, Guo G C, Lv R X, He W C, Huang Z N, Liu J F 2018 J. Solid State Chem. 265 42

Google Scholar

Google Scholar

[14] Nielsen A T, Chafin A P, Christian S L, Moore D W, Nadler M P, Nissan R A, Vanderah D J, Gilardi R D, George C F, Flippen-Anderson J L 1998 Tetrahedron 54 11793

Google Scholar

Google Scholar

[15] Liao W Q, Zhao D W, Tang Y Y, Zhang Y, Li P F, Shi P P, Chen X G, You Y M, Xiong R G 2019 Science 363 1206

Google Scholar

Google Scholar

[16] Ye H Y, Tang Y Y, Li P F, Liao W Q, Gao J X, Hua X N, Cai H, Shi P P, You Y M, Xiong R G 2018 Science 361 151

Google Scholar

Google Scholar

[17] 徐豪杰, 韩世国, 孙志华, 罗军华 2021 化学学报 79 23

Google Scholar

Google Scholar

Luo J H, Sun Z H, Han S G, Xu H J 2021 Acta Chim. Sin. 79 23

Google Scholar

Google Scholar

[18] He Y P, Galli G 2014 Chem. Mater. 26 5394

Google Scholar

Google Scholar

[19] Xing G, Mathews N, Lim S S, Yantara N, Liu X F, Sabba D, Grätzel M, Mhaisalkar S, Sum T C 2014 Nat. Mater. 13 476

Google Scholar

Google Scholar

[20] Guo Y L, Liu C, Tanaka H, Nakamura E 2015 J. Phys. Chem. Lett. 6 535

Google Scholar

Google Scholar

[21] Chen S L, Yang Z R, Wang B J, Shang Y, Sun L Y, He C T, Zhou H L, Zhang W X, Chen X M 2018 Sci. China Mater. 61 1123

Google Scholar

Google Scholar

[22] Chen S L, Shang Y, He C T, Sun L Y, Ye Z M, Zhang W X, Chen X M 2018 CrystEngComm 20 7458

Google Scholar

Google Scholar

[23] Shang Y, Huang R K, Chen S L, He C T, Yu Z H, Ye Z M, Zhang W X, Chen X M, Design 2020 Cryst. Growth Des. 20 1891

Google Scholar

Google Scholar

[24] Shang Y, Yu Z H, Huang R K, Chen S L, Liu D X, Chen X X, Zhang W X, Chen X M 2020 Eng. PRC. 6 1013

[25] Shang Y, Chen S L, Yu Z H, Huang R K, He C T, Ye Z M, Zhang W X, Chen X M 2022 Inorg. Chem. 61 4143

Google Scholar

Google Scholar

[26] Feng Y, Zhang J, Cao W, Zhang J, Shreeve J n M 2023 Nat. Commun. 14 7765

Google Scholar

Google Scholar

[27] Chen S, Yi Z, Jia C, Li Y, Chen H, Zhu S, Zhang L 2023 Small 19 2302631

Google Scholar

Google Scholar

[28] Zhou J, Ding L, Bi F, Wang B, Zhang J 2018 J. Anal. Appl. Pyrolysis 129 189

Google Scholar

Google Scholar

[29] An T, He W, Chen S W, Zuo B L, Qi X F, Zhao F Q, Luo Y J, Yan Q L 2018 J. Phys. Chem. C 122 26956

Google Scholar

Google Scholar

[30] Jia Q, Deng P, Li X X, Hu L S, Cao X 2020 Vacuum 175 109257

Google Scholar

Google Scholar

[31] Deng P, Wang H, Yang X, Ren H, Jiao Q J 2020 J. Alloy. Compd. 827 154257

Google Scholar

Google Scholar

[32] Zhou J, Ding L, Zhao F Q, Wang B, Zhang J L 2020 Chin. Chem. Lett. 31 554

Google Scholar

Google Scholar

[33] Li X X, Hu S Q, Cao X, Hu L S, Deng P, Xie Z B 2020 J. Energ. Mater. 38 162

Google Scholar

Google Scholar

[34] Jia Q, Bai X, Zhu S, Cao X, Deng P, Hu L 2019 J. Energ. Mater. 38 377

[35] Kresse G, Hafner J 1993 Phys. Rev. B 47 558

Google Scholar

Google Scholar

[36] Kresse G, Hafner J 1994 Phys. Rev. B 49 14251

Google Scholar

Google Scholar

[37] Kresse G, Furthmüller J 1996 Phys. Rev. B 54 11169

Google Scholar

Google Scholar

[38] Kresse G, Furthmüller J 1996 Comp. Mater. Sci. 6 15

Google Scholar

Google Scholar

[39] Kresse G, Joubert D 1999 Phys. Rev. B 59 1758

[40] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[41] Ganose A M, Savory C N, Scanlon D O 2015 J. Phys. Chem. Lett. 6 4594

Google Scholar

Google Scholar

[42] P J, Ruzsinszky A, Csonka G I, Vydrov O A, Scuseria G E, Constantin L A, Zhou X l, Burke K 2008 Phys. Rev. Lett. 100 136406

Google Scholar

Google Scholar

[43] Le Page Y, Saxe P 2002 Phys. Rev. B 65 104104

Google Scholar

Google Scholar

[44] Alyoubi R Y, Raffah B M, Hamioud F, Mubarak A A 2021 Mod. Phys. Lett. B 35 2150056

[45] Murnaghan F D 1944 P. Natl. Acad. Sci. USA 30 244

Google Scholar

Google Scholar

[46] Feng G Q, Jiang X X, Wei W J, Gong P F, Kang L, Li Z H, Li Y C, Li X D, Wu X S, Lin Z S 2016 Dalton T. 45 4303

Google Scholar

Google Scholar

[47] Agrawal P M, Rice B M, Zheng L Q, Velardez G F, Thompson D L 2006 J. Phys. Chem. B 110 5721

Google Scholar

Google Scholar

[48] Agrawal P M, Rice B M, Zheng L Q, Thompson D L 2006 J. Phys. Chem. B 110 26185

Google Scholar

Google Scholar

[49] Xiao H M, Li Y F 1995 Sci. China Ser. B 5 538

[50] Zhu W H, Xiao J J, Ji G F, Zhao F, Xiao H M 2007 J. Phys. Chem. B 111 12715

Google Scholar

Google Scholar

[51] Xu X J, Zhu W H, Xiao H M 2007 J. Phys. Chem. B 111 2090

Google Scholar

Google Scholar

[52] Zhu W H, Xiao H M 2008 J. Comput. Chem. 29 176

Google Scholar

Google Scholar

[53] Zhu W H, Xiao H M 2010 Struct. Chem. 21 657

Google Scholar

Google Scholar

[54] Fan J Y, Su Y, Zheng Z Y, Zhang Q Y, Zhao J J 2019 J. Raman Spectrosc. 50 889

Google Scholar

Google Scholar

[55] Wu Q, Zhu W, Xiao H 2014 Struct. Chem. 26 477

[56] Xiang F, Wu Q, Zhu W H, Xiao H M 2014 Struct. Chem. 25 1625

Google Scholar

Google Scholar

[57] Wang W P, Liu F S, Liu Q J, Wang Y G, Liu Z T 2016 Comp. Mater. Sci. 121 225

Google Scholar

Google Scholar

[58] Feng J 2014 APL Mater. 2 081801

Google Scholar

Google Scholar

[59] 袁文翎, 姚碧霞, 李喜, 胡顺波, 任伟 2024 73 086104

Google Scholar

Google Scholar

Yuan W L, Yao B X, Li X, Hu S B, Ren W 2024 Acta Phys. Sin. 73 086104

Google Scholar

Google Scholar

[60] Liu Q J, Ran Z, Liu F S, Liu Z T 2015 J. Alloys Compd. 631 192

Google Scholar

Google Scholar

[61] Chen S, Sun Y, Duan Y H, Huang B, Peng M J 2015 J. Alloys Compd. 630 202

Google Scholar

Google Scholar

[62] Pettifor D G 1992 Mater. Sci. Technol. 8 345

Google Scholar

Google Scholar

[63] Jund P, Viennois R, Tao X M, Niedziolka K, Tédenac J C 2012 Phys. Rev. B 85 224105

Google Scholar

Google Scholar

计量

- 文章访问数: 3864

- PDF下载量: 126

- 被引次数: 0

下载:

下载: