-

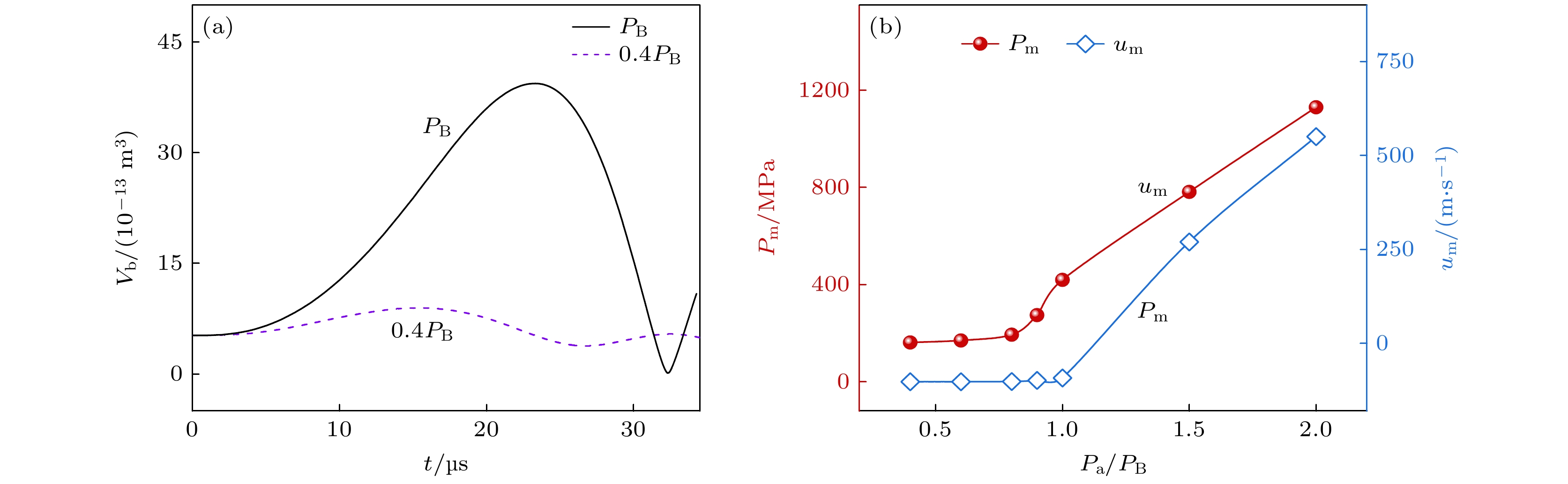

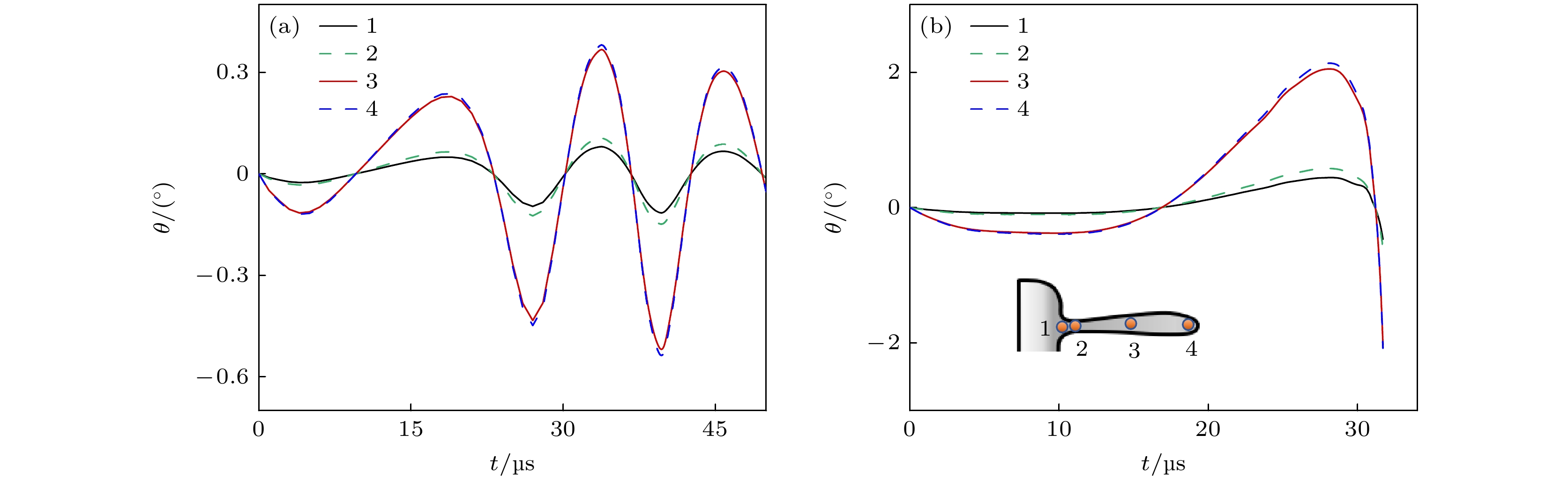

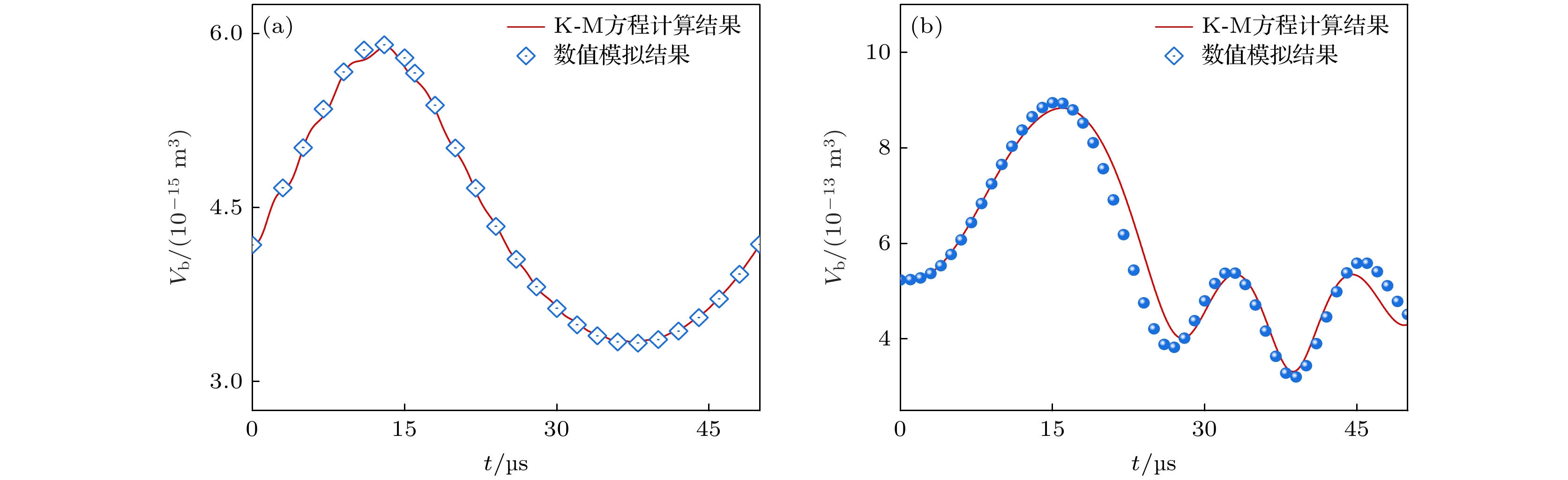

Ultrasound treatment (UST) has been demonstrated to be an effective approach to refining the microstructures of metallic alloys during solidification. The cavitation-induced fragmentation is considered as the major mechanism for grain refinement in the recent study, but the interaction between dynamic bubble motion and dendrite behaviour has been rarely investigated previously. In this work, the dynamic behaviour of cavitation bubbles and their interactions with succinonitrile (SCN)-2% (mole fraction) water organic transparent alloy are systematically investigated by high-speed digital image technique and numerical simulation. It is found that increasing the driving pressure transforms the bubble oscillation mode from volume oscillation to splitting oscillation, which significantly enhances the transient pressure and flow strength in the liquid. When a dendrite exists below the bubble, the fracture mode of the secondary branch undergoes a transition from high peripheral fatigue fracture to low peripheral fatigue fracture and to overload fracture with the increase of the driving acoustic pressure, and the fracture period is shortened in the form of a power function trend. The closer the bubble is to the dendrite, the longeritudinal radius of the bubble is gradually larger than the transverse radius during compression, and with the bubble shrink time increasing, the minimum bubble volume decreases. In addition, the decrease in distance between bubbles and dendrites leads to a significant reduction in the maximum pressure generated by bubble collapse, while the maximum flow rate shows a trend of first increasing and then decreasing. When the root radius of the secondary branch decreases or its length increases, the number of fatigue fracture cycles of the secondary branch decreases significantly. The calculated bubble expansion and contraction and secondary dendrite rupture processes are basically consistent with the experimental results, which indicates that the model constructed in this work can accurately predict the bubble motion and its interaction with dendrite in ultrasonic field.

[1] He L, Wu M, Li L, Hao H 2006 Appl. Phys. Lett. 89 131504

Google Scholar

Google Scholar

[2] Huang H, Qin L, Tang H B, Shu D, Yan W T, Sun B D, Mi J W 2021 Ultrason. Sonochem. 80 105832

Google Scholar

Google Scholar

[3] Wei X, Li X L, Zhang L Q, Lü Q G 2022 Int. J. Heat Mass Transfer 192 122914

Google Scholar

Google Scholar

[4] Wu W, Wang D, Zhai W, Wang J, Wei B 2023 J. Appl. Phys. 133 115102

Google Scholar

Google Scholar

[5] Sander J R G, Zeiger B W, Suslick K S 2014 Ultrason. Sonochem. 21 1908

Google Scholar

Google Scholar

[6] Cui B, Chen K, Yang Y, Lü Y, Zhang F, Liu S 2024 Mater. Chem. Phys. 318 129297

Google Scholar

Google Scholar

[7] Wang S, Kang J, Zhang X, Guo Z 2018 Ultrasonics 83 26

Google Scholar

Google Scholar

[8] Shu D, Sun B D, Mi J W, Grant P S 2012 Metall. Mater. Trans. A 43 3755

Google Scholar

Google Scholar

[9] Priyadarshi A, Khavari M, Subroto T, Conte M, Prentice P, Pericleous K, Eskin D, Durodola J, Tzanakis I J E 2021 Ultrason. Sonochem. 70 105260

Google Scholar

Google Scholar

[10] Wang B, Tan D Y, Lee T L, Khong J C, Wang F, Eskin D, Connolley T, Fezzaa K, Mi J W 2018 Acta Mater. 144 505

Google Scholar

Google Scholar

[11] 马艳, 林书玉, 徐洁 2018 物 理学报 67 034301

Google Scholar

Google Scholar

Ma Y, Lin S Y, Xu J 2018 Acta Phys. Sin. 67 034301

Google Scholar

Google Scholar

[12] Qu W X, Xie Y H, Shen Y, Han J, Zhu T 2017 Math. Model. Eng. Probl. 4 173

Google Scholar

Google Scholar

[13] Lind S J, Phillips T N 2012 Theor. Comput. Fluid Dyn. 26 245

Google Scholar

Google Scholar

[14] Samiei E, Shams M, Ebrahimi R 2011 Eur. J. Mech. B. Fluids 30 41

Google Scholar

Google Scholar

[15] 吴学由, 梁金福 2021 物 理学 报 70 184301

Google Scholar

Google Scholar

Wu X Y, Liang J F 2021 Acta Phys. Sin. 70 184301

Google Scholar

Google Scholar

[16] Wang X J, Ning Z, Lü M, Yao J S, Sun C H 2022 J. Phys. Soc. Jpn 91 014401

Google Scholar

Google Scholar

[17] Cao S, Wang G, Coutier-Delgosha O, Wang K 2021 J. Fluid Mech. 907 A17

Google Scholar

Google Scholar

[18] Shan M L, Yang Y, Kan X F, Yin C, Han Q B 2024 Chin. Phys. B 33 064701

Google Scholar

Google Scholar

[19] 张颖, 吴文华, 王建元, 翟薇 2022 71 244303

Google Scholar

Google Scholar

Zhang Y, Wu W H, Wang J Y, Zhai W 2022 Acta Phys. Sin. 71 244303

Google Scholar

Google Scholar

[20] Hosseinkhah N, Chen H, Matula T J, Burns P N, Hynynen K 2013 J. Acoust. Soc. Am. 134 1875

Google Scholar

Google Scholar

[21] Delale C F, Pasinlioğlu Ş 2023 Phys. Fluids 35 023330

Google Scholar

Google Scholar

[22] Zakerzadeh R, Zunino P 2018 Meccanica 54 101

Google Scholar

Google Scholar

[23] 秦对, 邹青钦, 李章勇, 王伟, 万明习, 冯怡 2021 70 154701

Google Scholar

Google Scholar

Qian D, Zhou Q Q, Li Z Y, Wang W, Wan M X, Feng Y 2021 Acta Phys. Sin. 70 154701

Google Scholar

Google Scholar

[24] Wang S, Guo Z P, Zhang X P, Zhang A, Kang J W 2019 Ultrason. Sonochem. 51 160

Google Scholar

Google Scholar

[25] Murakami K, Yamakawa Y, Zhao J, Johnsen E, Ando K 2021 J. Fluid Mech. 924 A38

Google Scholar

Google Scholar

[26] Chen X S, Bayanheshig, Jiao Q B, Tan X, Wang W 2021 Int. J. Heat Mass Transfer 171 121074

Google Scholar

Google Scholar

[27] Wang S, Kang J, Guo Z P, Lee T L, Mi J W 2018 Acta Mater. 165 388

Google Scholar

Google Scholar

[28] Wu W H, Wang J Y, Zhai W, Wei B B 2023 Metall. Mater. Trans. B 54 1845

Google Scholar

Google Scholar

-

图 1 超声场中气泡振荡和溃灭模型的几何示意 (a) 单个气泡运动模型; (b) 气泡与枝晶间相互作用模型; 1, 变幅杆; 2, 气泡; 3, SCN-H2O溶液; 4, SCN枝晶

Figure 1. Geometrical schematic of the bubble oscillation and collapse model within the ultrasonic field: (a) Model of single bubble motion; (b) model of bubble-dendrite interaction; 1, horn; 2, bubble; 3, SCN-H2O solution; 4, SCN dendrite.

图 4 声压幅值 0.4PB 时气泡振荡过程中二次分枝上应力分布 (a)二次分枝下表面应力分布; (b) 不同高度二次分枝根部应力

Figure 4. Stress distribution on the secondary branch during bubble oscillation at a sound pressure amplitude of 0.4PB: (a) Stress distribution on the lower surface of the secondary branch; (b) stress on the secondary branch root at different heights.

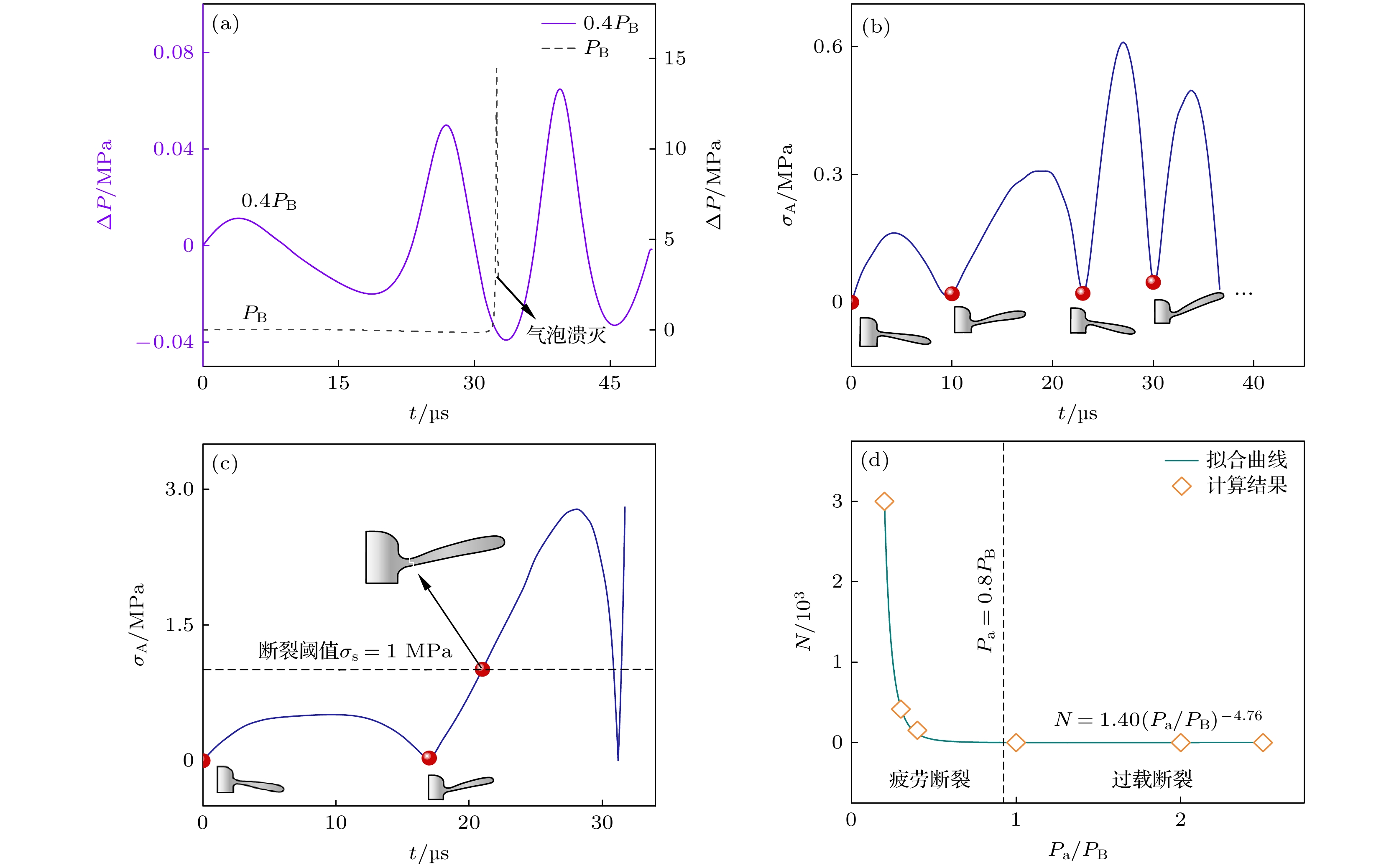

图 6 不同声压条件下二次分枝断裂机制 (a) 0.4PB 和 PB 振幅下气泡内外压差; (b) 0.4PB 驱动声压下A点应力随时间的变化; (c) PB 驱动声压下 A 点应力随时间的变化; (d) 分枝断裂所需弯折周期随声压幅值 Pa 的变化

Figure 6. Mechanism of secondary branch breakage under different sound pressures: (a) Pressure difference between inside and outside the bubble at 0.4PB and PB; (b) variation of stress at point A with time at the ultrasonic amplitude of 0.4PB; (c) variation of stress at point A with time at the ultrasonic amplitude of PB; (d) variation of fragmentation cycle number with sound pressure amplitude Pa.

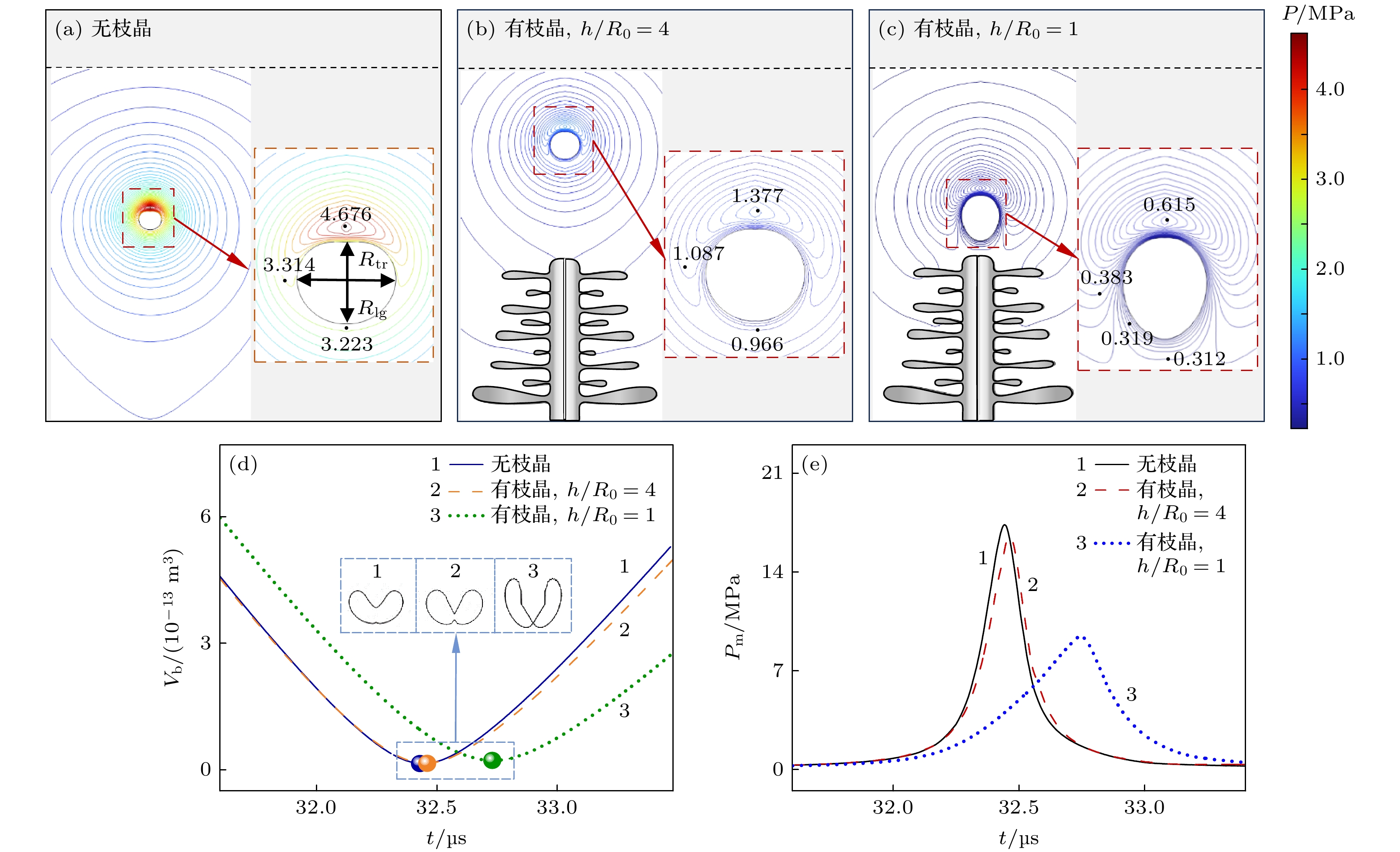

图 7 声压振幅 PB 条件下气泡体积及最大压强与枝晶距离的相关性 (a)—(c) 气泡顶部开始凹陷时刻的压强分布图; (d) 气泡体积随时间变化, 其中插图为气泡体积最小时的形貌; (e) 流体中最大压强随时间的变化规律

Figure 7. Correlation of bubble volume and maximum pressure with the distance of dendrites under acoustic pressure amplitude PB: (a)–(c) Pressure distributions at the moment when the top of the bubble starts to dimple; (d) variation of bubble volume with time, where the sugfigure shows the morphology of the bubble with the smallest volume; (e) evolution of the maximum pressure in the fluid with time.

图 8 Pa = PB 条件下间距h对气泡溃灭和二次分支断裂的作用规律 (a) 气泡溃灭在流体中产生的最大压强和流速; (b) 二次分枝上最大应力及其断裂所需时间的变化规律

Figure 8. Effect of distance h on the bubble collapse and secondary branch fragmentatio Pa = PB: (a) Maximum pressure and flow rate in the fluid produced by bubble collapse; (b) variation of the maximum stress on the secondary branch and fragmentation cycle number.

图 9 声压幅值 0.4PB 作用下二次分枝根部A点应力和断裂周期与其根部半径 r 和长度 L 的关系 (a) L = 100 μm 时A点应力随时间变化; (b) r = 3 μm时A点一个周期内的平均应力与 L 的相关性; (c) 断裂周期与 r 和 L 的关系

Figure 9. Relationship of the stress at point A and fragmentation cycle number to root radius r and length L of the secondary branch at Pa = 0.4PB: (a) Stress versus time for L = 100 μm; (b) correlation of the average stress over a cycle with L for r = 3 μm; (c) fragmentation cycle number versus r and L.

表 1 声场和流场计算所用物理量数值

Table 1. Values of physical parameters used in sound and flow field calculations.

-

[1] He L, Wu M, Li L, Hao H 2006 Appl. Phys. Lett. 89 131504

Google Scholar

Google Scholar

[2] Huang H, Qin L, Tang H B, Shu D, Yan W T, Sun B D, Mi J W 2021 Ultrason. Sonochem. 80 105832

Google Scholar

Google Scholar

[3] Wei X, Li X L, Zhang L Q, Lü Q G 2022 Int. J. Heat Mass Transfer 192 122914

Google Scholar

Google Scholar

[4] Wu W, Wang D, Zhai W, Wang J, Wei B 2023 J. Appl. Phys. 133 115102

Google Scholar

Google Scholar

[5] Sander J R G, Zeiger B W, Suslick K S 2014 Ultrason. Sonochem. 21 1908

Google Scholar

Google Scholar

[6] Cui B, Chen K, Yang Y, Lü Y, Zhang F, Liu S 2024 Mater. Chem. Phys. 318 129297

Google Scholar

Google Scholar

[7] Wang S, Kang J, Zhang X, Guo Z 2018 Ultrasonics 83 26

Google Scholar

Google Scholar

[8] Shu D, Sun B D, Mi J W, Grant P S 2012 Metall. Mater. Trans. A 43 3755

Google Scholar

Google Scholar

[9] Priyadarshi A, Khavari M, Subroto T, Conte M, Prentice P, Pericleous K, Eskin D, Durodola J, Tzanakis I J E 2021 Ultrason. Sonochem. 70 105260

Google Scholar

Google Scholar

[10] Wang B, Tan D Y, Lee T L, Khong J C, Wang F, Eskin D, Connolley T, Fezzaa K, Mi J W 2018 Acta Mater. 144 505

Google Scholar

Google Scholar

[11] 马艳, 林书玉, 徐洁 2018 物 理学报 67 034301

Google Scholar

Google Scholar

Ma Y, Lin S Y, Xu J 2018 Acta Phys. Sin. 67 034301

Google Scholar

Google Scholar

[12] Qu W X, Xie Y H, Shen Y, Han J, Zhu T 2017 Math. Model. Eng. Probl. 4 173

Google Scholar

Google Scholar

[13] Lind S J, Phillips T N 2012 Theor. Comput. Fluid Dyn. 26 245

Google Scholar

Google Scholar

[14] Samiei E, Shams M, Ebrahimi R 2011 Eur. J. Mech. B. Fluids 30 41

Google Scholar

Google Scholar

[15] 吴学由, 梁金福 2021 物 理学 报 70 184301

Google Scholar

Google Scholar

Wu X Y, Liang J F 2021 Acta Phys. Sin. 70 184301

Google Scholar

Google Scholar

[16] Wang X J, Ning Z, Lü M, Yao J S, Sun C H 2022 J. Phys. Soc. Jpn 91 014401

Google Scholar

Google Scholar

[17] Cao S, Wang G, Coutier-Delgosha O, Wang K 2021 J. Fluid Mech. 907 A17

Google Scholar

Google Scholar

[18] Shan M L, Yang Y, Kan X F, Yin C, Han Q B 2024 Chin. Phys. B 33 064701

Google Scholar

Google Scholar

[19] 张颖, 吴文华, 王建元, 翟薇 2022 71 244303

Google Scholar

Google Scholar

Zhang Y, Wu W H, Wang J Y, Zhai W 2022 Acta Phys. Sin. 71 244303

Google Scholar

Google Scholar

[20] Hosseinkhah N, Chen H, Matula T J, Burns P N, Hynynen K 2013 J. Acoust. Soc. Am. 134 1875

Google Scholar

Google Scholar

[21] Delale C F, Pasinlioğlu Ş 2023 Phys. Fluids 35 023330

Google Scholar

Google Scholar

[22] Zakerzadeh R, Zunino P 2018 Meccanica 54 101

Google Scholar

Google Scholar

[23] 秦对, 邹青钦, 李章勇, 王伟, 万明习, 冯怡 2021 70 154701

Google Scholar

Google Scholar

Qian D, Zhou Q Q, Li Z Y, Wang W, Wan M X, Feng Y 2021 Acta Phys. Sin. 70 154701

Google Scholar

Google Scholar

[24] Wang S, Guo Z P, Zhang X P, Zhang A, Kang J W 2019 Ultrason. Sonochem. 51 160

Google Scholar

Google Scholar

[25] Murakami K, Yamakawa Y, Zhao J, Johnsen E, Ando K 2021 J. Fluid Mech. 924 A38

Google Scholar

Google Scholar

[26] Chen X S, Bayanheshig, Jiao Q B, Tan X, Wang W 2021 Int. J. Heat Mass Transfer 171 121074

Google Scholar

Google Scholar

[27] Wang S, Kang J, Guo Z P, Lee T L, Mi J W 2018 Acta Mater. 165 388

Google Scholar

Google Scholar

[28] Wu W H, Wang J Y, Zhai W, Wei B B 2023 Metall. Mater. Trans. B 54 1845

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 4384

- PDF Downloads: 224

- Cited By: 0

DownLoad:

DownLoad: