-

Metal-matrix diamond composites have been extensively used and studied, but vacancies, doping, and other defects caused by the pretreatment of the diamond surface significantly affect the interface property between the metal base and diamond. Although techniques like transmission electron microscopy and spectroscopy analysis have been used to detect defects, they present certain limitations. Calculating the positron annihilation lifetime in diamond provides an accurate assessment of interface defect in the diamond. This study uses first-principles calculation methods and adopts various positron annihilation algorithms and enhancement factors, to compute the positron annihilation lifetimes in ideal diamond crystals, single vacancies, and diamond crystals doped with B, Cr, Mo, Ti, W, and Zr. The results, obtained by using local density functional in combination with Boronski & Nieminen algorithms and random-phase approximation restriction as annihilation enhancement factors, indicate that the computed positron annihilation lifetime of diamond is 119.87 ps, which is consistent closely with the experimental result in the literature. Furthermore, after B, Cr, Mo, Ti, W, and Zr atoms are doped into diamond (doping atomic concentration of 1.6%), the positron annihilation lifetimes change from a single vacancy 119.87 ps to 148.57, 156.82, 119.05, 116.5, 117.62, and 115.74 ps respectively. This implies that the defects due to doped atoms in diamond change their positron annihilation lifetimes, with the influence varying according to the different atoms doped. Based on the calculated electron density in diamond vacancies and doped atom areas, it is discovered that doping atoms do not cause severe distortion in the diamond lattice. However, after B and Cr atoms are doped, the positron annihilation lifetime increases significantly. The primary reason is that the relatively low positron affinity of B and Cr atoms results in an extended positron residence time in the vacancy, thereby increasing the annihilation lifetime. Overall, vacancies and doped atom defects in diamond will cause its positron annihilation lifetime to change. The above conclusions provide crucial theoretical references for detecting and identifying interface defects caused by doping treatment on the diamond surface during the preparation of metal-matrix diamond composites.

-

Keywords:

- diamond /

- doping /

- positron /

- annihilation lifetime

[1] Stachel T, Luth R W 2015 Lithos 220 – 223 200

[2] Bulanova G P 1995 J. Geochem. Explor. 53 1

Google Scholar

Google Scholar

[3] Wei L, Kuo P K, Thomas R L, et al. 1993 Phys. Rev. Lett. 70 3764

Google Scholar

Google Scholar

[4] Chakraborty P, Xiong G, Cao L, et al. 2018 Carbon 139 85

Google Scholar

Google Scholar

[5] Ciupiński Ł, Kruszewski M J, Grzonka J, et al. 2017 Mater. Des. 120 170

Google Scholar

Google Scholar

[6] Kidalov S V, Shakhov F M 2009 Materials 2 2467

Google Scholar

Google Scholar

[7] May P W 2000 Philos. Trans. R. Soc. London, Ser. A 358 473

Google Scholar

Google Scholar

[8] Liao M 2021 Funct. Diamond 1 29

Google Scholar

Google Scholar

[9] Gomez H, Groves M N, Neupane M R 2021 Carbon Trends 3 100033

Google Scholar

Google Scholar

[10] Pan Y, He X, Ren S, et al. 2018 Vacuum 153 74

Google Scholar

Google Scholar

[11] Soltani H M, Tayebi M 2020 Int. J. Refract. Met. Hard Mater. 87 105172

Google Scholar

Google Scholar

[12] Pillari L K, Bakshi S R, Chaudhuri P, et al. 2020 Adv. Powder Technol. 31 3657

Google Scholar

Google Scholar

[13] Zhang X Y, Xu M, Cao S Z, et al. 2020 Diamond Relat. Mater. 104 107755

Google Scholar

Google Scholar

[14] Jia J, Bai S, Xiong D, et al. 2019 Ceram. Int. 45 10810

Google Scholar

Google Scholar

[15] Liu Z, Zheng S, Lu Z, et al. 2018 Carbon 127 548

Google Scholar

Google Scholar

[16] Wu M, Chang L, Zhang L, et al. 2017 Surf. Coat. Technol. 325 490

Google Scholar

Google Scholar

[17] Contreras Cuevas A, Bedolla Becerril E, Martínez M S, et al. 2018 Metal Matrix Composites (Cham: Springer International Publishing

[18] Bai G, Li N, Wang X, et al. 2018 J. Alloys Compd. 735 1648

Google Scholar

Google Scholar

[19] Bai G, Wang L, Zhang Y, et al. 2019 Mater. Charact. 152 265

Google Scholar

Google Scholar

[20] Liu X, Sun F, Wang L, et al. 2020 Appl. Surf. Sci. 515 146046

Google Scholar

Google Scholar

[21] Kang Q, He X, Ren S, et al. 2013 J. Alloys Compd. 576 380

Google Scholar

Google Scholar

[22] Che Q L, Chen X K, Ji Y Q, et al. 2015 Mater. Sci. Semicond. Process. 30 104

Google Scholar

Google Scholar

[23] Li J, Zhang H, Wang L, et al. 2016 Composites Part A 91 189

Google Scholar

Google Scholar

[24] Abyzov A M, Kidalov S V, Shakhov F M 2012 Appl. Therm. Eng. 48 72

[25] He J, Wang X, Zhang Y, et al. 2015 Composites Part B 68 22

Google Scholar

Google Scholar

[26] Wang L, Li J, Bai G, et al. 2019 J. Alloys Compd. 781 800

Google Scholar

Google Scholar

[27] Dannefaer S 2007 Phys. Status Solidi C 4 3605

Google Scholar

Google Scholar

[28] Avalos V, Dannefaer S 2003 Phys. B: Condens. Matter 340 – 342 76

[29] Siegel R W 1980 Annu. Rev. Mater. Sci. 10 393

Google Scholar

Google Scholar

[30] Tuomisto F, Makkonen I 2013 Rev. Mod. Phys. 85 1583

Google Scholar

Google Scholar

[31] Pu A, Bretagnon T, Kerr D, et al. 2000 Diamond Relat. Mater. 9 1450

Google Scholar

Google Scholar

[32] Sachdeva A, Sudarshan K, Pujari P, et al. 2004 Diamond Relat. Mater. 13 1719

Google Scholar

Google Scholar

[33] Hu X J, Ye J S, Liu H J, et al. 2008 Thin Solid Films 516 1699

Google Scholar

Google Scholar

[34] Jones R 2009 Diamond Relat. Mater. 18 820

Google Scholar

Google Scholar

[35] Fujii S, Nishibayashi Y, Shikata S, et al. 1995 J. Appl. Phys. 78 1510

Google Scholar

Google Scholar

[36] Eseev M, Kuziv I, Kostin A, et al. 2022 Materials 16 203

Google Scholar

Google Scholar

[37] Gonze X, Amadon B, Antonius G, et al. 2020 Comput. Phys. Commun. 248 107042

Google Scholar

Google Scholar

[38] Romero A H, Allan D C, Amadon B, et al. 2020 J. Chem. Phys. 152 124102

Google Scholar

Google Scholar

[39] Gonze X, Jollet F, Abreu Araujo F, et al. 2016 Comput. Phys. Commun. 205 106

Google Scholar

Google Scholar

[40] Gonze X, Amadon B, Anglade P M, et al. 2009 Comput. Phys. Commun. 180 2582

Google Scholar

Google Scholar

[41] Torrent M, Jollet F, Bottin F, et al. 2008 Comput. Mater. Sci. 42 337

Google Scholar

Google Scholar

[42] Humphrey W, Dalke A, Schulten K 1996 J. Mol. Graphics 14 33

Google Scholar

Google Scholar

[43] Momma K, Izumi F 2011 J. Appl. Crystallogr. 44 1272

Google Scholar

Google Scholar

[44] Boroński E, Nieminen R M 1986 Phys. Rev. B 34 3820

Google Scholar

Google Scholar

[45] Arponen J, Pajanne E 1979 Ann. Phys. 121 343

Google Scholar

Google Scholar

[46] Nieminen R M, Boronski E, Lantto L J 1985 Phys. Rev. B 32 1377

Google Scholar

Google Scholar

[47] Wiktor J, Jomard G, Torrent M 2015 Phys. Rev. B 92 125113

Google Scholar

Google Scholar

[48] Hom T, Kiszenik W, Post B 1975 J. Appl. Crystallogr. 8 457

Google Scholar

Google Scholar

[49] Holloway H, Hass K C, Tamor M A, et al. 1991 Phys. Rev. B 44 7123

Google Scholar

Google Scholar

[50] Zhao Y, Yan F, An Y 2022 Coatings 12 619

Google Scholar

Google Scholar

[51] Uedono A, Fujii S, Morishita N, et al. 1999 J. Phys. Condens. Matter 11 4109

Google Scholar

Google Scholar

[52] Shiryaev A A, Iakoubovskii K, Schut H, et al. 2001 Mater. Sci. Forum 363 – 365 40

[53] Dannefaer S, Mascher P, Kerr D 1992 Diamond Relat. Mater. 1 407

Google Scholar

Google Scholar

[54] Kršjak V, Sojak S, Slugeň V, et al. 2011 J. Phys. Conf. Ser. 265 012014

Google Scholar

Google Scholar

[55] Dannefaer S, Iakoubovskii K 2008 J. Phys. Condens. Matter 20 235225

Google Scholar

Google Scholar

[56] Puska M J, Lanki P, Nieminen R M 1989 J. Phys. Condens. Matter 1 6081

Google Scholar

Google Scholar

[57] Maier K, Peo M, Saile B, et al. 1979 Philos. Mag. A 40 701

Google Scholar

Google Scholar

-

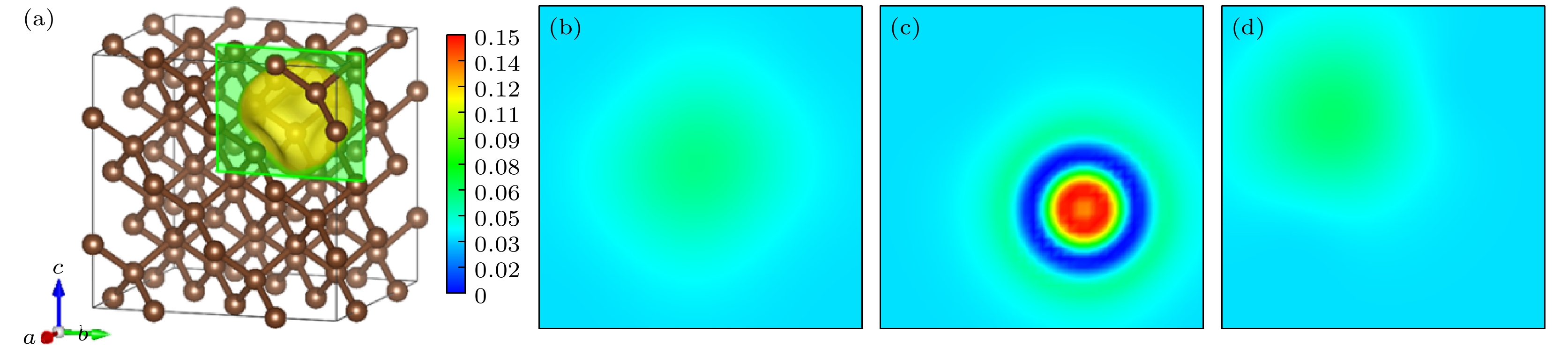

图 2 金刚石空位模型及电子密度图 (a) 金刚石空位模型及切面示意图; (b) 金刚石空位切面二维电子密度图; (c) 金刚石正电子模型及切面示意图; (d) 金刚石空位切面二维电子密度图

Figure 2. Diamond vacancy model and electron density diagrams: (a) Diamond vacancy model with cross-section; (b) 2D electron density map of the diamond vacancy cross-section; (c) diamond positron model with cross-section; (d) 2D electron density map of the diamond positron cross-section.

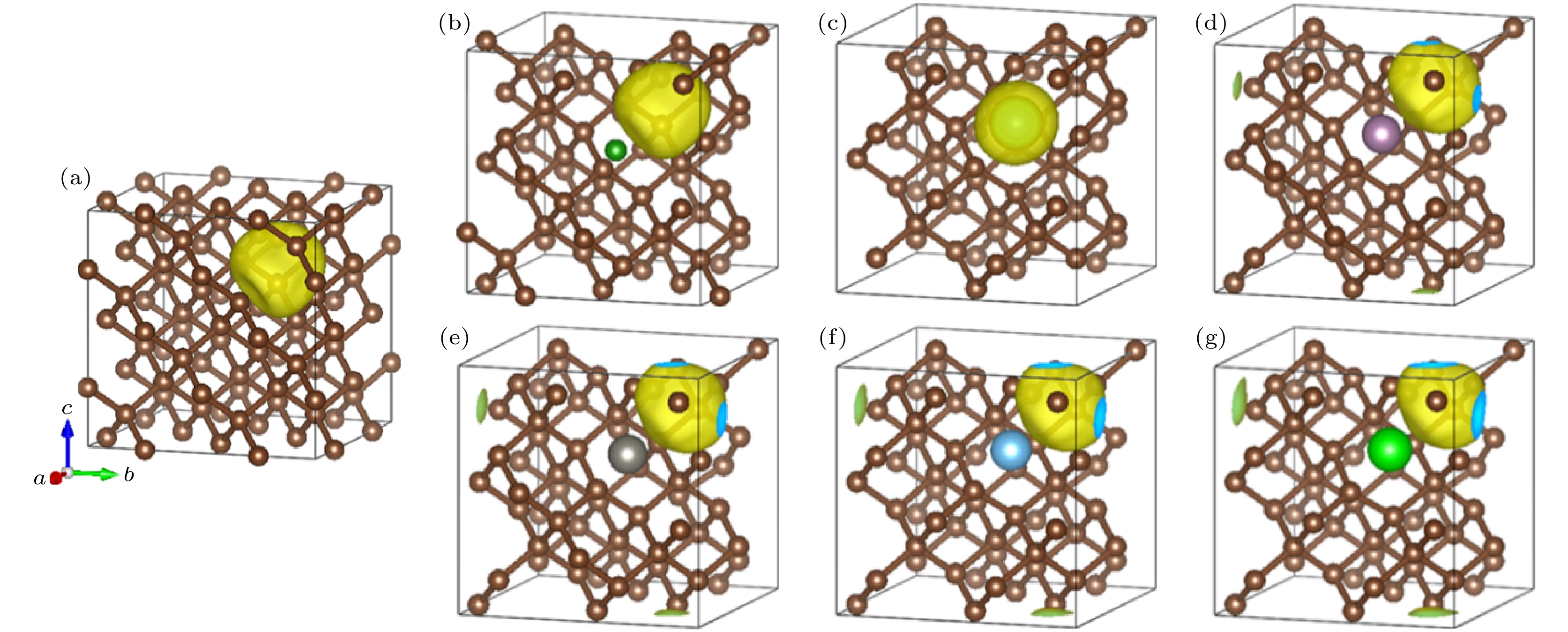

图 4 金刚石超胞掺杂后的二维电子密度图 (a) 金刚石超胞模型和切面示意; (b) 掺杂B; (c) 掺杂Cr; (d) 掺杂Mo; (e) 未掺杂; (f) 掺杂W; (g) 掺杂Ti; (h) 掺杂Zr

Figure 4. 2D electron density map of diamond supercell after doping: (a) Diamond supercell model and section illustration; (b) doped with B; (c) doped with Cr; (d) doped with Mo; (e) undoped atoms; (f) doped with W; (g) doped with Ti; (h) doped with Zr.

表 1 采用不同正电子–电子交换关联函数和增强因子计算的金刚石正电子湮灭寿命值

Table 1. Diamond positron annihilation lifetime values calculated using different positron electron exchange correlation functions and enhancement factors.

赝势文件 GGA-PBE LDA-PW 文献 计算方法 Boronski &

NieminenSterne &

KaiserBoronski &

NieminenSterne &

KaiserPuska, Seitsonen,

and Nieminen— 湮灭增强因子 RPA限制和

GGA修正GGA修正 RPA限制 Sterne &

KaiserPuska, Seitsonen

and Nieminen— 完美晶体/ps 106.55 108.86 99.8 102.18 107.59 97—115[31,35,51] 单位/ps 128.85 130.7 119.87 121.79 109.87 120[53] 电子-电子自洽/ps — — 129.54 122.11 122.24 — 表 2 掺杂B, Cr, Mo, Ti, W和Zr原子后, 金刚石中正电子湮灭寿命值

Table 2. Positron annihilation lifetime values in diamond after doping with B, Cr, Mo, Ti, W, and Zr atoms.

-

[1] Stachel T, Luth R W 2015 Lithos 220 – 223 200

[2] Bulanova G P 1995 J. Geochem. Explor. 53 1

Google Scholar

Google Scholar

[3] Wei L, Kuo P K, Thomas R L, et al. 1993 Phys. Rev. Lett. 70 3764

Google Scholar

Google Scholar

[4] Chakraborty P, Xiong G, Cao L, et al. 2018 Carbon 139 85

Google Scholar

Google Scholar

[5] Ciupiński Ł, Kruszewski M J, Grzonka J, et al. 2017 Mater. Des. 120 170

Google Scholar

Google Scholar

[6] Kidalov S V, Shakhov F M 2009 Materials 2 2467

Google Scholar

Google Scholar

[7] May P W 2000 Philos. Trans. R. Soc. London, Ser. A 358 473

Google Scholar

Google Scholar

[8] Liao M 2021 Funct. Diamond 1 29

Google Scholar

Google Scholar

[9] Gomez H, Groves M N, Neupane M R 2021 Carbon Trends 3 100033

Google Scholar

Google Scholar

[10] Pan Y, He X, Ren S, et al. 2018 Vacuum 153 74

Google Scholar

Google Scholar

[11] Soltani H M, Tayebi M 2020 Int. J. Refract. Met. Hard Mater. 87 105172

Google Scholar

Google Scholar

[12] Pillari L K, Bakshi S R, Chaudhuri P, et al. 2020 Adv. Powder Technol. 31 3657

Google Scholar

Google Scholar

[13] Zhang X Y, Xu M, Cao S Z, et al. 2020 Diamond Relat. Mater. 104 107755

Google Scholar

Google Scholar

[14] Jia J, Bai S, Xiong D, et al. 2019 Ceram. Int. 45 10810

Google Scholar

Google Scholar

[15] Liu Z, Zheng S, Lu Z, et al. 2018 Carbon 127 548

Google Scholar

Google Scholar

[16] Wu M, Chang L, Zhang L, et al. 2017 Surf. Coat. Technol. 325 490

Google Scholar

Google Scholar

[17] Contreras Cuevas A, Bedolla Becerril E, Martínez M S, et al. 2018 Metal Matrix Composites (Cham: Springer International Publishing

[18] Bai G, Li N, Wang X, et al. 2018 J. Alloys Compd. 735 1648

Google Scholar

Google Scholar

[19] Bai G, Wang L, Zhang Y, et al. 2019 Mater. Charact. 152 265

Google Scholar

Google Scholar

[20] Liu X, Sun F, Wang L, et al. 2020 Appl. Surf. Sci. 515 146046

Google Scholar

Google Scholar

[21] Kang Q, He X, Ren S, et al. 2013 J. Alloys Compd. 576 380

Google Scholar

Google Scholar

[22] Che Q L, Chen X K, Ji Y Q, et al. 2015 Mater. Sci. Semicond. Process. 30 104

Google Scholar

Google Scholar

[23] Li J, Zhang H, Wang L, et al. 2016 Composites Part A 91 189

Google Scholar

Google Scholar

[24] Abyzov A M, Kidalov S V, Shakhov F M 2012 Appl. Therm. Eng. 48 72

[25] He J, Wang X, Zhang Y, et al. 2015 Composites Part B 68 22

Google Scholar

Google Scholar

[26] Wang L, Li J, Bai G, et al. 2019 J. Alloys Compd. 781 800

Google Scholar

Google Scholar

[27] Dannefaer S 2007 Phys. Status Solidi C 4 3605

Google Scholar

Google Scholar

[28] Avalos V, Dannefaer S 2003 Phys. B: Condens. Matter 340 – 342 76

[29] Siegel R W 1980 Annu. Rev. Mater. Sci. 10 393

Google Scholar

Google Scholar

[30] Tuomisto F, Makkonen I 2013 Rev. Mod. Phys. 85 1583

Google Scholar

Google Scholar

[31] Pu A, Bretagnon T, Kerr D, et al. 2000 Diamond Relat. Mater. 9 1450

Google Scholar

Google Scholar

[32] Sachdeva A, Sudarshan K, Pujari P, et al. 2004 Diamond Relat. Mater. 13 1719

Google Scholar

Google Scholar

[33] Hu X J, Ye J S, Liu H J, et al. 2008 Thin Solid Films 516 1699

Google Scholar

Google Scholar

[34] Jones R 2009 Diamond Relat. Mater. 18 820

Google Scholar

Google Scholar

[35] Fujii S, Nishibayashi Y, Shikata S, et al. 1995 J. Appl. Phys. 78 1510

Google Scholar

Google Scholar

[36] Eseev M, Kuziv I, Kostin A, et al. 2022 Materials 16 203

Google Scholar

Google Scholar

[37] Gonze X, Amadon B, Antonius G, et al. 2020 Comput. Phys. Commun. 248 107042

Google Scholar

Google Scholar

[38] Romero A H, Allan D C, Amadon B, et al. 2020 J. Chem. Phys. 152 124102

Google Scholar

Google Scholar

[39] Gonze X, Jollet F, Abreu Araujo F, et al. 2016 Comput. Phys. Commun. 205 106

Google Scholar

Google Scholar

[40] Gonze X, Amadon B, Anglade P M, et al. 2009 Comput. Phys. Commun. 180 2582

Google Scholar

Google Scholar

[41] Torrent M, Jollet F, Bottin F, et al. 2008 Comput. Mater. Sci. 42 337

Google Scholar

Google Scholar

[42] Humphrey W, Dalke A, Schulten K 1996 J. Mol. Graphics 14 33

Google Scholar

Google Scholar

[43] Momma K, Izumi F 2011 J. Appl. Crystallogr. 44 1272

Google Scholar

Google Scholar

[44] Boroński E, Nieminen R M 1986 Phys. Rev. B 34 3820

Google Scholar

Google Scholar

[45] Arponen J, Pajanne E 1979 Ann. Phys. 121 343

Google Scholar

Google Scholar

[46] Nieminen R M, Boronski E, Lantto L J 1985 Phys. Rev. B 32 1377

Google Scholar

Google Scholar

[47] Wiktor J, Jomard G, Torrent M 2015 Phys. Rev. B 92 125113

Google Scholar

Google Scholar

[48] Hom T, Kiszenik W, Post B 1975 J. Appl. Crystallogr. 8 457

Google Scholar

Google Scholar

[49] Holloway H, Hass K C, Tamor M A, et al. 1991 Phys. Rev. B 44 7123

Google Scholar

Google Scholar

[50] Zhao Y, Yan F, An Y 2022 Coatings 12 619

Google Scholar

Google Scholar

[51] Uedono A, Fujii S, Morishita N, et al. 1999 J. Phys. Condens. Matter 11 4109

Google Scholar

Google Scholar

[52] Shiryaev A A, Iakoubovskii K, Schut H, et al. 2001 Mater. Sci. Forum 363 – 365 40

[53] Dannefaer S, Mascher P, Kerr D 1992 Diamond Relat. Mater. 1 407

Google Scholar

Google Scholar

[54] Kršjak V, Sojak S, Slugeň V, et al. 2011 J. Phys. Conf. Ser. 265 012014

Google Scholar

Google Scholar

[55] Dannefaer S, Iakoubovskii K 2008 J. Phys. Condens. Matter 20 235225

Google Scholar

Google Scholar

[56] Puska M J, Lanki P, Nieminen R M 1989 J. Phys. Condens. Matter 1 6081

Google Scholar

Google Scholar

[57] Maier K, Peo M, Saile B, et al. 1979 Philos. Mag. A 40 701

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 5455

- PDF Downloads: 181

- Cited By: 0

DownLoad:

DownLoad: