-

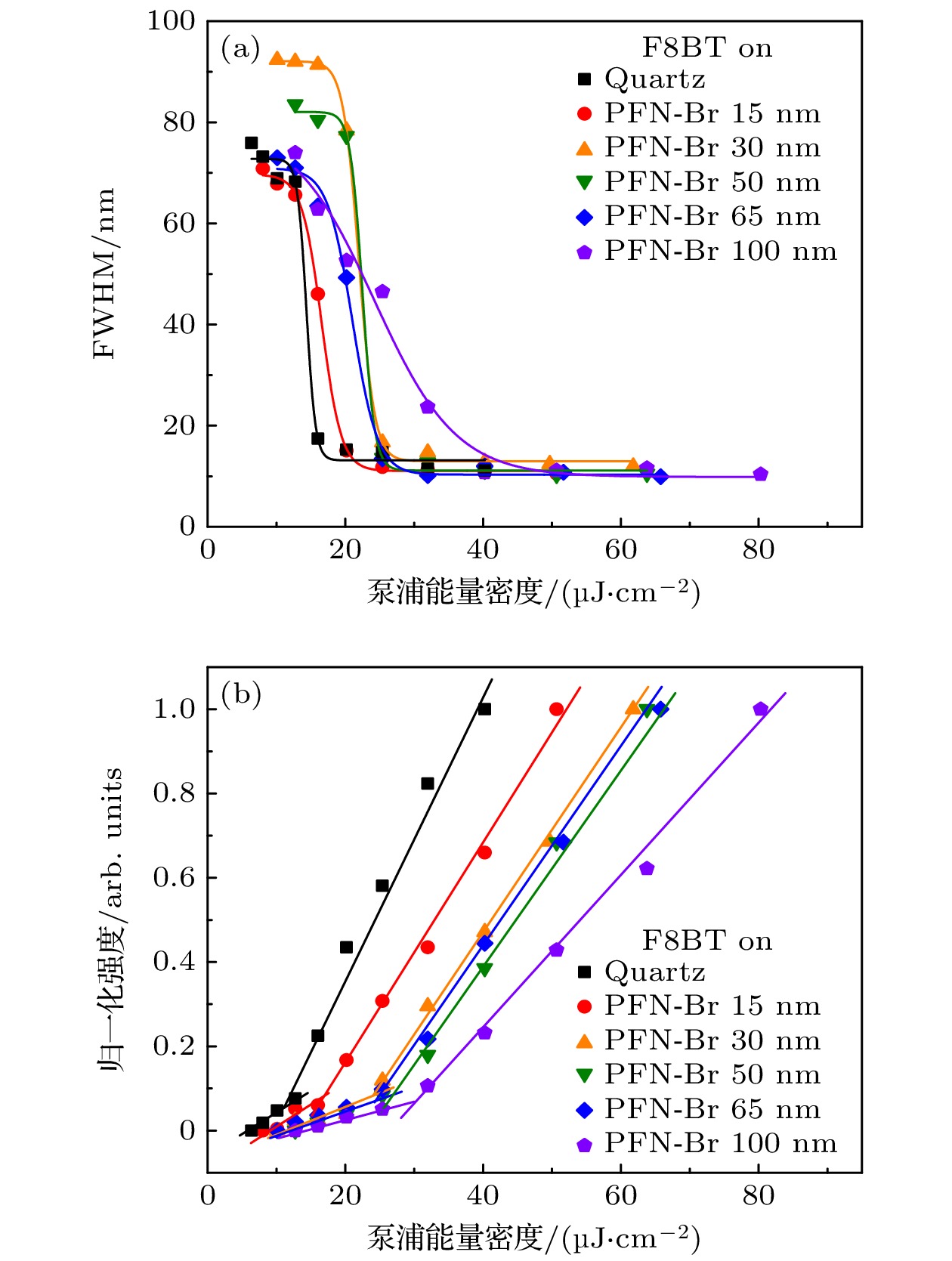

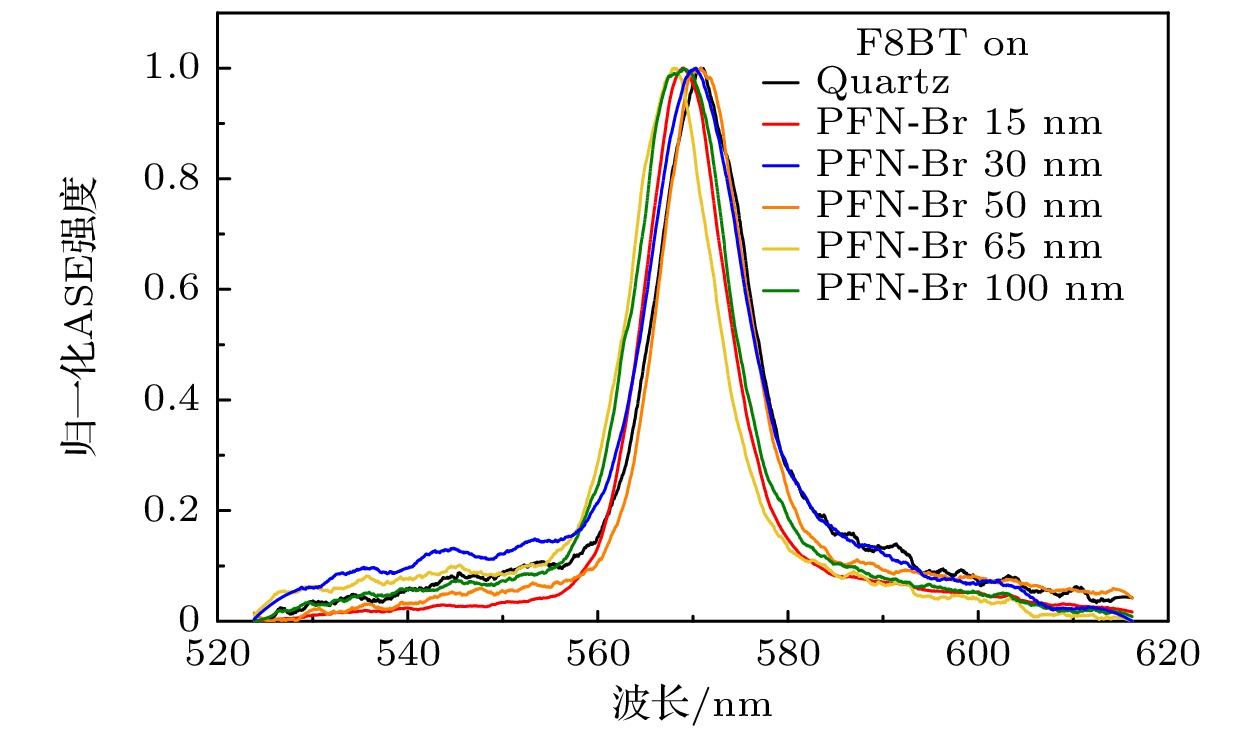

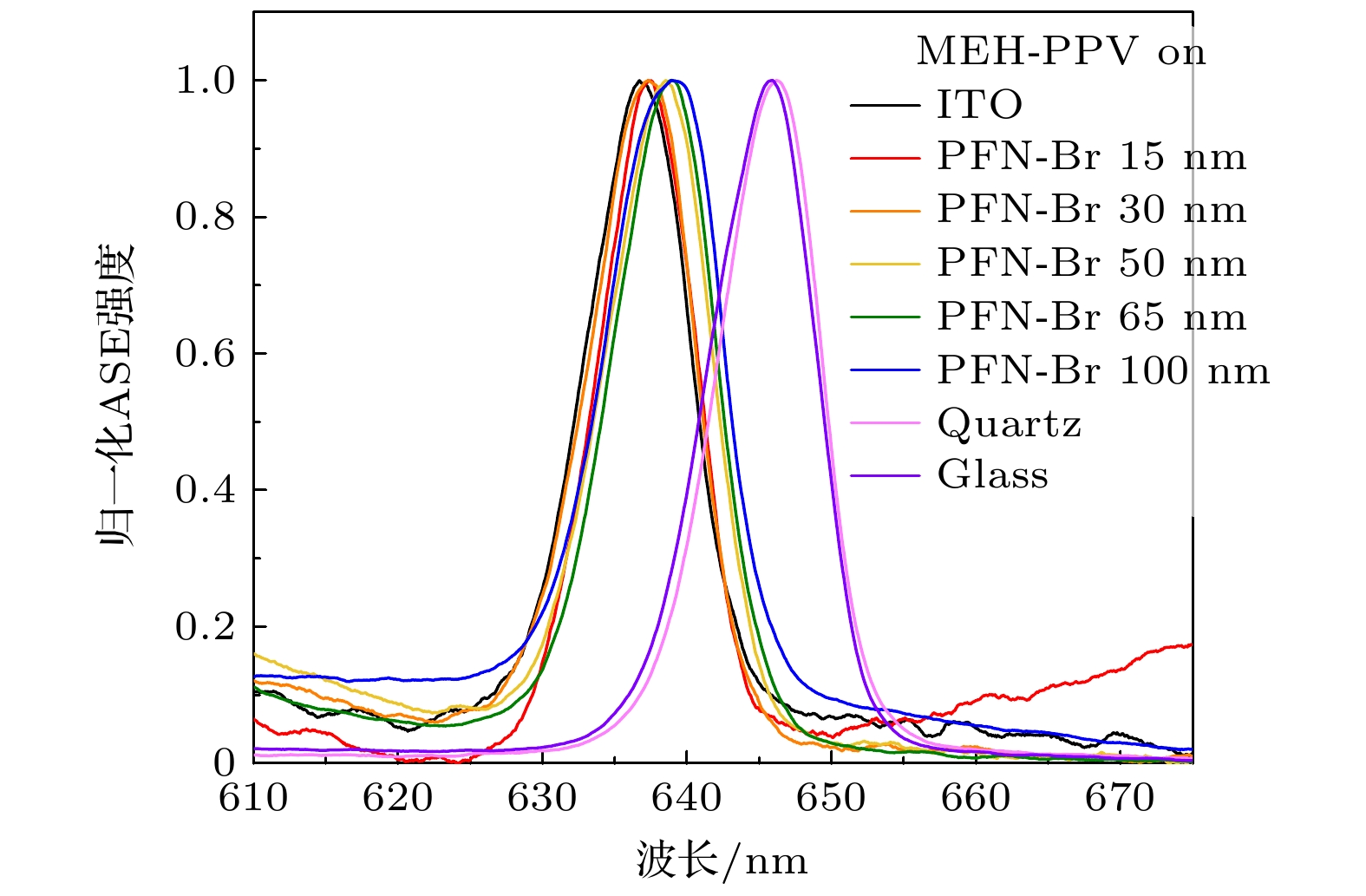

In this paper, the optical gain properties of the water/alcohol soluble conjugated polyelectrolyte (Poly[(9,9-bis(3′-((N,N-dimethyl)-N-ethylammonium)propyl)-2,7-fluorene)-alt-2,7-(9,9-dioctylfluorene)]) (PFN-Br) and its potential applications in future electrically pumped organic lasers are revealed and systematically studied. To the best of our knowledge, no studies on the optical gain properties of PFN-Br or its prototype, poly[(9,9-bis(3′-(N,N-dimethylamino)propyl)-2,7-fluorene)-alt-2,7-(9,9-dioctylfluorene)] have been reported before. These conjugated polyelectrolytes are widely used as the interlayers in organic light emitting diodes or organic solar cells. The thickness of such an interlayer is usually less than 10 nm, which is considered not sufficient for supporting light waveguiding. Therefore, the thickness of the PFN-Br layer used in this work is increased to more than 100 nm. Through careful study, the polymer is found to possess a low threshold of amplified spontaneous emission (ASE) (~11 μJ/cm2) and a small ASE cutoff thickness (<50 nm). It is an efficient blue emission (~456 nm) gain medium. The ASE peak of the PFN-Br film is red-shifted as the thickness increases from 50 to 220 nm. By utilizing the great resistance of PFN-Br against the organic solvent, such as toluene, PFN-Br/F8BT bilayer devices on quartz and PFN-Br/MEH-PPV bilayer devices on ITO glass are fabricated and characterized. In the PFN-Br/F8BT bilayer devices, it is found that the PFN-Br interlayer has very limited influence on F8BT. The ASE threshold of F8BT increases only twice, compared with that of F8BT monolayer device, when 100-nm-thick PFN-Br layer is introduced beneath the F8BT film. No significant change in optical gain or loss is observed. Most of the extra losses in F8BT due to the introduction of PFN-Br are attributed to the larger refractive index of PFN-Br than that of quartz substrate. Furthermore, in the PFN-Br/MEH-PPV bilayer devices on ITO glass, introducing PFN-Br interlayer resulting in optimal ASE performance of MEH-PPV compared with that on bare ITO surface. The ASE threshold of MEH-PPV is reduced as much as 60% (from 402 μJ/cm2 to 160 μJ/cm2) while the PFN-Br layer is sandwiched between ITO and MEH-PPV. The PFN-Br layer modifies the waveguiding modes, and reduces the interaction between excitons and ITO electrodes. As a result, the ASE performance of MEH-PPV is improved. The findings of this report indicate that the PFN-Br is not only a good carrier transport material but also a highly-efficient gain medium. PFN-Br, combined with its advantages in different fields, is expected to play various roles in future organic electrically pumped lasers.

-

Keywords:

- organic semiconductor laser /

- amplified spontaneous emission /

- polymeric film /

- water soluble polymer

[1] Chenais S, Forget S 2012 Polym. Int. 61 390

Google Scholar

Google Scholar

[2] Yap B K, Xia R D, Campoy-Quiles M, Stavrinou P N, Bradley D D C 2008 Nat. Mater. 7 376

Google Scholar

Google Scholar

[3] Kim H, Schulte N, Zhou G, Mullen K, Laquai F 2011 Adv. Mater. 23 894

Google Scholar

Google Scholar

[4] Feng Z J, Cheng Z, Jin H X, Lu P 2022 J. Mater. Chem. C Mater. 10 4497

Google Scholar

Google Scholar

[5] Sarma M, Chen L M, Chen Y S, Wong K T 2022 Mater. Sci. Eng. R Rep. 150 100689

Google Scholar

Google Scholar

[6] Al-Azzawi A G S, Aziz S B, Dannoun E M A, Iraqi A, Nofal M M, Murad A R, Hussein A M 2023 Polymers 15 164

Google Scholar

Google Scholar

[7] Li B, Yang X, Li S Y, Yuan J Y 2023 Energy Environ. Sci. 16 723

Google Scholar

Google Scholar

[8] Wang J J, Wen S G, Hu J, Han J H, Yang C P, Li J F, Bao X C, Yan S K 2022 Chem. Eng. J. 452 139462

Google Scholar

Google Scholar

[9] Yazdani S A, Mikaeili A, Bencheikh F, Adachi C 2022 Jpn. J. Appl. Phys. 61 074003

Google Scholar

Google Scholar

[10] Zhang Q, Tao W W, Huang J S, Xia R D, Cabanillas-Gonzalez J 2021 Adv. Photonics. Res. 2 2000155

Google Scholar

Google Scholar

[11] He Z C, Zhong C M, Su S J, Xu M, Wu H B, Cao Y 2012 Nat. Photonics 6 591

Google Scholar

Google Scholar

[12] Zhao Y Y, Zhang Q W, Liu Y F, Lv C, Guo S, Liu X P, Bi Y G, Li H W, Wu Y Q 2022 Org. Electron. 109 106620

Google Scholar

Google Scholar

[13] Feng C, Wang X J, He Z C, Cao Y 2021 Sol. RRL 5 2000753

Google Scholar

Google Scholar

[14] Hsu F C, Lin Y A, Li C P 2021 Org. Electron. 89 106008

Google Scholar

Google Scholar

[15] Li M Q, Jiang J X, Ning Y J, Zhao S L, Masri W F A, Wageh S, Al-Ghamdi A 2022 Synth. Met. 289 117122

Google Scholar

Google Scholar

[16] Hu Z C, Zhang K, Huang F, Cao Y 2015 Chem. Commun. 51 5572

Google Scholar

Google Scholar

[17] Huang F, Wu H B, Wang D, Yang W, Cao Y 2004 Chem. Mater. 16 708

Google Scholar

Google Scholar

[18] Wu H B, Huang F, Mo Y Q, Yang W, Wang D L Peng J B, Cao Y 2004 Adv. Mater. 16 1826

Google Scholar

Google Scholar

[19] Fu J F, Yuan L G, Ling F, Duan R M, Chen Q Y, Ma H, Zhou M, Song B, Zhou Y, Li Y F 2020 J. Power Sources 449 227474

Google Scholar

Google Scholar

[20] Xiong X, Xue X N, Zhang M, Hao T Y, Han Z Y, Sun Y Y, Zhang, Y M, Liu F, Pei S P, Zhu L 2021 ACS Energy Lett. 6 3582

Google Scholar

Google Scholar

[21] Ohisa S, Kato T, Takahashi T, Suzuki M, Hayashi Y, Koganezawa T, McNeill C R, Chiba T, Pu Y J, Kido J 2018 ACS Appl. Mater. Interfaces 10 17318

Google Scholar

Google Scholar

[22] Stevens M A, Silva C, Russell D M, Friend R H 2001 Phys. Rev. B 63 165213

Google Scholar

Google Scholar

[23] Xia R D, Heliotis G, Bradley D D C 2003 Appl. Phys. Lett. 82 3599

Google Scholar

Google Scholar

[24] Hayes G R, Samuel I D W, Phillips R T 1997 Synth. Met. 84 889

Google Scholar

Google Scholar

[25] Kretsch K P, Belton C, Lipson S, Blau W J, Henari F Z, Rost H, Pfeiffer S, Teuschel, A, Tillmann H, Horhold H H 1999 J. Appl. Phys. 86 6155

Google Scholar

Google Scholar

[26] Calzado E M, Villalvilla J M, Boj P G, Quintana J A, Diaz-Garcia M A 2005 J. Appl. Phys. 97 093103

Google Scholar

Google Scholar

[27] Anni M, Perulli A, Monti G 2012 J. Appl. Phys. 111 093109

Google Scholar

Google Scholar

[28] Heliotis G, Bradley D D C, Turnbull G A, Samuel I D W 2002 Appl. Phys. Lett. 81 415

Google Scholar

Google Scholar

[29] Peng X, Liu L Y, Wu J F, Li Y G, Hou Z J, Xu L, Wang W C, Li F M 2000 Opt. Lett. 25 314

Google Scholar

Google Scholar

[30] Feng Y J, Yu X L, Zhang R, Wu J W, Zhang P, Chen S J, Zhang, D K 2017 J. Alloys Compd. 729 513

Google Scholar

Google Scholar

[31] 杜惠军, 李睿, 骆逸夫, 王竹君, 吴霞, 伊书颖, 皮明雨, 张丁可 2019 中国科学: 化学 49 1475

Du H J, Li R, Luo Y F, Wang Z J, Wu X, Yi S Y, Pi M Y, Zhang D K 2019 Sci. Sin. Chim. 49 1475

[32] Lahoz F, Oton C J, Capuj N, Ferrer-Gonzalez M, Cheylan S, Navarro-Urrios D 2009 Opt. Express 17 16766

Google Scholar

Google Scholar

[33] Pauchard M, Swensen J, Moses D, Heeger A J, Perzon E, Andersson M R 2003 J. Appl. Phys. 94 3543

Google Scholar

Google Scholar

[34] Haugeneder A, Neges M, Kallinger C, Spirkl W, Lemmer U, Feldmann J, Amann M C, Scherf U 1999 J. Appl. Phys. 85 1124

Google Scholar

Google Scholar

[35] Reufer M, Feldmann J, Rudati P, Ruhl A, Muller D, Meerholz K, Karnutsch C, Gerken M, Lemmer U 2005 Appl. Phys. Lett. 86 221102

Google Scholar

Google Scholar

[36] Therezio E M, Hidalgo A A, Oliveira O N, Silva R A, Marletta A 2015 J. Braz. Chem. Soc. 26 1798

Google Scholar

Google Scholar

-

表 1 不同溶液浓度和转速制备的薄膜

Table 1. Thin films prepared at different solution concentrations and rotational speeds.

材料 溶液浓度/

(mg·mL–1)转速/(r·min–1) 膜厚/nm PFN-Br 3 2000 15 PFN-Br 4 2000 30 PFN-Br 5 2000 50 PFN-Br 6 2000 65 PFN-Br 7 2000 100 PFN-Br 12 4000 120 PFN-Br 12 3000 130 PFN-Br 12 2000 160 PFN-Br 12 1500 170 PFN-Br 12 1000 220 F8BT 25 2000 160 MEH-PPV 25 2000 210 -

[1] Chenais S, Forget S 2012 Polym. Int. 61 390

Google Scholar

Google Scholar

[2] Yap B K, Xia R D, Campoy-Quiles M, Stavrinou P N, Bradley D D C 2008 Nat. Mater. 7 376

Google Scholar

Google Scholar

[3] Kim H, Schulte N, Zhou G, Mullen K, Laquai F 2011 Adv. Mater. 23 894

Google Scholar

Google Scholar

[4] Feng Z J, Cheng Z, Jin H X, Lu P 2022 J. Mater. Chem. C Mater. 10 4497

Google Scholar

Google Scholar

[5] Sarma M, Chen L M, Chen Y S, Wong K T 2022 Mater. Sci. Eng. R Rep. 150 100689

Google Scholar

Google Scholar

[6] Al-Azzawi A G S, Aziz S B, Dannoun E M A, Iraqi A, Nofal M M, Murad A R, Hussein A M 2023 Polymers 15 164

Google Scholar

Google Scholar

[7] Li B, Yang X, Li S Y, Yuan J Y 2023 Energy Environ. Sci. 16 723

Google Scholar

Google Scholar

[8] Wang J J, Wen S G, Hu J, Han J H, Yang C P, Li J F, Bao X C, Yan S K 2022 Chem. Eng. J. 452 139462

Google Scholar

Google Scholar

[9] Yazdani S A, Mikaeili A, Bencheikh F, Adachi C 2022 Jpn. J. Appl. Phys. 61 074003

Google Scholar

Google Scholar

[10] Zhang Q, Tao W W, Huang J S, Xia R D, Cabanillas-Gonzalez J 2021 Adv. Photonics. Res. 2 2000155

Google Scholar

Google Scholar

[11] He Z C, Zhong C M, Su S J, Xu M, Wu H B, Cao Y 2012 Nat. Photonics 6 591

Google Scholar

Google Scholar

[12] Zhao Y Y, Zhang Q W, Liu Y F, Lv C, Guo S, Liu X P, Bi Y G, Li H W, Wu Y Q 2022 Org. Electron. 109 106620

Google Scholar

Google Scholar

[13] Feng C, Wang X J, He Z C, Cao Y 2021 Sol. RRL 5 2000753

Google Scholar

Google Scholar

[14] Hsu F C, Lin Y A, Li C P 2021 Org. Electron. 89 106008

Google Scholar

Google Scholar

[15] Li M Q, Jiang J X, Ning Y J, Zhao S L, Masri W F A, Wageh S, Al-Ghamdi A 2022 Synth. Met. 289 117122

Google Scholar

Google Scholar

[16] Hu Z C, Zhang K, Huang F, Cao Y 2015 Chem. Commun. 51 5572

Google Scholar

Google Scholar

[17] Huang F, Wu H B, Wang D, Yang W, Cao Y 2004 Chem. Mater. 16 708

Google Scholar

Google Scholar

[18] Wu H B, Huang F, Mo Y Q, Yang W, Wang D L Peng J B, Cao Y 2004 Adv. Mater. 16 1826

Google Scholar

Google Scholar

[19] Fu J F, Yuan L G, Ling F, Duan R M, Chen Q Y, Ma H, Zhou M, Song B, Zhou Y, Li Y F 2020 J. Power Sources 449 227474

Google Scholar

Google Scholar

[20] Xiong X, Xue X N, Zhang M, Hao T Y, Han Z Y, Sun Y Y, Zhang, Y M, Liu F, Pei S P, Zhu L 2021 ACS Energy Lett. 6 3582

Google Scholar

Google Scholar

[21] Ohisa S, Kato T, Takahashi T, Suzuki M, Hayashi Y, Koganezawa T, McNeill C R, Chiba T, Pu Y J, Kido J 2018 ACS Appl. Mater. Interfaces 10 17318

Google Scholar

Google Scholar

[22] Stevens M A, Silva C, Russell D M, Friend R H 2001 Phys. Rev. B 63 165213

Google Scholar

Google Scholar

[23] Xia R D, Heliotis G, Bradley D D C 2003 Appl. Phys. Lett. 82 3599

Google Scholar

Google Scholar

[24] Hayes G R, Samuel I D W, Phillips R T 1997 Synth. Met. 84 889

Google Scholar

Google Scholar

[25] Kretsch K P, Belton C, Lipson S, Blau W J, Henari F Z, Rost H, Pfeiffer S, Teuschel, A, Tillmann H, Horhold H H 1999 J. Appl. Phys. 86 6155

Google Scholar

Google Scholar

[26] Calzado E M, Villalvilla J M, Boj P G, Quintana J A, Diaz-Garcia M A 2005 J. Appl. Phys. 97 093103

Google Scholar

Google Scholar

[27] Anni M, Perulli A, Monti G 2012 J. Appl. Phys. 111 093109

Google Scholar

Google Scholar

[28] Heliotis G, Bradley D D C, Turnbull G A, Samuel I D W 2002 Appl. Phys. Lett. 81 415

Google Scholar

Google Scholar

[29] Peng X, Liu L Y, Wu J F, Li Y G, Hou Z J, Xu L, Wang W C, Li F M 2000 Opt. Lett. 25 314

Google Scholar

Google Scholar

[30] Feng Y J, Yu X L, Zhang R, Wu J W, Zhang P, Chen S J, Zhang, D K 2017 J. Alloys Compd. 729 513

Google Scholar

Google Scholar

[31] 杜惠军, 李睿, 骆逸夫, 王竹君, 吴霞, 伊书颖, 皮明雨, 张丁可 2019 中国科学: 化学 49 1475

Du H J, Li R, Luo Y F, Wang Z J, Wu X, Yi S Y, Pi M Y, Zhang D K 2019 Sci. Sin. Chim. 49 1475

[32] Lahoz F, Oton C J, Capuj N, Ferrer-Gonzalez M, Cheylan S, Navarro-Urrios D 2009 Opt. Express 17 16766

Google Scholar

Google Scholar

[33] Pauchard M, Swensen J, Moses D, Heeger A J, Perzon E, Andersson M R 2003 J. Appl. Phys. 94 3543

Google Scholar

Google Scholar

[34] Haugeneder A, Neges M, Kallinger C, Spirkl W, Lemmer U, Feldmann J, Amann M C, Scherf U 1999 J. Appl. Phys. 85 1124

Google Scholar

Google Scholar

[35] Reufer M, Feldmann J, Rudati P, Ruhl A, Muller D, Meerholz K, Karnutsch C, Gerken M, Lemmer U 2005 Appl. Phys. Lett. 86 221102

Google Scholar

Google Scholar

[36] Therezio E M, Hidalgo A A, Oliveira O N, Silva R A, Marletta A 2015 J. Braz. Chem. Soc. 26 1798

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 7014

- PDF Downloads: 142

- Cited By: 0

DownLoad:

DownLoad: