-

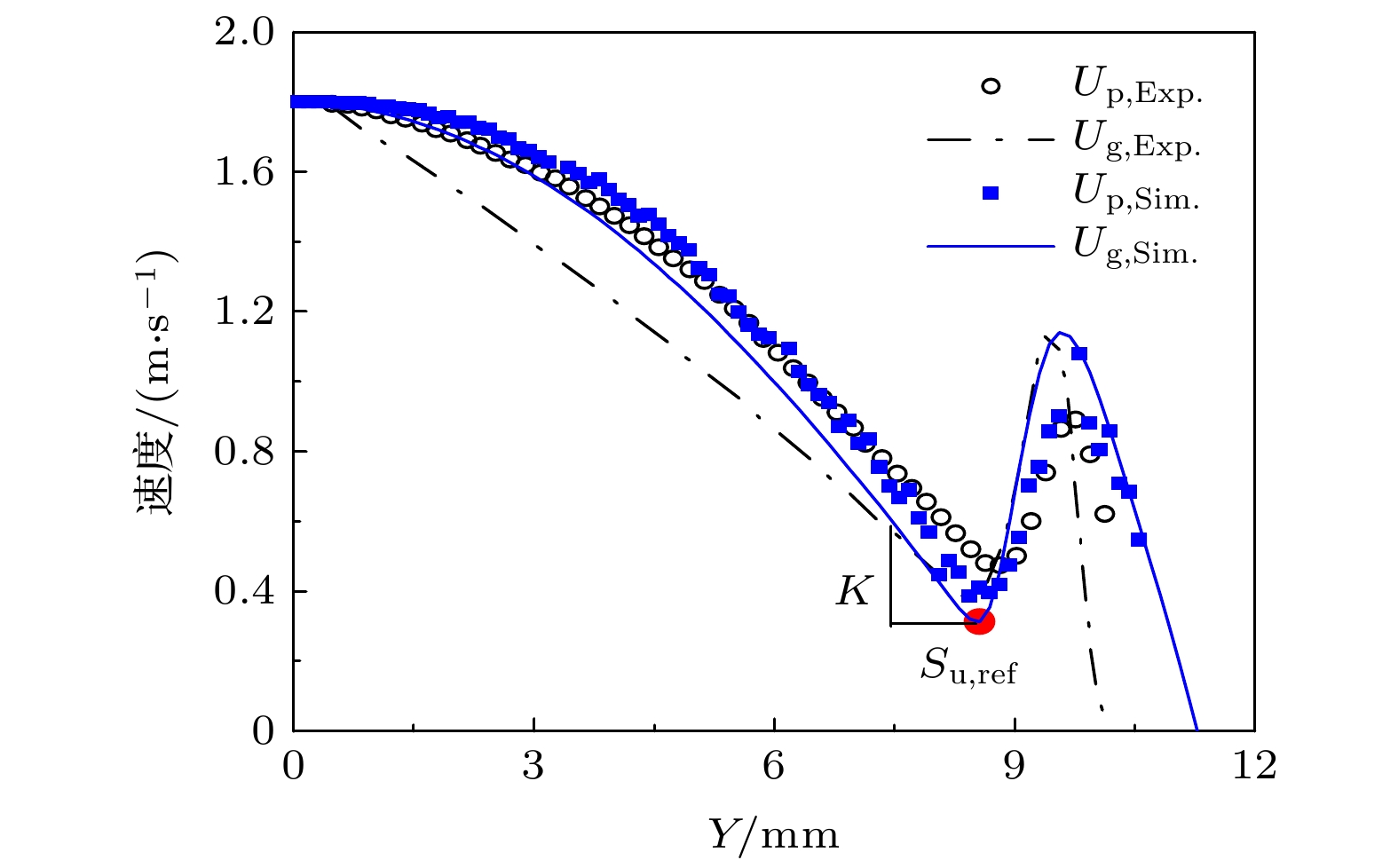

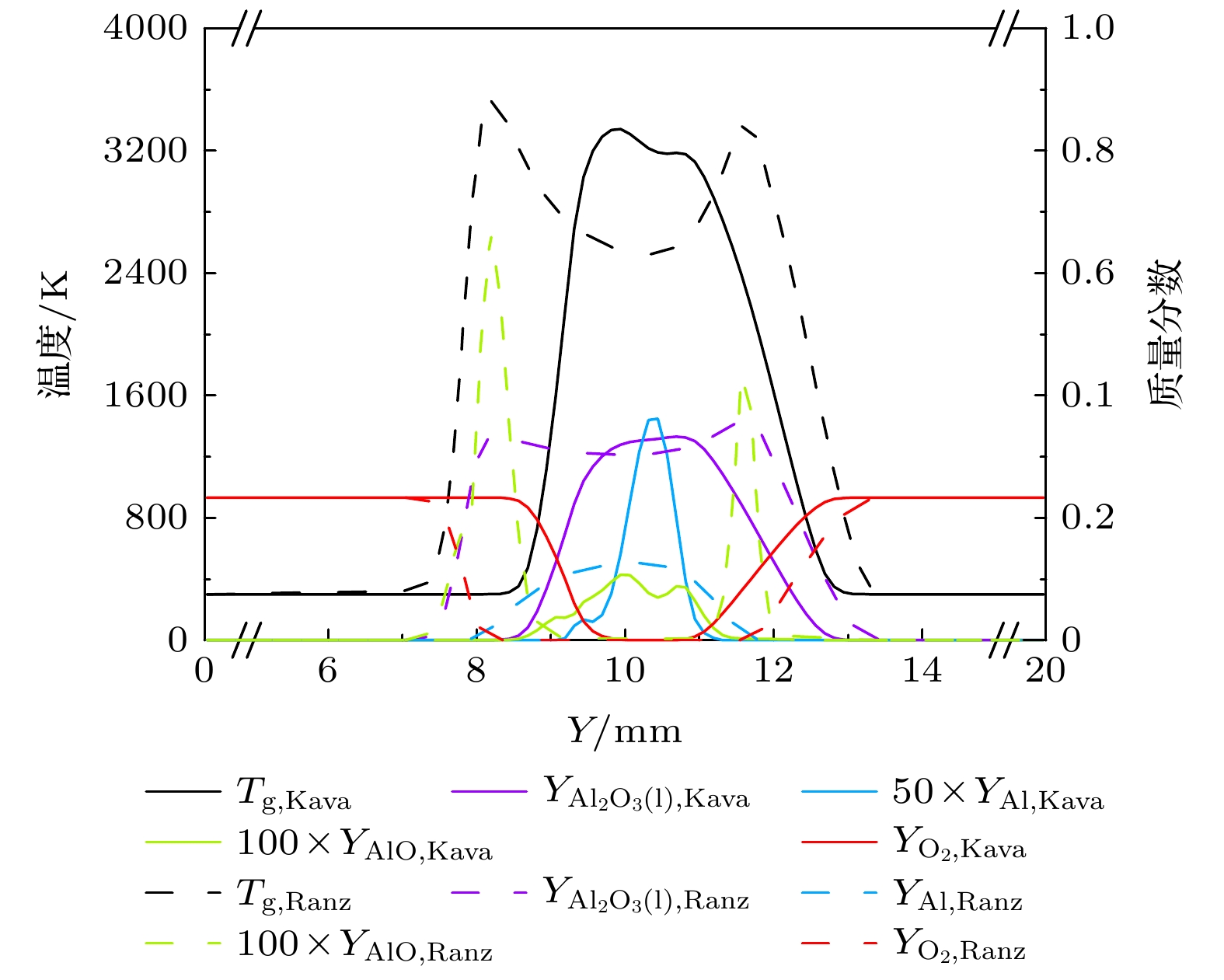

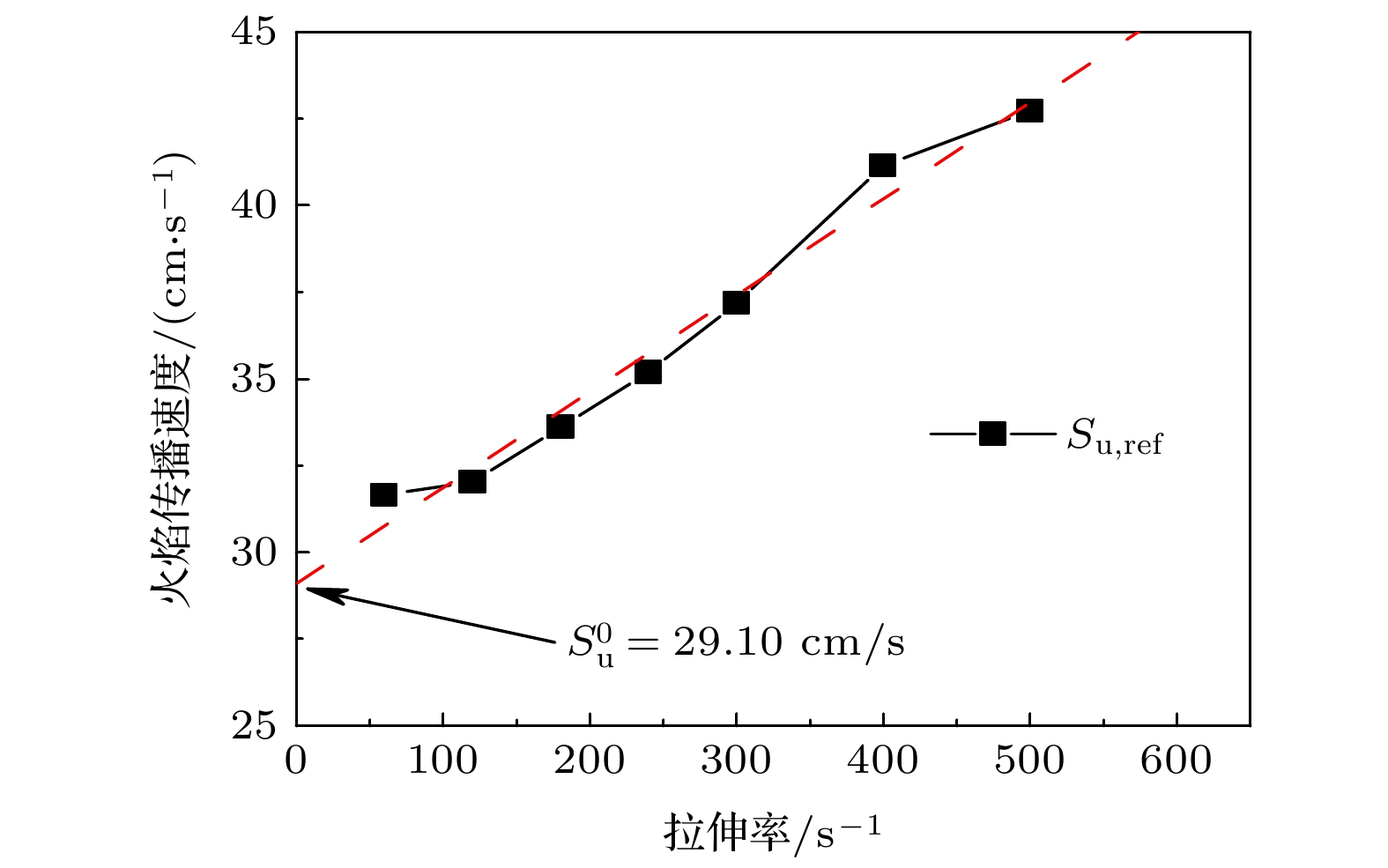

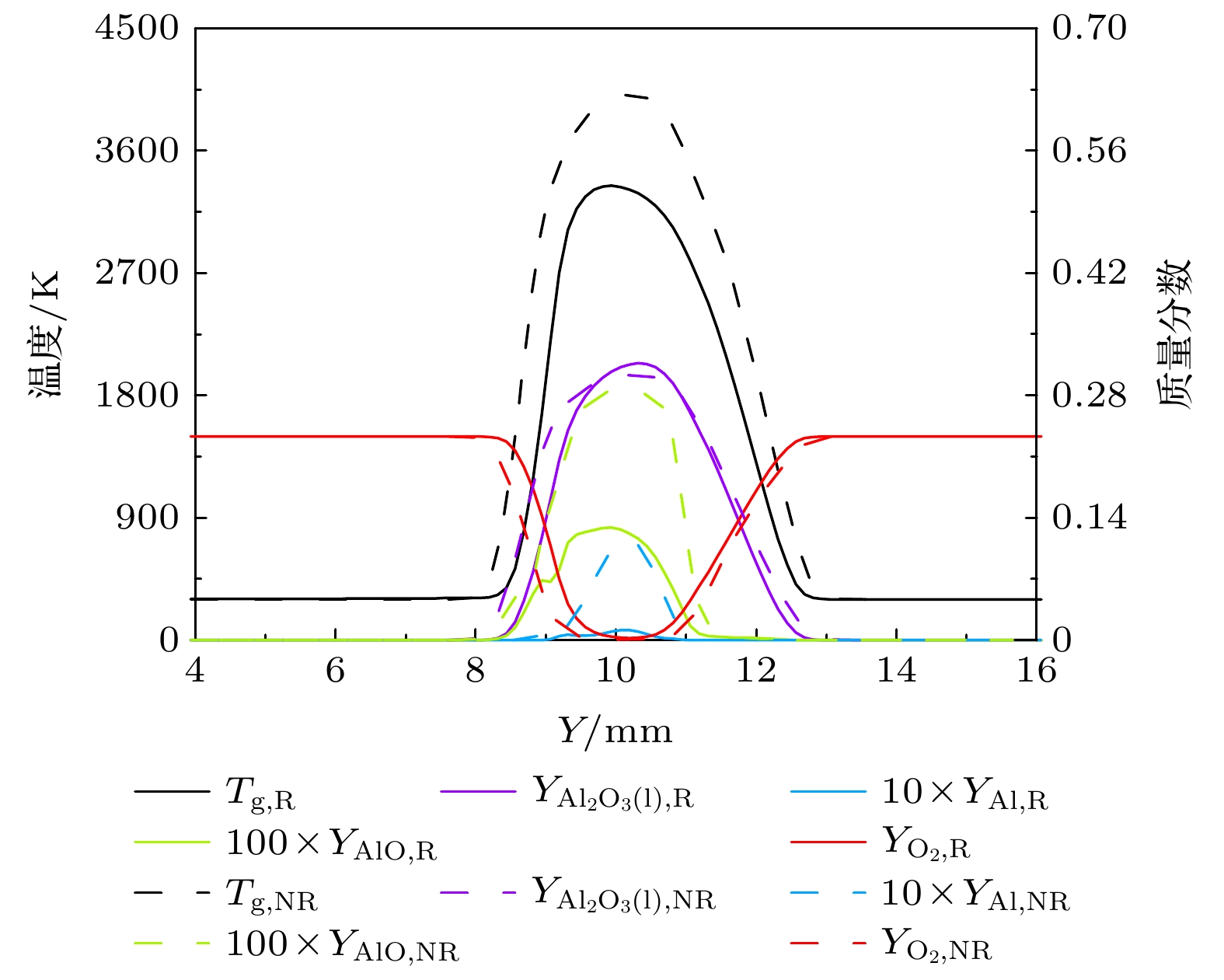

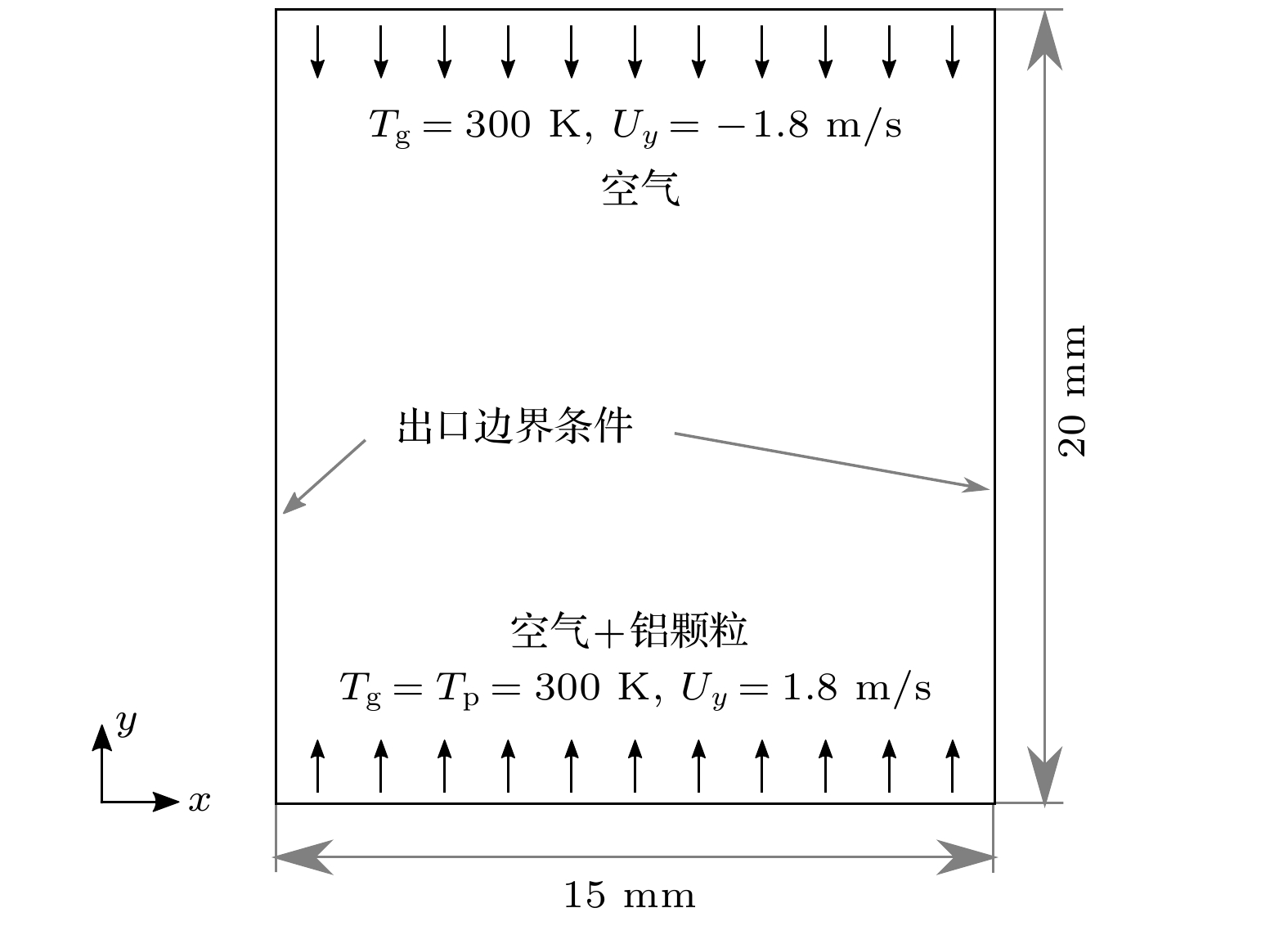

Aluminum is widely used as an additive in solid rocket propellants and pyrotechnics due to its outstanding characteristics such as high energy density and combustion temperature, environmentally benign products, and good stability. Recently, aluminum powders are found to present great potential serving as alternative fuel in a low-carbon economy. In this paper, a detailed model including the effects of interphase heat transfer, phase change, heterogeneous surface reactions, homogeneous combustion and radiation is employed to investigate aluminum dust counterflow flames. The numerical model is first validated by simulating the aluminum dust counterflow flames of McGill University. The results indicate that the particle velocity profile is in very good agreement with the experimental measurements. A detailed analysis of estimating the gas phase velocity based on the particle velocity is performed by using Stoke time τs. The results show that a correct value of τs is the key to this method, and using a single value of τs can bring a notable bias to the results, which may also affect the evaluation of flame speed from the counterflow flame. It is suggested that model validation should be carried out by directly comparing the particle velocity profiles from the simulations with those from the experiments. The flame structure of the aluminum dust counterflow flame is discussed, and the interphase heat transfer model is found to have a great influence on the flame for particle sizes smaller than 10 μm. Therefore, when simulating the aluminum dust flames with small particle sizes, the interphase heat transfer model should be selected carefully so that it can cover the transition heat transfer regime. The effect of particle diameter is examined. With the increase of the particle size, the flame speed continues to decrease, and most particles with a diameter of 15 μm cannot be fully burnt in the present configuration. The strain rate is found to be an important factor affecting the dust flame. As the strain rate increases, the residence time of the particles in the flame zone decreases, which ultimately leads the particles to be combusted incompletely. Moreover, the reaction zone of the counterflow flame, marked as AlO, is observed to be shrunk from a large double-peak structure into a small single-peak one along the burner centerline when strain increases. The reference flame speed increases with strain rate, and an unstretched reference flame speed of roughly 29 cm/s can be obtained by linear extrapolation of the predicted results. The effect of radiation is investigated by comparing two cases with and without radiative heat transfer. The results show that the heat loss caused by radiation can lead the temperature to decrease greatly in the gas phase, but the heating effect on the particles by radiation is relativelysmall. -

Keywords:

- aluminum combustion /

- counterflow flame /

- particle clouds /

- flame speed

[1] 王宁飞, 苏万兴, 李军伟, 张峤 2011 固体火箭技术 34 61

Google Scholar

Google Scholar

Wang N F, Sun W X, Li J W, Zhang Q 2011 J. Solid Rocket Technol. 34 61

Google Scholar

Google Scholar

[2] 李潮隆, 夏智勋, 马立坤, 赵翔, 罗振兵, 段一凡 2021 航空学报 40 26075

Li C L, Xia Z X, Ma L K, Zhao X, Luo Z B, Duan Y F 2021 Acta Aeronaut. Astronaut. Sin. 40 26075

[3] 王德全, 夏智勋, 胡建新 2010 航空学报 31 1074

Wang D Q, Xia Z X, Hu J X 2010 Acta Aeronaut. Astronaut. Sin. 31 1074

[4] 刘龙, 夏智勋, 黄利亚, 马立坤, 陈斌斌 2020 69

Google Scholar

Google Scholar

Liu L, Xia Z X, Huang L Y, Ma L K, Chen B B 2020 Acta Phys. Sin. 69

Google Scholar

Google Scholar

[5] 杨晋朝, 夏智勋, 胡建新 2013 62 074701

Google Scholar

Google Scholar

Yang J Z, Xia Z X, Hu J X 2013 Acta Phys. Sin. 62 074701

Google Scholar

Google Scholar

[6] Zhang J, Xia Z, Ma L, Huang L, Feng Y, Yang D 2021 Energy 214 118889

Google Scholar

Google Scholar

[7] Bergthorson J M 2018 Prog. Energy Combust. Sci. 68 169

Google Scholar

Google Scholar

[8] Goroshin S, Mamen J, Higgins A, Bazyn T, Glumac N, Krier H 2007 Proc. Combust. Inst. 31 2011

Google Scholar

Google Scholar

[9] Lomba R, Laboureur P, Dumand C, Chauveau C, Halter F 2019 Proc. Combust. Inst. 37 3143

Google Scholar

Google Scholar

[10] Xu W, Jiang Y 2018 Energies 11 3147

Google Scholar

Google Scholar

[11] 邓哲 2016 博士学位论文 (西安: 西北工业大学)

Deng Z 2016 Ph. D. Dissertation (Xi’an: Northwestern Polytechnical University) (in Chinese)

[12] Risha G, Huang Y, Yetter R, Yang, V 2005 Proceedings of the 43 rd AIAA Aerospace Sciences Meeting and Exhibit Reno, USA, January 10–13, 2005

[13] Goroshin S, Fomenko I, Lee J H S 1996 Symp. (Int.) Combust. 26 1961

Google Scholar

Google Scholar

[14] Julien P, Whiteley S, Soo M, Goroshin S, Frost D, Bergthorson J 2017 Proc. Combust. Inst. 36 2291

Google Scholar

Google Scholar

[15] Julien P, Vickery J, Goroshin S, Frost D, Bergthorson J 2015 Combust. Flame 162 4241

Google Scholar

Google Scholar

[16] Egolfopoulos F N, Hansen N, Ju Y, Kohse-Höinghaus K, Law C, Qi F 2014 Prog. Energy Combust. Sci. 43 36

Google Scholar

Google Scholar

[17] Huang Y, Risha G A, Yang V, Yetter R 2009 Combust. Flame 156 5

Google Scholar

Google Scholar

[18] Escot Bocanegra P, Davidenko D, Sarou-Kanian V, Chauveau C, Gökalp I 2010 Exp. Therm. Fluid Sci. 34 299

Google Scholar

Google Scholar

[19] Han D, Sung H 2019 Combust. Flame 206 112

Google Scholar

Google Scholar

[20] Zou X, Wang N, Wang J, Feng Y, Shi B 2021 Aerosp. Sci. Technol. 112 106604

Google Scholar

Google Scholar

[21] Zou X, Wang N, Liao L, Chu Q, Shi B 2020 Fuel 266 116952

Google Scholar

Google Scholar

[22] Khalili H, Madani S, Mohammadi M, Poorfar, A, Bidabadi M, Pendleton P, 2019 Combust. Explos. Shock Waves 55 65

Google Scholar

Google Scholar

[23] Najjar F, Ferry J, Haselbacher A, Balachandar S 2006 J. Spacecraft Rockets 43 1258

Google Scholar

Google Scholar

[24] 刘平安, 常浩, 李树声, 王文超 2018 固体火箭技术 41 156

Liu P A, Chang H, Li S S, Wang W H 2018 J. Solid Rocket Technol. 41 156

[25] Li C, Xia Z, Ma L, Chen B 2019 Energies 12 1235

Google Scholar

Google Scholar

[26] Li C, Xia Z, Ma L, Chen B 2019 Acta Astronaut. 162 145

Google Scholar

Google Scholar

[27] Yuen M, Chen L W 1976 Combust. Sci. Technol. 14 147

Google Scholar

Google Scholar

[28] Ranz W, Marshall W 1952 Chem. Eng. Prog. 48 141

[29] Mohan S, Trunov M, Dreizin E 2008 J. Heat Transfer 130 104505

Google Scholar

Google Scholar

[30] Crowe C, Schwarzkopf J, Sommerfeld M, Tsuji Y 2011 Multiphase flows with droplets and particles (2nd Ed.) (Boca Raton: CRC Press) p106

[31] Chase Mhttps://janaf.nist.gov/ [2020-9-6]

[32] Gurevich M, Ozerova G, Stepanov A 1970 Combust. Explos. Shock Waves 6 291

Google Scholar

Google Scholar

[33] Glorian J, Gallier S, Catoire L 2016 Combust. Flame 168 378

Google Scholar

Google Scholar

[34] Harrison J, Brewster M 2009 J. Thermophys. Heat Transfer 23 630

Google Scholar

Google Scholar

[35] Modest M 2013 Radiative Heat Transfer (3rd Ed.) (Amsterdam: Academic Press) p26

[36] Lynch P, Krier H, Glumac N 2010 J. Thermophys. Heat Transfer 24 301

Google Scholar

Google Scholar

[37] Munzar J, Akih-Kumgeh B, Denman B, Zia A, Bergthorson J 2013 Fuel 113 586

Google Scholar

Google Scholar

-

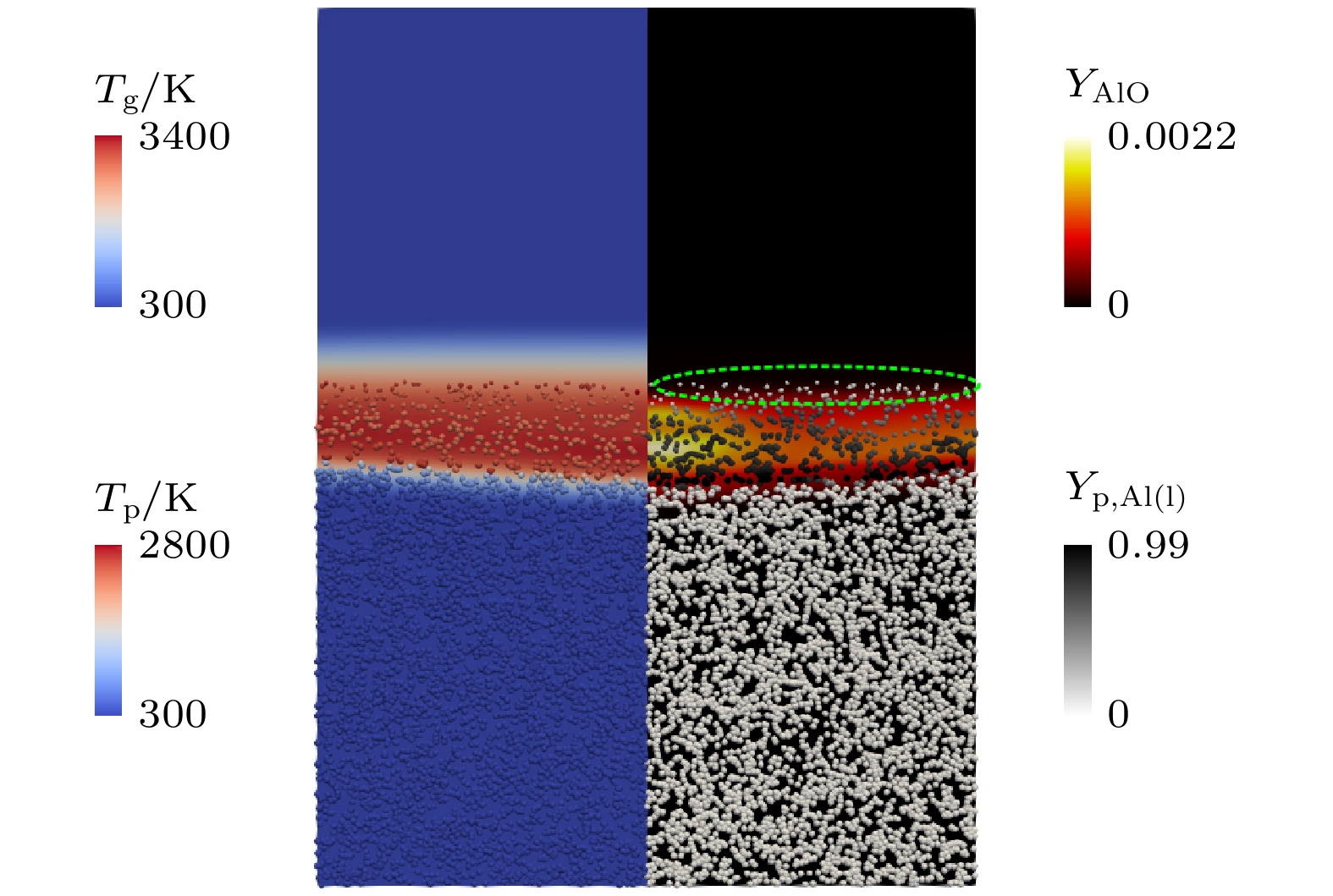

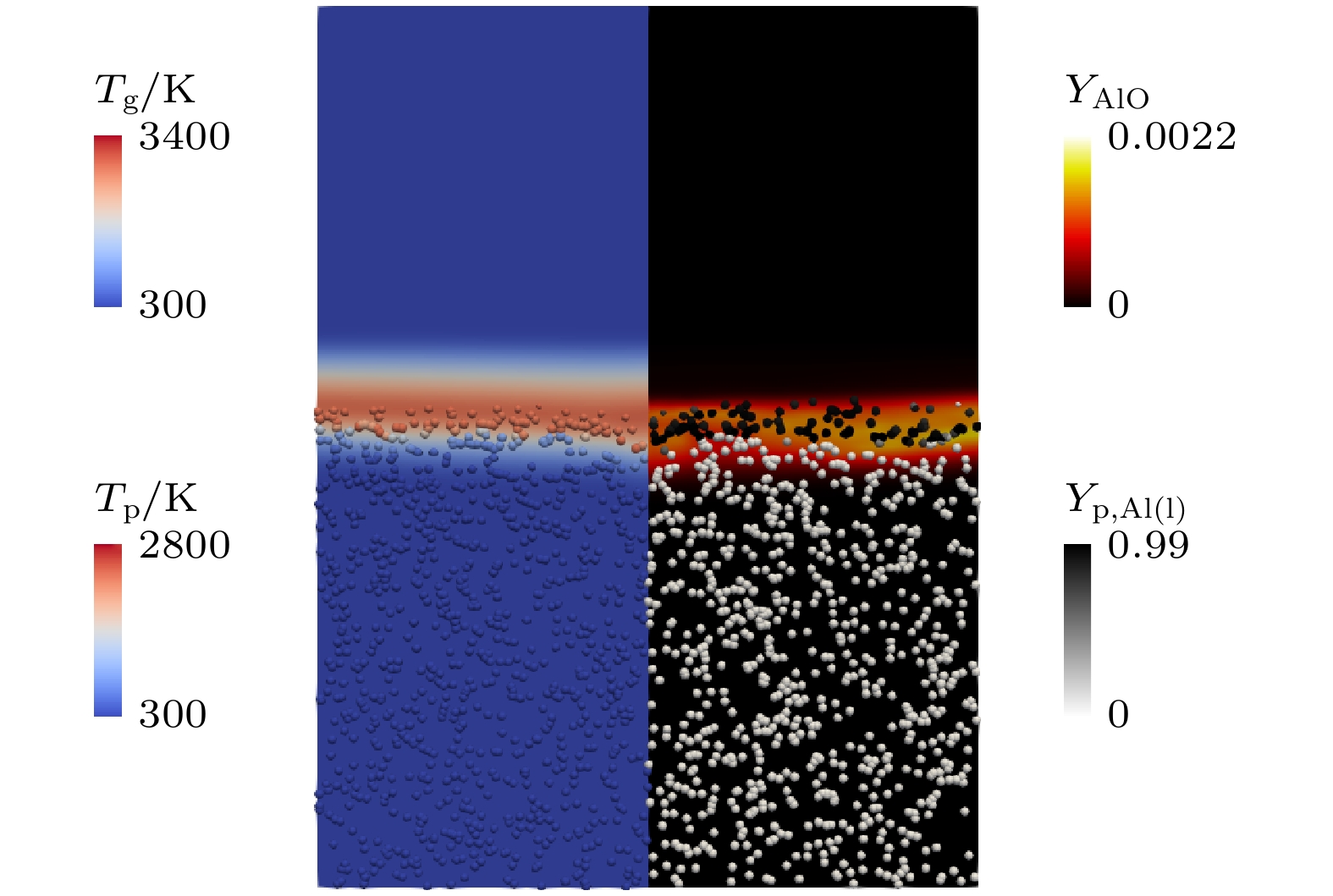

图 11 不同平均拉伸率(SR)下对冲火焰的时均气相温度(左)和AlO分布(右)和铝颗粒粉尘分布. 颗粒浓度: 500 g/m3, 颗粒直径: 5.6 μm

Figure 11. Time-averaged gas temperature and AlO mass fraction fields and instantaneous particle clouds of the counterflow flame under different average strain rates (SR). Dust concentration: 500 g/m3, particle diameter: 15 μm.

表 1 铝-空气详细化学反应机理

Table 1. Al/O2 gas-phase mechanism.

编号 基元反应 A/(cm3·mol–1·s–1) n E/(cal·mol–1) 1 Al + O2 = AlO + O 9.72 × 1013 0 159.95 2 Al + O + M = AlO + M 3.0 × 1017 –1.0 0 3 AlO + O2 = OAlO + O 4.62 × 1014 0 19885.9 4 Al2O3 = AlOAlO + O 3.0 × 1015 0 97649.99 5 Al2O3 = OAlO + AlO 3.0 × 1015 0 126999.89 6 AlOAlO = AlO + AlO 1.0 × 1015 0 117900 7 AlOAlO = Al + OAlO 1.0 × 1015 0 148900 8 AlOAlO = AlOAl + O 1.0 × 1015 0 104249.94 9 OAlO = AlO + O 1.0 × 1015 0 88549.86 10 AlOAl = AlO + Al 1.0 × 1015 0 133199.94 11 Al2O3 = Al2O3(l) 1.0 × 1014 0 0 表 2 网格分辨率及时间步长敏感性分析算例

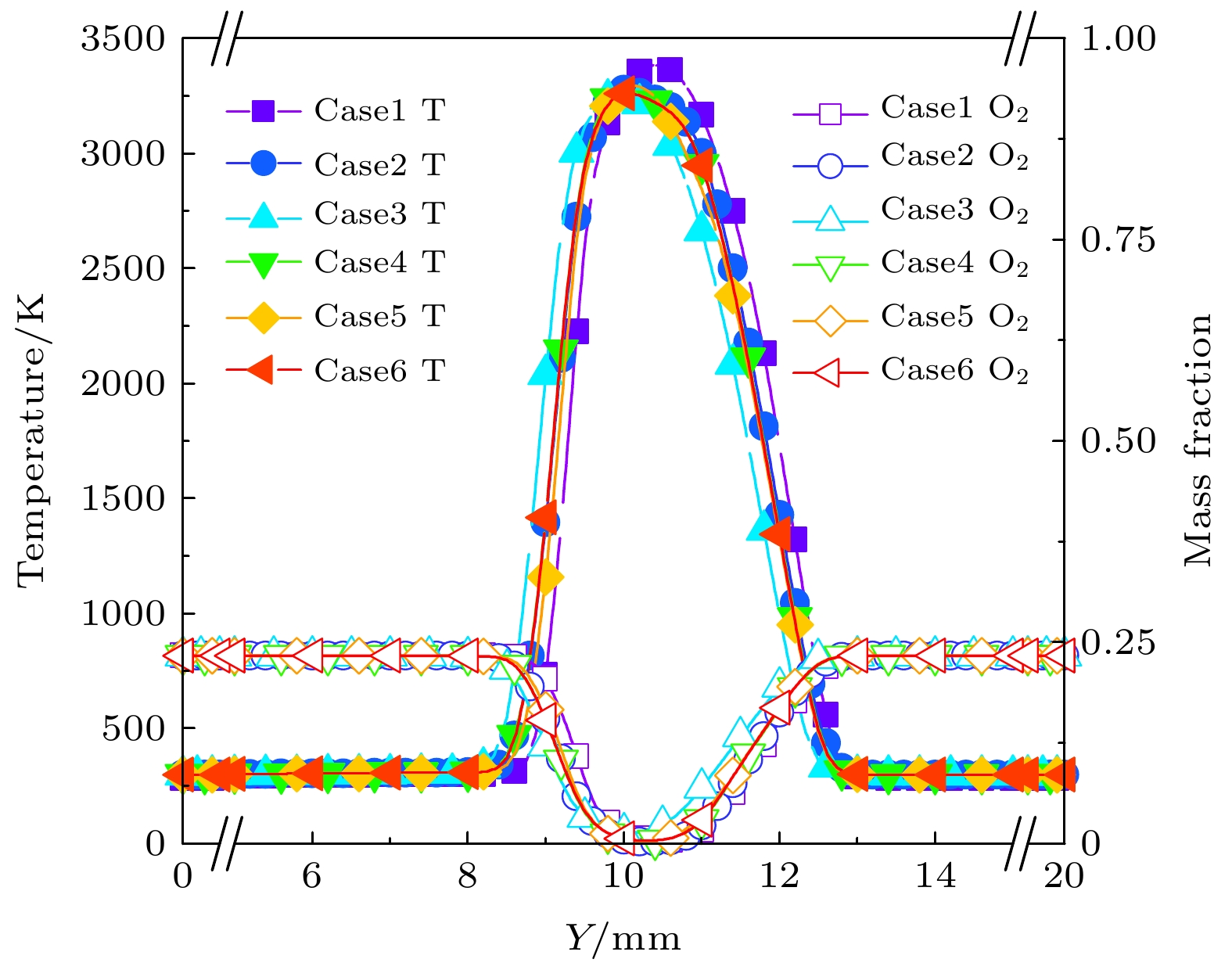

Table 2. Case setups for mesh resolution and time step sensitivity investigations.

No. 网格分辨率/μm 时间步长/s 计算域维数 Case 1 125 1 × 10–6 3 Case 2 125 1 × 10–6 2 Case 3 167 1 × 10–6 2 Case 4 100 1 × 10–6 2 Case 5 125 1.2 × 10–6 2 Case 6 125 5 × 10–7 2 -

[1] 王宁飞, 苏万兴, 李军伟, 张峤 2011 固体火箭技术 34 61

Google Scholar

Google Scholar

Wang N F, Sun W X, Li J W, Zhang Q 2011 J. Solid Rocket Technol. 34 61

Google Scholar

Google Scholar

[2] 李潮隆, 夏智勋, 马立坤, 赵翔, 罗振兵, 段一凡 2021 航空学报 40 26075

Li C L, Xia Z X, Ma L K, Zhao X, Luo Z B, Duan Y F 2021 Acta Aeronaut. Astronaut. Sin. 40 26075

[3] 王德全, 夏智勋, 胡建新 2010 航空学报 31 1074

Wang D Q, Xia Z X, Hu J X 2010 Acta Aeronaut. Astronaut. Sin. 31 1074

[4] 刘龙, 夏智勋, 黄利亚, 马立坤, 陈斌斌 2020 69

Google Scholar

Google Scholar

Liu L, Xia Z X, Huang L Y, Ma L K, Chen B B 2020 Acta Phys. Sin. 69

Google Scholar

Google Scholar

[5] 杨晋朝, 夏智勋, 胡建新 2013 62 074701

Google Scholar

Google Scholar

Yang J Z, Xia Z X, Hu J X 2013 Acta Phys. Sin. 62 074701

Google Scholar

Google Scholar

[6] Zhang J, Xia Z, Ma L, Huang L, Feng Y, Yang D 2021 Energy 214 118889

Google Scholar

Google Scholar

[7] Bergthorson J M 2018 Prog. Energy Combust. Sci. 68 169

Google Scholar

Google Scholar

[8] Goroshin S, Mamen J, Higgins A, Bazyn T, Glumac N, Krier H 2007 Proc. Combust. Inst. 31 2011

Google Scholar

Google Scholar

[9] Lomba R, Laboureur P, Dumand C, Chauveau C, Halter F 2019 Proc. Combust. Inst. 37 3143

Google Scholar

Google Scholar

[10] Xu W, Jiang Y 2018 Energies 11 3147

Google Scholar

Google Scholar

[11] 邓哲 2016 博士学位论文 (西安: 西北工业大学)

Deng Z 2016 Ph. D. Dissertation (Xi’an: Northwestern Polytechnical University) (in Chinese)

[12] Risha G, Huang Y, Yetter R, Yang, V 2005 Proceedings of the 43 rd AIAA Aerospace Sciences Meeting and Exhibit Reno, USA, January 10–13, 2005

[13] Goroshin S, Fomenko I, Lee J H S 1996 Symp. (Int.) Combust. 26 1961

Google Scholar

Google Scholar

[14] Julien P, Whiteley S, Soo M, Goroshin S, Frost D, Bergthorson J 2017 Proc. Combust. Inst. 36 2291

Google Scholar

Google Scholar

[15] Julien P, Vickery J, Goroshin S, Frost D, Bergthorson J 2015 Combust. Flame 162 4241

Google Scholar

Google Scholar

[16] Egolfopoulos F N, Hansen N, Ju Y, Kohse-Höinghaus K, Law C, Qi F 2014 Prog. Energy Combust. Sci. 43 36

Google Scholar

Google Scholar

[17] Huang Y, Risha G A, Yang V, Yetter R 2009 Combust. Flame 156 5

Google Scholar

Google Scholar

[18] Escot Bocanegra P, Davidenko D, Sarou-Kanian V, Chauveau C, Gökalp I 2010 Exp. Therm. Fluid Sci. 34 299

Google Scholar

Google Scholar

[19] Han D, Sung H 2019 Combust. Flame 206 112

Google Scholar

Google Scholar

[20] Zou X, Wang N, Wang J, Feng Y, Shi B 2021 Aerosp. Sci. Technol. 112 106604

Google Scholar

Google Scholar

[21] Zou X, Wang N, Liao L, Chu Q, Shi B 2020 Fuel 266 116952

Google Scholar

Google Scholar

[22] Khalili H, Madani S, Mohammadi M, Poorfar, A, Bidabadi M, Pendleton P, 2019 Combust. Explos. Shock Waves 55 65

Google Scholar

Google Scholar

[23] Najjar F, Ferry J, Haselbacher A, Balachandar S 2006 J. Spacecraft Rockets 43 1258

Google Scholar

Google Scholar

[24] 刘平安, 常浩, 李树声, 王文超 2018 固体火箭技术 41 156

Liu P A, Chang H, Li S S, Wang W H 2018 J. Solid Rocket Technol. 41 156

[25] Li C, Xia Z, Ma L, Chen B 2019 Energies 12 1235

Google Scholar

Google Scholar

[26] Li C, Xia Z, Ma L, Chen B 2019 Acta Astronaut. 162 145

Google Scholar

Google Scholar

[27] Yuen M, Chen L W 1976 Combust. Sci. Technol. 14 147

Google Scholar

Google Scholar

[28] Ranz W, Marshall W 1952 Chem. Eng. Prog. 48 141

[29] Mohan S, Trunov M, Dreizin E 2008 J. Heat Transfer 130 104505

Google Scholar

Google Scholar

[30] Crowe C, Schwarzkopf J, Sommerfeld M, Tsuji Y 2011 Multiphase flows with droplets and particles (2nd Ed.) (Boca Raton: CRC Press) p106

[31] Chase Mhttps://janaf.nist.gov/ [2020-9-6]

[32] Gurevich M, Ozerova G, Stepanov A 1970 Combust. Explos. Shock Waves 6 291

Google Scholar

Google Scholar

[33] Glorian J, Gallier S, Catoire L 2016 Combust. Flame 168 378

Google Scholar

Google Scholar

[34] Harrison J, Brewster M 2009 J. Thermophys. Heat Transfer 23 630

Google Scholar

Google Scholar

[35] Modest M 2013 Radiative Heat Transfer (3rd Ed.) (Amsterdam: Academic Press) p26

[36] Lynch P, Krier H, Glumac N 2010 J. Thermophys. Heat Transfer 24 301

Google Scholar

Google Scholar

[37] Munzar J, Akih-Kumgeh B, Denman B, Zia A, Bergthorson J 2013 Fuel 113 586

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 8623

- PDF Downloads: 115

- Cited By: 0

DownLoad:

DownLoad: