-

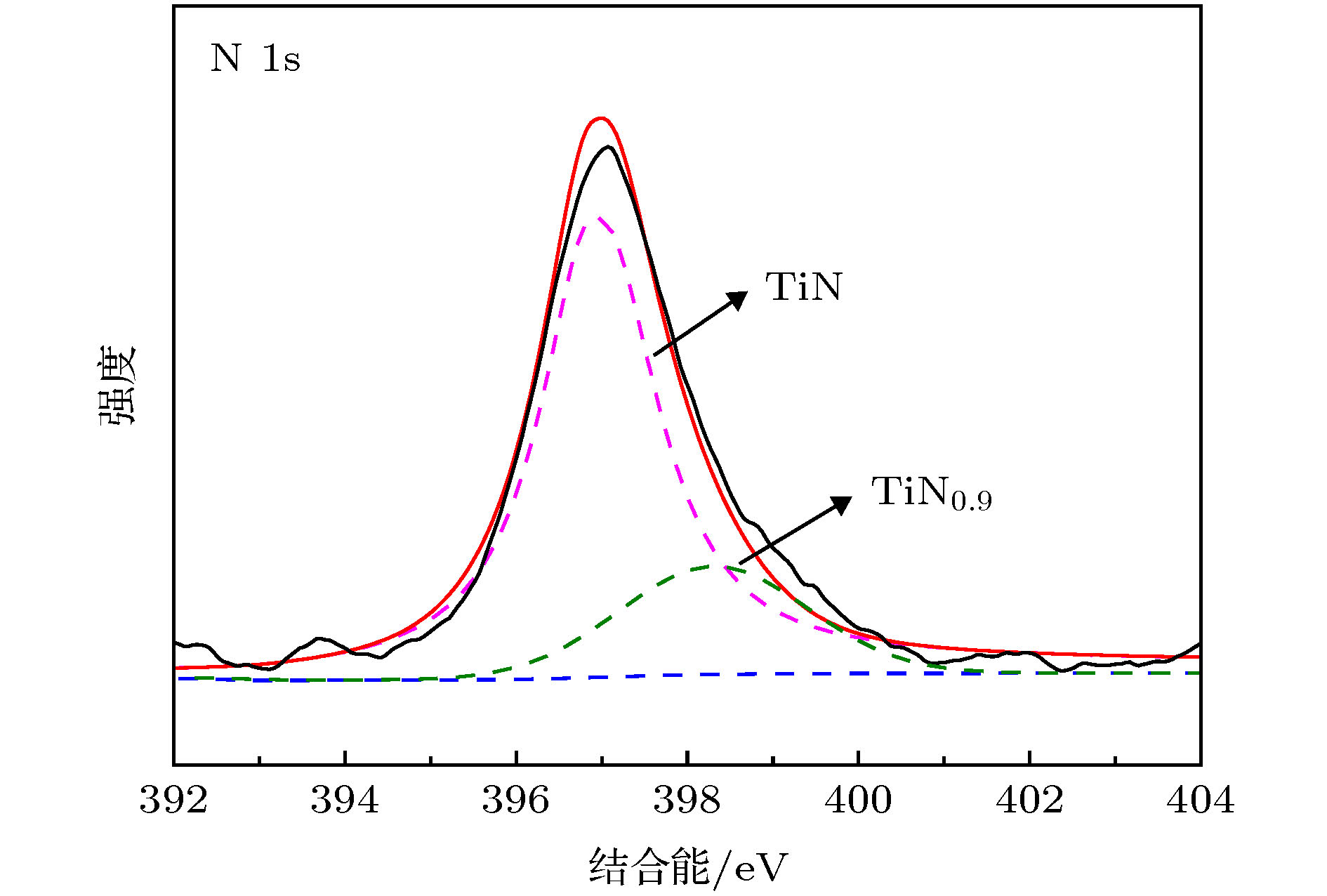

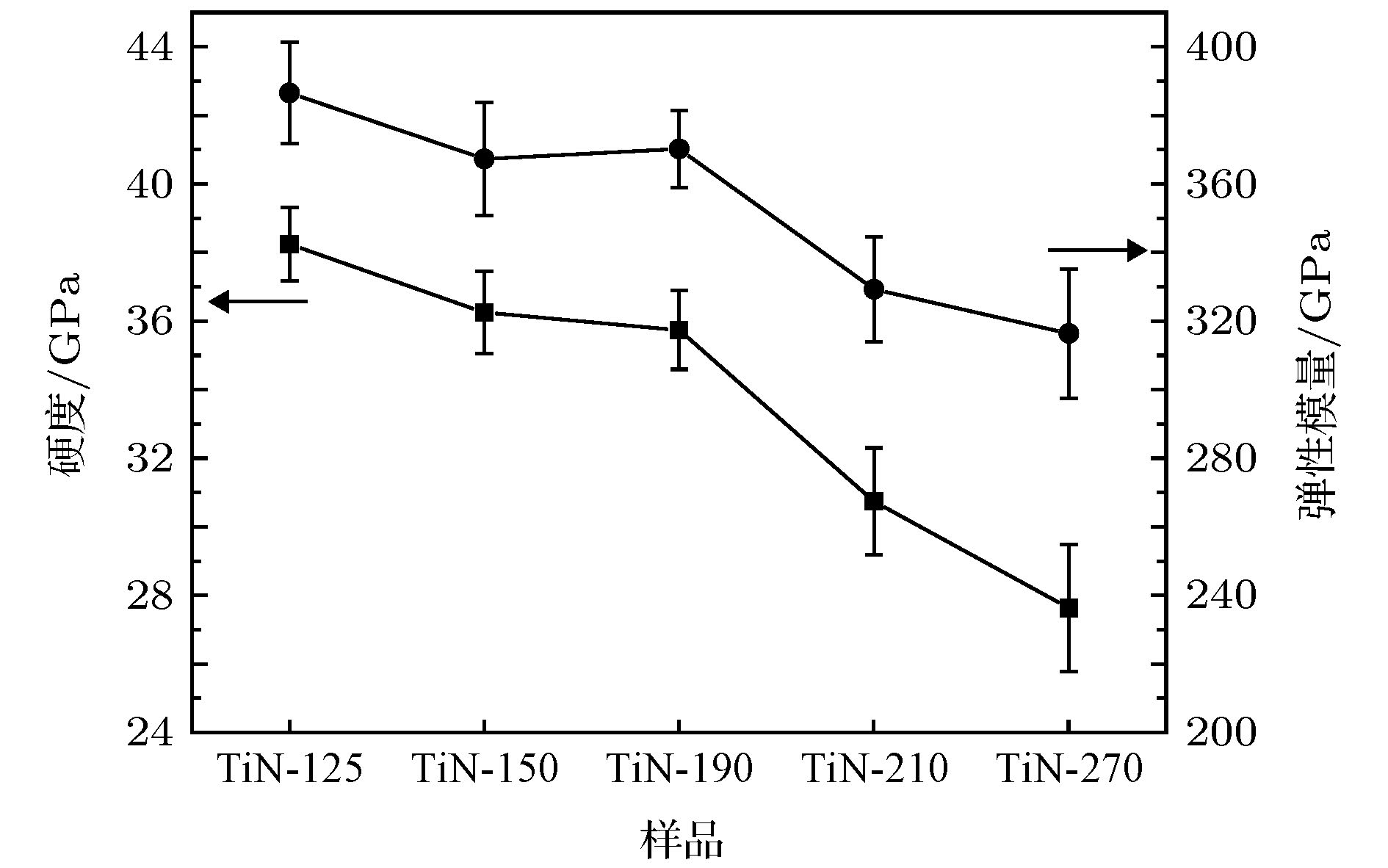

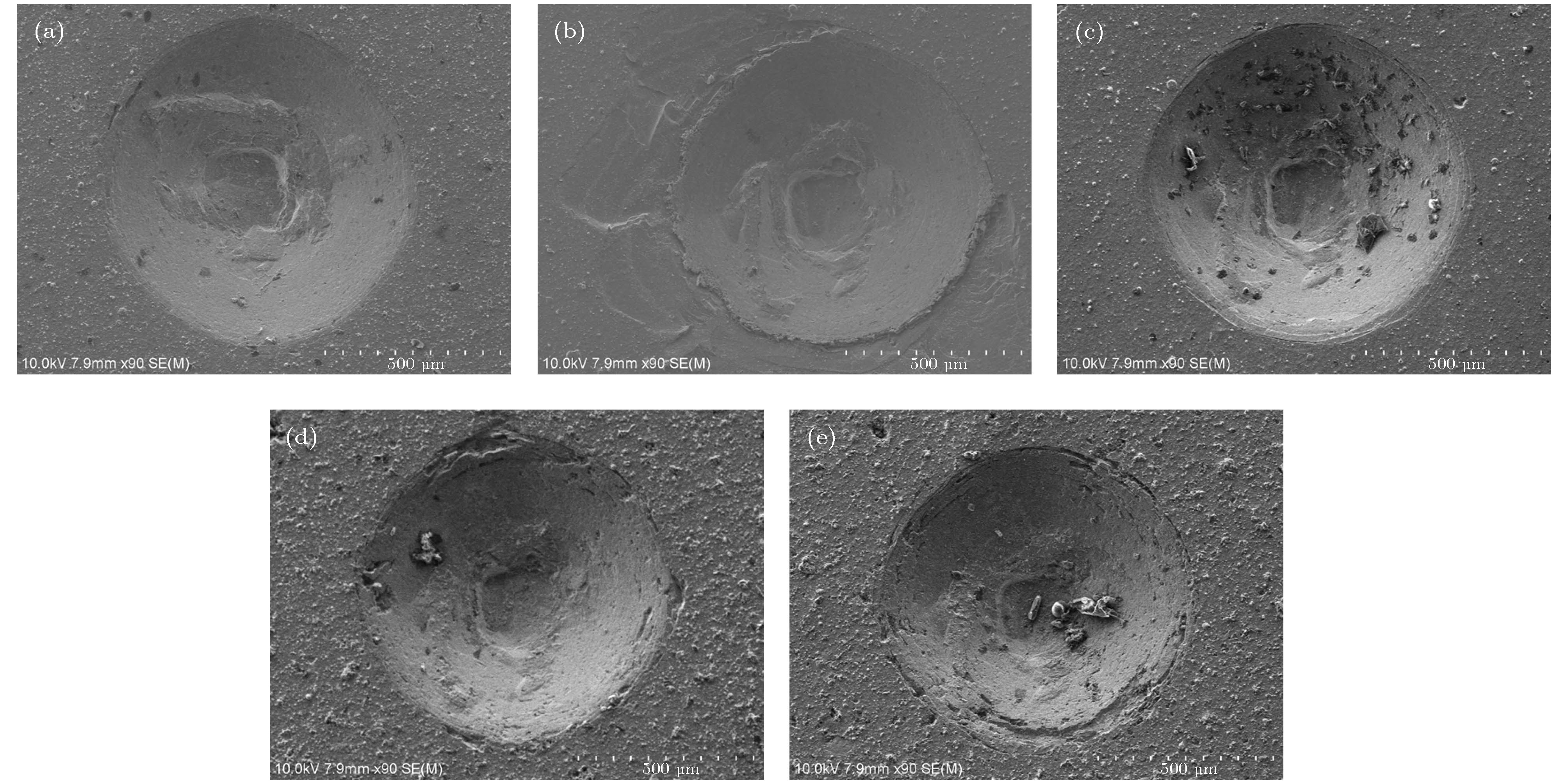

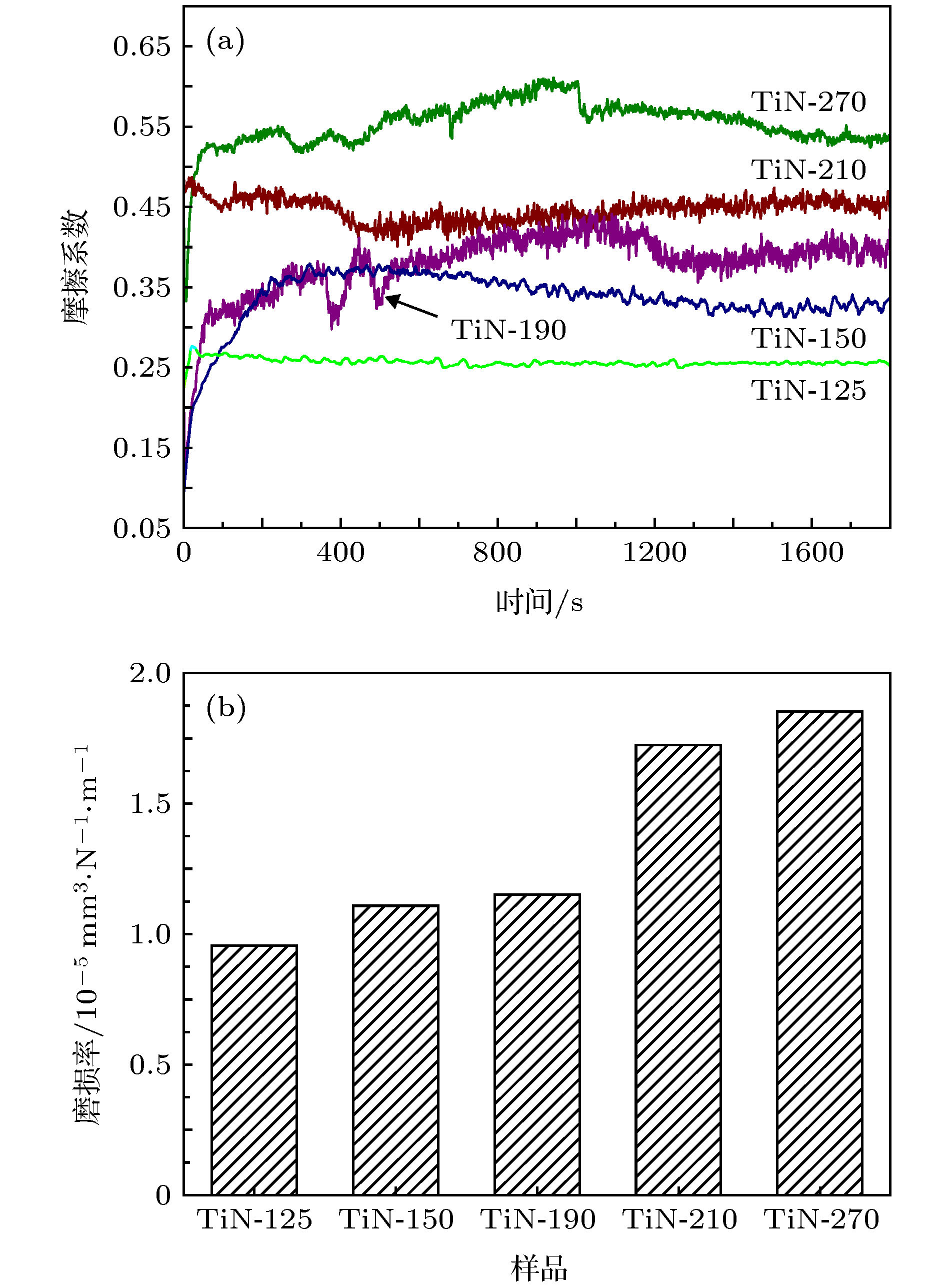

There are some high requirements for mechanical property to protective coatings of turbojet engine compressor blades as the appearance of extreme service conditions. The hard coating with high toughness, good adhesion, good wear resistance and excellent load carrying capacity is a potential coating for extreme service conditions in the future. Thick yet tough TiN hard coatings were successfully deposited on 304L stainless steel substrates by magnetic filtered cathodic vacuum arc technology. The morphology, structure and properties of the coatings were studied by SEM and XRD, etc.The results show that the continuous growth of TiN coatings attributed to periodic high energy ion bombardment which can suppress the large grain size and reduce the internal stress. The thickness of TiN coating can reach to 50 μm and the deposition rate was close to 0.2 μm/min. At the same time, the stable non stoichiometric TiN0.9 can be formed by controlling the constant N2 flow rate, which can improve the toughness of TiN coatings. All TiN ciatings belong to superhard coating and the max value of hardness and modulus of elasticity were 38.24 GPa and 386.53 GPa respectively. TiN coatings have good adhesion and excellent toughness.The highest

$ H/E^{*} $ and$ H^3/E^{*2} $ rate of TiN coating can reach to 0.0989 and 0.3742. Thick yet tough TiN hard coatings have excellent wear resistance with the lowest friction coefficient of 0.26.-

Keywords:

- compressor blades /

- thick yet tough TiN coatings /

- ion bombardment /

- wear resistance

[1] Chavda M R, Dave D P, Chauhan K V, Rawal S K 2016 Proc. Technol. 23 36

Google Scholar

Google Scholar

[2] Sun Z P, He G Y, Meng Q J, Li Y Q, Tian X D 2019 Chin. J. Aeronaut

[3] Liang W, Yang J J, Zhang F F, Lu C Y, Wang L M, Liao J L, Yang Y Y, Liu N 2018 J. Nucl. Mater. 501 388

Google Scholar

Google Scholar

[4] Swadźba L, Formanek B, Gabriel H M, Liberski P, Podolski P 1993 Surf. Coat. Technol. 62 486

Google Scholar

Google Scholar

[5] Zhou D P, Peng H, Zhu L, Guo H B, Gong S K 2014 Surf. Coat. Technol. 258 102

Google Scholar

Google Scholar

[6] Hetmańczyk M, Swadźba L, Mendala B 2007 J. Achiev. Mater. Manuf. Eng. 24 372

[7] Li J Z, Zheng H, Sinkovits T, Hee A C, Zhao Y 2015 Appl. Surf. Sci. 355 502

Google Scholar

Google Scholar

[8] Djabella H, Arnell R 1993 Thin Solid Films 235 156

Google Scholar

Google Scholar

[9] Hintermann H 1984 Wear 100 381

Google Scholar

Google Scholar

[10] Wang L, Zhong X H, Zhao YX, Tao S Y, Zhang W, Wang Y, Sun X G 2014 J.Asian Ceram. Soc. 2 102

Google Scholar

Google Scholar

[11] Wang J, Pu J, Zhang G G, Wang L P 2013 ACS Appl. Mater. Interfaces 5 5015

Google Scholar

Google Scholar

[12] Wei R, Langa E, Rincon C, Arps J H 2006 Surf. Coat. Technol. 201 4453

Google Scholar

Google Scholar

[13] Li Z C, Wang Y X, Cheng X Y, Zeng Z X, Li J L, Lu X, Wang L P, Xue Q J 2018 ACS Appl. Mater. Interfaces 10 2965

Google Scholar

Google Scholar

[14] Dong Y C, Yang Y, Chu Z H, Zhang J X, He J N, Yan D R, Li D Y 2017 Ceram. Int. 43 9303

Google Scholar

Google Scholar

[15] Janka L, Norpoth J, Eicher S, Rodríguez Ripoll M, Vuoristo P 2016 Mater. Des. 98 135

Google Scholar

Google Scholar

[16] Ou Y X, Lin J, Tong S, Sproul W D, Lei M K 2016 Surf. Coat. Technol. 293 21

Google Scholar

Google Scholar

[17] Wang L, Zhang S H, Chen Z, Li J L, Li M X 2012 Appl. Surf. Sci. 258 3629

Google Scholar

Google Scholar

[18] Volkhonskii A O, Vereshchaka A A, Blinkov I V, Vereshchaka A S, Batako A D 2016 Int. J. Adv. 84 1647

Google Scholar

Google Scholar

[19] Rebenne H E, Bhat D G 1994 Surf. Coat. Technol. 63 1

Google Scholar

Google Scholar

[20] Wang C T, Ye Y W, Guan X Y, Hu J M, Wang Y X, Li J L 2016 Tribol. Int. 96 77

Google Scholar

Google Scholar

[21] Guan X Y, Wang L P 2012 Tribol. Lett. 47 67

Google Scholar

Google Scholar

[22] Donnet C, Belin M, Auge J C, Martin J M, Grill A, Patel V 1994 Surf. Coat. Technol. 68 626

[23] Zhu Y, Cheng L F, Ma B S, Liu Y S, Zhang L T 2018 Surf. Coat. Technol. 337 209

Google Scholar

Google Scholar

[24] Lien S Y, Cho Y S, Hsu C H, Shen K Y, Zhang S, Wu W Y 2019 Surf. Coat. Technol. 359 247

Google Scholar

Google Scholar

[25] Ou Y X, Ouyang X P, Liao B, Zhang X, Zhang S 2019 Appl. Surf. Sci. 144 168

[26] Wang P, Wang X, Chen Y, Zhang G, Liu W, Zhang J 2007 Appl. Surf. Sci. 253 3722

Google Scholar

Google Scholar

[27] Lin Y H, Lin H D, Liu C K, Huang M W, Chen J R, Shih H C 2010 Diamond Relat. Mater. 19 1034

Google Scholar

Google Scholar

[28] Luo J, Ou Y X, Zhang Z Q, Pang P, Chen L, Liao B B, Shang H Z, Zhang X, Wu X Y 2019 Mater. Res. Express 6 096418

Google Scholar

Google Scholar

[29] Cao H S, Qi F G, Ouyang X P, Zhao N, Zhou Y, Li B, Luo W Z, Liao B, Luo J 2018 Materials 11 1742

Google Scholar

Google Scholar

[30] Pelleg J, Zevin L Z, Lungo S, Croitoru N 1991 Thin Solid Films 197 117

Google Scholar

Google Scholar

[31] Lee S C, Ho W Y, Huang C C, Meletis E L, Liu Y 1996 J. Mater. Eng. Perform. 5 64

Google Scholar

Google Scholar

[32] He Z, Zhang S, Sun D 2019 Thin Solid Films 676 60

Google Scholar

Google Scholar

[33] Hu J H, Shi Y N, Sauvage X, Sha G, Lu K 2017 Science 355 1292

Google Scholar

Google Scholar

[34] Shulga Y U M, Troitskii V N, Aivazov M I, Borodko Y U G 1976 Zh. Neorg. Khim. 21 2621

[35] Prieto P, Kirby R E 1995 J. Vac. Sci. Technol. A. 13 2819

[36] Lee K, Kang N, Bae J S, Lee C W 2016 Met. Mater.Int. 22 842

Google Scholar

Google Scholar

[37] Ou Y X, Lin J, Tong S E, Che H L, Sproul W D, Lei M K 2015 Appl. Surf. Sci. 351 332

Google Scholar

Google Scholar

[38] Ou Y X, Chen H, Li Z Y, Lin J, Pan W, Lei M K 2018 J. Am. Ceram. Soc. 101 5166

Google Scholar

Google Scholar

[39] Leyland A, Matthews A 2004 Surf. Coat. Technol. 177 317

[40] Dang C Q, Li J L, Wang Y, Chen J M 2016 Appl. Surf. Sci. 386 224

Google Scholar

Google Scholar

-

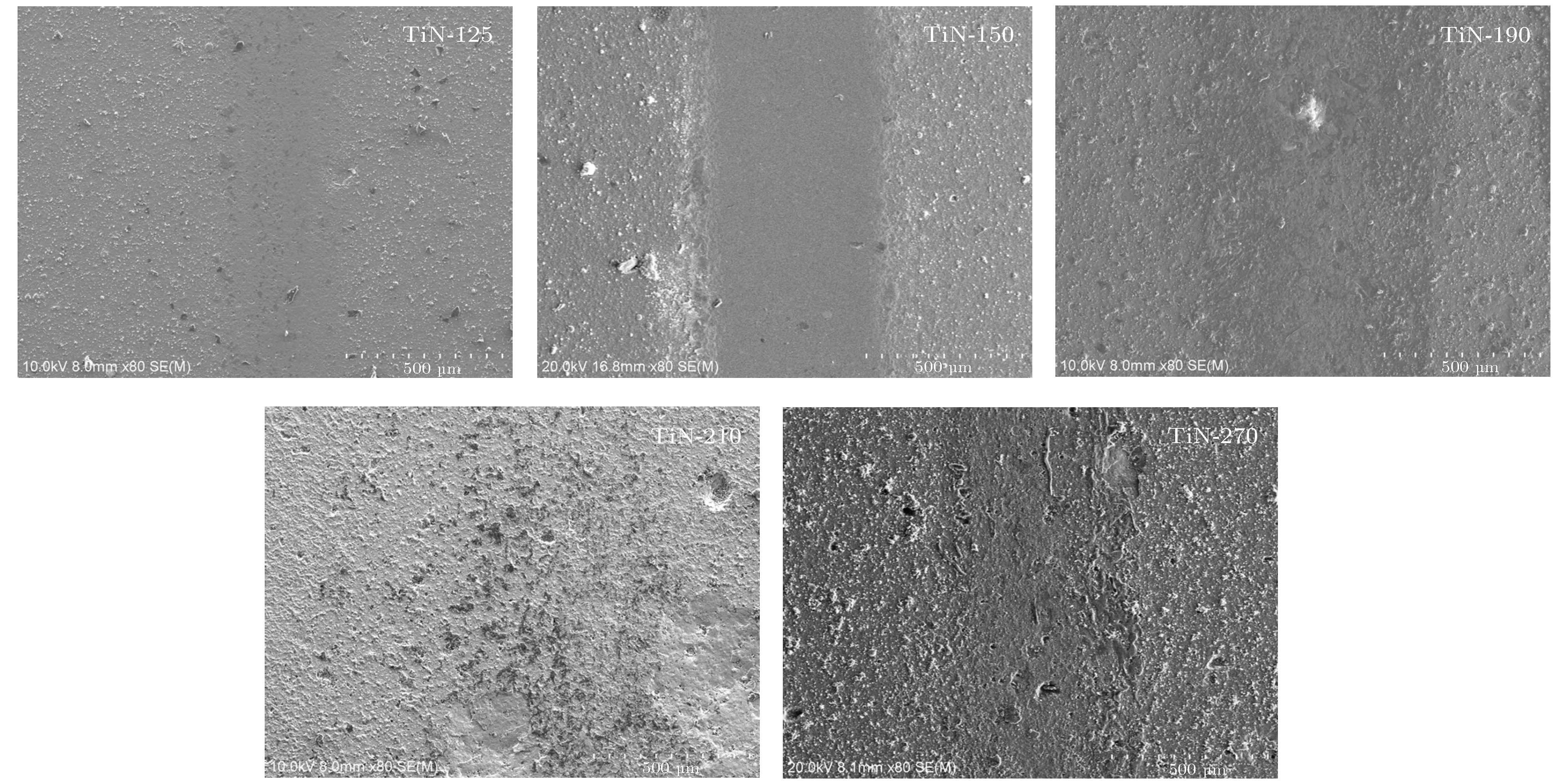

图 6 不同沉积时间下的TiN涂层的AFM图及表面粗糙度 (a) 125 min; (b) 150 min; (c) 190 min; (d) 210 min; (e) 270 min; (f) 不同TiN涂层的表面粗糙度

Figure 6. The AFM and roughness of all of the TiN coatings with different deposition time: (a) 125 min; (b) 150 min; (c) 190 min; (d) 210 min; (e) 270 min; (f) roughness of all of the TiN coatings.

-

[1] Chavda M R, Dave D P, Chauhan K V, Rawal S K 2016 Proc. Technol. 23 36

Google Scholar

Google Scholar

[2] Sun Z P, He G Y, Meng Q J, Li Y Q, Tian X D 2019 Chin. J. Aeronaut

[3] Liang W, Yang J J, Zhang F F, Lu C Y, Wang L M, Liao J L, Yang Y Y, Liu N 2018 J. Nucl. Mater. 501 388

Google Scholar

Google Scholar

[4] Swadźba L, Formanek B, Gabriel H M, Liberski P, Podolski P 1993 Surf. Coat. Technol. 62 486

Google Scholar

Google Scholar

[5] Zhou D P, Peng H, Zhu L, Guo H B, Gong S K 2014 Surf. Coat. Technol. 258 102

Google Scholar

Google Scholar

[6] Hetmańczyk M, Swadźba L, Mendala B 2007 J. Achiev. Mater. Manuf. Eng. 24 372

[7] Li J Z, Zheng H, Sinkovits T, Hee A C, Zhao Y 2015 Appl. Surf. Sci. 355 502

Google Scholar

Google Scholar

[8] Djabella H, Arnell R 1993 Thin Solid Films 235 156

Google Scholar

Google Scholar

[9] Hintermann H 1984 Wear 100 381

Google Scholar

Google Scholar

[10] Wang L, Zhong X H, Zhao YX, Tao S Y, Zhang W, Wang Y, Sun X G 2014 J.Asian Ceram. Soc. 2 102

Google Scholar

Google Scholar

[11] Wang J, Pu J, Zhang G G, Wang L P 2013 ACS Appl. Mater. Interfaces 5 5015

Google Scholar

Google Scholar

[12] Wei R, Langa E, Rincon C, Arps J H 2006 Surf. Coat. Technol. 201 4453

Google Scholar

Google Scholar

[13] Li Z C, Wang Y X, Cheng X Y, Zeng Z X, Li J L, Lu X, Wang L P, Xue Q J 2018 ACS Appl. Mater. Interfaces 10 2965

Google Scholar

Google Scholar

[14] Dong Y C, Yang Y, Chu Z H, Zhang J X, He J N, Yan D R, Li D Y 2017 Ceram. Int. 43 9303

Google Scholar

Google Scholar

[15] Janka L, Norpoth J, Eicher S, Rodríguez Ripoll M, Vuoristo P 2016 Mater. Des. 98 135

Google Scholar

Google Scholar

[16] Ou Y X, Lin J, Tong S, Sproul W D, Lei M K 2016 Surf. Coat. Technol. 293 21

Google Scholar

Google Scholar

[17] Wang L, Zhang S H, Chen Z, Li J L, Li M X 2012 Appl. Surf. Sci. 258 3629

Google Scholar

Google Scholar

[18] Volkhonskii A O, Vereshchaka A A, Blinkov I V, Vereshchaka A S, Batako A D 2016 Int. J. Adv. 84 1647

Google Scholar

Google Scholar

[19] Rebenne H E, Bhat D G 1994 Surf. Coat. Technol. 63 1

Google Scholar

Google Scholar

[20] Wang C T, Ye Y W, Guan X Y, Hu J M, Wang Y X, Li J L 2016 Tribol. Int. 96 77

Google Scholar

Google Scholar

[21] Guan X Y, Wang L P 2012 Tribol. Lett. 47 67

Google Scholar

Google Scholar

[22] Donnet C, Belin M, Auge J C, Martin J M, Grill A, Patel V 1994 Surf. Coat. Technol. 68 626

[23] Zhu Y, Cheng L F, Ma B S, Liu Y S, Zhang L T 2018 Surf. Coat. Technol. 337 209

Google Scholar

Google Scholar

[24] Lien S Y, Cho Y S, Hsu C H, Shen K Y, Zhang S, Wu W Y 2019 Surf. Coat. Technol. 359 247

Google Scholar

Google Scholar

[25] Ou Y X, Ouyang X P, Liao B, Zhang X, Zhang S 2019 Appl. Surf. Sci. 144 168

[26] Wang P, Wang X, Chen Y, Zhang G, Liu W, Zhang J 2007 Appl. Surf. Sci. 253 3722

Google Scholar

Google Scholar

[27] Lin Y H, Lin H D, Liu C K, Huang M W, Chen J R, Shih H C 2010 Diamond Relat. Mater. 19 1034

Google Scholar

Google Scholar

[28] Luo J, Ou Y X, Zhang Z Q, Pang P, Chen L, Liao B B, Shang H Z, Zhang X, Wu X Y 2019 Mater. Res. Express 6 096418

Google Scholar

Google Scholar

[29] Cao H S, Qi F G, Ouyang X P, Zhao N, Zhou Y, Li B, Luo W Z, Liao B, Luo J 2018 Materials 11 1742

Google Scholar

Google Scholar

[30] Pelleg J, Zevin L Z, Lungo S, Croitoru N 1991 Thin Solid Films 197 117

Google Scholar

Google Scholar

[31] Lee S C, Ho W Y, Huang C C, Meletis E L, Liu Y 1996 J. Mater. Eng. Perform. 5 64

Google Scholar

Google Scholar

[32] He Z, Zhang S, Sun D 2019 Thin Solid Films 676 60

Google Scholar

Google Scholar

[33] Hu J H, Shi Y N, Sauvage X, Sha G, Lu K 2017 Science 355 1292

Google Scholar

Google Scholar

[34] Shulga Y U M, Troitskii V N, Aivazov M I, Borodko Y U G 1976 Zh. Neorg. Khim. 21 2621

[35] Prieto P, Kirby R E 1995 J. Vac. Sci. Technol. A. 13 2819

[36] Lee K, Kang N, Bae J S, Lee C W 2016 Met. Mater.Int. 22 842

Google Scholar

Google Scholar

[37] Ou Y X, Lin J, Tong S E, Che H L, Sproul W D, Lei M K 2015 Appl. Surf. Sci. 351 332

Google Scholar

Google Scholar

[38] Ou Y X, Chen H, Li Z Y, Lin J, Pan W, Lei M K 2018 J. Am. Ceram. Soc. 101 5166

Google Scholar

Google Scholar

[39] Leyland A, Matthews A 2004 Surf. Coat. Technol. 177 317

[40] Dang C Q, Li J L, Wang Y, Chen J M 2016 Appl. Surf. Sci. 386 224

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 12036

- PDF Downloads: 183

- Cited By: 0

DownLoad:

DownLoad: