-

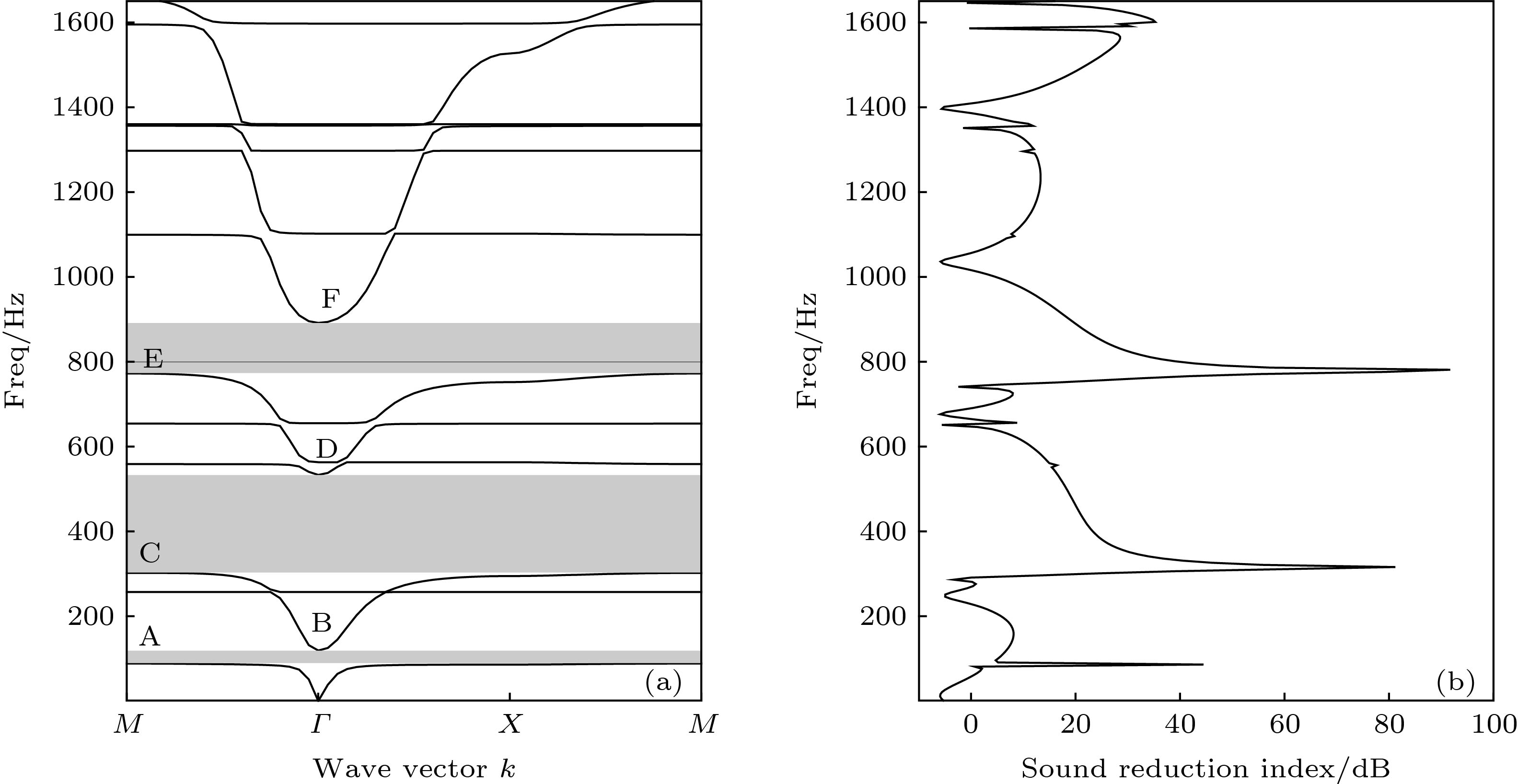

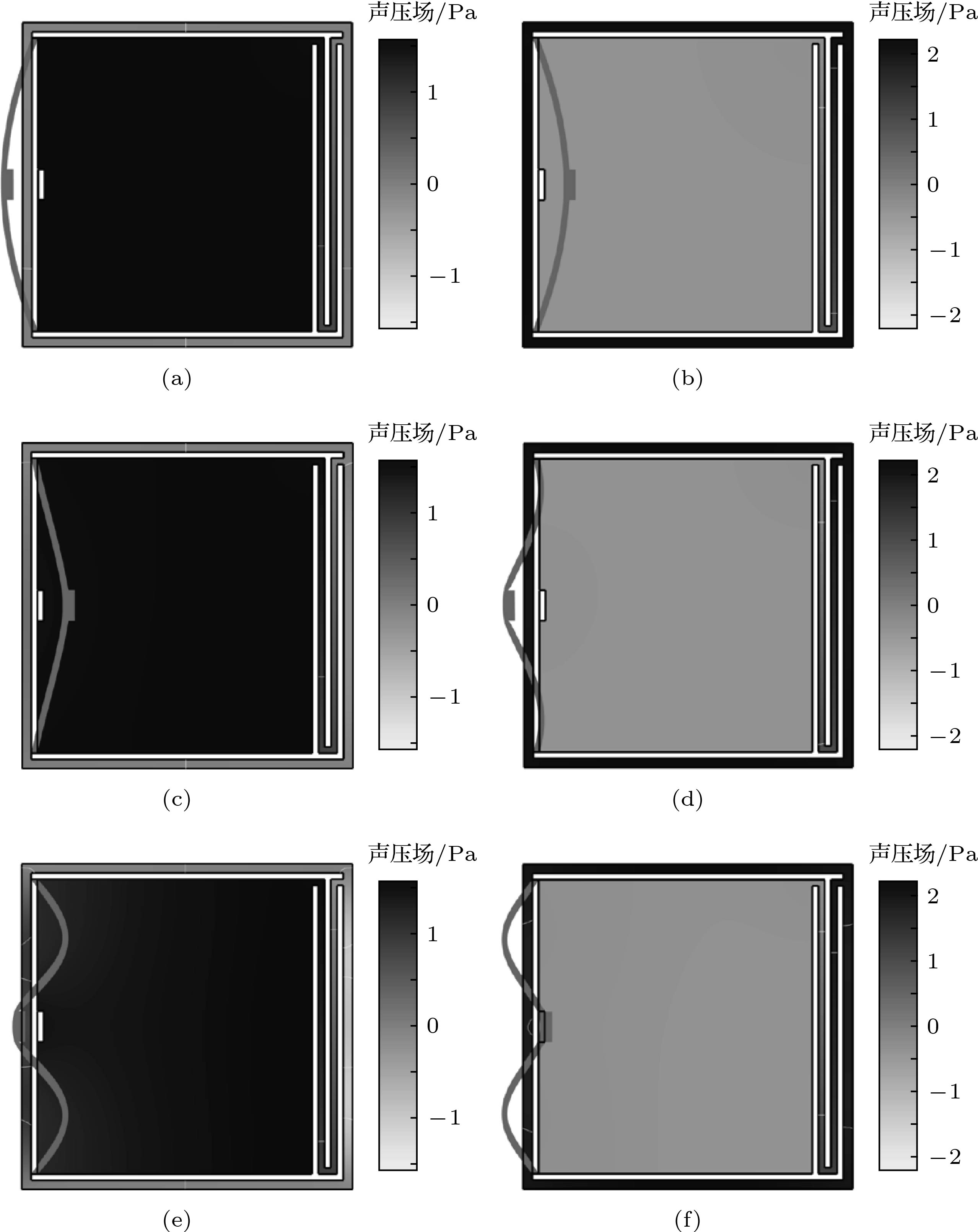

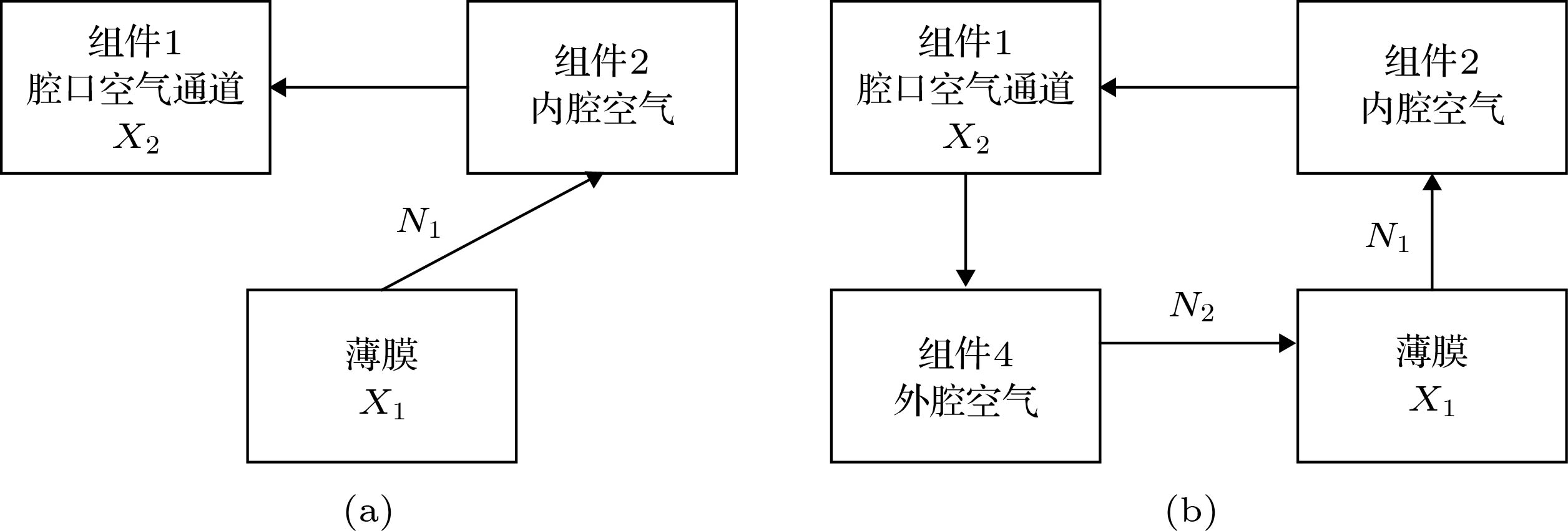

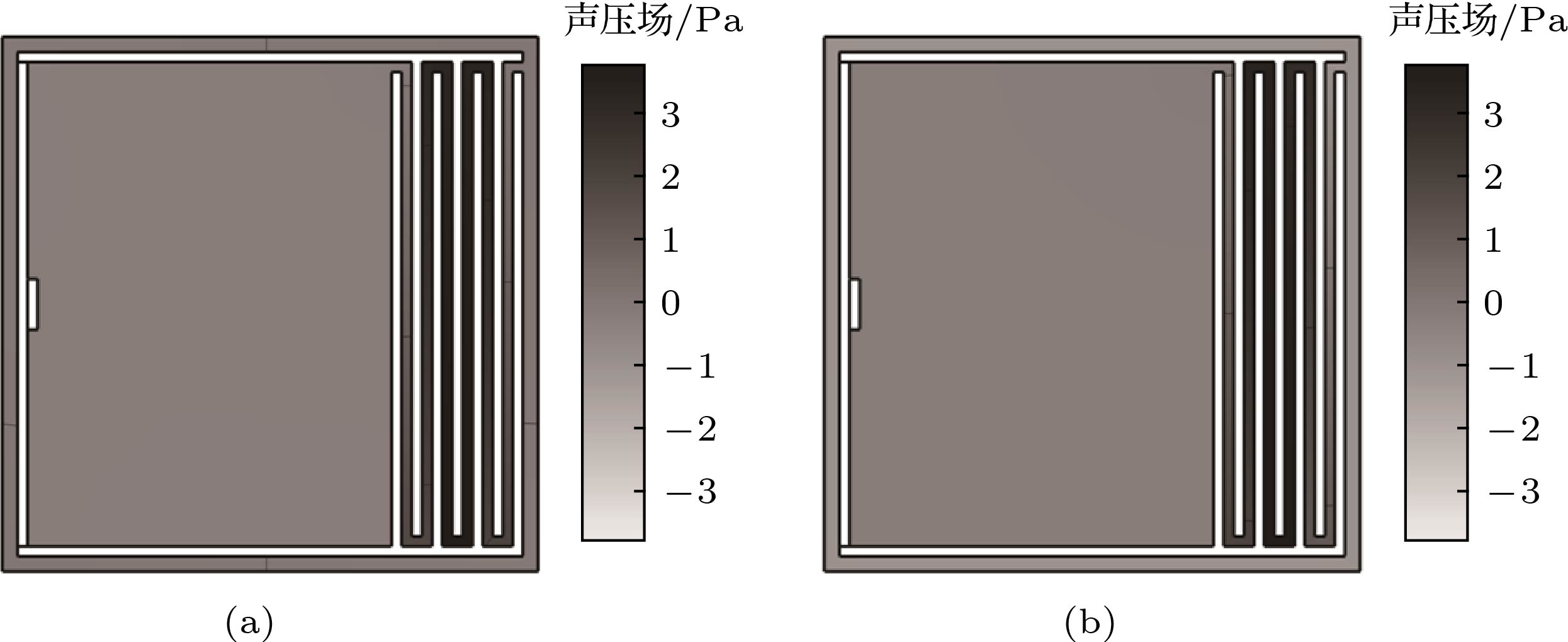

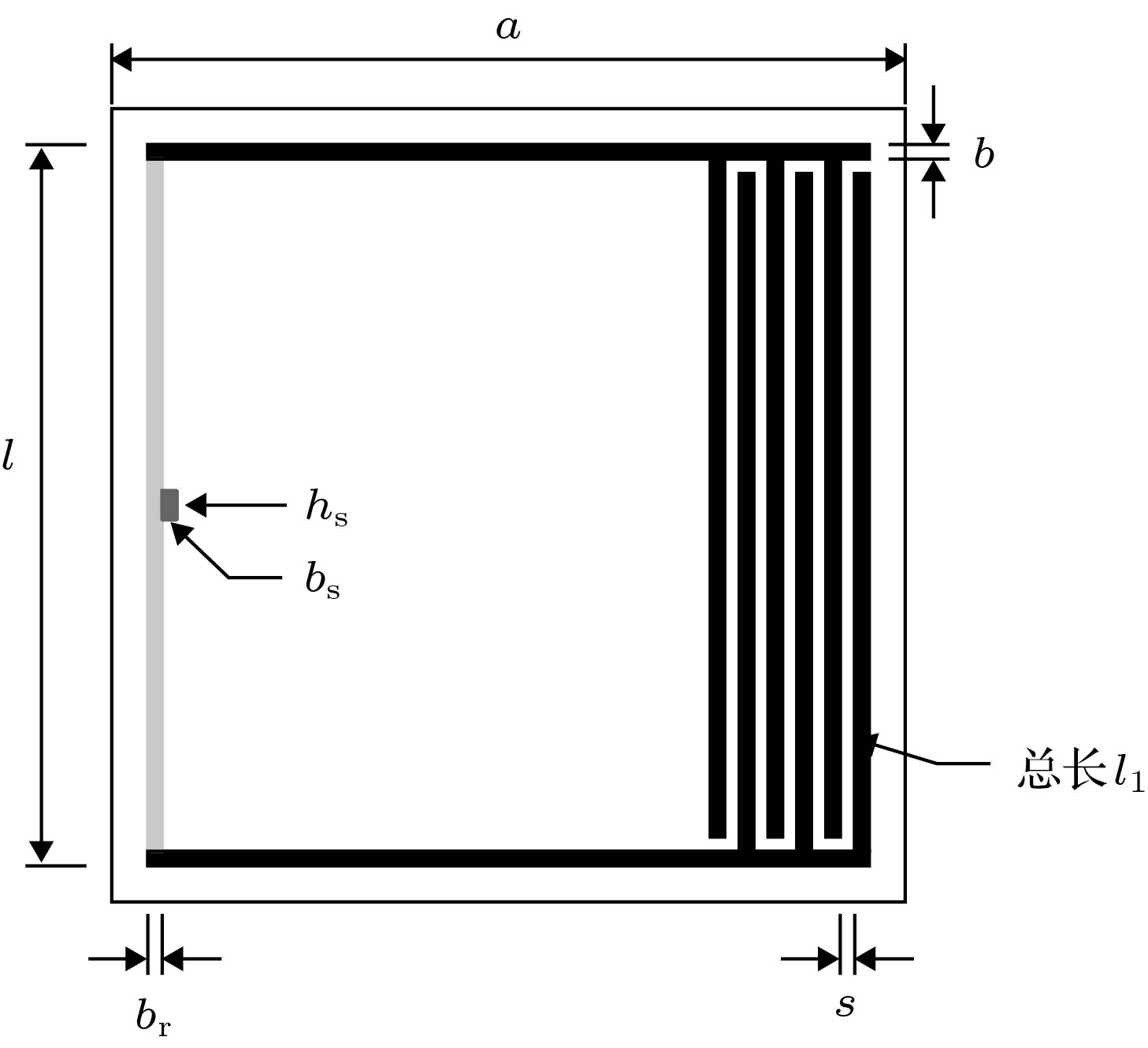

In this paper, a phononic crystal is designed using a Helmholtz resonator with a membrane wall, in which the coupled vibration of air and membrane is utilized. The structure of the Helmholtz resonator is a two-dimensional structure. On the basis of the square Helmholtz resonator, a " W”-type outlet is used as a cavity outlet to increase the air quality involved in resonance, and the cavity wall is replaced with a membrane with distribution mass to increase the number of resonance units. The finite element method is used to calculate the band gaps and transmission loss of sound below 1700 Hz. The results show that the starting frequency of the first band gap of the structure is further reduced. At the same time, it is lower than the starting frequency of ordinary Helmholtz structure and the natural frequency of membrane under the same conditions. Then, a new peak of transmission loss is obtained, and its value is greater than the original structure’s. And although the width of the first band gap is reduced, some new band gaps appear in the low-frequency range, so that the total band gap width is improved. By analyzing the vibration mode of the membrane and sound pressure distribution, it is found that the sum of the sound pressures of the outer cavity is zero at the starting frequencies of the band gaps, and the sound pressure of the inner and outer cavity are respectively positive and negative at the cut-off frequency. With the increase of frequency, the vibration mode of the membrane gradually turns from low-order to high-order, but no anti-symmetric-type mode participation is found at the starting and cut-off frequency. The components of the structure can be made equivalent to corresponding ones, respectively, i.e. air in the outlet is equivalent to uniform flexible rod, and the air in the inner and outer cavity are equivalent to a spring. So that the structure can be equivalent to a series system consisting of a rod, a spring and a membrane at starting frequency of the band gap, and a loop system consisting of a rod, two springs and a membrane at cut-off frequency. Thus, by the transfer matrix method and the Rayleigh-Ritz method considering the influence of tension and elastic modulus, it is possible to calculate the range of band gap which is extremely close to the result from the finite element method. Through the analysis of the formulas, it can be found that the new band gap is caused by the new vibration mode produced by the membrane or the air in the cavity outlet, and the lower starting frequency of the first band gap is due to the reduction of the equivalent extent of the system by the membrane. By adjusting the relevant parameters of the membrane and the cavity outlet respectively, it can be found that the band gaps of the structure correspond to the modes of different orders of the air in the cavity outlet and the membrane. In other words, the change of the natural frequency of a certain mode of air in the outlet or membrane only has a greater influence on the corresponding band gap but has less influence on other band gaps, also, the trends of change are the same, and the change values are very close to each other. But, changing the volume of the inner cavity and the outer cavity has a great influence on all the band gaps. Therefore, it is possible to adjust some band gaps through this method. -

Keywords:

- Helmholtz resonance /

- low-frequency bandgap /

- noise control /

- phononic crystal

[1] Kushwaha M S, Halevi P, Dobrzynski L, Djafari-Rouhani B 1993 Phys. Rev. Lett. 71 2022

Google Scholar

Google Scholar

[2] 王莎, 林书玉 2019 68 024303

Google Scholar

Google Scholar

Wang S, Lin S Y 2019 Acta Phys. Sin. 68 024303

Google Scholar

Google Scholar

[3] 张振方, 郁殿龙, 刘江伟, 温激鸿 2018 67 074301

Google Scholar

Google Scholar

Zhang Z F, Yu D L, Liu J W, Wen J H 2018 Acta Phys. Sin. 67 074301

Google Scholar

Google Scholar

[4] 廖涛, 孙小伟, 宋婷, 田俊红, 康太凤, 孙伟彬 2018 67 214208

Google Scholar

Google Scholar

Liao T, Sun X W, Song T, Tian J H, Kang T F, Sun W B 2018 Acta Phys. Sin. 67 214208

Google Scholar

Google Scholar

[5] Li S B, Dou Y H, Chen T N, Wan Z G, Guan Z R 2018 Mod. Phys. Lett. B 32 1850221

[6] Korozlu N, Kaya O A, Cicek A, Ulug B 2018 J. Acoust. Soc. Am. 143 756

Google Scholar

Google Scholar

[7] Quan L, Ra Di Y, Sounas D L, Alù A 2018 Phys. Rev. Lett. 120 254301

Google Scholar

Google Scholar

[8] Zhao L X, Zhou S X 2019 Sensors-Basel 19 788

Google Scholar

Google Scholar

[9] Yuan M, Cao Z, Luo J, Pang Z 2018 AIP Adv. 8 85012

Google Scholar

Google Scholar

[10] Wang Y, Zhu X, Zhang T S, Bano S, Pan H Y, Qi L F, Zhang Z T, Yuan Y P 2018 Appl. Energ. 230 52

Google Scholar

Google Scholar

[11] Quan L, Qian F, Liu X Z, Gong X F, Johnson P A 2015 Phys. Rev. B 92 104105

Google Scholar

Google Scholar

[12] Quan L, Zhong X, Liu X, Gong X, Johnson P A 2014 Nat. Commun. 5 3188

Google Scholar

Google Scholar

[13] Hu X, Chan C T, Zi J 2005 Phys. Rev. E 71 55601

Google Scholar

Google Scholar

[14] Chalmers L, Elford D P, Kusmartsev F V, Swallowe G M 2009 Int. J. Mod. Phys. B 23 4234

Google Scholar

Google Scholar

[15] Guan D, Wu J H, Jing L, Gao N, Hou M 2015 Noise Control Eng. J. 63 20

Google Scholar

Google Scholar

[16] Jiang J, Yao H, Du J, Zhao J 2016 AIP Adv. 6 115024

Google Scholar

Google Scholar

[17] 姜久龙, 姚宏, 杜军, 赵静波, 邓涛 2017 66 064301

Google Scholar

Google Scholar

Jiang J L, Yao H, Du J, Zhao J B, Deng T 2017 Acta Phys. Sin. 66 064301

Google Scholar

Google Scholar

[18] 刘敏, 侯志林, 傅秀军 2012 61 104302

Google Scholar

Google Scholar

Liu M, Hou Z L, Fu X J 2012 Acta Phys. Sin. 61 104302

Google Scholar

Google Scholar

[19] 包凯, 陈天宁, 王小鹏, 王放, 张振华 2016 西安交通大学学报 50 124

Google Scholar

Google Scholar

Bao K, Chen T N, Wang X P, Wang F, Zhang Z H 2016 J. Xi’an Jiaotong Univ. 50 124

Google Scholar

Google Scholar

[20] Liu C R, Wu J H, Chen X, Ma F Y 2019 J. Phys. D: Appl. Phys. 52 105302

Google Scholar

Google Scholar

[21] Ang L Y L, Koh Y K, Lee H P 2017 Appl. Phys. Lett. 111 41903

Google Scholar

Google Scholar

[22] Wang X, Zhao H, Luo X, Huang Z 2016 Appl. Phys. Lett. 108 41905

Google Scholar

Google Scholar

[23] Langfeldt F, Gleine W, von Estorff O 2015 J. Sound Vib. 349 315

Google Scholar

Google Scholar

[24] 周榕, 吴卫国, 闻轶凡 2017 声学技术 36 297

Zhou R, Wu W G, Wen Y F 2017 Technical Acoustics 36 297

[25] Abbad A, Rabenorosoa K, Ouisse M, Atalla N, Park G 2017 Proc. SPIE 10164 101640P

[26] Langfeldt F, von Estorff O 2016 Inter-Noise and Noise-Con Congress and Conference Proceedings 253 3413

[27] Elayouch A, Addouche M, Herth E, Khelif A 2013 Appl. Phys. Lett. 103 83504

Google Scholar

Google Scholar

[28] Liu C R, Wu J H, Lu K, Zhao Z T, Huang Z 2019 Appl. Acoust. 148 1

Google Scholar

Google Scholar

[29] Zhu X, Chen Z, Jiao Y, Wang Y 2018 J.Vibr. Acoust. 140 31014

Google Scholar

Google Scholar

[30] 陈鑫, 姚宏, 赵静波, 张帅, 贺子厚, 蒋娟娜 2019 68 084302

Google Scholar

Google Scholar

Chen X, Yao H, Zhao J B, Zhang S, He Z H, Jiang J N 2019 Acta Phys. Sin. 68 084302

Google Scholar

Google Scholar

[31] 芮筱亭, 贠来峰, 陆毓琪, 何斌, 王国平 2008 多体系统的传递矩阵法及其应用 (北京: 科学出版社) 第425页

Rui X T, Yuan L F, Lu Y Q, He B, Wang G P 2008 Transfer Matrix Method of Multibody System and Its Applications (Beijing: Science Press) p425 (in Chinese)

[32] 倪振华 1989 振动力学 (西安: 西安交通大学出版社) 第410页

Nie Z H 1989 Vibration Mechanics (Xi'an: Xi'an Jiaotong University Press) p410 (in Chinese)

-

图 4 (a) 模态A (88.40 Hz)、(b) 模态B (119.06 Hz)、(c) 模态C (302.09 Hz)、(d) 模态D (533.03 Hz)、(e) 模态E (772.31 Hz)、(f) 模态F (891.44 Hz) 的薄膜振型和声场压力图

Figure 4. Vibration mode of the membrane and sound pressure distribution diagrams of point A (88.40 Hz) (a), B (119.06 Hz) (b), C (302.09 Hz) (c), D (533.03 Hz) (d), E (772.31 Hz) (e), and F (891.44 Hz) (f).

表 2 薄膜附加金属片长度l s对薄膜固有频率的影响

Table 2. Effect of the parameter l s on natural frequency of membrane.

l s/10–3 m 4 6 8 10 12 14 1阶固有频率 252.4 237.9 226.8 218.2 211.6 206.6 2阶固有频率 751.3 782.8 794.0 814.8 843.4 879.1 表 1 薄膜附加金属片长度l s对低频带隙的影响

Table 1. Effect of the parameter l s on low-frequency band gaps.

ls/10–3 m 第一带隙下限 第一带隙上限 第二带隙下限 第二带隙上限 第三带隙下限 第三带隙上限 FEM

TMM误差/% FEM

TMM误差/% FEM

TMM误差/% FEM

TMM误差/% FEM

TMM误差/% FEM

TMM误差/% 4 89.2 3.7 121.4 4.4 314.2 2.8 557.7 0.6 790.7 2.2 900.3 1.6 92.5 126.7 323.0 561.2 808.3 914.7 6 88.9 3.6 120.1 4.2 297.7 1.8 526.8 –0.8 789.1 0.4 905.2 0.8 92.2 125.1 303.1 522.8 792.4 912.2 8 88.7 3.5 118.9 3.9 285.1 0.9 508.3 –2.1 795.6 –1.1 916.1 –0.5 91.9 123.5 287.6 497.5 786.8 912.0 10 88.6 3.4 117.9 3.5 275.6 –0.1 497.9 –3.5 815.9 –3.7 932.5 –2.3 91.6 122.0 275.4 480.5 786.0 910.8 12 88.5 3.1 117.2 3.0 268.4 –1.0 492.6 –4.8 843.8 –6.9 953.9 –5.2 91.3 120.7 265.6 469.1 785.3 904.4 14 88.5 2.8 116.7 2.3 262.9 –2.0 490.5 –5.9 878.5 –11 966.3 –8.2 91.0 119.4 257.6 461.5 779.9 887.3 表 3 薄膜张力T对低频带隙的影响

Table 3. Effect of the parameter T on low-frequency band gaps.

T/106 N·m–1 第一带隙下限 第一带隙上限 第二带隙下限 第二带隙上限 第三带隙下限 第三带隙上限 FEM

TMM误差/% FEM

TMM误差/% FEM

TMM误差/% FEM

TMM误差/% FEM

TMM误差/% FEM

TMM误差/% 0.5 74.3 3.4 89.3 2.8 259.2 0.7 440.3 –1.2 574.1 0.1 770.1 0.5 76.8 91.8 261.0 434.9 574.4 774.3 1.5 96.3 3.4 143.1 4.6 345.5 3.2 589.6 0.2 952.1 2.2 1035.1 1.7 99.6 149.7 356.7 591.0 973.0 1053.1 2.5 103.3 2.9 174.6 4.6 415.0 4.2 648.0 0.7 1217.4 2.8 1274.1 2.3 106.4 182.7 432.6 652.4 1251.0 1303.2 3.5 106.8 2.7 196.4 4.4 474.9 4.8 691.4 1.1 1434.1 3.0 1478.6 2.5 109.6 205.0 497.6 698.8 1477.6 1516.1 4.5 108.8 2.5 212.5 4.1 528.2 5.1 729.6 1.4 1621.6 3.2 1642.5 3.3 111.5 221.3 555.2 740.1 1673.4 1696.5 10 113.0 2.1 257.8 3.0 757.3 5.9 907.9 2.7 1645.9 5.8 1741.8 3.1 115.3 265.6 801.7 932.8 1740.6 1796.2 100 116.2 1.8 311.0 1.2 1654.1 5.2 1737.3 3.1 2270.8 9.0 2375.3 6.1 118.3 314.9 1740.4 1791.6 2475.7 2520.3 表 4 腔口空气通道长度l1对低频带隙的影响

Table 4. Effect of the parameter l1 on low-frequency band gaps.

l1/mm 第一带隙下限 第一带隙上限 第二带隙下限 第二带隙上限 第三带隙下限 第三带隙上限 FEM

TMM误差/% FEM

TMM误差/% FEM

TMM误差/% FEM

TMM误差/% FEM

TMM误差/% FEM

TMM误差/% 99 88.4 4.4 119.1 5.7 302.1 3.4 533.0 1.3 772.3 3.4 891.4 2.4 92.3 125.9 312.5 540.0 798.6 912.9 148 74.5 3.4 101.5 5.1 301.2 3.5 513.3 1.1 772.6 3.4 873.7 2.4 77.1 106.7 311.7 519.1 798.9 894.4 197 66.0 2.9 89.9 4.7 301.9 3.5 500.0 1.1 772.4 3.3 836.0 1.9 67.9 94.1 312.5 505.3 798.2 851.8 246 60.1 2.6 81.4 4.5 303.2 3.5 488.5 1.0 697.6 1.2 734.1 0.9 61.7 85.1 313.7 493.3 705.9 740.6 295 55.8 2.5 75.0 4.3 304.7 3.4 475.7 0.9 587.8 0.7 637.5 0.7 57.2 78.2 315.2 479.9 591.9 642.3 344 52.5 2.4 69.8 4.2 306.3 3.4 458.4 0.7 507.5 0.6 558.9 3.1 53.7 72.7 316.6 461.5 510.8 576.4 表 5 内腔体积V2对低频带隙的影响

Table 5. Effect of the parameter V2 on low-frequency band gaps.

V2/10–4 m3 第一带隙下限 第一带隙上限 第二带隙下限 第二带隙上限 第三带隙下限 第三带隙上限 FEM

TMM误差/% FEM

TMM误差/% FEM

TMM误差/% FEM

TMM误差/% FEM

TMM误差/% FEM

TMM误差/% 7.07 108.5 6.3 120.5 5.8 406.9 1.0 566.2 1.0 809.9 1.9 953.1 1.2 115.3 127.6 411.0 571.8 825.3 964.2 10.57 103.3 4.8 121.1 4.8 361.4 1.6 558.3 –0.1 796.5 1.9 925.4 1.4 108.3 126.8 367.2 557.8 811.4 938.7 14.07 98.0 4.2 121.0 4.4 335.0 1.9 550.0 –0.1 790.9 1.8 913.1 1.4 102.2 126.4 341.3 549.4 804.9 925.8 17.57 93.3 3.9 120.9 4.3 317.7 2.1 544.4 –0.1 788.3 1.6 906.5 1.3 96.9 126.1 324.4 543.9 801.1 918.1 19.32 91.1 3.8 120.8 4.3 311.1 2.2 542.3 –0.1 787.4 1.6 904.1 1.2 94.5 126.0 317.9 541.8 799.7 915.3 -

[1] Kushwaha M S, Halevi P, Dobrzynski L, Djafari-Rouhani B 1993 Phys. Rev. Lett. 71 2022

Google Scholar

Google Scholar

[2] 王莎, 林书玉 2019 68 024303

Google Scholar

Google Scholar

Wang S, Lin S Y 2019 Acta Phys. Sin. 68 024303

Google Scholar

Google Scholar

[3] 张振方, 郁殿龙, 刘江伟, 温激鸿 2018 67 074301

Google Scholar

Google Scholar

Zhang Z F, Yu D L, Liu J W, Wen J H 2018 Acta Phys. Sin. 67 074301

Google Scholar

Google Scholar

[4] 廖涛, 孙小伟, 宋婷, 田俊红, 康太凤, 孙伟彬 2018 67 214208

Google Scholar

Google Scholar

Liao T, Sun X W, Song T, Tian J H, Kang T F, Sun W B 2018 Acta Phys. Sin. 67 214208

Google Scholar

Google Scholar

[5] Li S B, Dou Y H, Chen T N, Wan Z G, Guan Z R 2018 Mod. Phys. Lett. B 32 1850221

[6] Korozlu N, Kaya O A, Cicek A, Ulug B 2018 J. Acoust. Soc. Am. 143 756

Google Scholar

Google Scholar

[7] Quan L, Ra Di Y, Sounas D L, Alù A 2018 Phys. Rev. Lett. 120 254301

Google Scholar

Google Scholar

[8] Zhao L X, Zhou S X 2019 Sensors-Basel 19 788

Google Scholar

Google Scholar

[9] Yuan M, Cao Z, Luo J, Pang Z 2018 AIP Adv. 8 85012

Google Scholar

Google Scholar

[10] Wang Y, Zhu X, Zhang T S, Bano S, Pan H Y, Qi L F, Zhang Z T, Yuan Y P 2018 Appl. Energ. 230 52

Google Scholar

Google Scholar

[11] Quan L, Qian F, Liu X Z, Gong X F, Johnson P A 2015 Phys. Rev. B 92 104105

Google Scholar

Google Scholar

[12] Quan L, Zhong X, Liu X, Gong X, Johnson P A 2014 Nat. Commun. 5 3188

Google Scholar

Google Scholar

[13] Hu X, Chan C T, Zi J 2005 Phys. Rev. E 71 55601

Google Scholar

Google Scholar

[14] Chalmers L, Elford D P, Kusmartsev F V, Swallowe G M 2009 Int. J. Mod. Phys. B 23 4234

Google Scholar

Google Scholar

[15] Guan D, Wu J H, Jing L, Gao N, Hou M 2015 Noise Control Eng. J. 63 20

Google Scholar

Google Scholar

[16] Jiang J, Yao H, Du J, Zhao J 2016 AIP Adv. 6 115024

Google Scholar

Google Scholar

[17] 姜久龙, 姚宏, 杜军, 赵静波, 邓涛 2017 66 064301

Google Scholar

Google Scholar

Jiang J L, Yao H, Du J, Zhao J B, Deng T 2017 Acta Phys. Sin. 66 064301

Google Scholar

Google Scholar

[18] 刘敏, 侯志林, 傅秀军 2012 61 104302

Google Scholar

Google Scholar

Liu M, Hou Z L, Fu X J 2012 Acta Phys. Sin. 61 104302

Google Scholar

Google Scholar

[19] 包凯, 陈天宁, 王小鹏, 王放, 张振华 2016 西安交通大学学报 50 124

Google Scholar

Google Scholar

Bao K, Chen T N, Wang X P, Wang F, Zhang Z H 2016 J. Xi’an Jiaotong Univ. 50 124

Google Scholar

Google Scholar

[20] Liu C R, Wu J H, Chen X, Ma F Y 2019 J. Phys. D: Appl. Phys. 52 105302

Google Scholar

Google Scholar

[21] Ang L Y L, Koh Y K, Lee H P 2017 Appl. Phys. Lett. 111 41903

Google Scholar

Google Scholar

[22] Wang X, Zhao H, Luo X, Huang Z 2016 Appl. Phys. Lett. 108 41905

Google Scholar

Google Scholar

[23] Langfeldt F, Gleine W, von Estorff O 2015 J. Sound Vib. 349 315

Google Scholar

Google Scholar

[24] 周榕, 吴卫国, 闻轶凡 2017 声学技术 36 297

Zhou R, Wu W G, Wen Y F 2017 Technical Acoustics 36 297

[25] Abbad A, Rabenorosoa K, Ouisse M, Atalla N, Park G 2017 Proc. SPIE 10164 101640P

[26] Langfeldt F, von Estorff O 2016 Inter-Noise and Noise-Con Congress and Conference Proceedings 253 3413

[27] Elayouch A, Addouche M, Herth E, Khelif A 2013 Appl. Phys. Lett. 103 83504

Google Scholar

Google Scholar

[28] Liu C R, Wu J H, Lu K, Zhao Z T, Huang Z 2019 Appl. Acoust. 148 1

Google Scholar

Google Scholar

[29] Zhu X, Chen Z, Jiao Y, Wang Y 2018 J.Vibr. Acoust. 140 31014

Google Scholar

Google Scholar

[30] 陈鑫, 姚宏, 赵静波, 张帅, 贺子厚, 蒋娟娜 2019 68 084302

Google Scholar

Google Scholar

Chen X, Yao H, Zhao J B, Zhang S, He Z H, Jiang J N 2019 Acta Phys. Sin. 68 084302

Google Scholar

Google Scholar

[31] 芮筱亭, 贠来峰, 陆毓琪, 何斌, 王国平 2008 多体系统的传递矩阵法及其应用 (北京: 科学出版社) 第425页

Rui X T, Yuan L F, Lu Y Q, He B, Wang G P 2008 Transfer Matrix Method of Multibody System and Its Applications (Beijing: Science Press) p425 (in Chinese)

[32] 倪振华 1989 振动力学 (西安: 西安交通大学出版社) 第410页

Nie Z H 1989 Vibration Mechanics (Xi'an: Xi'an Jiaotong University Press) p410 (in Chinese)

Catalog

Metrics

- Abstract views: 11234

- PDF Downloads: 168

- Cited By: 0

DownLoad:

DownLoad: