-

为提高Helmholtz型声子晶体低频隔声性能, 设计了一种Helmholtz腔与弹性振子的耦合结构, 通过声压场及固体振型对其带隙产生机理进行了详细分析, 建立了相应的弹簧-振子系统等效模型, 并采用理论计算和有限元计算两种方法研究了各结构参数对其带隙的影响情况. 研究表明, 该结构可等效为双自由度系统振动, 在低频范围内具有两个带隙; 在6 cm的尺寸下, 其第一带隙下限可低至24.5 Hz, 而同尺寸无弹性振子结构只能达到42.1 Hz, 带隙下限降低了40%, 较传统Helmholtz结构具有更为优良的低频隔声特性. 另外, 在框体尺寸一定的情况下, 降低结构间距、增大开口空气通道长度及振子质量、增大左侧腔体体积等方式, 是增大带隙宽度、提高低频隔声效果的主要手段.

-

关键词:

- Helmholtz共振 /

- 低频带隙 /

- 局域共振 /

- 噪声控制

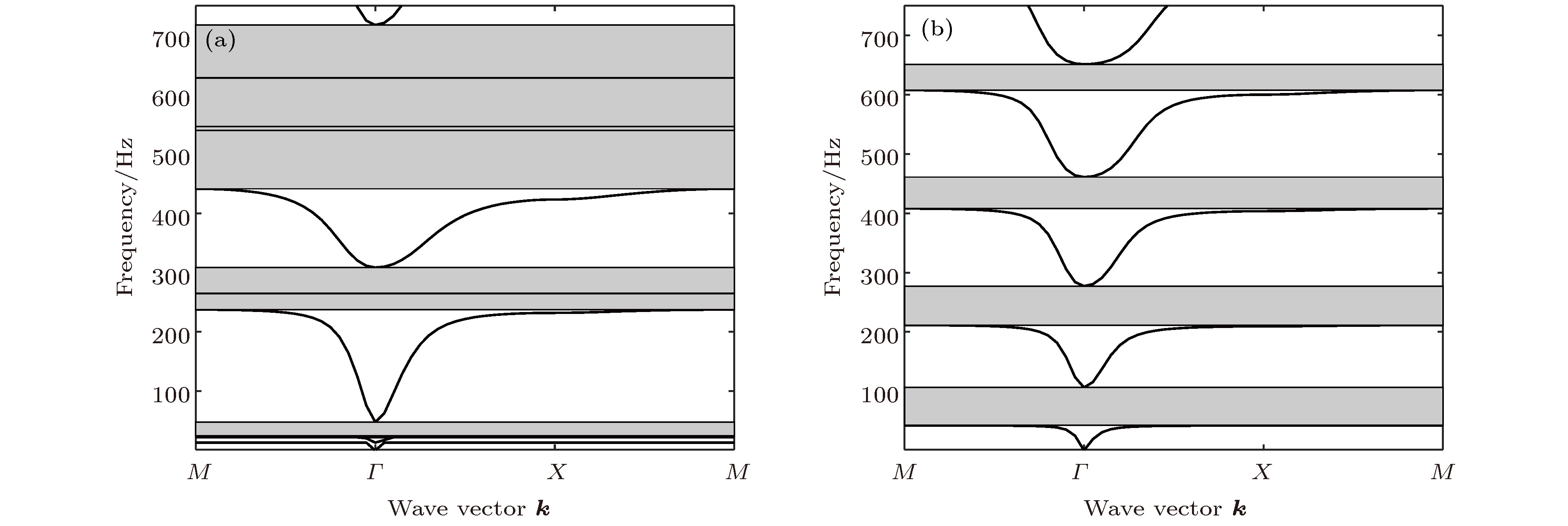

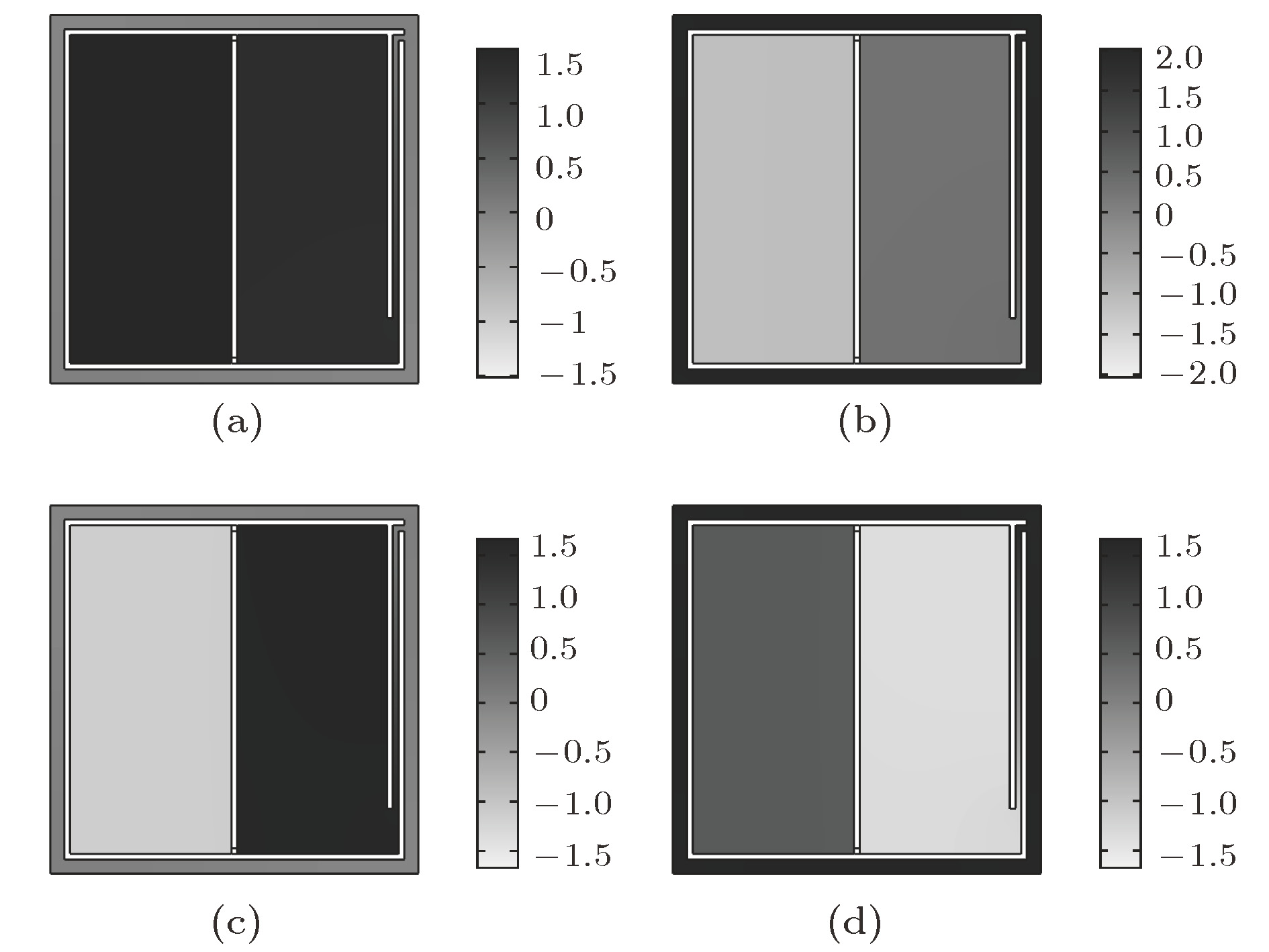

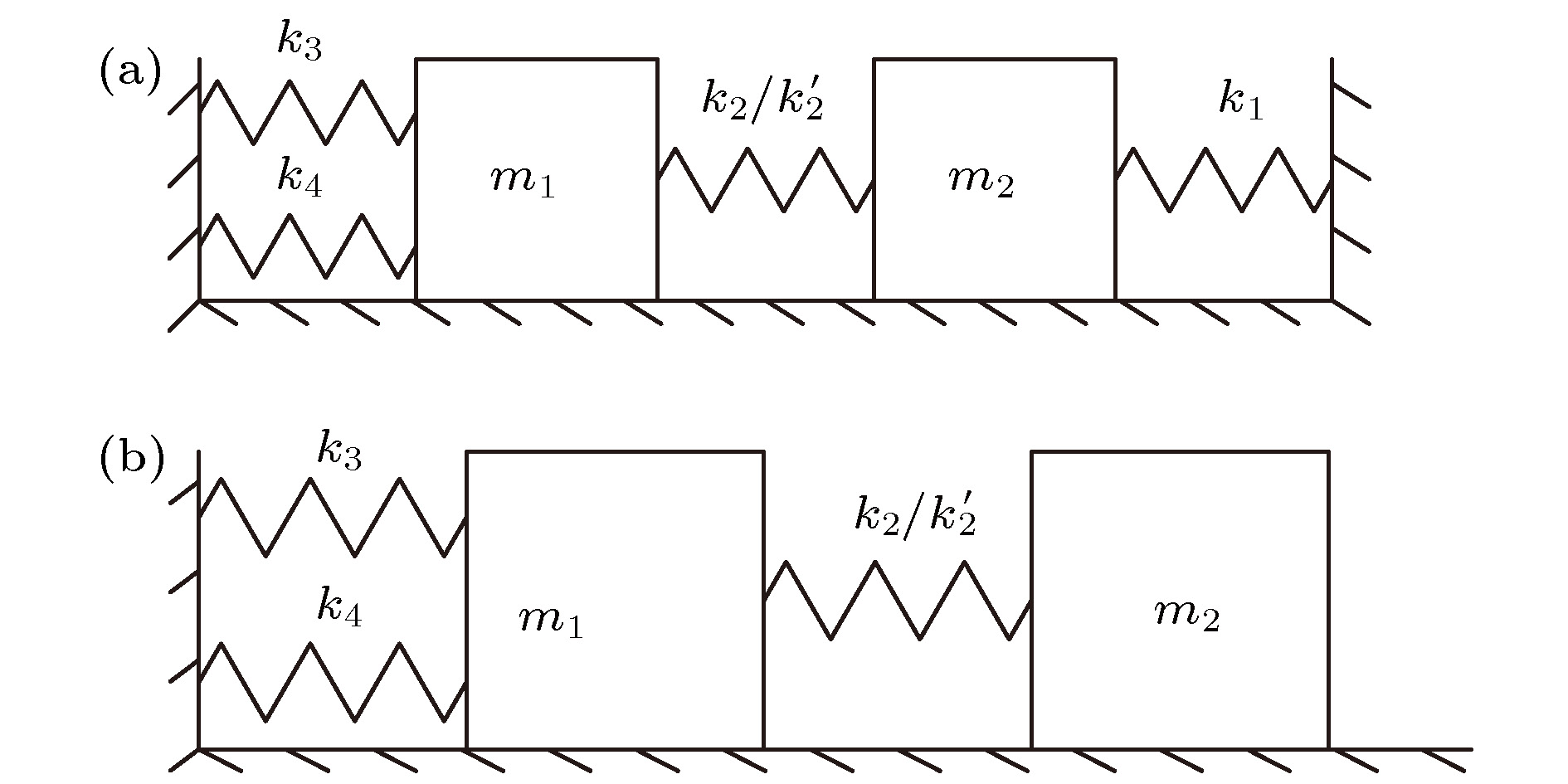

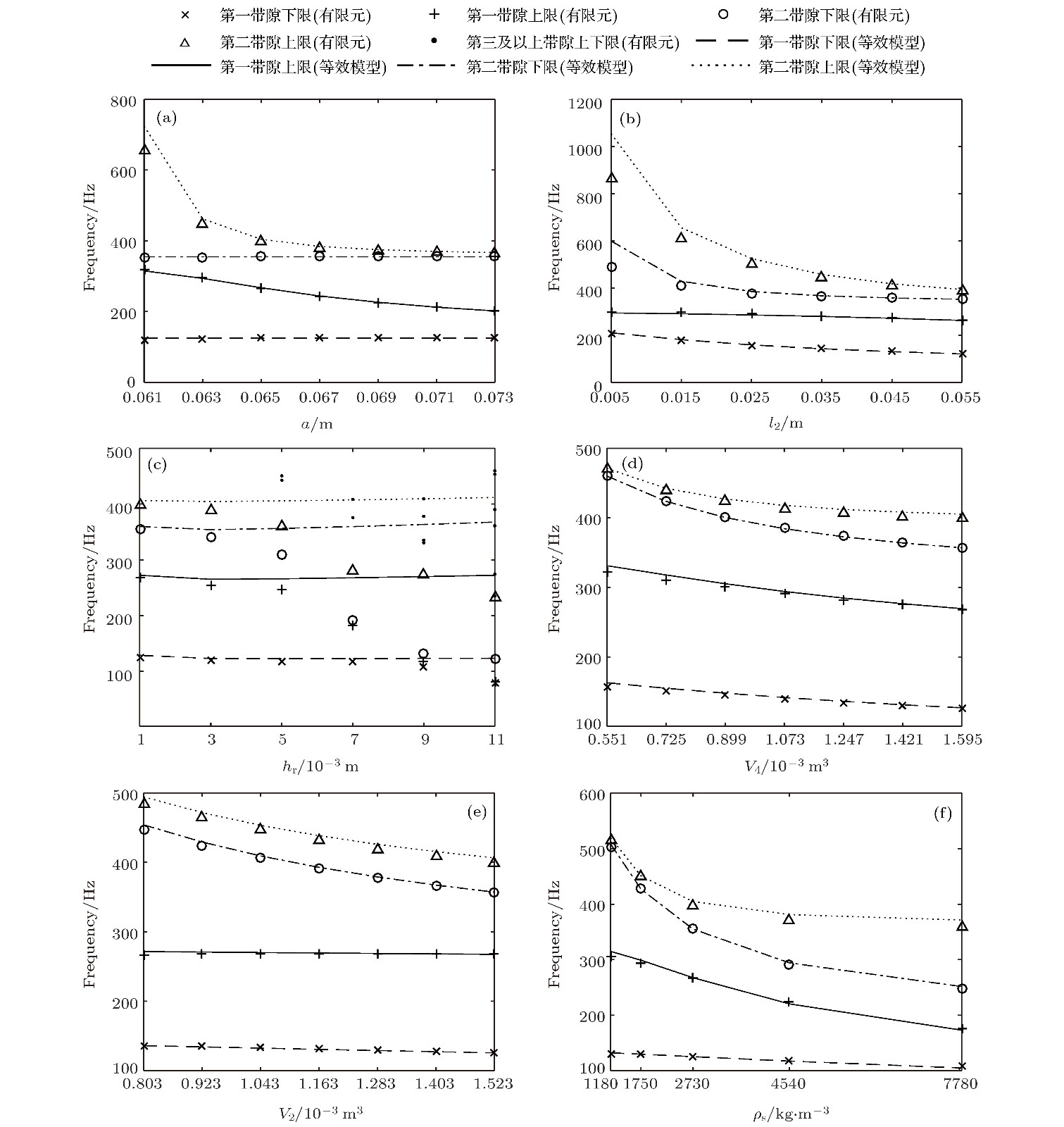

In order to improve the low-frequency acoustical insulation performance of Helmholtz phononic crystals, a structure coupling Helmholtz resonator with elastic oscillator is designed. This structure combines the characteristics of Helmholtz resonators with those of the local resonant solid-solid phononic crystals. In this structure, the elastic oscillator is bonded to the inner wall of the conventional Helmholtz resonator by rubber. The structure has two bandgaps in the low-frequency range, i.e. 24.5−47.7 Hz and 237.6−308.6 Hz for a lattice constant of 6 cm. However, for the same lattice constant, the lower limit of the bandgap of the traditional Helmholtz resonator without the elastic oscillator structure is only 42.1 Hz. Our structure reduces the minimum lower limit of the bandgap by 40% compared with the traditional Helmholtz structure and has better low-frequency acoustical insulation characteristics. In this study, the generation mechanism of the bandgap is analyzed with the sound pressure field and vibration mode. It is found that the elastic oscillator and the air in the air passage of the resonator vibrate in the same direction at the frequency of upper and lower limit for the first bandgap while they vibrate in the reverse direction for the second bandgap. Outside the resonator, air sound pressure is zero at the lower limit of the bandgap. The spring-oscillator system is established as an equivalent model. In the model, the elastic oscillator and the air in the passage are regarded as oscillators, and the air separated by the elastic oscillator, the air outside the resonator, and the rubber connected with the elastic oscillator are all regarded as springs. Besides, it can be found that the air in the resonator shows different equivalent stiffness for different vibration mode. In the discussion, the effects of structural parameters on the bandgap are studied by theoretical calculation and the finite element method. The results show that when the lattice constant decreases without changing the side length of the resonator, the bandgap width increases without affecting the lower limit of the bandgap. The increase of the length of the air passage can increase the width of the first bandgap while the second bandgap decreases. However, the increase of the mass effect of the elastic oscillator results in the first bandgap width decreasing and the second bandgap width increasing. The increase of the length of the air passage and the mass of the elastic oscillator both can reduce the bandgap frequency. It can be found that the volume of the right cavity only affects the frequency of the second bandgap, while the volume of the left cavity can influence the frequency of each bandgap. Therefore, the shorter distance between the elastic oscillator and the passage, the better low-frequency acoustical insulation performance of the structure can be reached. Finally, the increase of the length of the rubber produces new vibration modes, which leads to the generation of new small bandgaps and the change of the frequency of the original bandgaps. However, it is found that the influence of the mode of vibration on the bandgap is smaller than that of the mass of the elastic oscillator, and the regularity of its impact is not apparent. -

Keywords:

- Helmholtz resonance /

- low-frequency bandgap /

- local resonant /

- noise control

[1] Li J, Wang W, Xie Y, Popa B I, Cummer S A 2016 Appl. Phys. Lett. 109 091908

Google Scholar

Google Scholar

[2] Atak O, Huybrechs D, Pluymers B, Desmet W 2014 J. Sound Vibr. 333 3367

Google Scholar

Google Scholar

[3] Yangbo X, Bogdan-Ioan P, Lucian Z, Cummer S A 2012 Phys. Rev. Lett. 110 175501

Google Scholar

Google Scholar

[4] Shu Z, Leilei Y, Nicholas F 2009 Phys. Rev. Lett. 102 194301

Google Scholar

Google Scholar

[5] Liu Z, Zhang X, Mao Y, Zhu Y Y, Yang Z, Chan C T, Sheng P 2000 Science 289 1734

Google Scholar

Google Scholar

[6] Hu X, Chan C T, Zi J 2005 Phys. Rev. E 71 055601

Google Scholar

Google Scholar

[7] Wang Z G, Lee S H, Kim C K, Park C M 2008 J. Appl. Phys. 103 064907

Google Scholar

Google Scholar

[8] Hsu J C 2011 Jpn. J. Appl. Phys. 50 07HB01

Google Scholar

Google Scholar

[9] Murray A R, Summers I R, Sambles J R, Hibbins A P 2014 J. Acoust. Soc. Am. 136 980

Google Scholar

Google Scholar

[10] Campos B V L, Babinet A, Dos Santos J M C 2017 Proceedings of the XXXVIII Iberian Latin-American Congress on Computational Methods in Engineering Florianópolis, Brazil, November 5−8, 2017

[11] Wang Y, Zhu X, Zhang T, Bano S, Pan H, Qi L, Zhang Z, Yuan Y 2018 Appl. Energy 230 52

Google Scholar

Google Scholar

[12] Guan D, Wu J H, Jing L, Gao N, Hou M 2015 Noise Control Eng. J. 63 20

Google Scholar

Google Scholar

[13] 刘敏, 侯志林, 傅秀军 2012 61 104302

Google Scholar

Google Scholar

Liu M, Hou Z L, Fu X J 2012 Acta Phys. Sin. 61 104302

Google Scholar

Google Scholar

[14] 姜久龙, 姚宏, 杜军, 赵静波, 邓涛 2017 66 064301

Google Scholar

Google Scholar

Jiang J L, Yao H, Du J, Zhao J B, Deng T 2017 Acta Phys. Sin. 66 064301

Google Scholar

Google Scholar

[15] Jiang J L, Yao H, Du J, Zhao J B 2016 AIP Adv. 6 115024

Google Scholar

Google Scholar

[16] Abbad, Ahmed 2016 SAE Tech. Pap. 2016-01 1842

Google Scholar

Google Scholar

[17] Zhu X Z, Chen Z B, Jiao Y H, Wang Y P 2018 J. Vib. Acoust. 140 031014

Google Scholar

Google Scholar

[18] Zhang Y, Wen J, Xiao Y, Wen X, Wang J 2012 Phys. Lett. A 376 1489

Google Scholar

Google Scholar

[19] Lee S H, Park C M, Seo Y M, Wang Z G, Kim C K 2015 Phys. Rev. Lett. 104 054301

Google Scholar

Google Scholar

[20] Lin G C, Chen S Q, Li Y L, Tan H F 2017 Mater. Sci. Forum. 898 1749

Google Scholar

Google Scholar

[21] Hirsekorn M 2004 Appl. Phys. Lett. 84 3364

Google Scholar

Google Scholar

[22] 温熙森, 温激鸿, 郁殿龙, 王刚, 刘耀宗, 韩小云 2009 声子晶体 (北京: 国防工业出版社) 第170页

Wen X S, Wen J H, Yu D L, Wang G, Liu Y Z, Han X Y 2009 Phononic Crystals (Beijing: National Defense Industry Press) p170 (in Chinese)

[23] 倪振华 1989 振动力学 (西安: 西安交通大学出版社) 第167页

Nie Z H 1989 Vibration Mechanics (Xi'an: Xi'an Jiaotong University Press) p167 (in Chinese)

[24] Alster M 1972 J. Sound Vibr. 24 63

Google Scholar

Google Scholar

[25] Rajalingham C, Bhat R B, Xistris G D 1998 Int. J. Mech. Sci. 40 723

Google Scholar

Google Scholar

[26] Eftekhari S A 2017 J. Braz. Soc. Mech. Sci. Eng. 39 1119

Google Scholar

Google Scholar

-

图 7 晶格常数a (a), 开口长度l2 (b), 左腔体积V2 (d), 右腔体积V4 (e), 弹性振子密度

$\rho_{\rm{s}}$ (f)对第一、二低频带隙的影响; (c) 橡胶长度hr对各低频带隙的影响;Fig. 7. The impact of different parameters a on first and second low frequency bandgap: (a) The lattice constant a; (b) the length of the cavity opening l2; (d) the volume of the left cavity V2; (e) the volume of the right cavity V4; (c) the impact of the parameter hr on each low frequency bandgap

表 1 各结构参数组合

Table 1. Combination of various structural parameters

名称 a/mm l2/mm l3/mm br/mm hr/mm bs/mm 振子材料 Helmholtz腔与弹性振子耦合结构带隙下限最低参数 61 [61, 65] 50 [1, 1680] 40 [1, 56] 4 [1, 5] 9 [1, 9] 25 [1, 25] 钢 传统Helmholtz腔结构带隙下限最低参数 61 [61, 65] 848 [1, 1680] — — — — — 初始结构参数 65 50 28.5 1 1 1 铝 表 2 各材料参数

Table 2. Material parameters

材料名称 硅橡胶 环氧树脂 碳 铝 钛 钢 密度/k·m–3 1300 1180 1750 2730 4540 7780 弹性模量/1010 Pa 1.175 × 10–5 0.435 23.01 7.76 11.70 21.06 剪切模量/1010 Pa 4 × 10–6 0.159 8.85 2.87 4.43 8.10 -

[1] Li J, Wang W, Xie Y, Popa B I, Cummer S A 2016 Appl. Phys. Lett. 109 091908

Google Scholar

Google Scholar

[2] Atak O, Huybrechs D, Pluymers B, Desmet W 2014 J. Sound Vibr. 333 3367

Google Scholar

Google Scholar

[3] Yangbo X, Bogdan-Ioan P, Lucian Z, Cummer S A 2012 Phys. Rev. Lett. 110 175501

Google Scholar

Google Scholar

[4] Shu Z, Leilei Y, Nicholas F 2009 Phys. Rev. Lett. 102 194301

Google Scholar

Google Scholar

[5] Liu Z, Zhang X, Mao Y, Zhu Y Y, Yang Z, Chan C T, Sheng P 2000 Science 289 1734

Google Scholar

Google Scholar

[6] Hu X, Chan C T, Zi J 2005 Phys. Rev. E 71 055601

Google Scholar

Google Scholar

[7] Wang Z G, Lee S H, Kim C K, Park C M 2008 J. Appl. Phys. 103 064907

Google Scholar

Google Scholar

[8] Hsu J C 2011 Jpn. J. Appl. Phys. 50 07HB01

Google Scholar

Google Scholar

[9] Murray A R, Summers I R, Sambles J R, Hibbins A P 2014 J. Acoust. Soc. Am. 136 980

Google Scholar

Google Scholar

[10] Campos B V L, Babinet A, Dos Santos J M C 2017 Proceedings of the XXXVIII Iberian Latin-American Congress on Computational Methods in Engineering Florianópolis, Brazil, November 5−8, 2017

[11] Wang Y, Zhu X, Zhang T, Bano S, Pan H, Qi L, Zhang Z, Yuan Y 2018 Appl. Energy 230 52

Google Scholar

Google Scholar

[12] Guan D, Wu J H, Jing L, Gao N, Hou M 2015 Noise Control Eng. J. 63 20

Google Scholar

Google Scholar

[13] 刘敏, 侯志林, 傅秀军 2012 61 104302

Google Scholar

Google Scholar

Liu M, Hou Z L, Fu X J 2012 Acta Phys. Sin. 61 104302

Google Scholar

Google Scholar

[14] 姜久龙, 姚宏, 杜军, 赵静波, 邓涛 2017 66 064301

Google Scholar

Google Scholar

Jiang J L, Yao H, Du J, Zhao J B, Deng T 2017 Acta Phys. Sin. 66 064301

Google Scholar

Google Scholar

[15] Jiang J L, Yao H, Du J, Zhao J B 2016 AIP Adv. 6 115024

Google Scholar

Google Scholar

[16] Abbad, Ahmed 2016 SAE Tech. Pap. 2016-01 1842

Google Scholar

Google Scholar

[17] Zhu X Z, Chen Z B, Jiao Y H, Wang Y P 2018 J. Vib. Acoust. 140 031014

Google Scholar

Google Scholar

[18] Zhang Y, Wen J, Xiao Y, Wen X, Wang J 2012 Phys. Lett. A 376 1489

Google Scholar

Google Scholar

[19] Lee S H, Park C M, Seo Y M, Wang Z G, Kim C K 2015 Phys. Rev. Lett. 104 054301

Google Scholar

Google Scholar

[20] Lin G C, Chen S Q, Li Y L, Tan H F 2017 Mater. Sci. Forum. 898 1749

Google Scholar

Google Scholar

[21] Hirsekorn M 2004 Appl. Phys. Lett. 84 3364

Google Scholar

Google Scholar

[22] 温熙森, 温激鸿, 郁殿龙, 王刚, 刘耀宗, 韩小云 2009 声子晶体 (北京: 国防工业出版社) 第170页

Wen X S, Wen J H, Yu D L, Wang G, Liu Y Z, Han X Y 2009 Phononic Crystals (Beijing: National Defense Industry Press) p170 (in Chinese)

[23] 倪振华 1989 振动力学 (西安: 西安交通大学出版社) 第167页

Nie Z H 1989 Vibration Mechanics (Xi'an: Xi'an Jiaotong University Press) p167 (in Chinese)

[24] Alster M 1972 J. Sound Vibr. 24 63

Google Scholar

Google Scholar

[25] Rajalingham C, Bhat R B, Xistris G D 1998 Int. J. Mech. Sci. 40 723

Google Scholar

Google Scholar

[26] Eftekhari S A 2017 J. Braz. Soc. Mech. Sci. Eng. 39 1119

Google Scholar

Google Scholar

计量

- 文章访问数: 9754

- PDF下载量: 138

- 被引次数: 0

下载:

下载: