-

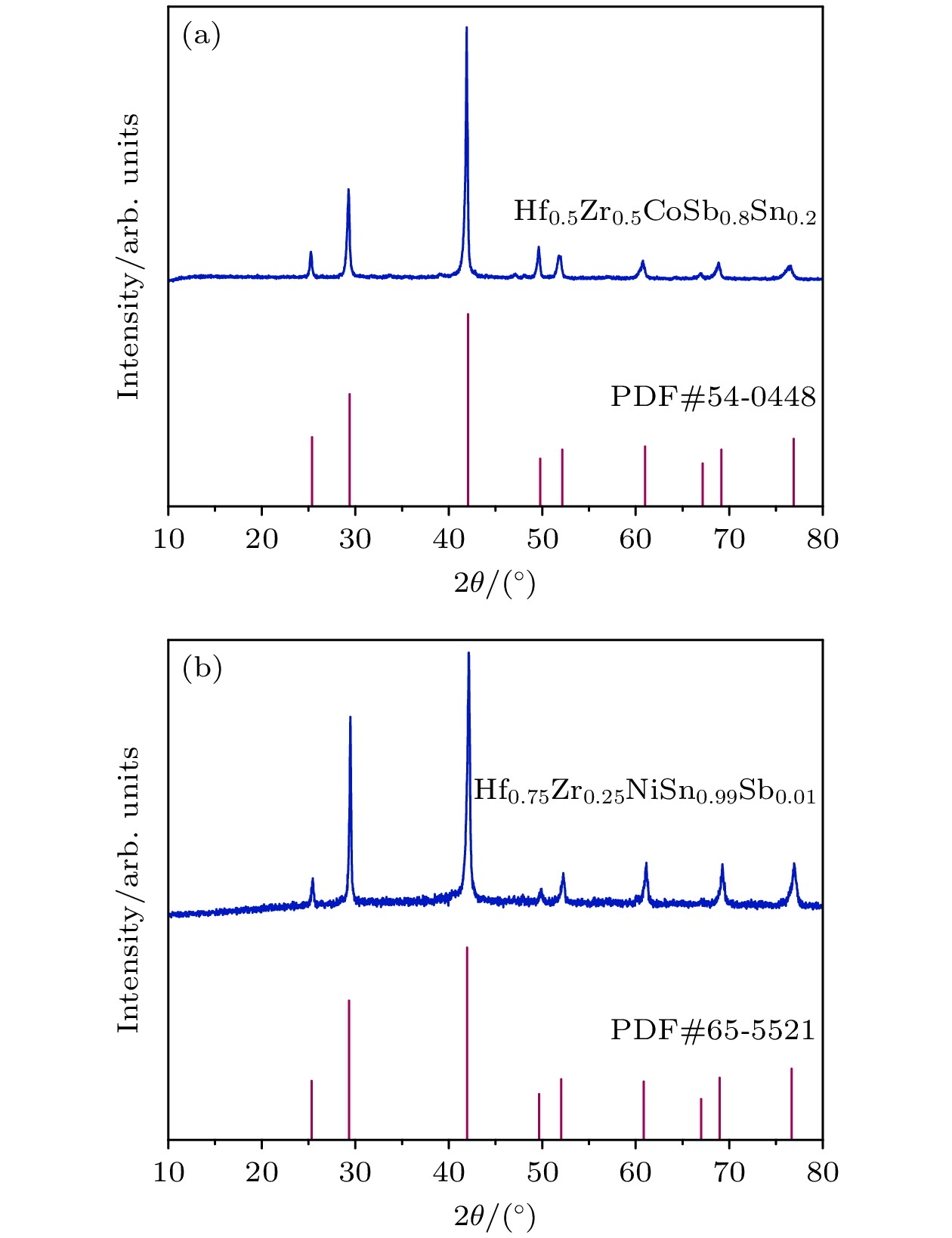

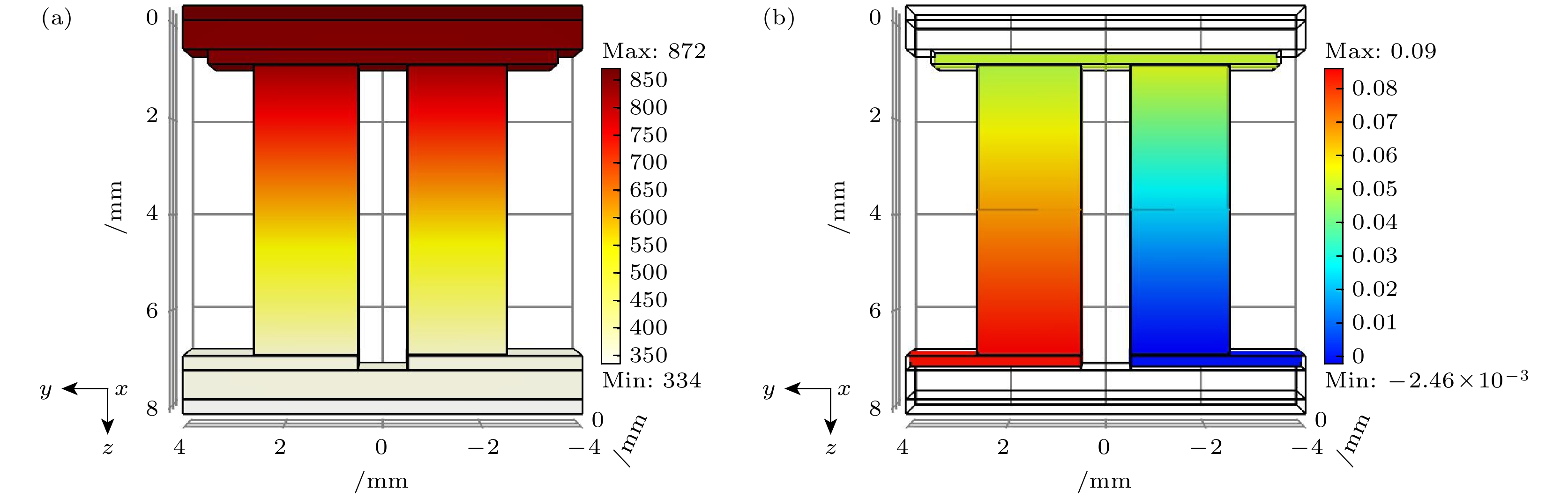

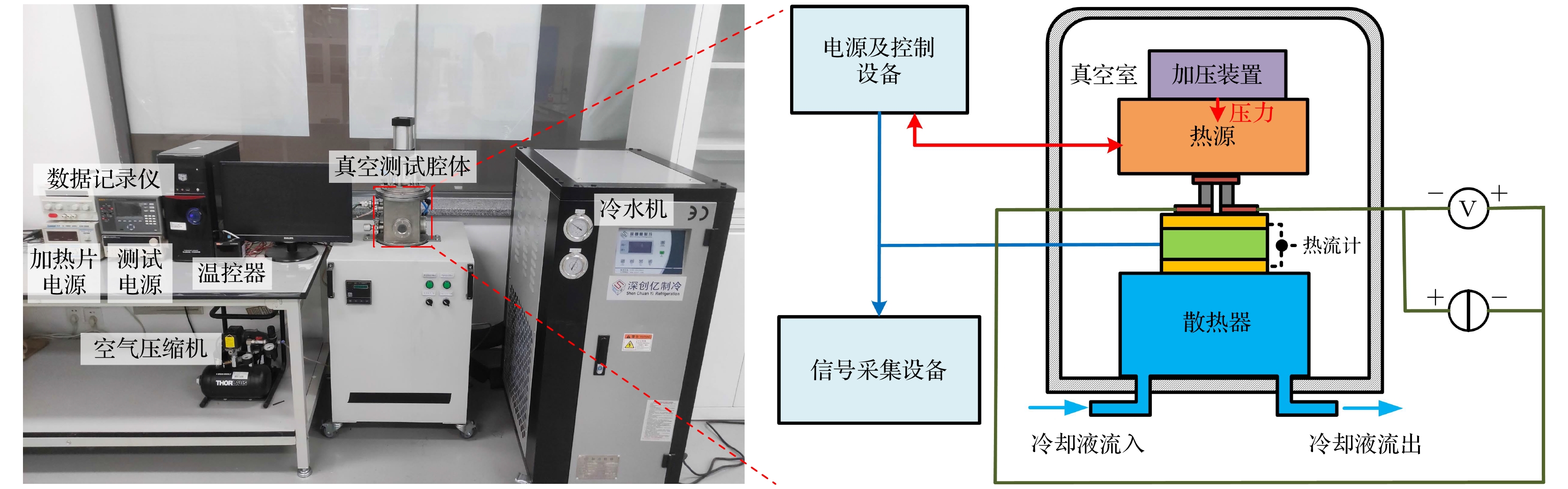

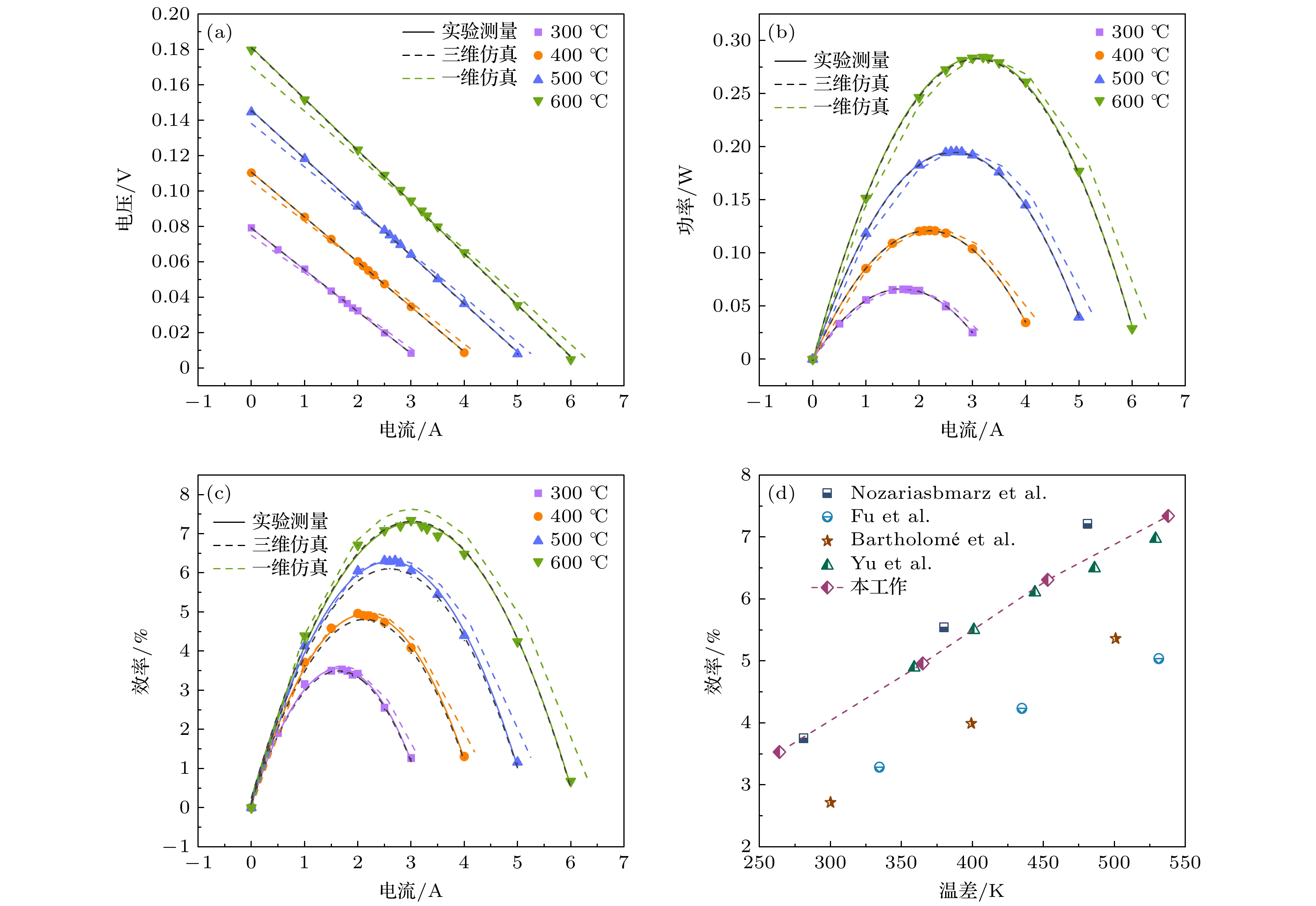

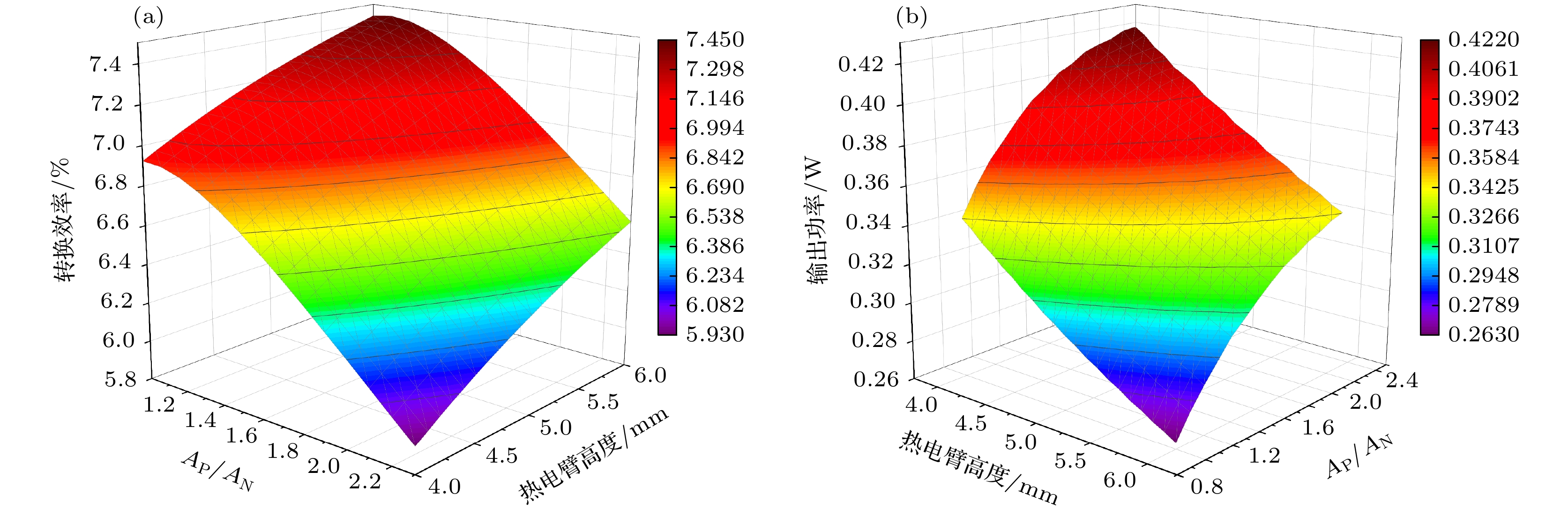

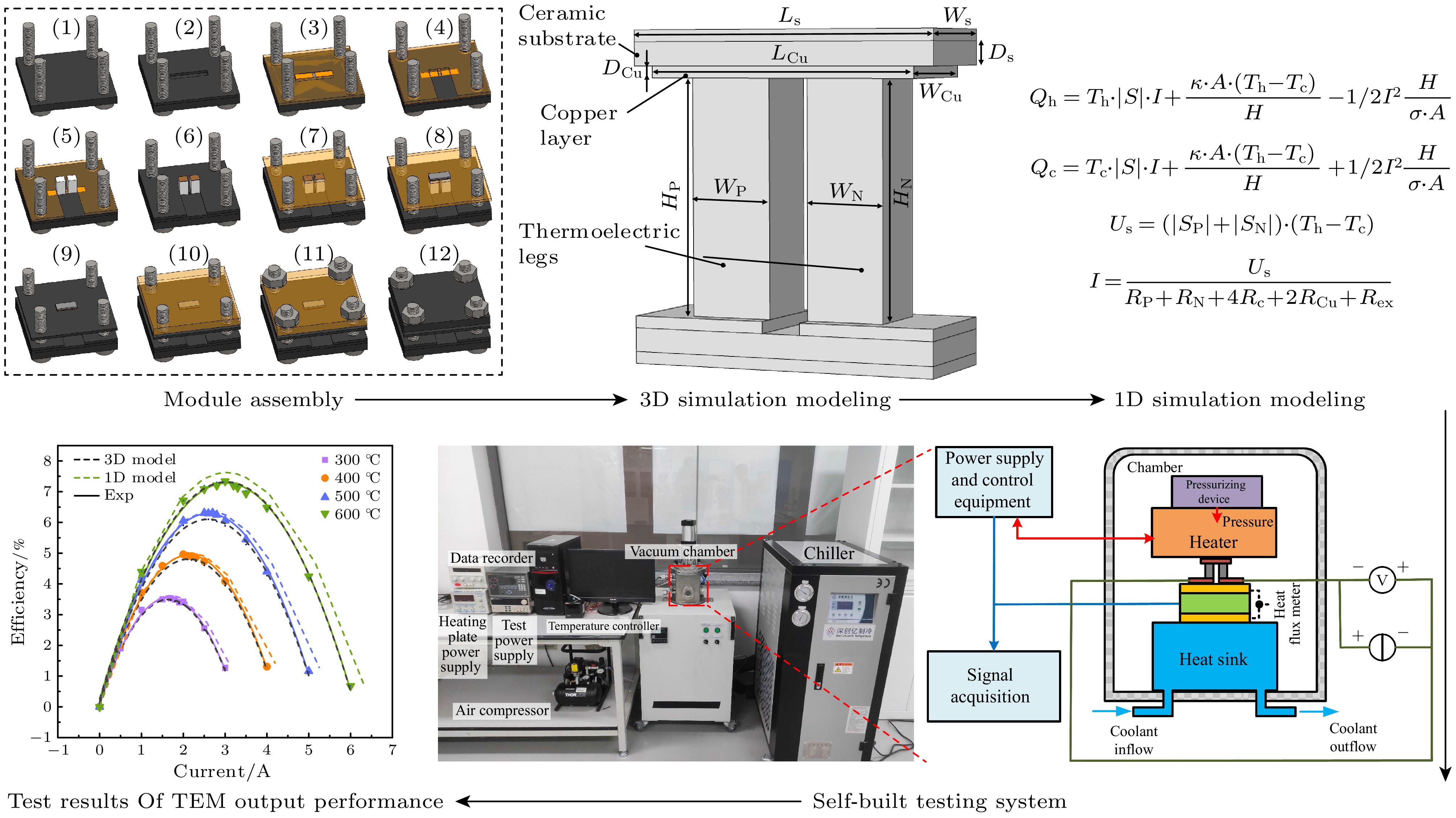

由于能够实现热能和电能的直接转换, 中高温区热电器件在深空探测、工业余废热回收等领域具有巨大的应用潜力. 半赫斯勒合金由于优异的机械性能、热稳定性和良好的热电表现, 成为中高温区热电器件制作的有潜力的候选材料. 然而与半赫斯勒热电材料的研究相比, 相应的器件研究还远远滞后, 制约了其大规模的工业应用. 本文首先制备了高性能P型和N型半赫斯勒合金, 采用自主设计的石墨模具成功钎焊组装了单对半赫斯勒热电器件. 之后采用有限元分析方法对单对器件进行三维仿真建模, 同时建立一维数值模型进行对比. 除此之外, 开发了一套自主集成的综合测试系统, 系统地表征了单对器件的输出功率、转换效率等关键热电性能. 两种模型仿真预测结果与实验测量数据高度一致, 在工作温差达到538 K时, 最大输出功率和最大转换效率分别为0.28 W和7.34%, 能够与目前报道的器件最佳性能相媲美. 本研究结果可以为半赫斯勒热电器件的实际制作、仿真建模和表征测量提供参考.Due to the ability to directly convert thermal energy into electrical energy, thermoelectric devices operating in the medium-to-high temperature range hold significant potential for applications such as deep space exploration and industrial waste heat recovery. Among candidate materials, half-Heusler alloys have emerged as promising options for device fabrication in this temperature range, owing to their excellent mechanical properties, thermal stability, and favorable thermoelectric performance. However, research on half-Heusler-based thermoelectric devices remains far behind study of the materials, which limits their large-scale industrial application. In this study, high-performance P-type Hf0.5Zr0.5CoSb0.8Sn0.2 and N-type Hf0.75Zr0.25NiSn0.99Sb0.01 half-Heusler alloys are firstly synthesized. Then the single-pair thermoelectric module is successfully brazed and assembled by using the graphite mold designed by ourselves. After that, three-dimensional (3D) finite element modeling and one-dimensional (1D) numerical modeling are conducted to simulate the module behaviors, and their results are highly consistent with experimental measurements, thereby validating the accuracy of the simulation models. Using the established simulation models, the influence of geometric parameters on module performance is investigated. The result shows that optimizing the leg height and cross-sectional area ratio is critical for achieving maximum conversion efficiency. Additionally, a self-integrated comprehensive testing system (Model: TE-X-MS) is developed to systematically characterize key thermoelectric properties, including output power and conversion efficiency. The fabricated device achieves a maximum output power of 0.28 W and a peak conversion efficiency of 7.34% at a temperature difference of 538 K, which is comparable to the best-performing devices reported to date. These results provide valuable reference for fabricating, modeling, and characterizing the half-Heusler thermoelectric devices in practical applications.

-

Keywords:

- half-Heusler alloy /

- thermoelectric generator /

- finite element simulation /

- numerical simulation

[1] 王雅宁, 陈少平, 樊文浩, 郭敬云, 吴玉程, 王文先 2020 69 246801

Google Scholar

Google Scholar

Wang Y N, Chen S P, Fan W H, Guo J Y, Wu Y C, Wang W X 2020 Acta Phys. Sin. 69 246801

Google Scholar

Google Scholar

[2] 杨士冠, 林鑫, 何俊松, 翟立军, 程林, 吕明豪, 刘虹霞, 张艳, 孙志刚 2023 72 228401

Google Scholar

Google Scholar

Yang S G, Lin X, He J S, Zhai L J, Chen L, Lü M H, Liu H X, Zhang Y, Sun Z G 2023 Acta Phys. Sin. 72 228401

Google Scholar

Google Scholar

[3] 谢忠祥, 喻霞, 贾聘真, 陈学坤, 邓元祥, 张勇, 周五星 2023 72 124401

Google Scholar

Google Scholar

Xie Z X, Yu X, Jia P Z, Chen X K, Deng Y X, Zhang Y, Zhou W X 2023 Acta Phys. Sin. 72 124401

Google Scholar

Google Scholar

[4] He H L, Fang Z X, Niu C P, Wu Y, Rong M Z 2021 Energy Convers. Manag. 241 114314

Google Scholar

Google Scholar

[5] Yu K, Wu Y, He H L, Niu C P, Rong M Z, Wu D, Liu S X, Zhang Y Q 2021 J. Alloys Compd. 885 161378

Google Scholar

Google Scholar

[6] Zhang P, Ouyang T, Tang C, He C Y, Li J, Zhang C X, Zhong J X 2021 Chin. Phys. B 30 128401

Google Scholar

Google Scholar

[7] 许易, 许小言, 张薇, 欧阳滔, 唐超 2019 68 247202

Google Scholar

Google Scholar

Xu Y, Xu X Y, Zhang W, Ouyang T, Tang C 2019 Acta Phys. Sin. 68 247202

Google Scholar

Google Scholar

[8] Lu J Y, Cui C F, Ouyang T, Li J, He C Y, Tang C, Zhong J X 2023 Chin. Phys. B 32 048401

Google Scholar

Google Scholar

[9] Zhang P, Ouyang T, Tang C, He C Y, Li J, Zhang C X, Zhong J X 2020 Chin. Phys. B 29 118401

Google Scholar

Google Scholar

[10] Ovik R, Long B D, Barma M C, Riaz M, Sabri M F M, Said S M, Saidur R 2016 Renewable Sustainable Energy Rev. 64 635

Google Scholar

Google Scholar

[11] Eddine A N, Chalet D, Faure X, Faure X, Chessé P 2018 Energy 143 682

Google Scholar

Google Scholar

[12] Haddad C, Périlhon C, Danlos A, François M X, Descombes G 2014 Energy Procedia 50 1056

Google Scholar

Google Scholar

[13] Shen Z G, Tian L L, Liu X 2019 Energy Convers. Manag. 195 1138

Google Scholar

Google Scholar

[14] Holgate T C, Bennett R, Hammel T, Caillat T, Keyser S, Sievers B 2015 J. Electron. Mater. 44 1814

Google Scholar

Google Scholar

[15] 柏胜强, 廖锦城, 夏绪贵, 陈立东 2020 深空探测学报 7 525

Google Scholar

Google Scholar

Bai S Q, Liao J C, Xia X G, Chen L D 2020 J. Deep Space Explor. 7 525

Google Scholar

Google Scholar

[16] Xiao Y, Zhao L D 2018 npj Quantum Mater. 3 55

Google Scholar

Google Scholar

[17] Rogl G, Rogl P 2017 Curr. Opin. Green Sustainable Chem. 4 50

Google Scholar

Google Scholar

[18] Huang L H, Zhang Q Y, Yuan B, Xiang L, Yan X, Ren Z F 2016 Mater. Res. Bull. 76 107

Google Scholar

Google Scholar

[19] Gelbstein Y, Gotesman G, Lishzinker Y, Dashevsky Z, Dariel M P 2008 Scr. Mater. 58 251

Google Scholar

Google Scholar

[20] Rull-Bravo M, Moure A, Fernández J F, Martín-González M 2015 RSC Adv. 5 41653

Google Scholar

Google Scholar

[21] Rogl G, Grytsiv A, Gürth M, Tavassoli A, Ebner C, Wünschek A, Puchegger S, Soprunyuk V, Schranz W, Bauer E, Müller H, Zehetbauer M, Rogl P 2016 Acta Mater. 107 178

Google Scholar

Google Scholar

[22] Silpawilawan W, Kurosaki K, Ohishi Y, Muta H, Yamanaka S 2017 J. Mater. Chem. C 5 6677

Google Scholar

Google Scholar

[23] Poon S J 2018 Metals 8 989

Google Scholar

Google Scholar

[24] He H L, Zhao Y B, Ren H R, Niu C P, Fang Z X, Wu Y, Rong M Z 2022 Appl. Therm. Eng. 215 118900

Google Scholar

Google Scholar

[25] Nozariasbmarz A, Saparamadu U, Li W, Kang H B, Dettor C, Zhu H T, Poudel B, Priya S 2021 J. Power Sources 493 229695

Google Scholar

Google Scholar

[26] Yu J J, Xing Y F, Hu C L, Huang Z J, Qiu Q Y, Wang C, Xia K Y, Wang Z Y, Bai S Q, Zhao X B, Chen L D, Zhu T J 2020 Adv. Energy Mater. 10 2000888

Google Scholar

Google Scholar

[27] Xing Y F, Liu R H, Liao J C, Zhang Q H, Xia X G, Wang C, Huang H, Chu J, Gu M, Zhu T J, Zhu C X, Xu F F, Yao D X, Zeng Y P, Bai S Q, Uher C, Chen L D 2019 Energy Environ. Sci. 12 3390

Google Scholar

Google Scholar

[28] 苗圃, 韩屾, 高梓恒, 付晨光, 朱铁军 2022 中国材料进展 41 1029

Google Scholar

Google Scholar

Miao P, Han S, Gao Z H, Fu C G, Zhu T J 2022 Mater. Chin. 41 1029

Google Scholar

Google Scholar

[29] Moh'd A A N, Tashtoush B M, Jaradat A A 2015 Energy 90 1239

Google Scholar

Google Scholar

[30] Chen W H, Huang S R, Wang X D, Wu P H, Lin Y L 2017 Energy 133 257

Google Scholar

Google Scholar

[31] Meng F K, Chen L G, Sun F R 2016 Low-Carbon Technol. 11 375

Google Scholar

Google Scholar

[32] Ouyang Z, Li D 2016 Sci. Rep. 6 24123

Google Scholar

Google Scholar

-

图 7 热端温度分别为300 ℃, 400 ℃, 500 ℃, 600 ℃时单对器件在不同电流负载下的特性变化 (a) 电压; (b) 输出功率; (c) 转换效率. (d) 本文不同温差下的最大转换效率与其他文献中报道的半赫斯勒器件的最大效率的对比

Fig. 7. Characteristic curves of a single pair of devices under different current loads when the hot end temperatures are 300 ℃, 400 ℃, 500 ℃ and 600 ℃ respectively: (a) Voltage; (b) output power; (c) conversion efficiency. (d) Comparison between the maximum conversion efficiency under different temperature differences in this work and other literatures.

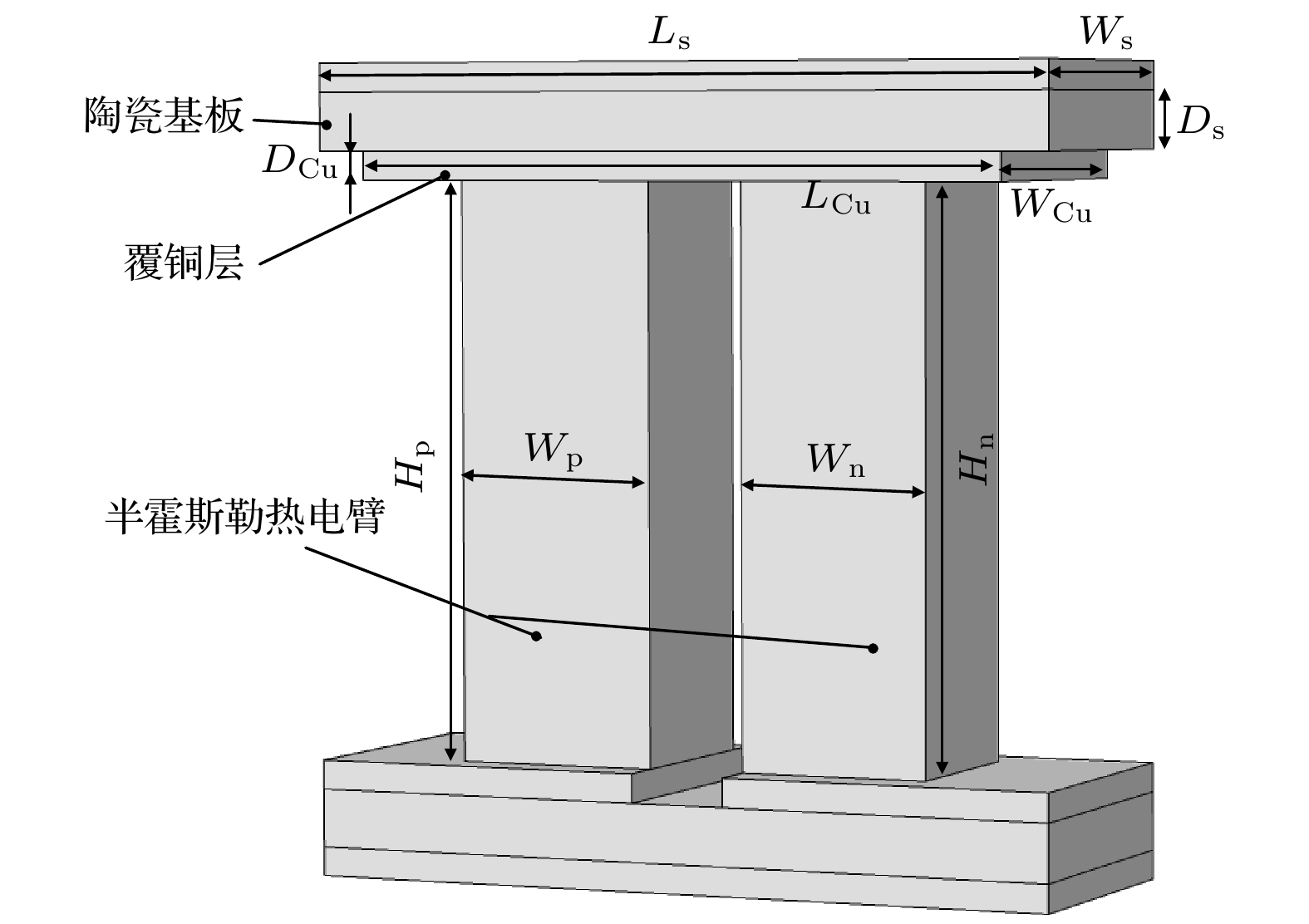

表 1 单对器件建模参数

Table 1. Single pair device’s modeling parameters.

参 数 数 值 陶瓷基板长度Ls/mm 8 陶瓷基板宽度Ws/mm 3 陶瓷基板厚度Ds/mm 0.6 覆铜层长度LCu/mm 7 覆铜层宽度WCu/mm 3 覆铜层厚度DCu/mm 0.3 P型热电臂宽度Wp/mm 2.1 P型热电臂高度Hp/mm 6 N型热电臂宽度Wn/mm 2 N型热电臂宽度Hn/mm 6 表 2 热电材料物性参数

Table 2. Physical parameters of thermoelectric materials.

参数 温度相关表达式 P型 S/(μV·K–1) $-2.37478\times 10^{-13}T^3+2.00399\times 10^{-10} T^2 + 1.45119\times 10^{-7} T + 0.0000646145 $ σ/(S⋅cm–1) $-6.40884\times 10^{-9}T^3+0.0000127913T^2 -0.00898933T + 6.35472 $ κ/(W⋅m–1⋅K–1) $-0.000461149T^3 + 1.02189T^2 -825.929T +327500.0 $ N型 S/(μV⋅K–1) $2.37915\times 10^{-13}T^3 -1.39249\times 10^{-10}T^2 -2.14638\times 10^{-7} T -0.0000648974 $ σ/(S⋅cm–1) $-1.25489\times 10^{-8} T^3 + 0.0000285845T^2 -0.0223619T +10.403 $ κ/(W⋅m–1⋅K–1) $0.0000727835T^3 + 0.0782446T^2 -271.589T +266246.0$ -

[1] 王雅宁, 陈少平, 樊文浩, 郭敬云, 吴玉程, 王文先 2020 69 246801

Google Scholar

Google Scholar

Wang Y N, Chen S P, Fan W H, Guo J Y, Wu Y C, Wang W X 2020 Acta Phys. Sin. 69 246801

Google Scholar

Google Scholar

[2] 杨士冠, 林鑫, 何俊松, 翟立军, 程林, 吕明豪, 刘虹霞, 张艳, 孙志刚 2023 72 228401

Google Scholar

Google Scholar

Yang S G, Lin X, He J S, Zhai L J, Chen L, Lü M H, Liu H X, Zhang Y, Sun Z G 2023 Acta Phys. Sin. 72 228401

Google Scholar

Google Scholar

[3] 谢忠祥, 喻霞, 贾聘真, 陈学坤, 邓元祥, 张勇, 周五星 2023 72 124401

Google Scholar

Google Scholar

Xie Z X, Yu X, Jia P Z, Chen X K, Deng Y X, Zhang Y, Zhou W X 2023 Acta Phys. Sin. 72 124401

Google Scholar

Google Scholar

[4] He H L, Fang Z X, Niu C P, Wu Y, Rong M Z 2021 Energy Convers. Manag. 241 114314

Google Scholar

Google Scholar

[5] Yu K, Wu Y, He H L, Niu C P, Rong M Z, Wu D, Liu S X, Zhang Y Q 2021 J. Alloys Compd. 885 161378

Google Scholar

Google Scholar

[6] Zhang P, Ouyang T, Tang C, He C Y, Li J, Zhang C X, Zhong J X 2021 Chin. Phys. B 30 128401

Google Scholar

Google Scholar

[7] 许易, 许小言, 张薇, 欧阳滔, 唐超 2019 68 247202

Google Scholar

Google Scholar

Xu Y, Xu X Y, Zhang W, Ouyang T, Tang C 2019 Acta Phys. Sin. 68 247202

Google Scholar

Google Scholar

[8] Lu J Y, Cui C F, Ouyang T, Li J, He C Y, Tang C, Zhong J X 2023 Chin. Phys. B 32 048401

Google Scholar

Google Scholar

[9] Zhang P, Ouyang T, Tang C, He C Y, Li J, Zhang C X, Zhong J X 2020 Chin. Phys. B 29 118401

Google Scholar

Google Scholar

[10] Ovik R, Long B D, Barma M C, Riaz M, Sabri M F M, Said S M, Saidur R 2016 Renewable Sustainable Energy Rev. 64 635

Google Scholar

Google Scholar

[11] Eddine A N, Chalet D, Faure X, Faure X, Chessé P 2018 Energy 143 682

Google Scholar

Google Scholar

[12] Haddad C, Périlhon C, Danlos A, François M X, Descombes G 2014 Energy Procedia 50 1056

Google Scholar

Google Scholar

[13] Shen Z G, Tian L L, Liu X 2019 Energy Convers. Manag. 195 1138

Google Scholar

Google Scholar

[14] Holgate T C, Bennett R, Hammel T, Caillat T, Keyser S, Sievers B 2015 J. Electron. Mater. 44 1814

Google Scholar

Google Scholar

[15] 柏胜强, 廖锦城, 夏绪贵, 陈立东 2020 深空探测学报 7 525

Google Scholar

Google Scholar

Bai S Q, Liao J C, Xia X G, Chen L D 2020 J. Deep Space Explor. 7 525

Google Scholar

Google Scholar

[16] Xiao Y, Zhao L D 2018 npj Quantum Mater. 3 55

Google Scholar

Google Scholar

[17] Rogl G, Rogl P 2017 Curr. Opin. Green Sustainable Chem. 4 50

Google Scholar

Google Scholar

[18] Huang L H, Zhang Q Y, Yuan B, Xiang L, Yan X, Ren Z F 2016 Mater. Res. Bull. 76 107

Google Scholar

Google Scholar

[19] Gelbstein Y, Gotesman G, Lishzinker Y, Dashevsky Z, Dariel M P 2008 Scr. Mater. 58 251

Google Scholar

Google Scholar

[20] Rull-Bravo M, Moure A, Fernández J F, Martín-González M 2015 RSC Adv. 5 41653

Google Scholar

Google Scholar

[21] Rogl G, Grytsiv A, Gürth M, Tavassoli A, Ebner C, Wünschek A, Puchegger S, Soprunyuk V, Schranz W, Bauer E, Müller H, Zehetbauer M, Rogl P 2016 Acta Mater. 107 178

Google Scholar

Google Scholar

[22] Silpawilawan W, Kurosaki K, Ohishi Y, Muta H, Yamanaka S 2017 J. Mater. Chem. C 5 6677

Google Scholar

Google Scholar

[23] Poon S J 2018 Metals 8 989

Google Scholar

Google Scholar

[24] He H L, Zhao Y B, Ren H R, Niu C P, Fang Z X, Wu Y, Rong M Z 2022 Appl. Therm. Eng. 215 118900

Google Scholar

Google Scholar

[25] Nozariasbmarz A, Saparamadu U, Li W, Kang H B, Dettor C, Zhu H T, Poudel B, Priya S 2021 J. Power Sources 493 229695

Google Scholar

Google Scholar

[26] Yu J J, Xing Y F, Hu C L, Huang Z J, Qiu Q Y, Wang C, Xia K Y, Wang Z Y, Bai S Q, Zhao X B, Chen L D, Zhu T J 2020 Adv. Energy Mater. 10 2000888

Google Scholar

Google Scholar

[27] Xing Y F, Liu R H, Liao J C, Zhang Q H, Xia X G, Wang C, Huang H, Chu J, Gu M, Zhu T J, Zhu C X, Xu F F, Yao D X, Zeng Y P, Bai S Q, Uher C, Chen L D 2019 Energy Environ. Sci. 12 3390

Google Scholar

Google Scholar

[28] 苗圃, 韩屾, 高梓恒, 付晨光, 朱铁军 2022 中国材料进展 41 1029

Google Scholar

Google Scholar

Miao P, Han S, Gao Z H, Fu C G, Zhu T J 2022 Mater. Chin. 41 1029

Google Scholar

Google Scholar

[29] Moh'd A A N, Tashtoush B M, Jaradat A A 2015 Energy 90 1239

Google Scholar

Google Scholar

[30] Chen W H, Huang S R, Wang X D, Wu P H, Lin Y L 2017 Energy 133 257

Google Scholar

Google Scholar

[31] Meng F K, Chen L G, Sun F R 2016 Low-Carbon Technol. 11 375

Google Scholar

Google Scholar

[32] Ouyang Z, Li D 2016 Sci. Rep. 6 24123

Google Scholar

Google Scholar

计量

- 文章访问数: 367

- PDF下载量: 4

- 被引次数: 0

下载:

下载: