-

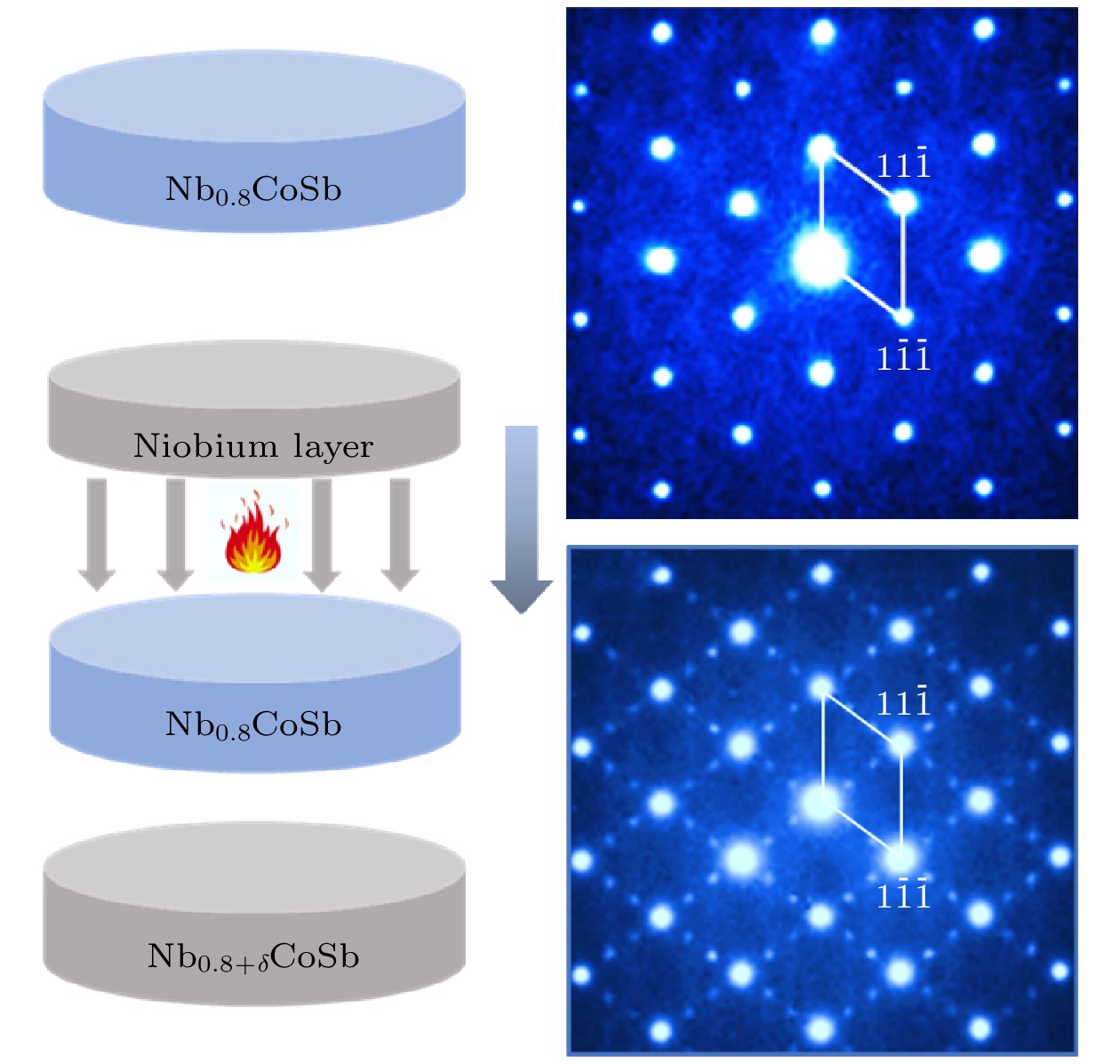

本文以覆盖Nb薄膜的半赫斯勒合金Nb0.8CoSb为研究对象, 成功利用原位加热透射电镜技术在高温下诱导Nb扩散, 致使Nb0.8CoSb转变为有序度更高的Nb0.8+δCoSb, 即倒空间漫散带代表的短程有序结构转变为超结构衍射点代表的长程有序结构. 进一步的分析表明, 这种超结构的调制波矢为

$ q= ({a}^{*}+{b}^{*}-{c}^{*})/{3} $ , 其形成主要源自于Sb和Nb组分的变化. 与离位合成的Nb0.84CoSb的微观结构进行对比, 发现二者中超结构不同, 这种超结构的调制波矢为$ q= ({2a}^{*}-2{c}^{*})/3 $ , 主要源自于Nb组分的变化. 此项研究揭示了组分导致超结构的多样性以及半赫斯勒合金结构相变的复杂性, 丰富了对半赫斯勒合金材料的理解, 对相变材料的设计以及功能调控具有重要指导意义.This study focuses on the investigation of Nb0.8CoSb half-Heusler alloy covered with Nb films. By employing in-situ heating transmission electron microscopy (TEM) technique, diffusion of Nb is observed at high temperature, showing the ordering transformation from Nb0.8CoSb to Nb0.8+δCoSb. Through observations of high-angle annular dark-field (HAADF) images and selected-area electron diffraction (SAED) patterns, it is found that under elevated temperatures, the diffuse streaks representing short-range disorder in Nb0.8CoSb sample transform into superlattice diffraction spots representing long-range order. The modulation wave vector of this superstructure is determined to be $ q={1}/{3}({a}^{*}+{b}^{*}-{c}^{*}) $ . This structural evolution primarily arises from the diffusion of Nb atoms from the Nb film into the Nb0.8CoSb sample at high temperature, leading to compositional changes in Sb and Nb.Further comparative analysis reveals significant differences between in-situ synthesized Nb0.8+δCoSb samples and ex-situ synthesized Nb0.84CoSb samples despite both exhibiting superstructures. In the ex-situ synthesized Nb0.84CoSb, the modulation wave vector of the superstructure is $ q={1}/{3}({2a}^{*}-2{c}^{*}) $ , which is mainly attributed to Nb compositional variations. Moreover, the superstructure in Nb0.84CoSb sample can remain stable from room temperature to high temperature, whereas in Nb0.8+δCoSb samples, it only exists at elevated temperatures and gradually weakens as the temperature decreases, suggesting that it may be a metastable structure between Nb0.8CoSb and Nb0.84CoSb.This study reveals the diversity of superstructures induced by compositional variations and the complexity of structural phase transitions in half-Heusler alloys, enriching the understanding of these materials and providing important guidance for the design and functional control of phase-change materials. -

Keywords:

- solid-state phase transition /

- in-situ heating /

- short-range ordering /

- half-Heusler alloy

[1] Lu N P, Zhang P F, Zhang Q H, Qiao R M, He Q, Li H B, Wang Y J, Guo J W, Zhang D, Duan Z, Li Z L, Wang M, Yang S Z, Yan M Z, Arenholz E, Zhou S Y, Yang W L, Gu L, Nan C W, Wu J, Tokura Y, Yu P 2017 Nature 546 124

Google Scholar

Google Scholar

[2] Yun H, Zhang D L, Birol T, Wang J P, Mkhoyan K A 2023 Nano Lett. 23 7576

Google Scholar

Google Scholar

[3] Tracy C L, Park S, Rittman D R, Zinkle S J, Bei H, Lang M, Ewing R C, Mao W L 2017 Nat. Commun. 8 15634

Google Scholar

Google Scholar

[4] Liu T, Dou X Y, Xu Y H, Chen Y J, Han Y S 2020 Research 2020 4370817

[5] Sato T, Yoshikawa K, Zhao W, Kobayashi T, Rajendra H B, Yonemura M, Yabuuchi N 2021 Energy Mater. Adv. 2021 9857563

[6] He R J, Lei S, Liu M C, Qin M S, Zhong W, Cheng S J, Xie J 2022 Energy Mater. Adv. 2022 0003

[7] Zhu W, Ren L, Li Y H, Lu C, Lin X, Zhang Q Y, Yang X, Hu Z G, Cheng T, Zhao Y Y, Zou J X 2023 Energy Mater. Adv. 4 0069

Google Scholar

Google Scholar

[8] Kozlovskiy A L, Kenzhina I E, Zdorovets M V 2020 Ceram. Int. 46 10262

Google Scholar

Google Scholar

[9] Yu C L, Li G, Kumar S, Yang K, Jin R C 2014 Adv. Mater. 26 892

Google Scholar

Google Scholar

[10] Wu L Z, Hu H C, Xu Y, Jiang S, Chen M, Zhong Q X, Yang D, Liu Q P, Zhao Y, Sun B Q, Zhang Q, Yin Y D 2017 Nano Lett. 17 5799

Google Scholar

Google Scholar

[11] Ito H, Muromoto M, Kurenuma S, Ishizaka S, Kitamura N, Sato H, Seki T 2013 Nat. Commun. 4 2009

Google Scholar

Google Scholar

[12] Tezuka N, Ikeda N, Miyazaki A, Sugimoto S, Kikuchi M, Inomata K 2006 Appl. Phys. Lett. 89 112514

Google Scholar

Google Scholar

[13] Goll G, Marz M, Hamann A, Tomanic T, Grube K, Yoshino T, Takabatake T 2008 Physica B 403 1065

Google Scholar

Google Scholar

[14] Opeil C P, Mihaila B, Schulze R K, Mañosa L, Planes A, Hults W L, Fisher R A, Riseborough P S, Littlewood P B, Smith J L, Lashley J C 2008 Phys. Rev. Lett. 100 165703

Google Scholar

Google Scholar

[15] Liu Z H, Zhang M, Cui Y T, Zhou Y Q, Wang W H, Wu G H, Zhang X X, Xiao G 2003 Appl. Phys. Lett. 82 424

Google Scholar

Google Scholar

[16] Sutou Y, Imano Y, Koeda N, Omori T, Kainuma R, Ishida K, Oikawa K 2004 Appl. Phys. Lett. 85 4358

Google Scholar

Google Scholar

[17] Hu F X, Shen B G, Sun J R, Wu G H 2001 Phys. Rev. B 64 132412

Google Scholar

Google Scholar

[18] Hu F X, Shen B G, Sun J R 2000 Appl. Phys. Lett. 76 3460

Google Scholar

Google Scholar

[19] Li Z, Jing C, Chen J P, Yuan S J, Cao S X, Zhang J C 2007 Appl. Phys. Lett. 91 112505

Google Scholar

Google Scholar

[20] Khan M, Dubenko I, Stadler S, Ali N 2007 Appl. Phys. Lett. 91 072510

Google Scholar

Google Scholar

[21] Xia K Y, Nan P F, Tan S H, Wang Y M, Ge B H, Zhang W Q, Anand S, Zhao X B, Snyder G J, Zhu T J 2019 Energy Environ. Sci. 12 1568

Google Scholar

Google Scholar

[22] Nan P F, Wu K P, Liu Y M, Xia K Y, Zhu T J, Lin F, He J, Ge B H 2020 Nanoscale 12 21624

Google Scholar

Google Scholar

[23] Liu Y, Fu C, Xia K Y, Yu J, Zhao X, Pan H F, Felser C, Zhu T J 2018 Adv. Mater. 30 1800881

Google Scholar

Google Scholar

[24] Xia K Y, Liu Y, Anand S, Snyder G J, Xin J, Yu J, Zhao X, Zhu T 2018 Adv. Funct. Mater. 28 1705845

Google Scholar

Google Scholar

[25] Pu Y H, He B W, Niu Y M, Liu X, Zhang B S 2023 Research 6 0043

Google Scholar

Google Scholar

[26] Zhang H T, Wang W, Sun J, Zhong L, He L B, Sun L T 2022 Research 2022 9834636

[27] 南鹏飞, 杨丽霞, 王玉梅, 夏凯阳, 朱铁军, 葛炳辉 2019 电子显微学报 38 477

Google Scholar

Google Scholar

Nan P F, Yang L X, Wang Y M, Xia K Y, Zhu T J, Ge B H 2019 J. Chin. Electron Microsc. Soc. 38 477

Google Scholar

Google Scholar

[28] Pennycook S J, Boatner L A 1988 Nature 336 565

Google Scholar

Google Scholar

[29] Pennycook S J 1989 Ultramicroscopy 30 58

Google Scholar

Google Scholar

-

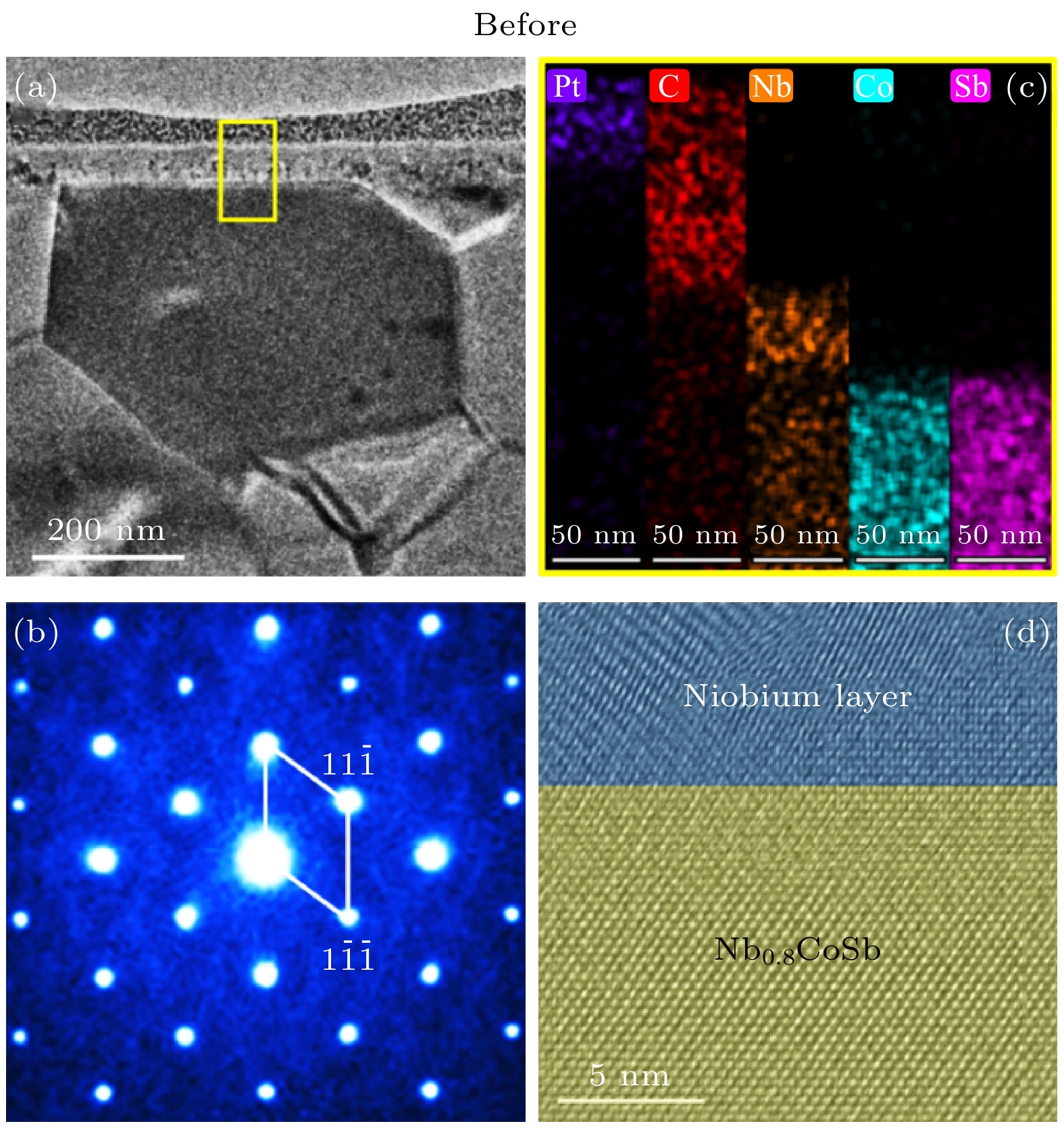

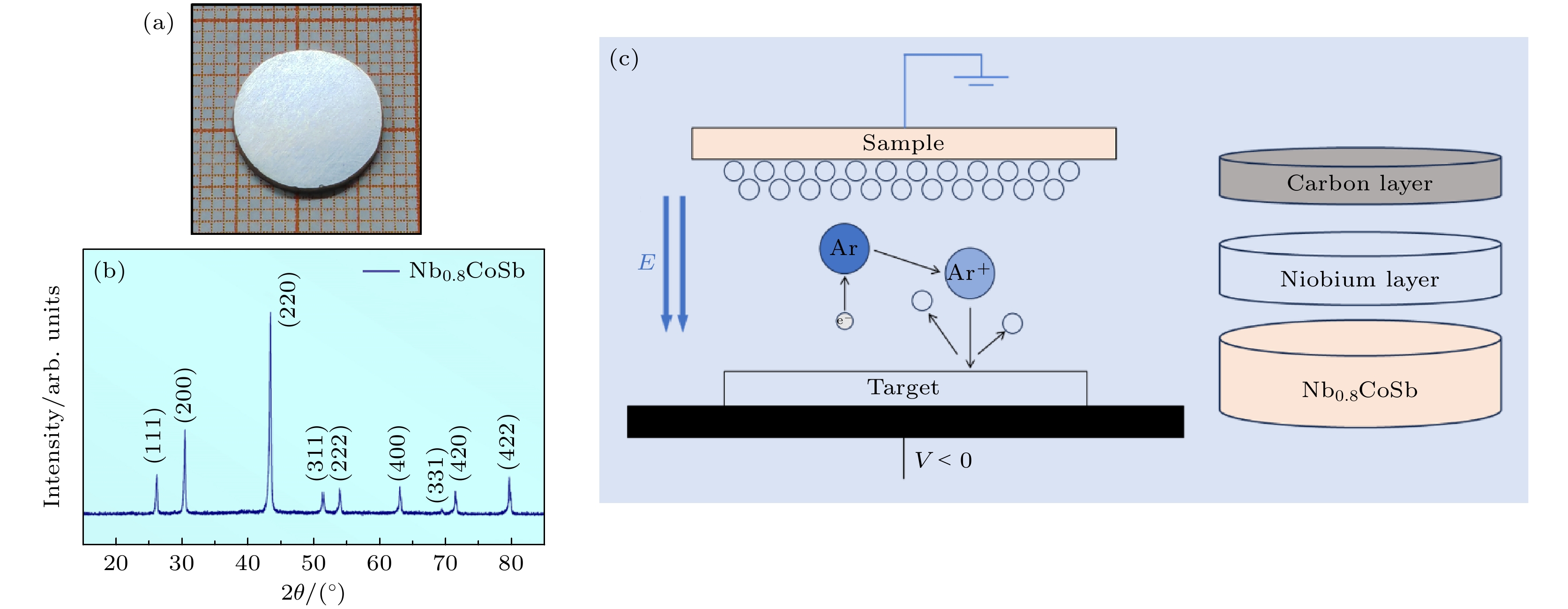

图 1 (a) 离位制备的Nb0.8CoSb合金的宏观形貌; (b) 离位制备的Nb0.8CoSb合金的XRD图谱; (c) 直流磁控溅射技术镀膜流程图

Fig. 1. (a) Macroscopic morphology of the ex-situ prepared Nb0.8CoSb alloy; (b) XRD of the ex-situ prepared Nb0.8CoSb alloy; (c) schematic diagram of the magnetron sputtering deposition process using direct current magnetron sputtering.

图 2 (a), (b) 原位加热实验Nb0.8CoSb样品大角度环形暗场(HAADF)像以及相应的[110]带轴的选区电子衍射花样; (c) 图 (a) 中黄色选框处能量色散谱图; (d) Nb膜与Nb0.8CoSb的界面区域的高分辨TEM像

Fig. 2. (a) High-angle annular dark-field (HAADF) image of the Nb0.8CoSb sample before in-situ heating experiments; (b) corresponding selected-area electron diffraction patterns along the [110] zone axis; (c) energy dispersive spectroscopy (EDS) map at the yellow-boxed region in Fig. (a); (d) HRTEM image of the interface region between the Nb film and Nb0.8CoSb.

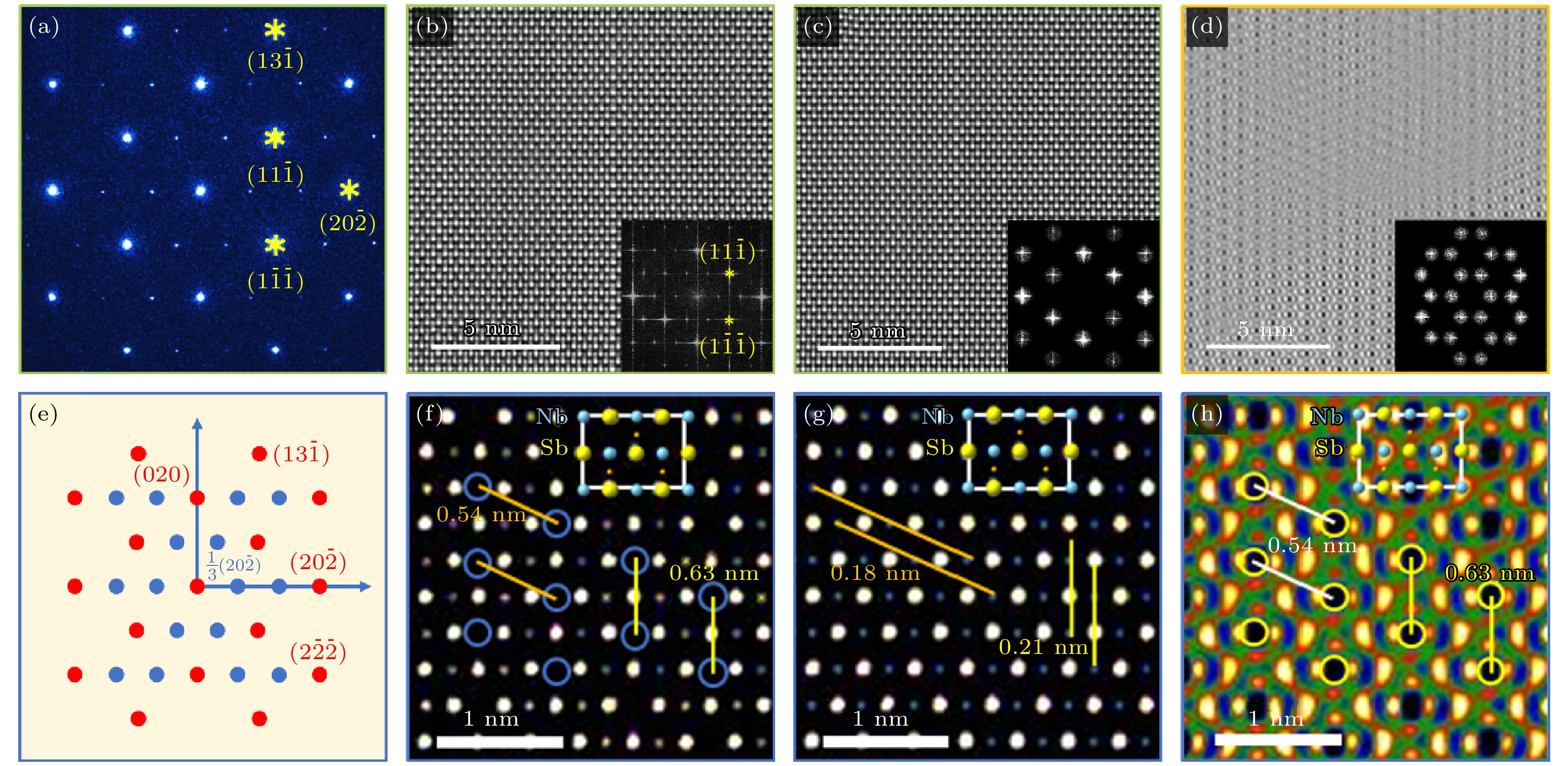

图 3 (a)—(c) 原位加热实验样品HAADF像及橙色框区域的[110]带轴选区电子衍射花样及其示意图; (d) 图 (a) 中橙色框区域的高分辨TEM像

Fig. 3. (a)–(c) HAADF image of the sample during in-situ heating experiment, the corresponding selected-area electron diffraction patterns along the [110] zone axis, and the schematic diagram of superlattice diffraction spots; (d) HRTEM image of the orange-boxed region in Fig. (a).

图 4 (a) Nb0.8+δCoSb [110]取向的滤波像; (b), (c) 分别仅包含主衍射点信息和超结构衍射信息的滤波像; (d)—(f) 图(a)—(c)的放大像

Fig. 4. (a) Filtered image of Nb0.8+δCoSb [110] orientation; (b), (c) filtered images containing only main diffraction spot information and superlattice diffraction information, respectively; (d)–(f) magnified views of images in (a)–(c).

图 5 (a) Nb0.84CoSb [110]取向的选区电子衍射花样; (b) Nb0.84CoSb [110]取向的滤波像; (c), (d) 分别仅包含主衍射点信息和超结构衍射信息的滤波像; (e) Nb0.84CoSb超结构衍射点示意图; (f)—(h) 图 (b)—(d) 的放大像

Fig. 5. (a) Selected area electron diffraction pattern of Nb0.84CoSb [110] orientation; (b) filtered image of Nb0.84CoSb [110] orientation; (c), (d) filtered images containing only main diffraction spot information and superlattice diffraction information, respectively; (e) schematic diagram of superlattice diffraction spots in Nb0.84CoSb; (f)–(h) magnified views of images in Figs. (b)–(d).

-

[1] Lu N P, Zhang P F, Zhang Q H, Qiao R M, He Q, Li H B, Wang Y J, Guo J W, Zhang D, Duan Z, Li Z L, Wang M, Yang S Z, Yan M Z, Arenholz E, Zhou S Y, Yang W L, Gu L, Nan C W, Wu J, Tokura Y, Yu P 2017 Nature 546 124

Google Scholar

Google Scholar

[2] Yun H, Zhang D L, Birol T, Wang J P, Mkhoyan K A 2023 Nano Lett. 23 7576

Google Scholar

Google Scholar

[3] Tracy C L, Park S, Rittman D R, Zinkle S J, Bei H, Lang M, Ewing R C, Mao W L 2017 Nat. Commun. 8 15634

Google Scholar

Google Scholar

[4] Liu T, Dou X Y, Xu Y H, Chen Y J, Han Y S 2020 Research 2020 4370817

[5] Sato T, Yoshikawa K, Zhao W, Kobayashi T, Rajendra H B, Yonemura M, Yabuuchi N 2021 Energy Mater. Adv. 2021 9857563

[6] He R J, Lei S, Liu M C, Qin M S, Zhong W, Cheng S J, Xie J 2022 Energy Mater. Adv. 2022 0003

[7] Zhu W, Ren L, Li Y H, Lu C, Lin X, Zhang Q Y, Yang X, Hu Z G, Cheng T, Zhao Y Y, Zou J X 2023 Energy Mater. Adv. 4 0069

Google Scholar

Google Scholar

[8] Kozlovskiy A L, Kenzhina I E, Zdorovets M V 2020 Ceram. Int. 46 10262

Google Scholar

Google Scholar

[9] Yu C L, Li G, Kumar S, Yang K, Jin R C 2014 Adv. Mater. 26 892

Google Scholar

Google Scholar

[10] Wu L Z, Hu H C, Xu Y, Jiang S, Chen M, Zhong Q X, Yang D, Liu Q P, Zhao Y, Sun B Q, Zhang Q, Yin Y D 2017 Nano Lett. 17 5799

Google Scholar

Google Scholar

[11] Ito H, Muromoto M, Kurenuma S, Ishizaka S, Kitamura N, Sato H, Seki T 2013 Nat. Commun. 4 2009

Google Scholar

Google Scholar

[12] Tezuka N, Ikeda N, Miyazaki A, Sugimoto S, Kikuchi M, Inomata K 2006 Appl. Phys. Lett. 89 112514

Google Scholar

Google Scholar

[13] Goll G, Marz M, Hamann A, Tomanic T, Grube K, Yoshino T, Takabatake T 2008 Physica B 403 1065

Google Scholar

Google Scholar

[14] Opeil C P, Mihaila B, Schulze R K, Mañosa L, Planes A, Hults W L, Fisher R A, Riseborough P S, Littlewood P B, Smith J L, Lashley J C 2008 Phys. Rev. Lett. 100 165703

Google Scholar

Google Scholar

[15] Liu Z H, Zhang M, Cui Y T, Zhou Y Q, Wang W H, Wu G H, Zhang X X, Xiao G 2003 Appl. Phys. Lett. 82 424

Google Scholar

Google Scholar

[16] Sutou Y, Imano Y, Koeda N, Omori T, Kainuma R, Ishida K, Oikawa K 2004 Appl. Phys. Lett. 85 4358

Google Scholar

Google Scholar

[17] Hu F X, Shen B G, Sun J R, Wu G H 2001 Phys. Rev. B 64 132412

Google Scholar

Google Scholar

[18] Hu F X, Shen B G, Sun J R 2000 Appl. Phys. Lett. 76 3460

Google Scholar

Google Scholar

[19] Li Z, Jing C, Chen J P, Yuan S J, Cao S X, Zhang J C 2007 Appl. Phys. Lett. 91 112505

Google Scholar

Google Scholar

[20] Khan M, Dubenko I, Stadler S, Ali N 2007 Appl. Phys. Lett. 91 072510

Google Scholar

Google Scholar

[21] Xia K Y, Nan P F, Tan S H, Wang Y M, Ge B H, Zhang W Q, Anand S, Zhao X B, Snyder G J, Zhu T J 2019 Energy Environ. Sci. 12 1568

Google Scholar

Google Scholar

[22] Nan P F, Wu K P, Liu Y M, Xia K Y, Zhu T J, Lin F, He J, Ge B H 2020 Nanoscale 12 21624

Google Scholar

Google Scholar

[23] Liu Y, Fu C, Xia K Y, Yu J, Zhao X, Pan H F, Felser C, Zhu T J 2018 Adv. Mater. 30 1800881

Google Scholar

Google Scholar

[24] Xia K Y, Liu Y, Anand S, Snyder G J, Xin J, Yu J, Zhao X, Zhu T 2018 Adv. Funct. Mater. 28 1705845

Google Scholar

Google Scholar

[25] Pu Y H, He B W, Niu Y M, Liu X, Zhang B S 2023 Research 6 0043

Google Scholar

Google Scholar

[26] Zhang H T, Wang W, Sun J, Zhong L, He L B, Sun L T 2022 Research 2022 9834636

[27] 南鹏飞, 杨丽霞, 王玉梅, 夏凯阳, 朱铁军, 葛炳辉 2019 电子显微学报 38 477

Google Scholar

Google Scholar

Nan P F, Yang L X, Wang Y M, Xia K Y, Zhu T J, Ge B H 2019 J. Chin. Electron Microsc. Soc. 38 477

Google Scholar

Google Scholar

[28] Pennycook S J, Boatner L A 1988 Nature 336 565

Google Scholar

Google Scholar

[29] Pennycook S J 1989 Ultramicroscopy 30 58

Google Scholar

Google Scholar

计量

- 文章访问数: 4064

- PDF下载量: 175

- 被引次数: 0

下载:

下载: