-

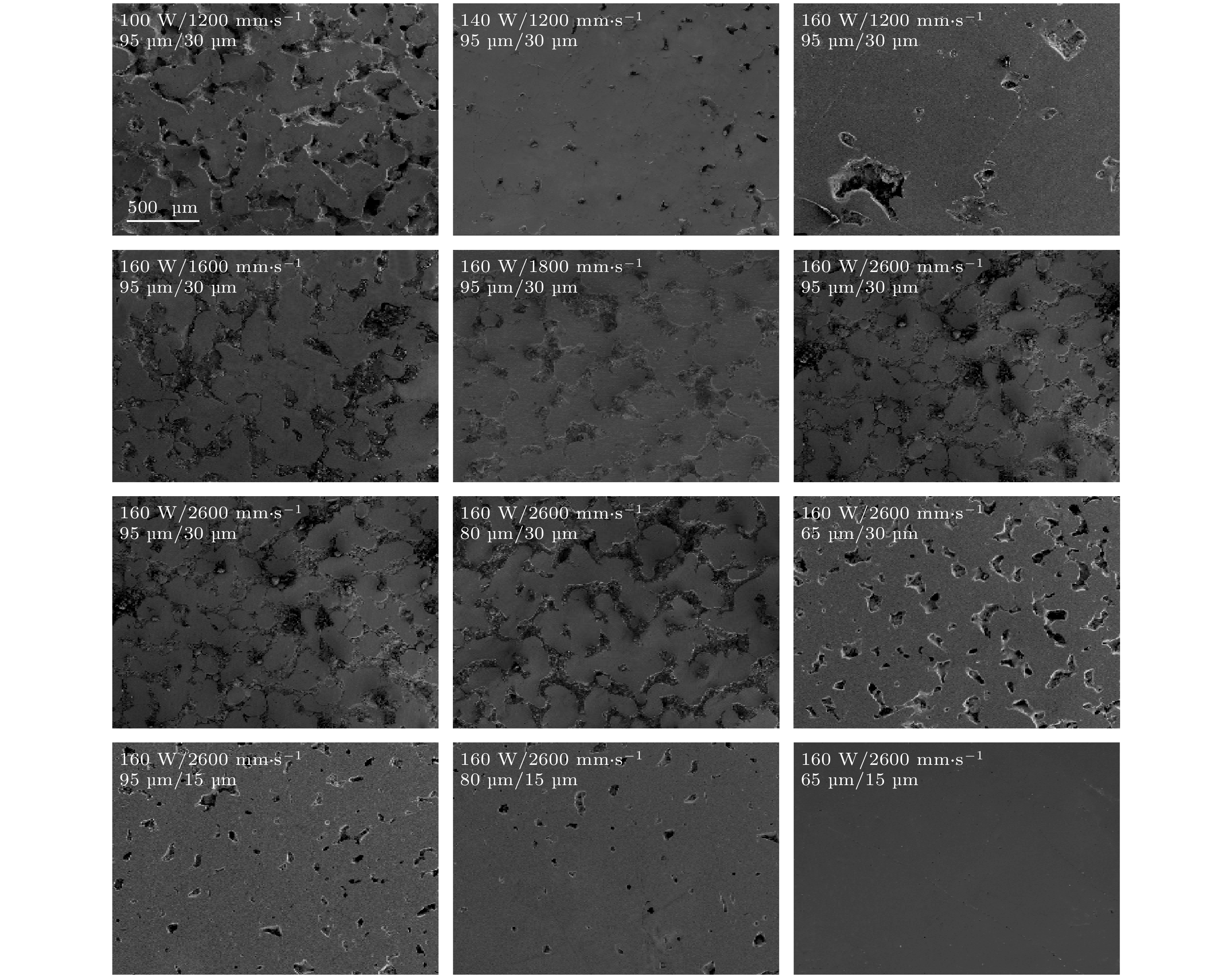

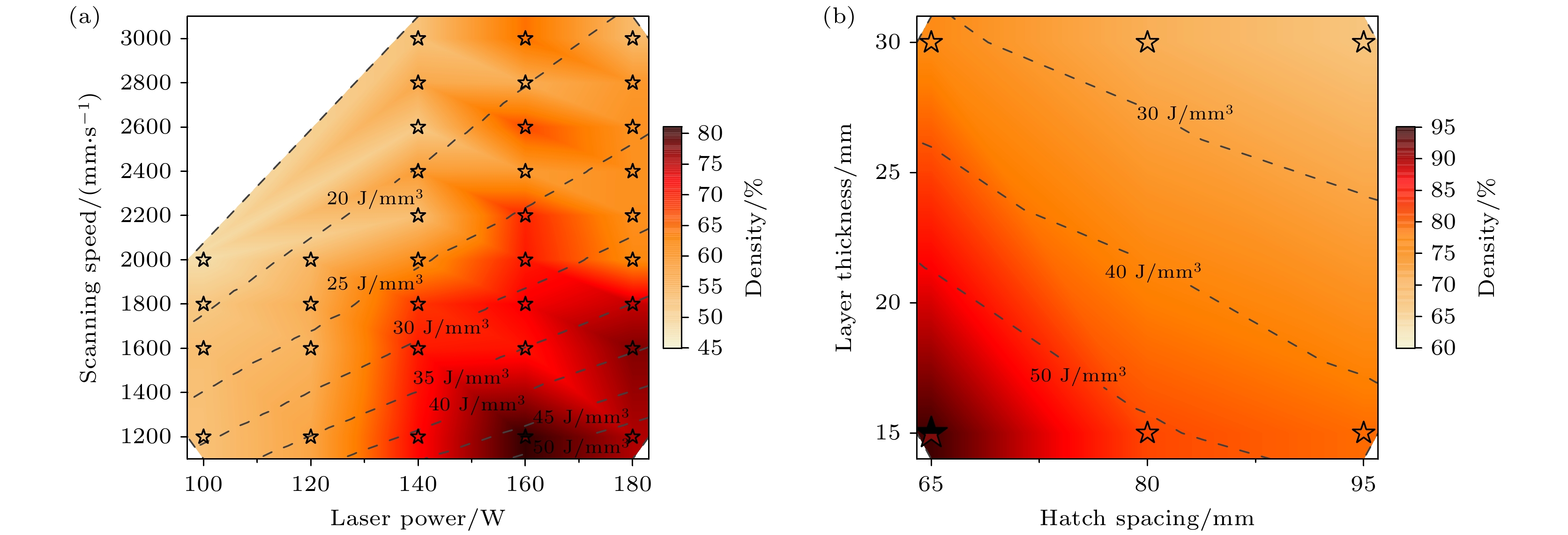

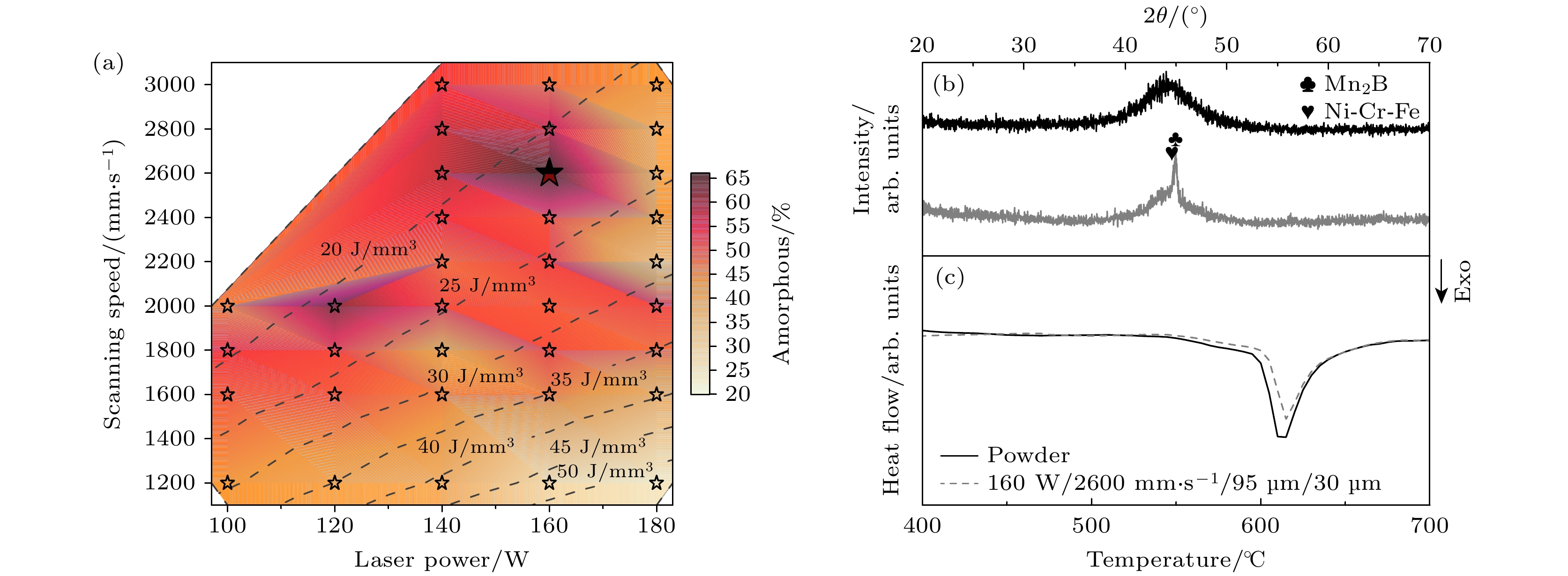

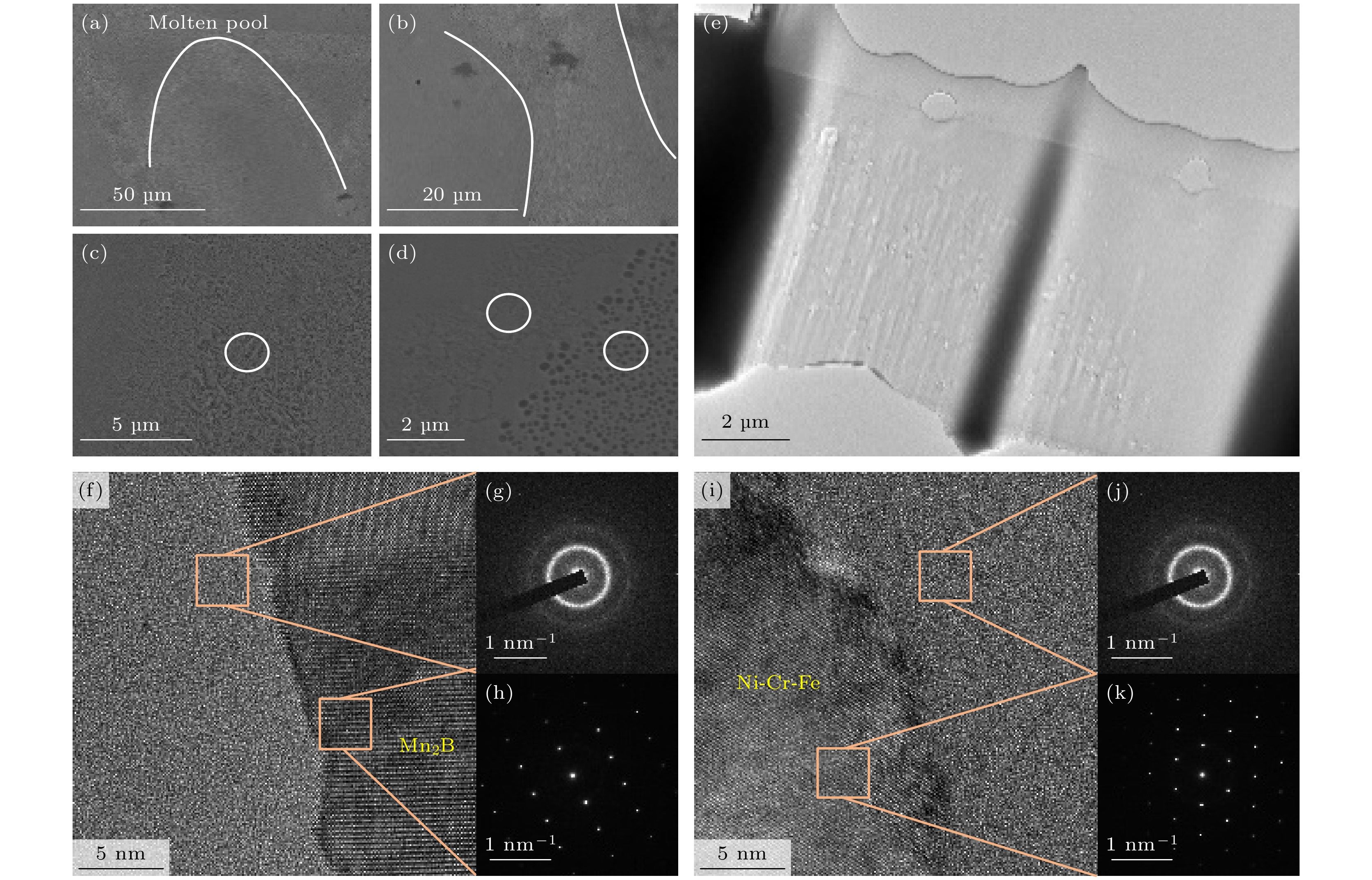

铁基非晶合金具有低矫顽力、低损耗等优异性能, 但受制于非晶形成能力和力学性能限制, 难以制备复杂结构器件. 3D打印理论上可以制备任意结构的器件. 本文利用选择性激光熔化3D打印技术, 通过打印参数优化, 获得低能量输入熔池, 并提高熔池轨道和成型层的搭接质量, 成功克服制备过程中非晶相与成型质量相互制约的瓶颈, 获得致密度为94.3%、矫顽力为0.5 Oe的铁基非晶合金, 且相比粉末, 所得铁基非晶合金的饱和磁化强度提升至0.89 T, 并制备出复杂结构的铁基非晶器件. 本文研究为3D打印高质量铁基非晶器件提供了新的思路, 对推动铁基非晶合金的应用具有重要意义.Fe-based amorphous alloys have exceptional properties such as low coercivity and core loss. In recent years, the development of amorphous alloys by using selective laser melting (SLM) technology has become the focus of attention. However, the glass-forming ability (GFA) and mechanical properties pose challenges for fabricating Fe-based amorphous alloys with complex geometries. This work aims to establish fundamental processing-(micro) structure-property links in Fe-based amorphous alloys processed by selective laser melting (SLM). With that purpose, a low-energy-input melt pool is achieved and the overlap quality between adjacent melt tracks and successive deposition layers is enhanced, through optimization of printing parameters. The Fe-based amorphous alloy is obtained with a high relative density of 94.3% and low coercivity of 0.5 Oe. Furthermore, the saturation magnetization of the printed alloy increases to 0.89 T compared with that of the powder feedstock. This work overcomes the mutual constraint between the GFA and part quality in fabricating of complex-structure Fe-based amorphous alloys, and is of great significance for promoting the application of Fe-based amorphous alloys.

[1] Wang Y J, Lucia O, Zhang Z, Guan Y S, Xu D G 2020 IET Power Electron. 13 1711

Google Scholar

Google Scholar

[2] Battal F, Balci S, Sefa I 2020 Meas. J. Int. Meas. Confed. 171 108848

Google Scholar

Google Scholar

[3] Mahesh M, Kumar K V, Abebe M, Udayakumar L, Mathankumar M 2021 Mater. Today Proc. 46 3888

Google Scholar

Google Scholar

[4] 姚可夫, 施凌翔, 陈双琴, 邵洋, 陈娜, 贾蓟丽 2018 67 016101

Google Scholar

Google Scholar

Yao K F, Shi L X, Chen S Q, Shao Y, Chen N, Jia J L 2018 Acta Phys. Sin. 67 016101

Google Scholar

Google Scholar

[5] Li H X, Lu Z C, Wang S L, Wu Y, Lu Z P 2019 Prog. Mater. Sci. 103 235

Google Scholar

Google Scholar

[6] Inoue A, Shinohara Y, Gook J S 1995 Mater. Trans. 36 1427

Google Scholar

Google Scholar

[7] Ponnambalam V, Poon S J, Shiflet G J 2004 J. Mater. Res. 19 1320

Google Scholar

Google Scholar

[8] Amiya K, Inoue A 2006 Mater. Trans. 47 1615

Google Scholar

Google Scholar

[9] 张雅楠, 王有骏, 孔令体, 李金富 2012 61 454

Google Scholar

Google Scholar

Zhang Y N, Wang Y J, Kong L T, Li J F 2012 Acta Phys. Sin. 61 454

Google Scholar

Google Scholar

[10] Suryanarayana C, Inoue A 2013 Int. Mater. Rev. 58 131

Google Scholar

Google Scholar

[11] 孙吉, 沈鹏飞, 尚其忠, 张鹏雁, 刘莉, 李明瑞, 侯龙, 李维火 2023 72 026101

Google Scholar

Google Scholar

Sun J, Shen P F, Shang Q Z, Zhang P Y, Liu L, Li M R, Hong L, Li W H 2023 Acta Phys. Sin. 72 026101

Google Scholar

Google Scholar

[12] Sohrabi S, Fu J N, Li L Y, Zhang Y, Li X, Sun F, Ma J, Wang W H 2024 Prog. Mater. Sci. 144 101283

Google Scholar

Google Scholar

[13] DebRoy T, Wei H L, Zuback J S, Mukherjee T, Elmer J W, Milewski J O, Beese A M, Wilson-Heid A D, De A, Zhang W 2018 Prog. Mater. Sci. 92 112

Google Scholar

Google Scholar

[14] Pauly S, Löber L, Petters R, Stoica M, Scudino S, Kühn U, Eckert J 2013 Mater. Today 16 37

Google Scholar

Google Scholar

[15] Mahbooba Z, Thorsson L, Unosson M, Skoglund P, West H, Horn T, Rock C, Vogli E, Harrysson O 2018 Appl. Mater. Today 11 264

Google Scholar

Google Scholar

[16] Thorsson L, Unosson M, Pérez-Prado M T, Jin X, Tiberto P, Barrera G, Adam B, Neuber N, Ghavimi A, Frey M, Busch R 2022 Mat. Design 215 110483

Google Scholar

Google Scholar

[17] Lu Y Z, Huang Y J, Wu J, Lu X, Qin Z X, Daisenberger D, Chiu Y L 2018 Intermetallics 103 67

Google Scholar

Google Scholar

[18] Ouyang D, Xing W, Li N, Li Y C, Liu L 2018 Addit. Manuf. 23 246

[19] Marattukalam J J, Pacheco V, Karlsson D, Riekehr L, Lindwall J, Forsberg F, Jansson U, Sahlberg M, Hjörvarsson B 2020 Addit. Manuf. 33 101124

[20] Qiu C, Panwisawas C, Ward M, Basoalto H C, Brooks J W, Attallah M M 2015 Acta Mater. 96 72

Google Scholar

Google Scholar

[21] Xing W, Ouyang D, Li N, Liu L 2018 Intermetallics 103 101

Google Scholar

Google Scholar

[22] Ren Z, Zhang D Z, Fu G, Jiang J, Zhao M 2021 Mat. Design 207 109857

Google Scholar

Google Scholar

[23] Ge Y Q, Qiao J F, Chang Z X, Hou M, Xu H J, Yang A A, Song Y, Bi W H, Ma N S 2024 Mater. Today Commun. 39 108597

Google Scholar

Google Scholar

[24] Nguyen Q B, Luu D N, Nai S M, Zhu Z, Chen Z, Wei J 2018 Arch. Civ. Mech. Eng. 18 948

Google Scholar

Google Scholar

[25] Yang G L, Lin X, Liu F C, Hu Q, Ma L, Li J F, Huang W D 2012 Intermetallics 22 110

Google Scholar

Google Scholar

[26] Nam Y G, Koo B, Chang M S, Yang S, Yu J, Park Y H, Jeong J W 2020 Mater. Lett. 261 127068

Google Scholar

Google Scholar

[27] 石岩, 魏登松 2023 中国激光 50 131

Google Scholar

Google Scholar

Shi Y, Wei D S 2023 Chin. J. Lasers 50 131

Google Scholar

Google Scholar

[28] Han Q, Gu H, Setchi R 2019 Powder Technol. 352 91

Google Scholar

Google Scholar

[29] Luo N, Scheitler C, Ciftci N, Galgon F, Fu Z, Uhlenwinkel V, Schmidt M, Körner C 2020 Mater. Charact. 162 110206

Google Scholar

Google Scholar

[30] Yadroitsev I, Yadroitsava I, Bertrand P, Smurov I 2012 Rapid Prototyp. J. 18 201

Google Scholar

Google Scholar

[31] Yuan W, Chen H, Cheng T, Wei Q 2020 Mat. Design 189 108542

Google Scholar

Google Scholar

[32] Zhang Y, Liu H S, Mo J Y, Wang M Z, Chen Z, He Y Z, Yang W M, Tang C G 2019 Phys. Chem. Chem. Phys. 21 12406

Google Scholar

Google Scholar

[33] Özden M G, Morley N A 2023 J. Alloys Compd. 960 170644

Google Scholar

Google Scholar

[34] Sun H, Flores K M 2013 Intermetallics 43 53

Google Scholar

Google Scholar

[35] Li S Y, Fu G, Li H L, Ren Z H, Li S B, Xiao H Q, Peng Q G 2023 J. Alloys Compd. 967 171778

Google Scholar

Google Scholar

[36] Murayama S, Inaba H, Hoshi K, Obi Y 1993 IEEE Trans. Magn. 29 2682

Google Scholar

Google Scholar

[37] Żrodowski Ł, Wysocki B, Wróblewski R, Krawczyńska A, Adamczyk-Cieślak B, Zdunek J, Błyskun P, Ferenc J, Leonowicz M, Święszkowski W 2019 J. Alloys Compd. 771 769

Google Scholar

Google Scholar

[38] 邬小萍, 刘淑凤, 马通达, 王书明, 王梦圆 2024 金属功能材料 31 99

Google Scholar

Google Scholar

Wu X P, Liu S F, Ma T D, Wang S M, Wang M Y 2024 AM& D. 31 99

Google Scholar

Google Scholar

[39] 郭子政, 胡旭波 2013 62 057501

Google Scholar

Google Scholar

Guo Z Z, Hu X B 2013 Acta Phys. Sin. 62 057501

Google Scholar

Google Scholar

[40] Jung H Y, Choi S J, Prashanth K G, Stoica M, Scudino S, Yi S, Kühn U, Kim D H, Kim K B, Eckert J 2015 Mat. Design 86 703

Google Scholar

Google Scholar

[41] Rodríguez-Sánchez M, Sadanand S, Ghavimi A, Busch R, Tiberto P, Ferrara E, Barrera G, Thorsson L, Wachter H J, Gallino I, Pérez-Prado M T 2024 Mater. 35 102111

-

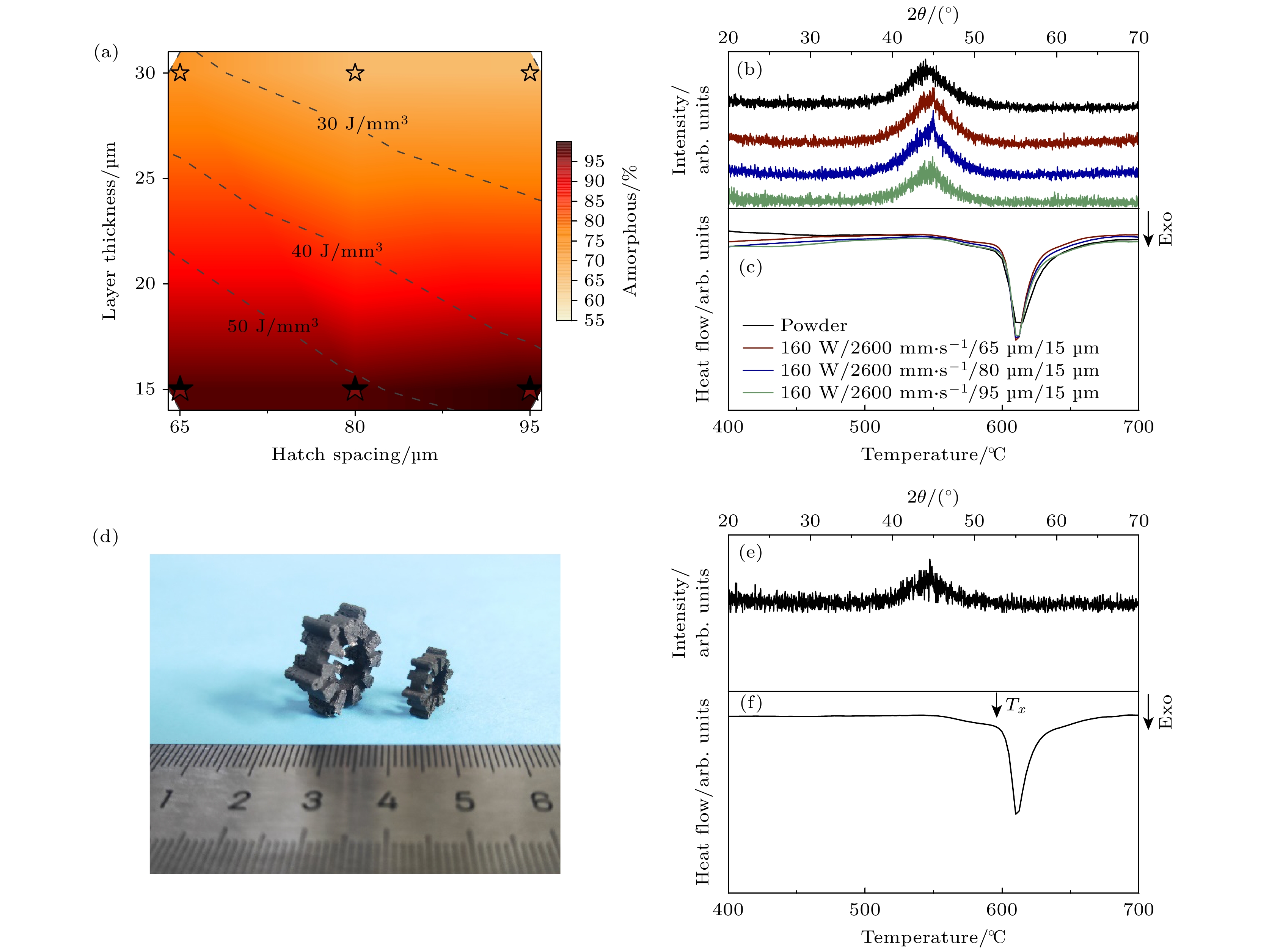

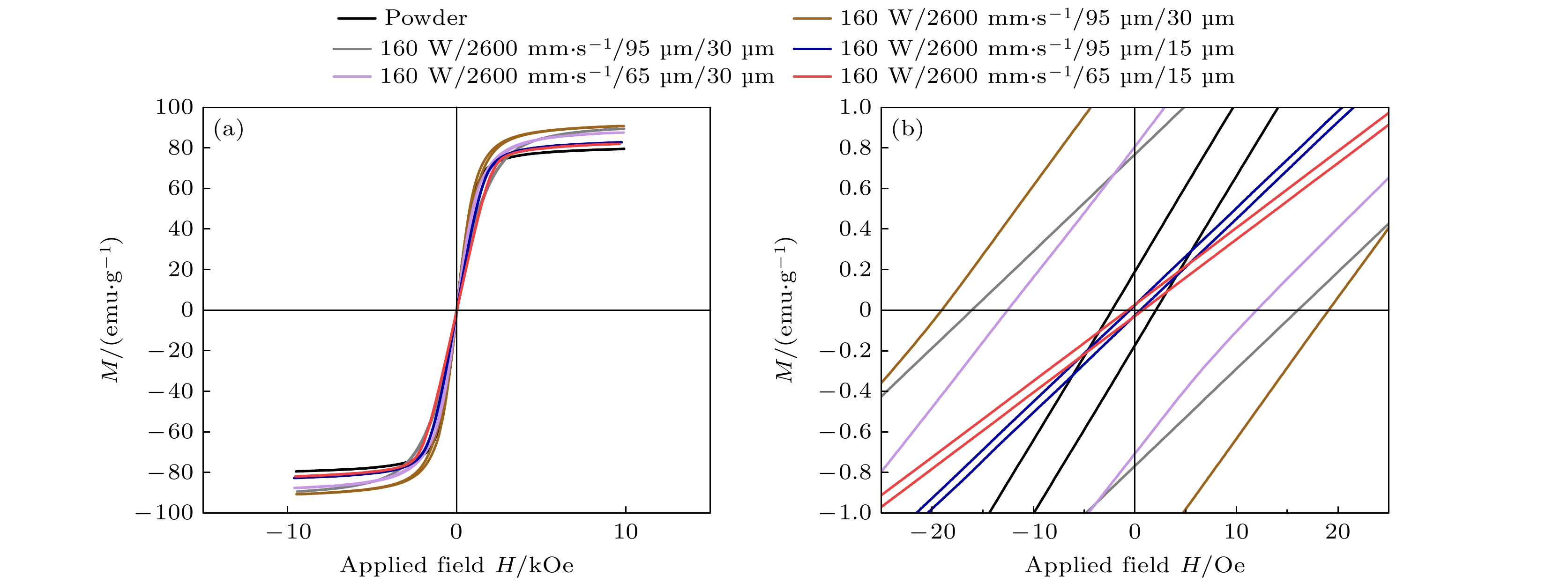

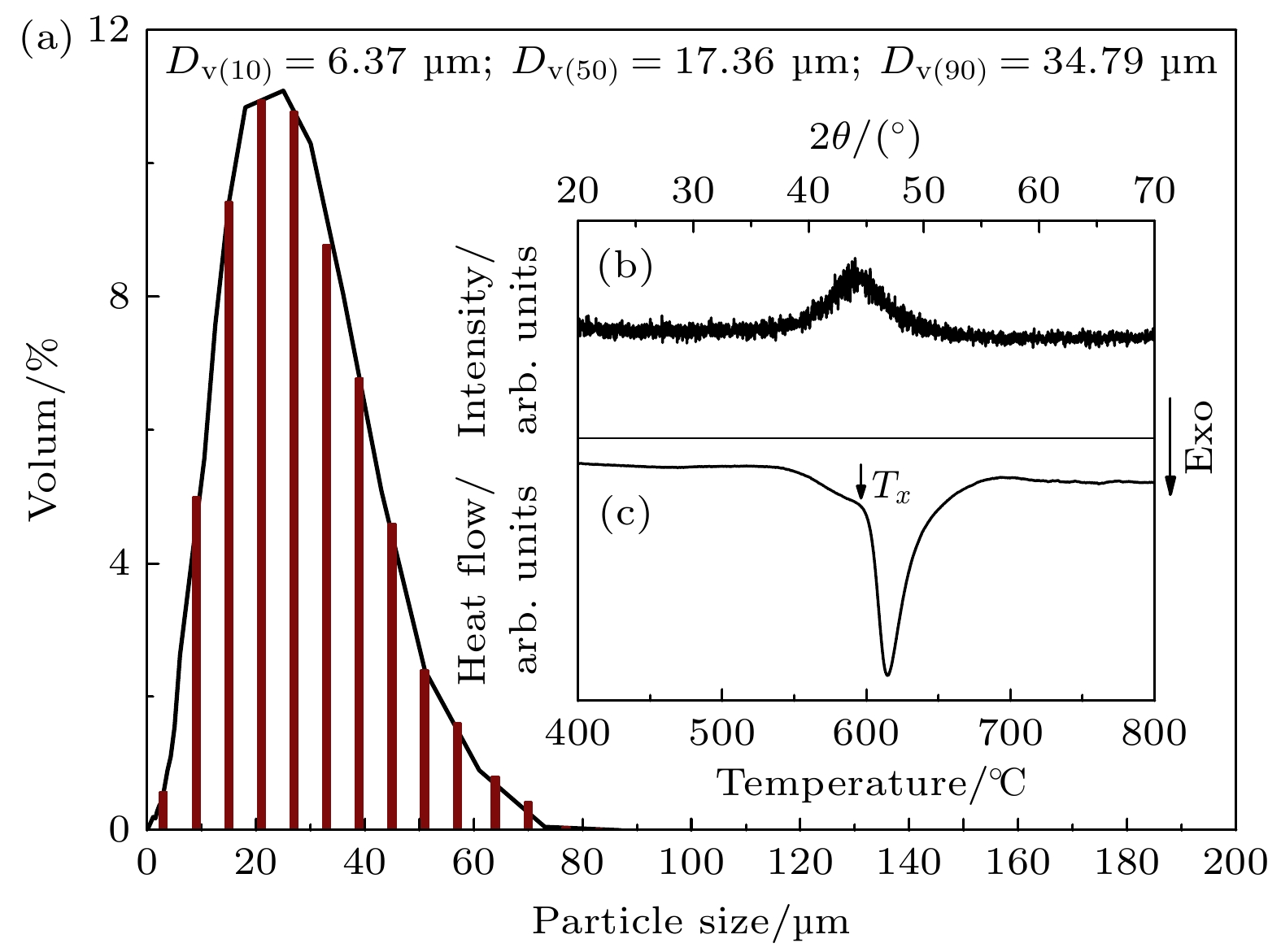

图 6 (a)不同h和t下样品的非晶含量; (b)不同h和t下样品的XRD图; (c) DSC图; (d) 电机结构; (e)电机结构的XRD图; (f) DSC图

Fig. 6. (a) Amorphous content of samples under different h and t conditions; (b) XRD diagram of samples under different h and t conditions; (c) DSC diagram; (d) motor structure; (e) XRD diagram of motor structure; (f) DSC diagram.

表 1 本研究中获得的相对密度、非晶分数和磁性能, 并与文献报道的对比

Table 1. Comparison of the relative density, amorphous fraction, and magnetic properties achieved in this study with those reported in the literature for similar alloys.

BMG Composition Density

/%Amorphous fraction/% Ms/

THc/

OeReference Fe68.3C6.9Si2.5B6.7P8.7Cr2.3Mo2.5Al2.1 99.7 — 1.08 0.35 [40] Fe71Si10B11C6Cr2 94 90 1.3 4.98 [37] Fe73.7B11Si11Cr2.3C2 96 47 1.22 20.1 [26,32] Fe73Si11B11C3Cr2 98 70 1.29 6.4 [16] Fe73.7B11Si11Cr2.3C2 74 46 1.19 35.06 [41] Powder (Fe70W9Mo3Cr5Ni3Si4B4CMn)

—

100

0.84

2

This workBulk (160 W/2600 mm/s /95 μm/15 μm)

79.1

98.1

0.89

0.7

This workBulk (160 W/2600 mm/s /65 μm /15 μm)

94.3

100

0.88

0.5

This work -

[1] Wang Y J, Lucia O, Zhang Z, Guan Y S, Xu D G 2020 IET Power Electron. 13 1711

Google Scholar

Google Scholar

[2] Battal F, Balci S, Sefa I 2020 Meas. J. Int. Meas. Confed. 171 108848

Google Scholar

Google Scholar

[3] Mahesh M, Kumar K V, Abebe M, Udayakumar L, Mathankumar M 2021 Mater. Today Proc. 46 3888

Google Scholar

Google Scholar

[4] 姚可夫, 施凌翔, 陈双琴, 邵洋, 陈娜, 贾蓟丽 2018 67 016101

Google Scholar

Google Scholar

Yao K F, Shi L X, Chen S Q, Shao Y, Chen N, Jia J L 2018 Acta Phys. Sin. 67 016101

Google Scholar

Google Scholar

[5] Li H X, Lu Z C, Wang S L, Wu Y, Lu Z P 2019 Prog. Mater. Sci. 103 235

Google Scholar

Google Scholar

[6] Inoue A, Shinohara Y, Gook J S 1995 Mater. Trans. 36 1427

Google Scholar

Google Scholar

[7] Ponnambalam V, Poon S J, Shiflet G J 2004 J. Mater. Res. 19 1320

Google Scholar

Google Scholar

[8] Amiya K, Inoue A 2006 Mater. Trans. 47 1615

Google Scholar

Google Scholar

[9] 张雅楠, 王有骏, 孔令体, 李金富 2012 61 454

Google Scholar

Google Scholar

Zhang Y N, Wang Y J, Kong L T, Li J F 2012 Acta Phys. Sin. 61 454

Google Scholar

Google Scholar

[10] Suryanarayana C, Inoue A 2013 Int. Mater. Rev. 58 131

Google Scholar

Google Scholar

[11] 孙吉, 沈鹏飞, 尚其忠, 张鹏雁, 刘莉, 李明瑞, 侯龙, 李维火 2023 72 026101

Google Scholar

Google Scholar

Sun J, Shen P F, Shang Q Z, Zhang P Y, Liu L, Li M R, Hong L, Li W H 2023 Acta Phys. Sin. 72 026101

Google Scholar

Google Scholar

[12] Sohrabi S, Fu J N, Li L Y, Zhang Y, Li X, Sun F, Ma J, Wang W H 2024 Prog. Mater. Sci. 144 101283

Google Scholar

Google Scholar

[13] DebRoy T, Wei H L, Zuback J S, Mukherjee T, Elmer J W, Milewski J O, Beese A M, Wilson-Heid A D, De A, Zhang W 2018 Prog. Mater. Sci. 92 112

Google Scholar

Google Scholar

[14] Pauly S, Löber L, Petters R, Stoica M, Scudino S, Kühn U, Eckert J 2013 Mater. Today 16 37

Google Scholar

Google Scholar

[15] Mahbooba Z, Thorsson L, Unosson M, Skoglund P, West H, Horn T, Rock C, Vogli E, Harrysson O 2018 Appl. Mater. Today 11 264

Google Scholar

Google Scholar

[16] Thorsson L, Unosson M, Pérez-Prado M T, Jin X, Tiberto P, Barrera G, Adam B, Neuber N, Ghavimi A, Frey M, Busch R 2022 Mat. Design 215 110483

Google Scholar

Google Scholar

[17] Lu Y Z, Huang Y J, Wu J, Lu X, Qin Z X, Daisenberger D, Chiu Y L 2018 Intermetallics 103 67

Google Scholar

Google Scholar

[18] Ouyang D, Xing W, Li N, Li Y C, Liu L 2018 Addit. Manuf. 23 246

[19] Marattukalam J J, Pacheco V, Karlsson D, Riekehr L, Lindwall J, Forsberg F, Jansson U, Sahlberg M, Hjörvarsson B 2020 Addit. Manuf. 33 101124

[20] Qiu C, Panwisawas C, Ward M, Basoalto H C, Brooks J W, Attallah M M 2015 Acta Mater. 96 72

Google Scholar

Google Scholar

[21] Xing W, Ouyang D, Li N, Liu L 2018 Intermetallics 103 101

Google Scholar

Google Scholar

[22] Ren Z, Zhang D Z, Fu G, Jiang J, Zhao M 2021 Mat. Design 207 109857

Google Scholar

Google Scholar

[23] Ge Y Q, Qiao J F, Chang Z X, Hou M, Xu H J, Yang A A, Song Y, Bi W H, Ma N S 2024 Mater. Today Commun. 39 108597

Google Scholar

Google Scholar

[24] Nguyen Q B, Luu D N, Nai S M, Zhu Z, Chen Z, Wei J 2018 Arch. Civ. Mech. Eng. 18 948

Google Scholar

Google Scholar

[25] Yang G L, Lin X, Liu F C, Hu Q, Ma L, Li J F, Huang W D 2012 Intermetallics 22 110

Google Scholar

Google Scholar

[26] Nam Y G, Koo B, Chang M S, Yang S, Yu J, Park Y H, Jeong J W 2020 Mater. Lett. 261 127068

Google Scholar

Google Scholar

[27] 石岩, 魏登松 2023 中国激光 50 131

Google Scholar

Google Scholar

Shi Y, Wei D S 2023 Chin. J. Lasers 50 131

Google Scholar

Google Scholar

[28] Han Q, Gu H, Setchi R 2019 Powder Technol. 352 91

Google Scholar

Google Scholar

[29] Luo N, Scheitler C, Ciftci N, Galgon F, Fu Z, Uhlenwinkel V, Schmidt M, Körner C 2020 Mater. Charact. 162 110206

Google Scholar

Google Scholar

[30] Yadroitsev I, Yadroitsava I, Bertrand P, Smurov I 2012 Rapid Prototyp. J. 18 201

Google Scholar

Google Scholar

[31] Yuan W, Chen H, Cheng T, Wei Q 2020 Mat. Design 189 108542

Google Scholar

Google Scholar

[32] Zhang Y, Liu H S, Mo J Y, Wang M Z, Chen Z, He Y Z, Yang W M, Tang C G 2019 Phys. Chem. Chem. Phys. 21 12406

Google Scholar

Google Scholar

[33] Özden M G, Morley N A 2023 J. Alloys Compd. 960 170644

Google Scholar

Google Scholar

[34] Sun H, Flores K M 2013 Intermetallics 43 53

Google Scholar

Google Scholar

[35] Li S Y, Fu G, Li H L, Ren Z H, Li S B, Xiao H Q, Peng Q G 2023 J. Alloys Compd. 967 171778

Google Scholar

Google Scholar

[36] Murayama S, Inaba H, Hoshi K, Obi Y 1993 IEEE Trans. Magn. 29 2682

Google Scholar

Google Scholar

[37] Żrodowski Ł, Wysocki B, Wróblewski R, Krawczyńska A, Adamczyk-Cieślak B, Zdunek J, Błyskun P, Ferenc J, Leonowicz M, Święszkowski W 2019 J. Alloys Compd. 771 769

Google Scholar

Google Scholar

[38] 邬小萍, 刘淑凤, 马通达, 王书明, 王梦圆 2024 金属功能材料 31 99

Google Scholar

Google Scholar

Wu X P, Liu S F, Ma T D, Wang S M, Wang M Y 2024 AM& D. 31 99

Google Scholar

Google Scholar

[39] 郭子政, 胡旭波 2013 62 057501

Google Scholar

Google Scholar

Guo Z Z, Hu X B 2013 Acta Phys. Sin. 62 057501

Google Scholar

Google Scholar

[40] Jung H Y, Choi S J, Prashanth K G, Stoica M, Scudino S, Yi S, Kühn U, Kim D H, Kim K B, Eckert J 2015 Mat. Design 86 703

Google Scholar

Google Scholar

[41] Rodríguez-Sánchez M, Sadanand S, Ghavimi A, Busch R, Tiberto P, Ferrara E, Barrera G, Thorsson L, Wachter H J, Gallino I, Pérez-Prado M T 2024 Mater. 35 102111

计量

- 文章访问数: 431

- PDF下载量: 19

- 被引次数: 0

下载:

下载: