-

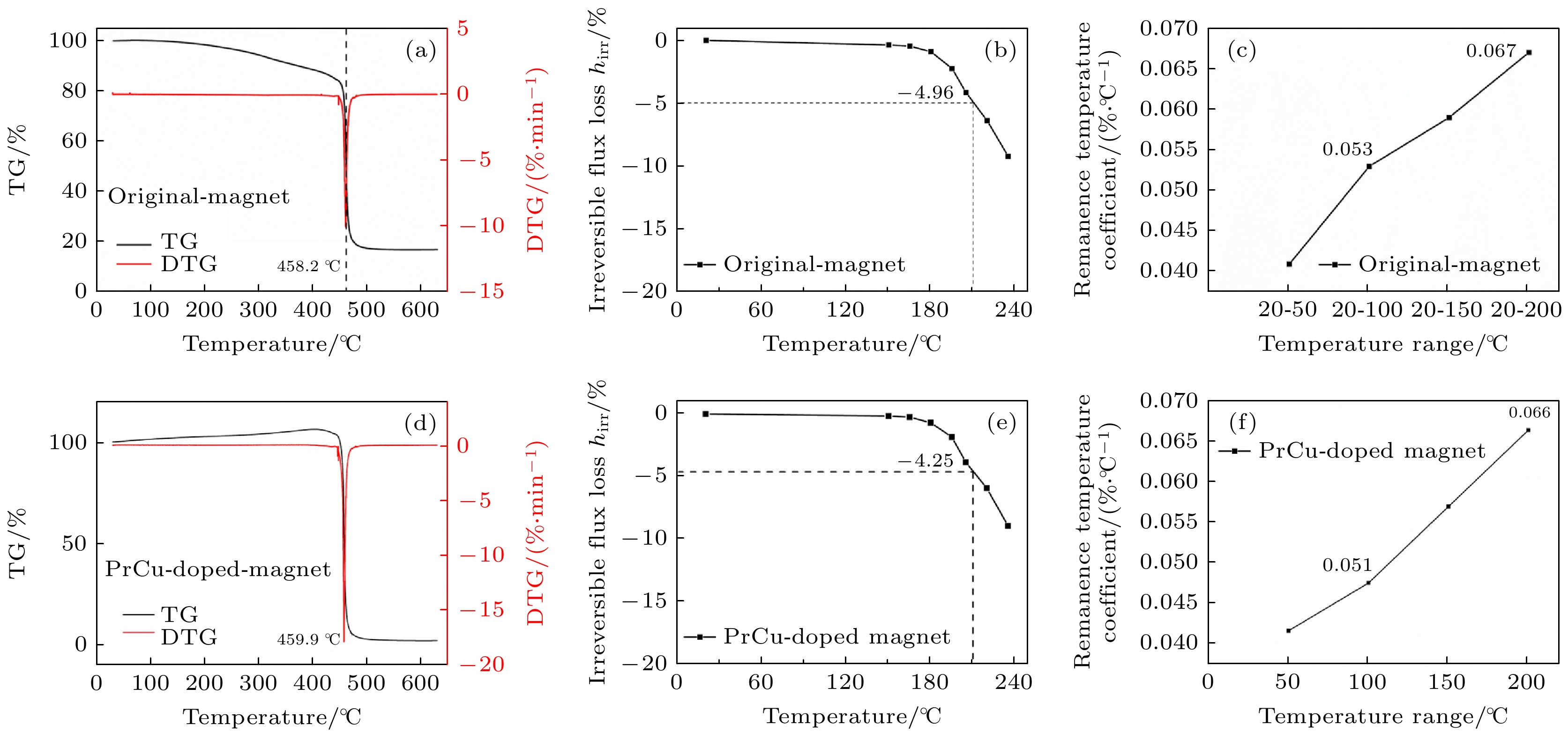

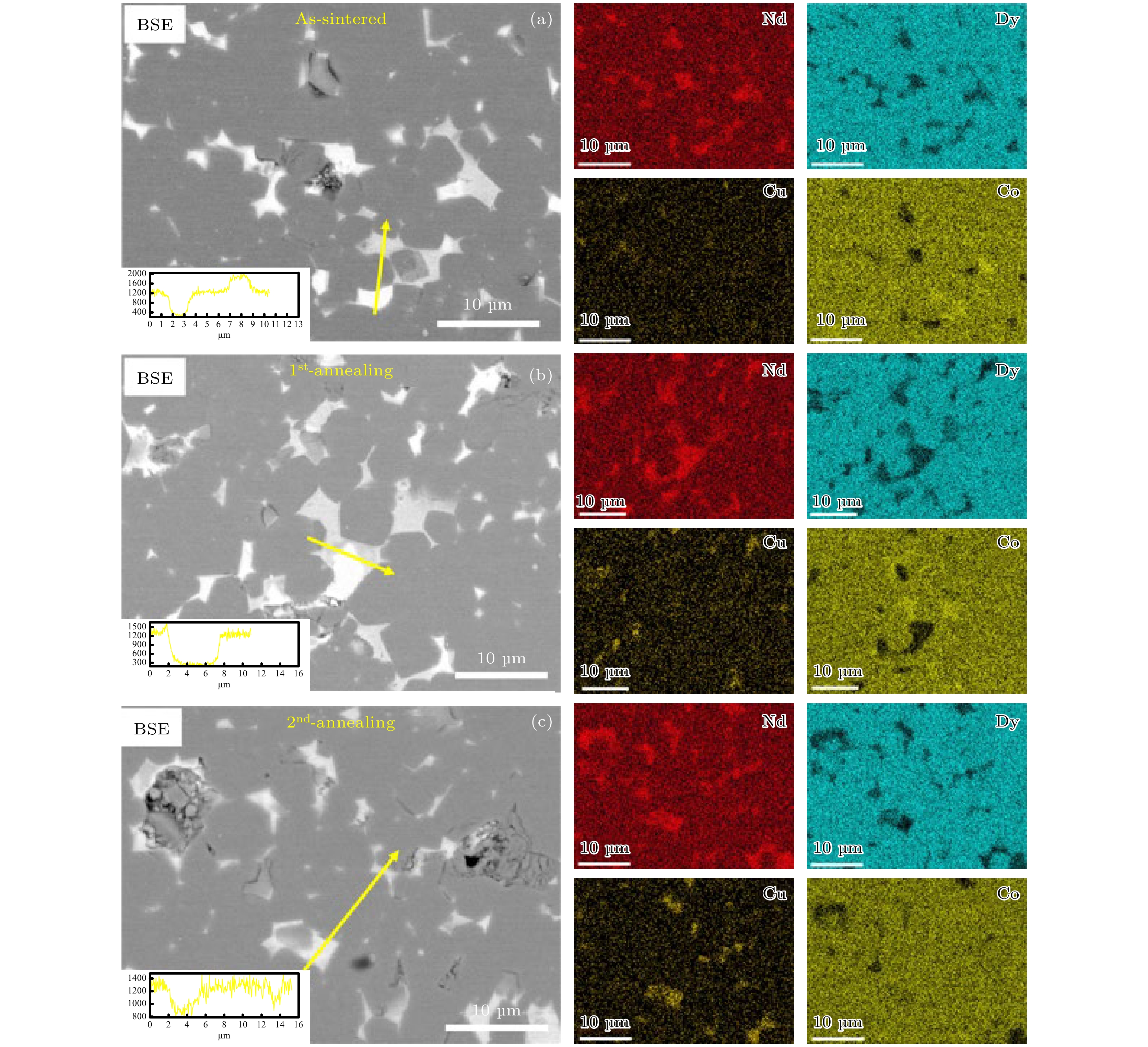

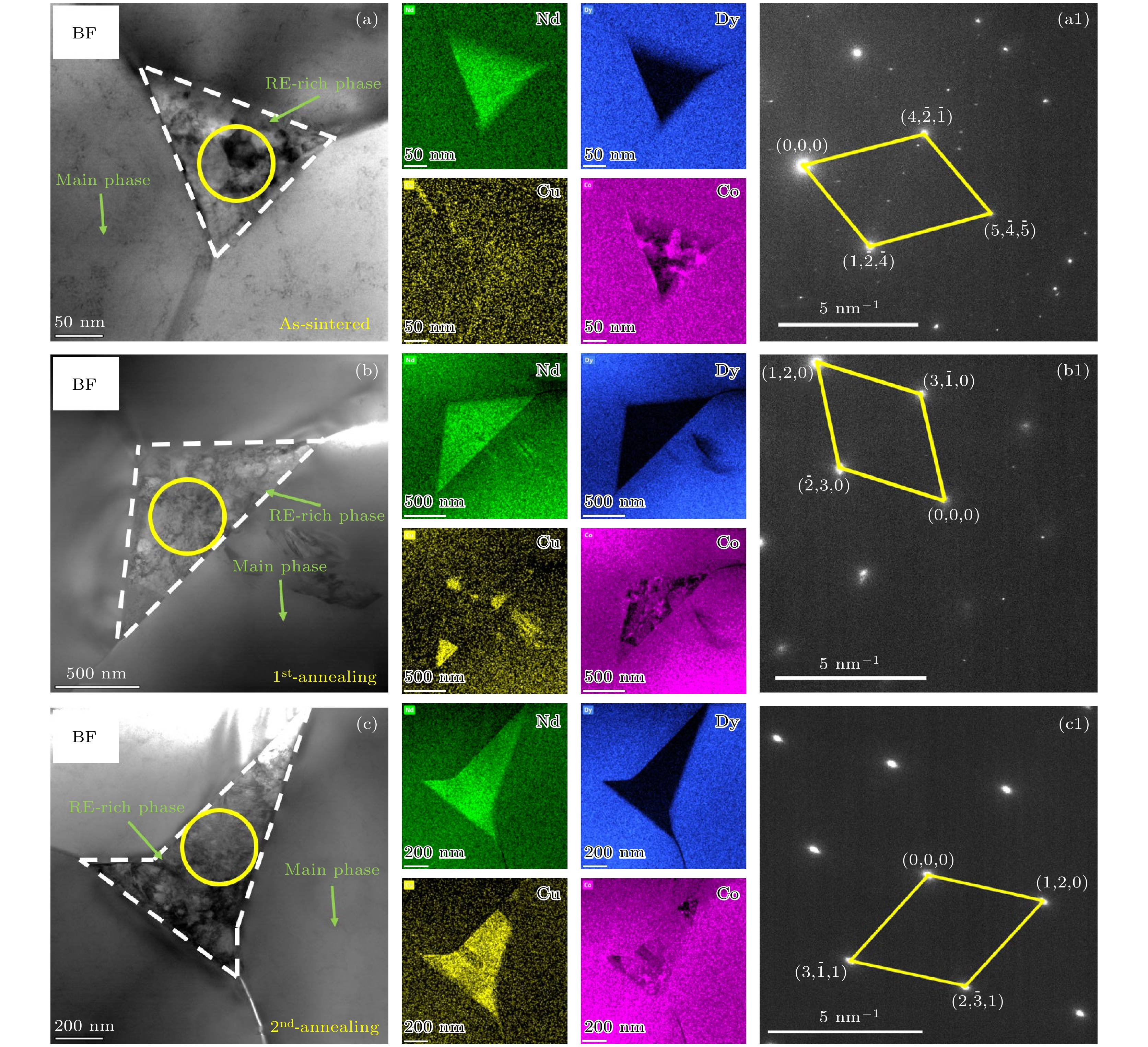

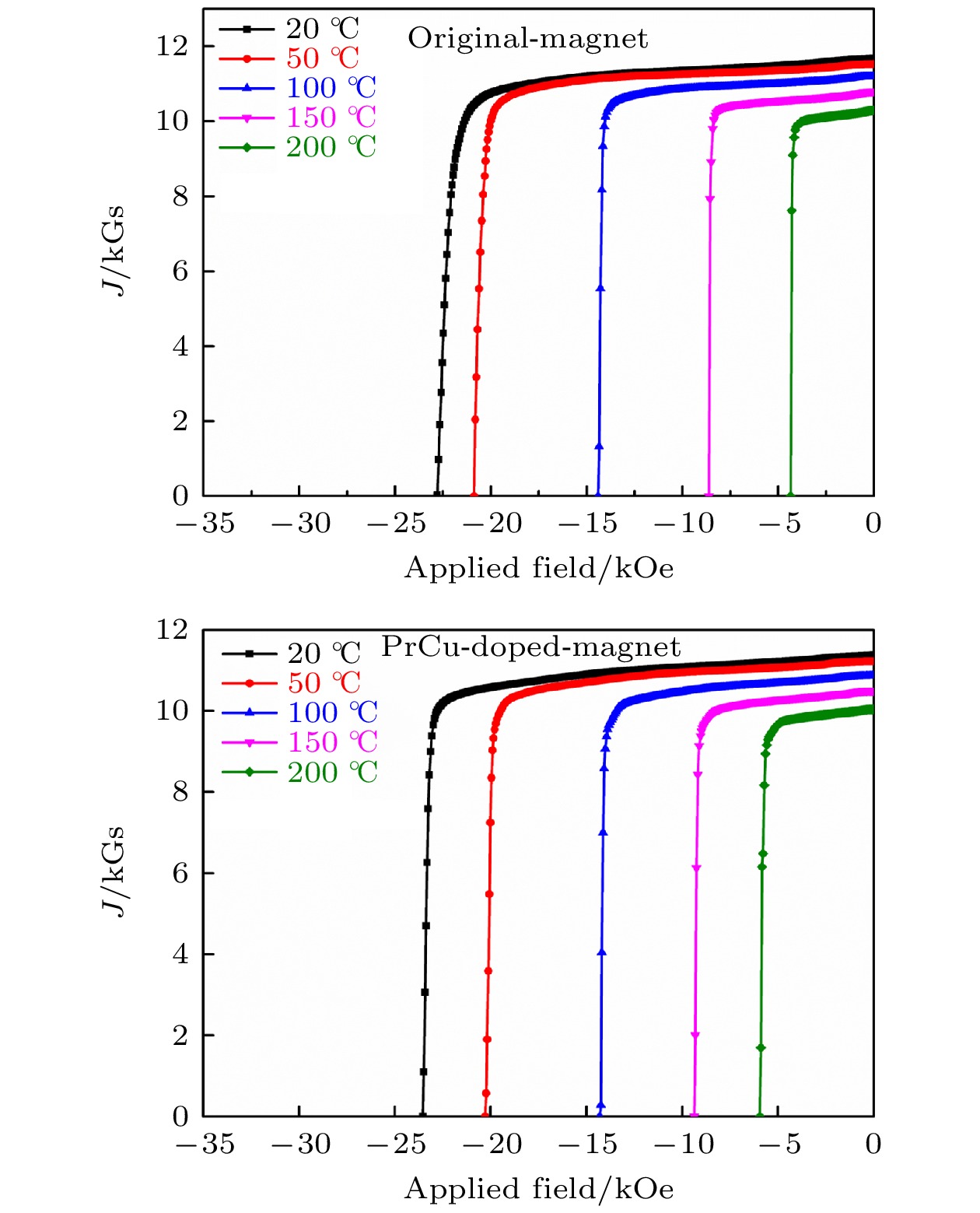

通过在(Pr, Nd, Dy)32.2Co13Cu0.4FebalB0.98M1.05(M = Al, Ga, Zr)磁体中添加低熔点合金Pr80Cu20, 提高磁体中的Cu含量, 从而调控Co在富稀土相中的分布. 相较于原磁体, 掺PrCu磁体的剩磁保持不变, 矫顽力提升约1.3 kOe, 居里温度、剩磁温度系数和不可逆磁损均有所改善. 通过微观组织观察发现, 原磁体二级回火态晶界处同时存在贫Co相与富Co相, 但掺PrCu磁体二级回火态中, Cu和Co在晶界相中的分布均匀性明显改善, 从而有效地消除了富Co相. 由于软磁性相R2(Fe, Co)17 (R = Pr, Nd, Dy) 容易与富Co相共生, 有害于永磁性能, 富Co相的消除可能是掺PrCu磁体二级回火态矫顽力提升的重要原因.With the aim of increasing Cu concentration to regulate the distribution of Co elements in RE-rich phase, the low-melting-point Pr80Cu20 intergranular alloy is introduced into the (Pr, Nd, Dy)32.2Co13Cu0.4FebalB0.98M1.05 (M = Al, Ga, Zr) magnet. Comparing with the original magnet, the remanence of PrCu-doped magnet is basically unchanged, and the coercivity is increased by approximately 1.3 kOe. Simultaneously, the Curie temperature, remanence temperature coefficient and irreversible flux loss are slightly improved. Microstructural study reveals that the Co-lean phase and the Co-rich phase coexist in the grain boundary in the 2nd-annealed original magnet. However, for the PrCu-doped magnet, the uniform distribution of Cu and Co elements in the intergranular phase are evidently improved, resulting in the elimination of the Co-rich phase. Since the R2(Fe, Co)17 (R = Pr, Nd, Dy) soft magnetic phase easily coexist with the Co-rich phase and are detrimental to the coercivity, the elimination of Co-rich intergranular phase may be an important reason for the higher coercivity of the 2nd-annealed PrCu-doped magnet than that of the original magnet.

-

Keywords:

- sintered NdFeB magnet /

- intergranular addition /

- annealing /

- opposite distribution between Cu and Co /

- coercivity

[1] Sagawa M, Fujimura S, Togawa N, Yamamoto H, Matsuura Y 1984 J. Appl. Phys. 55 2083

Google Scholar

Google Scholar

[2] Yan G L, McGuiness P J, Farr J P G, Harris I R 2010 J. Alloys Compd. J. Alloys Compd. 491 L20

Google Scholar

Google Scholar

[3] Mottram R S, Williams A J, Harris I R 2000 J. Magn. Magn. Mater. 217 27

Google Scholar

Google Scholar

[4] Hu Z H, Lian F Z, Zhu M G, Li W 2008 J. Magn. Magn. Mater. 320 2364

Google Scholar

Google Scholar

[5] Kostyuchenko N V, Tereshina I S, Gorbunoy D I, Tereshina-Chitrova E A, Rogacki K, Andreev A V, Doerr M, Politova G A, Zvezdin A K 2020 Intermetallics 124 106840

Google Scholar

Google Scholar

[6] Cui X G, Yan M, Ma T Y, Luo W, Tu S J 2009 Sci. Sinter. 41 91

Google Scholar

Google Scholar

[7] Brown D, Ma B M, Chen Z M 2002 J. Magn. Magn. Mater. 248 432

Google Scholar

Google Scholar

[8] Yan M, Yu L Q, Luo W, Wang W, Zhang W Y, Wen Y H 2006 J. Magn. Magn. Mater. 301 1

Google Scholar

Google Scholar

[9] Li W F, Ohkubo T, Hono K 2009 Acta Mater. 57 1337

Google Scholar

Google Scholar

[10] 李栋, 董生智, 李磊, 徐吉元, 陈红升, 李卫 2020 69 147501

Google Scholar

Google Scholar

Li D, Dong S Z, Li L, Xu J Y, Chen H S, Li W 2020 Acta Phys. Sin. 69 147501

Google Scholar

Google Scholar

[11] Kim A S, Camp F E 1996 J. Appl. Phys. 79 5035

Google Scholar

Google Scholar

[12] Pandian S, Chandrasekaran V, Markandeyulu G, Lyer K J L, Rao R 2002 J. Appl. Phys. 92 6082

Google Scholar

Google Scholar

[13] Ni J J, Ma T Y, Yan M 2011 J. Magn. Magn. Mater. 323 2549

Google Scholar

Google Scholar

[14] Li M, Tamura T 2021 J. Alloys Compd. 883 160915

Google Scholar

Google Scholar

[15] Luo S E, Lu Y J, Zou Y R, Zhong S W, Wu Y, Yang M N 2021 J. Magn. Magn. Mater. 523 167620

Google Scholar

Google Scholar

[16] 张家滕, 徐吉元, 胡成林, 孟睿阳, 董生智 2022 中国稀土学报 40 235

Zhang J T, Xu J Y, Hu C L, Meng R Y, Dong S Z. 2022 J. Chin. Rare Earth Soc. 40 235

[17] 胡伯平, 饶晓雷, 王亦忠 2017 稀土永磁材料(上册) (北京: 冶金工业出版社) 第197页

Hu B P, Rao X L, Wang Y Z 2017 Rare-earth Permanent Magnet Materials (Vol. 1) (Beijing: Metallurgical Industry Press) p197 (in Chinese)

[18] Kou X C, Zhao T S, R. Grössinger, de Boer F R 1992 Phys. Rev. B 46 6225

Google Scholar

Google Scholar

-

表 1 原磁体和掺PrCu磁体的室温磁性能对比

Table 1. Comparison of magnetic properties between original-magnet and PrCu-doped magnet.

剩磁Br/kGs 矫顽力Hcj/kOe 最大磁能积

(BH)max/

MGOe方形度

Hk/Hcj/%原磁体 烧结态 11.32 15.64 31.04 94.4 一级回火态 11.30 17.22 30.88 95.0 二级回火态 11.30 22.24 31.39 95.9 掺PrCu

磁体烧结态 11.31 16.34 30.89 88.9 一级回火态 11.30 17.60 30.51 89.3 二级回火态 11.30 23.53 31.36 95.1 表 2 掺PrCu磁体三种状态样品中不同相的元素含量

Table 2. Element content of different phases in three kinds of PrCu-doped magnets.

wt.% O Fe Co Cu Pr Nd Dy 烧结态 主相 0.89 56.185 13.14 0.31 4.87 15.32 9.28 贫Co相 4.02 4.63 1.98 1.13 24.68 56.75 6.83 富Co相 0.96 20.54 23.62 0.47 13.66 34.62 6.14 一级

回火态主相 0.93 56.74 13.24 0.38 4.6 14.87 9.24 贫Co相 4.79 2.67 1.79 1.61 25.37 56.98 6.79 富Co相 1.15 11.72 16.01 0.58 20.15 44.2 6.19 二级

回火态主相 0.81 56.23 13.89 0.3 4.86 14.78 9.14 贫Co相1 2.21 5.61 9.02 1.47 23.86 51.67 6.16 贫Co相2 2.03 6.16 4.05 1.52 25.39 54.54 6.31 -

[1] Sagawa M, Fujimura S, Togawa N, Yamamoto H, Matsuura Y 1984 J. Appl. Phys. 55 2083

Google Scholar

Google Scholar

[2] Yan G L, McGuiness P J, Farr J P G, Harris I R 2010 J. Alloys Compd. J. Alloys Compd. 491 L20

Google Scholar

Google Scholar

[3] Mottram R S, Williams A J, Harris I R 2000 J. Magn. Magn. Mater. 217 27

Google Scholar

Google Scholar

[4] Hu Z H, Lian F Z, Zhu M G, Li W 2008 J. Magn. Magn. Mater. 320 2364

Google Scholar

Google Scholar

[5] Kostyuchenko N V, Tereshina I S, Gorbunoy D I, Tereshina-Chitrova E A, Rogacki K, Andreev A V, Doerr M, Politova G A, Zvezdin A K 2020 Intermetallics 124 106840

Google Scholar

Google Scholar

[6] Cui X G, Yan M, Ma T Y, Luo W, Tu S J 2009 Sci. Sinter. 41 91

Google Scholar

Google Scholar

[7] Brown D, Ma B M, Chen Z M 2002 J. Magn. Magn. Mater. 248 432

Google Scholar

Google Scholar

[8] Yan M, Yu L Q, Luo W, Wang W, Zhang W Y, Wen Y H 2006 J. Magn. Magn. Mater. 301 1

Google Scholar

Google Scholar

[9] Li W F, Ohkubo T, Hono K 2009 Acta Mater. 57 1337

Google Scholar

Google Scholar

[10] 李栋, 董生智, 李磊, 徐吉元, 陈红升, 李卫 2020 69 147501

Google Scholar

Google Scholar

Li D, Dong S Z, Li L, Xu J Y, Chen H S, Li W 2020 Acta Phys. Sin. 69 147501

Google Scholar

Google Scholar

[11] Kim A S, Camp F E 1996 J. Appl. Phys. 79 5035

Google Scholar

Google Scholar

[12] Pandian S, Chandrasekaran V, Markandeyulu G, Lyer K J L, Rao R 2002 J. Appl. Phys. 92 6082

Google Scholar

Google Scholar

[13] Ni J J, Ma T Y, Yan M 2011 J. Magn. Magn. Mater. 323 2549

Google Scholar

Google Scholar

[14] Li M, Tamura T 2021 J. Alloys Compd. 883 160915

Google Scholar

Google Scholar

[15] Luo S E, Lu Y J, Zou Y R, Zhong S W, Wu Y, Yang M N 2021 J. Magn. Magn. Mater. 523 167620

Google Scholar

Google Scholar

[16] 张家滕, 徐吉元, 胡成林, 孟睿阳, 董生智 2022 中国稀土学报 40 235

Zhang J T, Xu J Y, Hu C L, Meng R Y, Dong S Z. 2022 J. Chin. Rare Earth Soc. 40 235

[17] 胡伯平, 饶晓雷, 王亦忠 2017 稀土永磁材料(上册) (北京: 冶金工业出版社) 第197页

Hu B P, Rao X L, Wang Y Z 2017 Rare-earth Permanent Magnet Materials (Vol. 1) (Beijing: Metallurgical Industry Press) p197 (in Chinese)

[18] Kou X C, Zhao T S, R. Grössinger, de Boer F R 1992 Phys. Rev. B 46 6225

Google Scholar

Google Scholar

计量

- 文章访问数: 4705

- PDF下载量: 78

- 被引次数: 0

下载:

下载: