-

稀土元素的原子结构特殊, 具有内层未成对4f轨道电子多、原子磁矩高、自旋轨道耦合作用强的性质, 故其电子能级极为丰富, 易形成多种价态、多种配位的化合物, 通常表现出特殊的磁学性质和丰富的磁畴结构, 成为高新技术产业发展的关键材料. 这类材料中复杂的磁结构形式、多样的磁耦合类型及多种直接或间接的磁交换作用, 为开发新型功能器件提供便利的同时, 也对基础研究提出了严峻挑战. 随着数据挖掘技术的快速发展, 大数据和人工智能的出现给研究人员提供了一个新的选择, 可以高效地分析大量实验和计算数据, 从而加速稀土磁性材料的研究与开发. 本文围绕稀土永磁材料、稀土磁致冷材料、稀土磁致伸缩材料等, 详细阐述了数据挖掘技术在其性能预测、成分与工艺优化、微观结构分析等方面的应用进展, 深入探讨了当前面临的挑战, 并对未来发展趋势进行展望, 为推动数据挖掘技术与稀土磁性材料研究的深度融合提供理论基础.Rare-earth elements possess unique atomic structures characterized by multiple unpaired 4f orbital electrons in inner shells, high atomic magnetic moments, and strong spin-orbit coupling. These attributes endow them with rich electronic energy levels, enabling them to form compounds with different valence states and coordination environments. Consequently, rare-earth materials typically exhibit excellent magnetic properties and complex magnetic domain structures, making them critical for the development of high-tech industries. The intricate magnetic configurations, different types of magnetic coupling, and direct/indirect magnetic exchange interactions in these materials not only facilitate the development of novel functional devices but also pose significant challenges to fundamental research. With the rapid advancement of data mining techniques, the emergence of big data and artificial intelligence provides researchers with a new method to efficiently analyze vast experimental and computational datasets, thereby accelerating the exploration and development of rare-earth magnetic materials. This work focuses on rare-earth permanent magnetic materials, rare-earth magnetocaloric materials, and rare-earth magnetostrictive materials, detailing the application progress of data mining techniques in property prediction, composition and process optimization, and microstructural analysis. This work also delves into the current challenges and future trends, aiming to provide a theoretical foundation for deepening the integration of data mining technologies with rare-earth magnetic material research.

[1] 中华人民共和国国务院2024-06-29 稀土管理条例 https://www.gov.cn/zhengce/zhengceku/202406/content_6960153.htm

[2] 中华人民共和国国务院 2023-12-26中华人民共和国国民经济和社会发展第十四个五年规划和2035年远景目标纲要 https://www.gov.cn/zhuanti/shisiwuguihua/sdb.htm

[3] Tai D Q, Li B, Xue H Y, Zheng T, Wu J G 2024 Acta Mater. 262 119411

Google Scholar

Google Scholar

[4] Swamynadhan M J, O’Hara A, Ghosh S, Pantelides S T 2024 Adv. Funct. Mater. 34 2400195

Google Scholar

Google Scholar

[5] Ding S L, Kang M G, Legrand W, Gambardella P 2024 Phys. Rev. Lett. 132 236702

Google Scholar

Google Scholar

[6] 邓祥文, 伍力源, 赵锐, 王嘉鸥, 赵丽娜 2024 73 210701

Google Scholar

Google Scholar

Deng X W, Wu L Y, Zhao R, Wang J O, Zhao L N 2024 Acta Phys. Sin. 73 210701

Google Scholar

Google Scholar

[7] Möller J J, Körner W, Krugel G, Urban D F, Elsässer C 2018 Acta Mater. 153 53

Google Scholar

Google Scholar

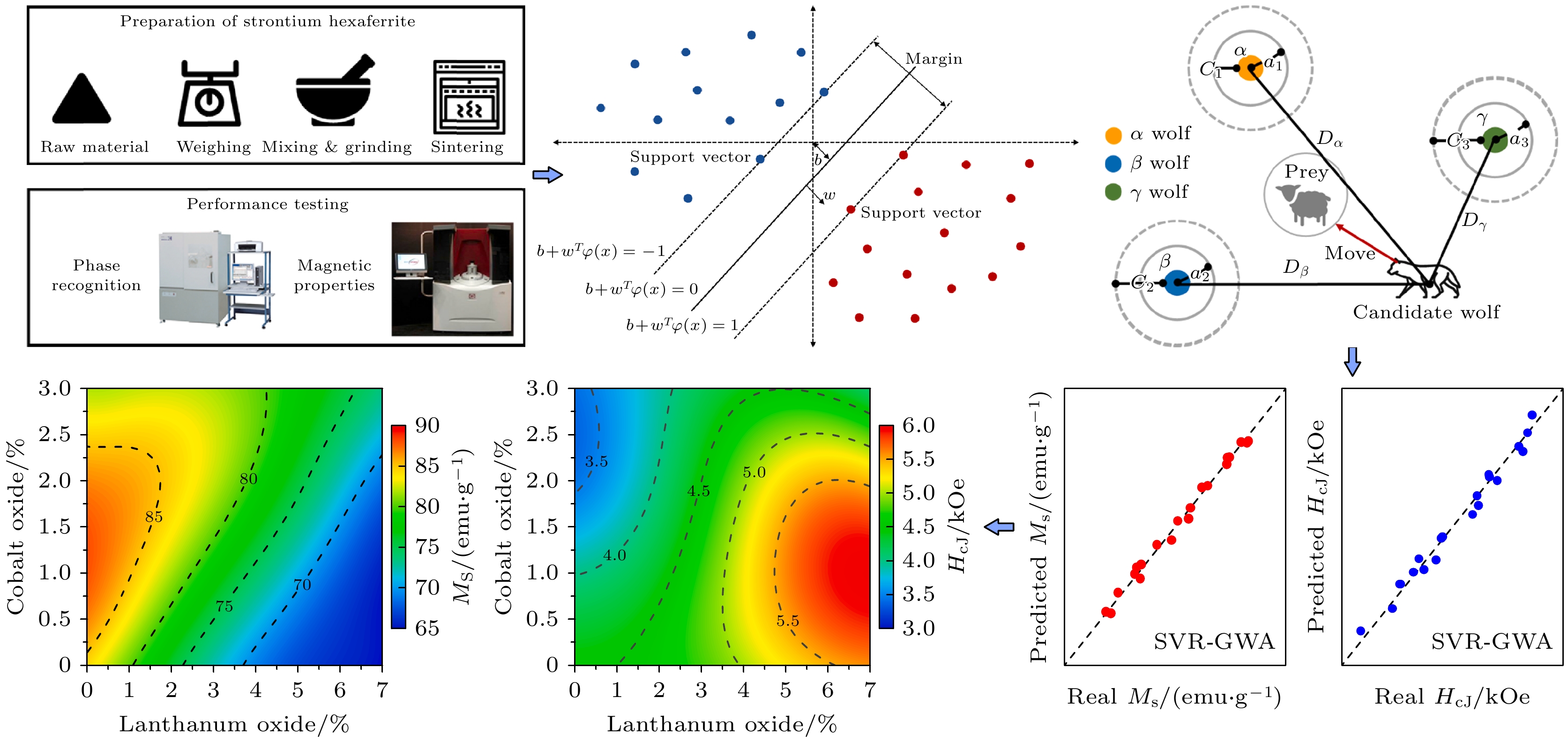

[8] Butler K T, Davies D W, Cartwright H, Isayev O, Walsh A 2018 Nature 559 547

Google Scholar

Google Scholar

[9] 张桥, 谭薇, 宁勇祺, 聂国政, 蔡孟秋, 王俊年, 朱慧平, 赵宇清 2024 73 230201

Google Scholar

Google Scholar

Zhang Q, Tan W, Ning Y Q, Nie G Z, Cai M Q, Wang J N, Zhu H P, Zhao Y Q 2024 Acta Phys. Sin. 73 230201

Google Scholar

Google Scholar

[10] Wang Z, Sun Z H, Yin H, Liu X H, Wang J L, Zhao H T, Pang C H, Wu T, Li S Z, Yin Z Y, Yu X F 2022 Adv. Mater. 34 2104113

Google Scholar

Google Scholar

[11] 彭向凯, 吉经纬, 李琳, 任伟, 项静峰, 刘亢亢, 程鹤楠, 张镇, 屈求智, 李唐, 刘亮, 吕德胜 2019 68 130701

Google Scholar

Google Scholar

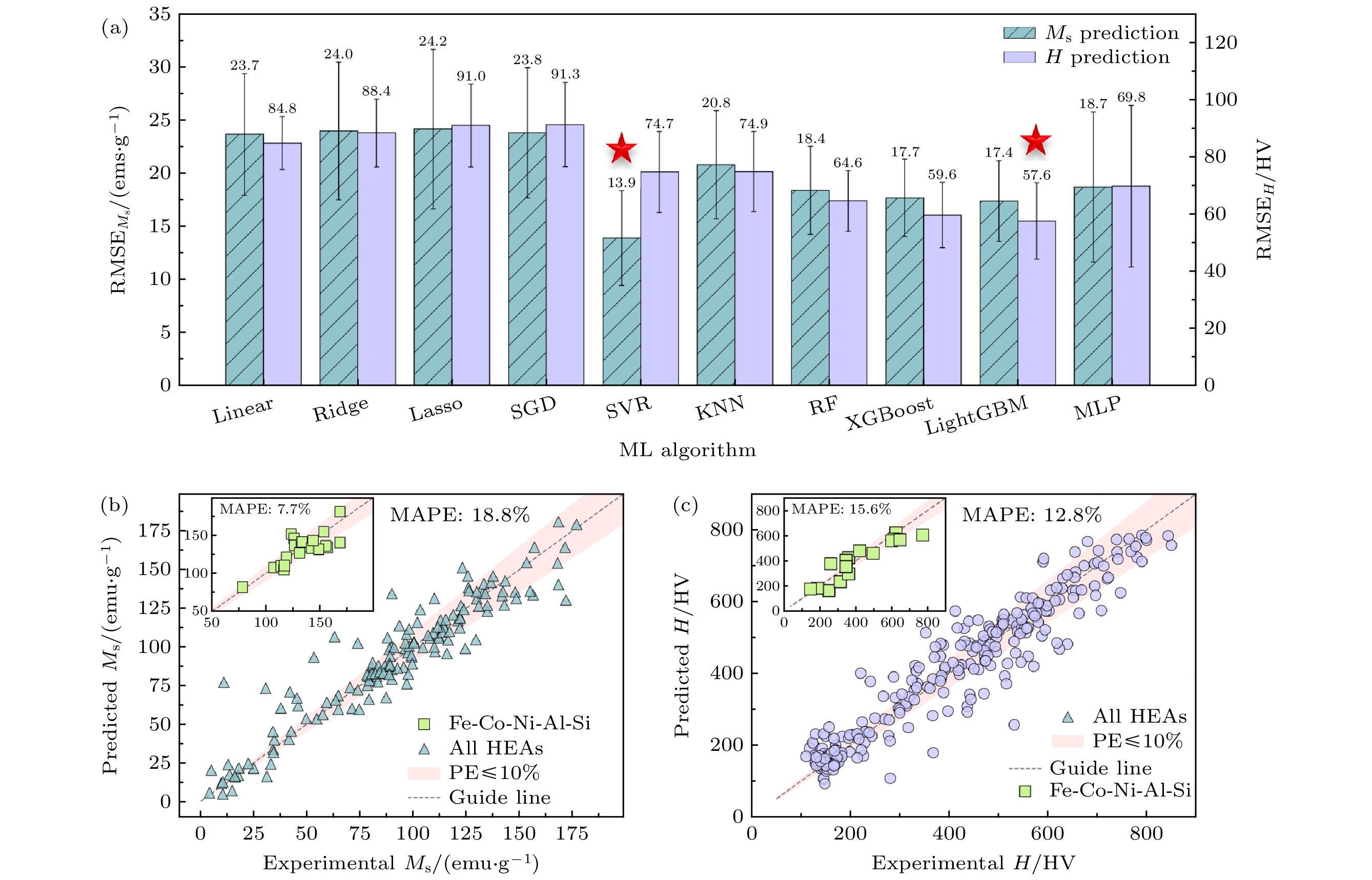

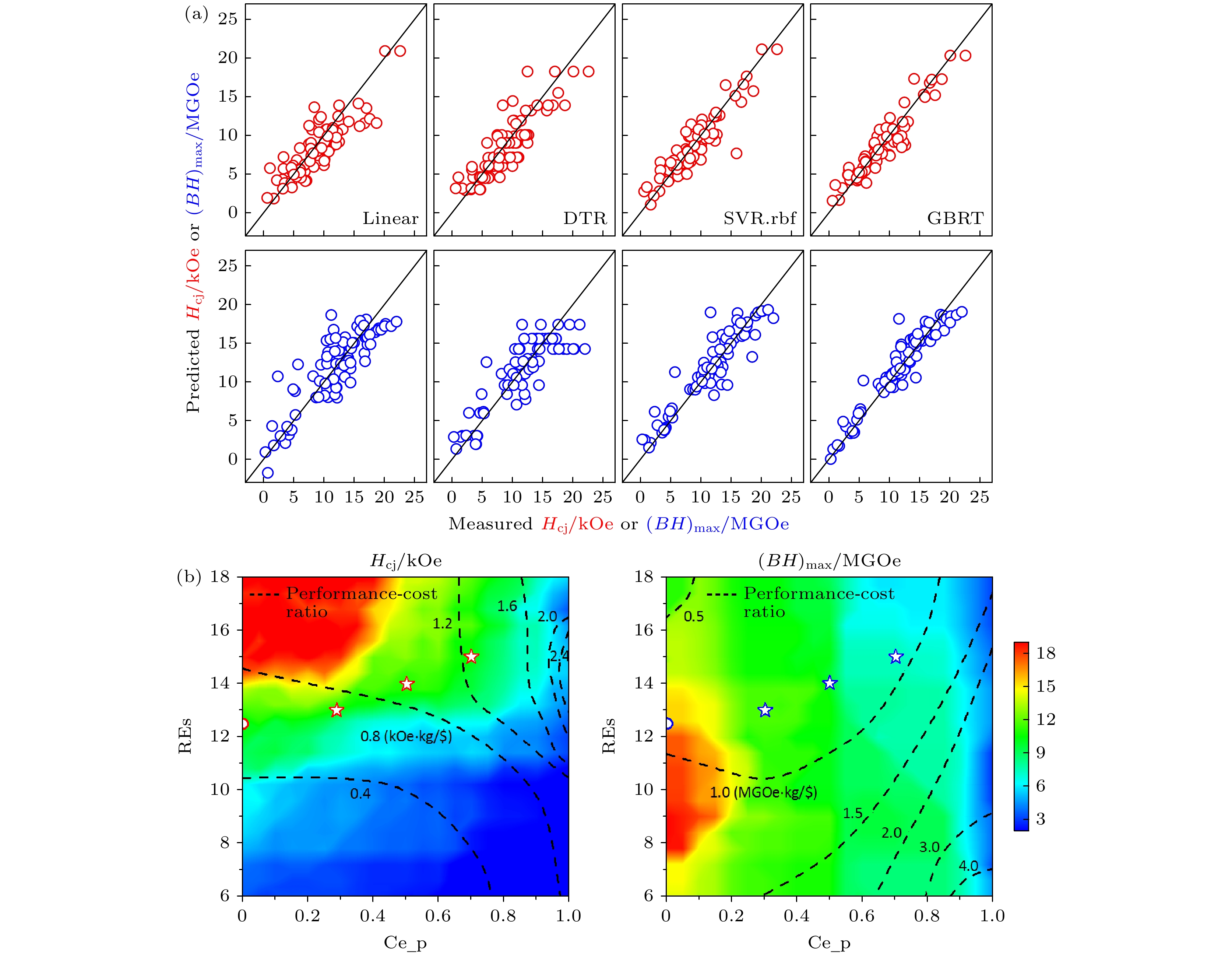

Peng X K, Ji J W, Li L, Ren W, Xiang J F, Liu K K, Cheng H N, Zhang Z, Qu Q Z, Li T, Liu L, Lü D S 2019 Acta Phys. Sin. 68 130701

Google Scholar

Google Scholar

[12] 李锐 2018博士学位论文(北京: 中国科学院大学)

Li R 2018 Ph. D. Dissertation (Beijing: University of Chinese Academy of Sciences

[13] Kovacs A, Fischbacher J, Oezelt H, Kornell A, Ali Q, Gusenbauer M, Yano M, Sakuma N, Kinoshita A, Shoji T, Kato A, Hong Y, Grenier S, Devillers T, Dempsey N M, Fukushima T, Akai H, Kawashima N, Miyake T, Schrefl T 2023 Front. Mater. 9 1094055

Google Scholar

Google Scholar

[14] Hosokawa H, Calvert E L, Shimojima K 2021 J. Magn. Magn. Mater. 526 167651

Google Scholar

Google Scholar

[15] Guo K, Lu H, Zhao Z, Tang F W, Wang H B, Song X Y 2022 Comp. Mater. Sci. 205 111232

Google Scholar

Google Scholar

[16] Wen J T, Hu H G, An J S, Han T, Hu J F 2024 J. Supercond. Nov. Magn. 37 1443

Google Scholar

Google Scholar

[17] Liu R S, Wang L C, Xu Z Y, Qin C Y, Li Z Y, Yu X, Liu D, Gong H Y, Zhao T Y, Sun J R, Hu F X, Shen B G 2022 Mater. Today Commun. 32 103996

Google Scholar

Google Scholar

[18] Nguyen D N, Pham T L, Nguyen V C, Kino H, Miyake T, Dam H C 2019 J. Phys. Mater. 2 034009

Google Scholar

Google Scholar

[19] Xu G J, Cheng F, Lu H, Hou C, Song X Y 2024 Acta Mater. 274 120026

Google Scholar

Google Scholar

[20] Halder A, Rom S, Ghosh A, Dasgupta T S 2020 Phys. Rev. Appl. 14 034024

Google Scholar

Google Scholar

[21] Lambard G, Sasakib T T, Sodeyama K, Ohkubo T, Hono K 2022 Scripta Mater. 209 114341

Google Scholar

Google Scholar

[22] Lu S F, Liu Y L, Yin Q S, Chen J F, Wu J, Li J, Zhan P J, Chen Z C 2024 J. Eur. Ceram. Soc. 44 5677

Google Scholar

Google Scholar

[23] Choudhary A K, Grubesa T, Jansche A, Bernthaler T, Goll D, Schneider G 2024 Acta Mater. 264 119563

Google Scholar

Google Scholar

[24] Kusne A G, Gao T, Mehta A, Ke L Q, Nguyen M C, Ho K M, Antropov V, Wang C Z, Kramer M J, Long C, Takeuchi I 2014 Sci. Rep. 4 63

Google Scholar

Google Scholar

[25] Nieves P, Arapan S, Hadjipanayis G C, Niarchos D, Barandiaran J M, Cuesta-López S 2016 Phys. Status Solidi C 13 942

Google Scholar

Google Scholar

[26] Xia W Y, Sakurai M, Balasubramanian B, Liao T, Wang R H, Zhang C, Sun H J, Ho K M, Chelikowsky J R, Sellmyer D J, Wang C Z 2022 Proc. Natl. Acad. Sci. 119 2204485119

Google Scholar

Google Scholar

[27] Zhang B, Zheng X Q, Zhao T Y, Hu F X, Sun J R, Shen B G 2018 Chin. Phys. B 27 067503

Google Scholar

Google Scholar

[28] 张博 2018 博士学位论文 (北京: 中国科学院大学)

Zhang B 2018 Ph. D. Dissertation (Beijing: University of Chinese Academy of Sciences

[29] Ucar H, Paudyal D, Choudhary K 2022 Comp. Mater. Sci. 209 111414

Google Scholar

Google Scholar

[30] Alqahtani A 2024 Sustainability 16 1542

Google Scholar

Google Scholar

[31] Shamsah S M I 2024 Int. J. Refrig. 168 122

Google Scholar

Google Scholar

[32] Zhao Q, Yan K L, Cui Z, Wen B Y, Xue F, Li J T, Guo J N, Xu A, Qiao K M, Ye R C, Long Y, Zhang D W, Luo H, Taskaev S, Zhang H 2023 Corros. Sci. 216 111115

Google Scholar

Google Scholar

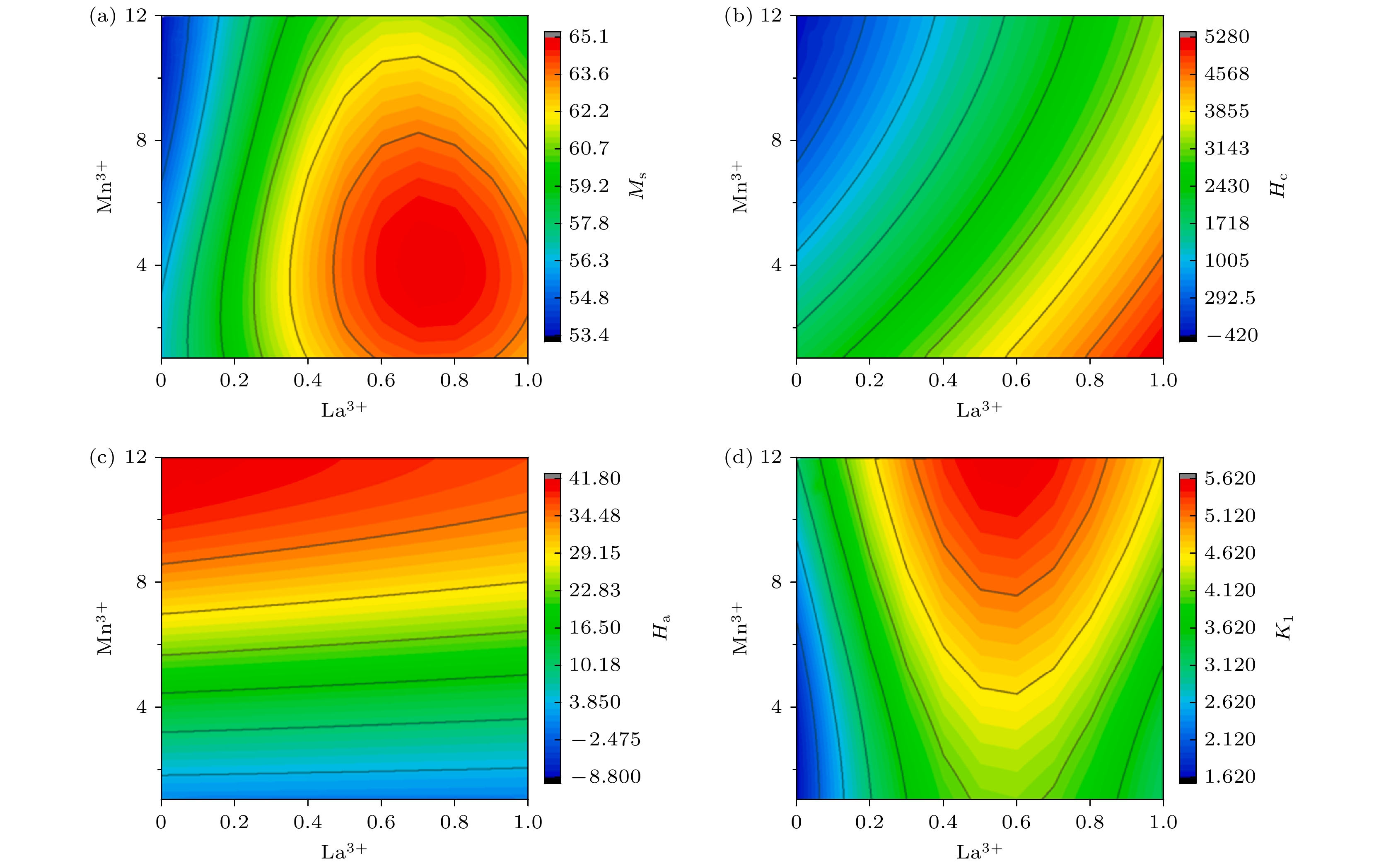

[33] Gong J H, Zhang Z M, Zhang C L, Hu P Q, Zhou C, Wang D H, Yang S 2024 Rare Met. 43 2251

Google Scholar

Google Scholar

[34] Hu P Q, Zhou C, Zhang R S, Ding S D, Guo Y J, Wang B, Xue D Z, Ma Y Z, Dai Z Y, Zhang Y, Tian F H, Yang S 2025 Mater. Design 252 113799

Google Scholar

Google Scholar

[35] Foggiatto A L, Mizutori Y, Yamazaki T, Sato S, Masuzawa K, Nagaoka R, Taniwaki M, Fujieda S, Suzuki S, Ishiyama K, Fukuda T, Igarashi Y, Mitsumata C, Kotsugi M 2023 IEEE T. Magn. 59 2501604

[36] 黎威, 龙连春, 刘静毅, 杨洋 2022 71 060202

Google Scholar

Google Scholar

Li W, Long L C, Liu J Y, Yang Y 2022 Acta Phys. Sin. 71 060202

Google Scholar

Google Scholar

[37] Liu D, Liu Z X, Zhang J E, Yin Y N, Xi J F, Wang L C, Xiong J F, Zhang M, Zhao T Y, Jin J Y, Sun J R, Hu F X, Shen J, Shen B G 2023 Research 6 0082

Google Scholar

Google Scholar

[38] Liu D, Song J H, Liu Z X, Zhang J E, Chen W Q, Yin Y N, Xi J F, Zheng X Q, Hao J Z, Zhao T Y, Hu F X, Sun J R, Shen B G 2025 Mater. Design 251 113710

Google Scholar

Google Scholar

[39] Li X, Shek C H, Liaw P K, Shan G C 2024 Prog. Mater. Sci. 146 101332

Google Scholar

Google Scholar

-

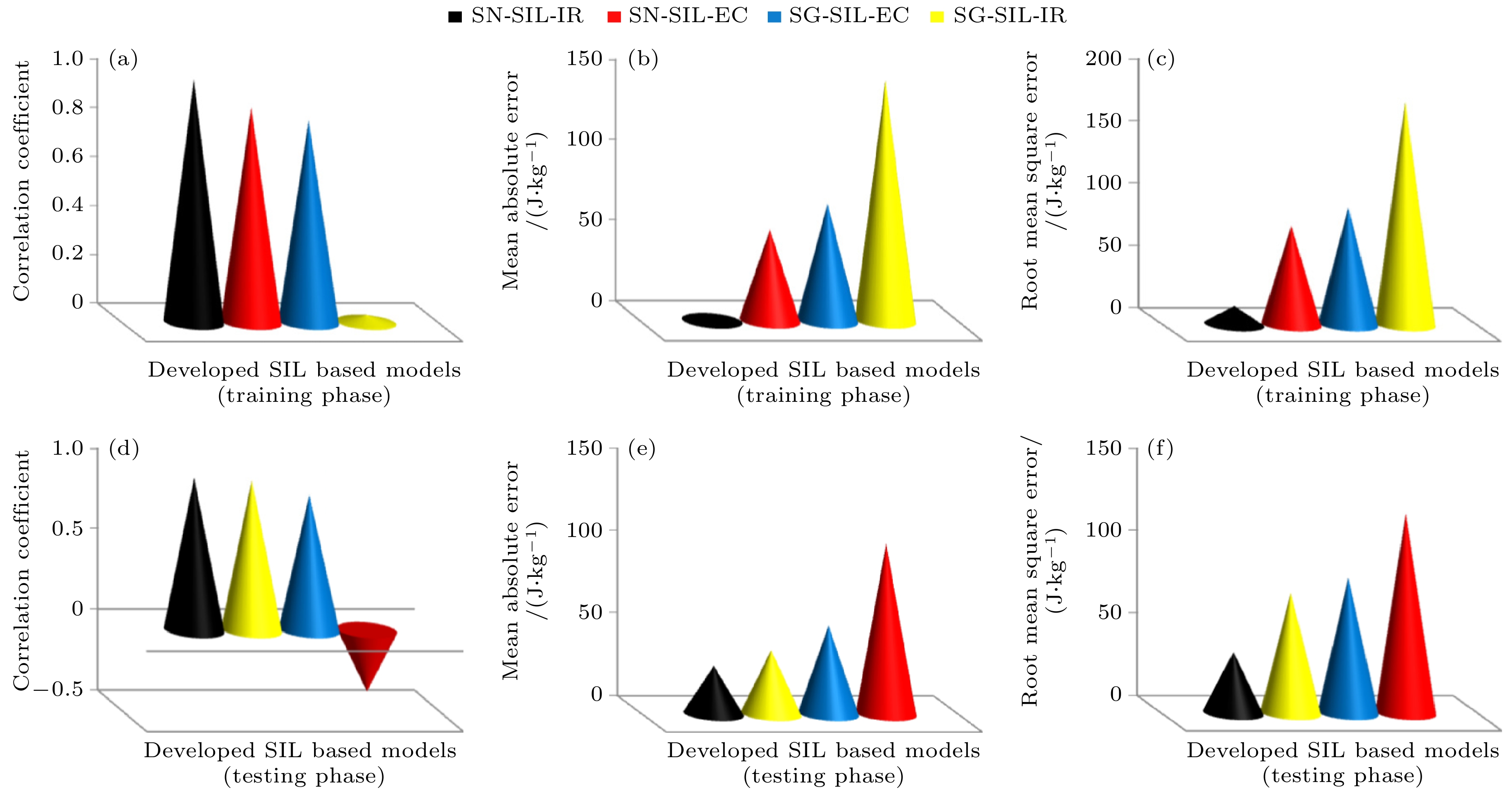

图 12 单隐层模型SIL的泛化能力评估[30] (a) 训练样本的相关系数; (b) 训练样本的平均绝对误差; (c) 训练样本的均方根误差; (d) 测试样本的相关系数; (e) 测试样本的平均绝对误差; (f) 测试样本的均方根误差

Fig. 12. Generalization capacity evaluation of developed SIL-based models[30]: (a) Training samples coefficient of correlation; (b) training samples mean absolute error; (c) training samples root mean square error; (d) testing samples coefficient of correlation; (e) testing samples mean absolute error; (f) testing samples root mean square error.

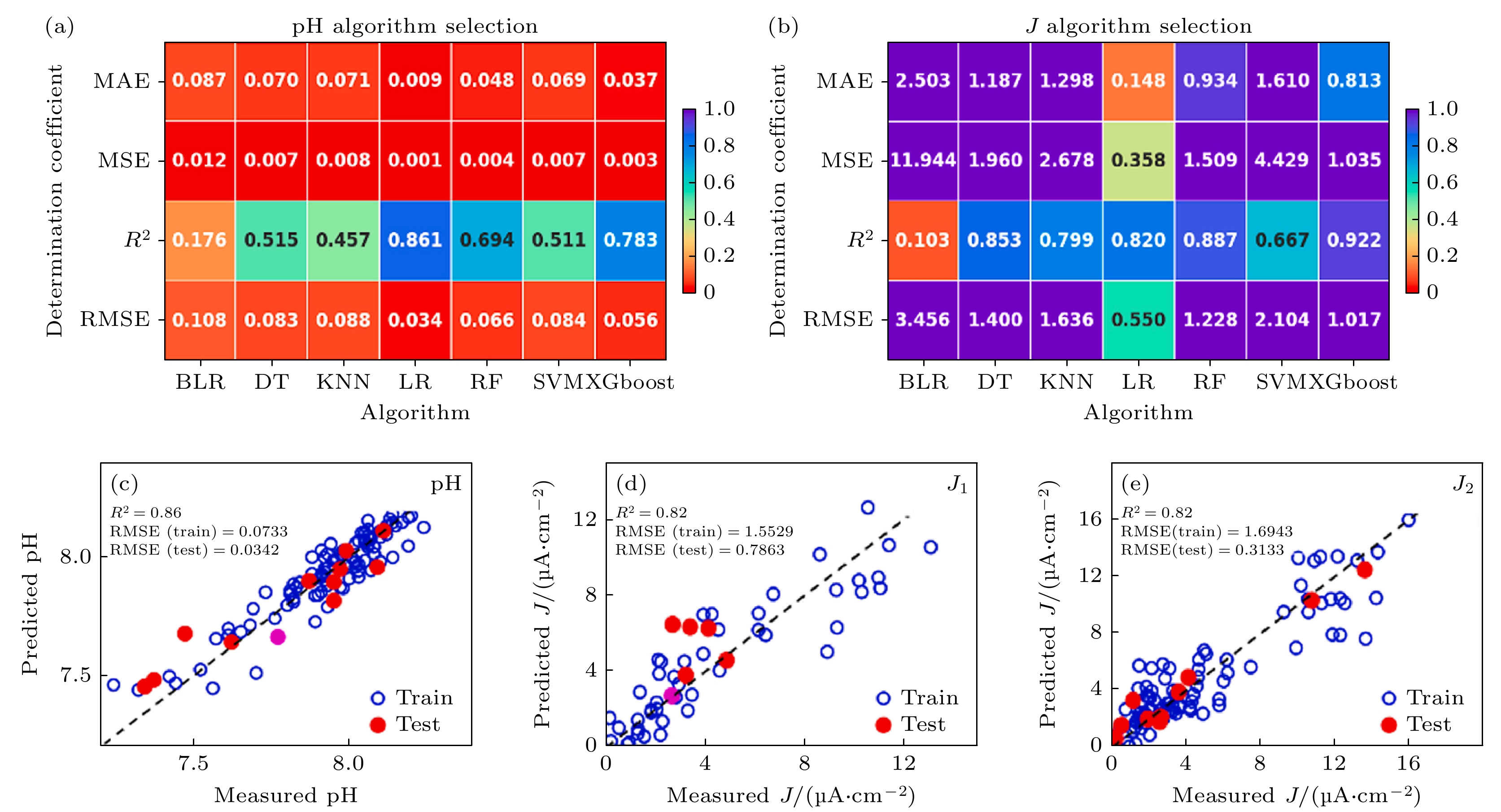

图 14 ML建模过程及缓蚀剂最佳配比的求解[32] (a) 酸碱度pH算法选择; (b) 腐蚀电流密度J算法选择; (c) 基于线性回归算法pH值的预测值与测量值对比; (d) 基于线性回归算法的J1值; (e) J2值的预测值与测量值对比

Fig. 14. ML modeling process and solving the optimal composition of corrosion inhibitor[32]: (a) The pH model algorithm selection; (b) J model algorithm selection; (c) measured-predicted pH value plot for LR algorithm; (d) measured-predicted J1 value plot for LR algorithm; (e) measured-predicted J2 value plot for LR algorithm.

表 1 常用的机器学习算法的优势与缺陷

Table 1. Advantages and disadvantages of commonly used machine learning algorithms.

模型 优势 不足 MLR 简单易懂, 计算效率高; 可解释性强, 参数直接反映特征重要性 无法捕捉非线性关系; 对异常值敏感 SVM 擅长处理高维空间中的非线性分类; 小样本数据表现优异 核函数选择依赖经验; 计算成本高, 扩展性差 DT 无需数据标准化; 可视化清晰; 擅长处理分类问题 易过拟合, 需剪枝优化; 对连续特征处理能力有限 RF 抗过拟合能力强, 适合高维数据; 可输出特征重要性, 便于特征

选择计算复杂度较高; 对小样本数据表现不佳 K-means 无需标注数据, 自动发现数据模式; 计算效率高 需要预先指定聚类数 GA 全局搜索能力, 避免局部最优; 并行处理, 适合高维问题 计算成本高; 复杂问题的收敛速度慢; 依赖高质量

的训练数据粒子群优化

算法(PSO)适用于目标函数不连续的场景; 参数少, 易于与实验工具集成 收敛速度慢; 参数敏感性; 局部搜索能力弱 PCA 有效降维, 保留关键信息; 可视化高维数据的潜在结构 无法捕捉非线性关系; 忽略特征间的相关性 ANN 强大的非线性建模能力; 适用于复杂模式识别, 如图像、

分子结构需要大量数据和计算资源; 可解释性差, 存在

“黑箱” 问题CNN 无需人工设计特征; 擅长高维数据处理; 鲁棒性强 计算资源需求大; 数据依赖性; 解释性差 -

[1] 中华人民共和国国务院2024-06-29 稀土管理条例 https://www.gov.cn/zhengce/zhengceku/202406/content_6960153.htm

[2] 中华人民共和国国务院 2023-12-26中华人民共和国国民经济和社会发展第十四个五年规划和2035年远景目标纲要 https://www.gov.cn/zhuanti/shisiwuguihua/sdb.htm

[3] Tai D Q, Li B, Xue H Y, Zheng T, Wu J G 2024 Acta Mater. 262 119411

Google Scholar

Google Scholar

[4] Swamynadhan M J, O’Hara A, Ghosh S, Pantelides S T 2024 Adv. Funct. Mater. 34 2400195

Google Scholar

Google Scholar

[5] Ding S L, Kang M G, Legrand W, Gambardella P 2024 Phys. Rev. Lett. 132 236702

Google Scholar

Google Scholar

[6] 邓祥文, 伍力源, 赵锐, 王嘉鸥, 赵丽娜 2024 73 210701

Google Scholar

Google Scholar

Deng X W, Wu L Y, Zhao R, Wang J O, Zhao L N 2024 Acta Phys. Sin. 73 210701

Google Scholar

Google Scholar

[7] Möller J J, Körner W, Krugel G, Urban D F, Elsässer C 2018 Acta Mater. 153 53

Google Scholar

Google Scholar

[8] Butler K T, Davies D W, Cartwright H, Isayev O, Walsh A 2018 Nature 559 547

Google Scholar

Google Scholar

[9] 张桥, 谭薇, 宁勇祺, 聂国政, 蔡孟秋, 王俊年, 朱慧平, 赵宇清 2024 73 230201

Google Scholar

Google Scholar

Zhang Q, Tan W, Ning Y Q, Nie G Z, Cai M Q, Wang J N, Zhu H P, Zhao Y Q 2024 Acta Phys. Sin. 73 230201

Google Scholar

Google Scholar

[10] Wang Z, Sun Z H, Yin H, Liu X H, Wang J L, Zhao H T, Pang C H, Wu T, Li S Z, Yin Z Y, Yu X F 2022 Adv. Mater. 34 2104113

Google Scholar

Google Scholar

[11] 彭向凯, 吉经纬, 李琳, 任伟, 项静峰, 刘亢亢, 程鹤楠, 张镇, 屈求智, 李唐, 刘亮, 吕德胜 2019 68 130701

Google Scholar

Google Scholar

Peng X K, Ji J W, Li L, Ren W, Xiang J F, Liu K K, Cheng H N, Zhang Z, Qu Q Z, Li T, Liu L, Lü D S 2019 Acta Phys. Sin. 68 130701

Google Scholar

Google Scholar

[12] 李锐 2018博士学位论文(北京: 中国科学院大学)

Li R 2018 Ph. D. Dissertation (Beijing: University of Chinese Academy of Sciences

[13] Kovacs A, Fischbacher J, Oezelt H, Kornell A, Ali Q, Gusenbauer M, Yano M, Sakuma N, Kinoshita A, Shoji T, Kato A, Hong Y, Grenier S, Devillers T, Dempsey N M, Fukushima T, Akai H, Kawashima N, Miyake T, Schrefl T 2023 Front. Mater. 9 1094055

Google Scholar

Google Scholar

[14] Hosokawa H, Calvert E L, Shimojima K 2021 J. Magn. Magn. Mater. 526 167651

Google Scholar

Google Scholar

[15] Guo K, Lu H, Zhao Z, Tang F W, Wang H B, Song X Y 2022 Comp. Mater. Sci. 205 111232

Google Scholar

Google Scholar

[16] Wen J T, Hu H G, An J S, Han T, Hu J F 2024 J. Supercond. Nov. Magn. 37 1443

Google Scholar

Google Scholar

[17] Liu R S, Wang L C, Xu Z Y, Qin C Y, Li Z Y, Yu X, Liu D, Gong H Y, Zhao T Y, Sun J R, Hu F X, Shen B G 2022 Mater. Today Commun. 32 103996

Google Scholar

Google Scholar

[18] Nguyen D N, Pham T L, Nguyen V C, Kino H, Miyake T, Dam H C 2019 J. Phys. Mater. 2 034009

Google Scholar

Google Scholar

[19] Xu G J, Cheng F, Lu H, Hou C, Song X Y 2024 Acta Mater. 274 120026

Google Scholar

Google Scholar

[20] Halder A, Rom S, Ghosh A, Dasgupta T S 2020 Phys. Rev. Appl. 14 034024

Google Scholar

Google Scholar

[21] Lambard G, Sasakib T T, Sodeyama K, Ohkubo T, Hono K 2022 Scripta Mater. 209 114341

Google Scholar

Google Scholar

[22] Lu S F, Liu Y L, Yin Q S, Chen J F, Wu J, Li J, Zhan P J, Chen Z C 2024 J. Eur. Ceram. Soc. 44 5677

Google Scholar

Google Scholar

[23] Choudhary A K, Grubesa T, Jansche A, Bernthaler T, Goll D, Schneider G 2024 Acta Mater. 264 119563

Google Scholar

Google Scholar

[24] Kusne A G, Gao T, Mehta A, Ke L Q, Nguyen M C, Ho K M, Antropov V, Wang C Z, Kramer M J, Long C, Takeuchi I 2014 Sci. Rep. 4 63

Google Scholar

Google Scholar

[25] Nieves P, Arapan S, Hadjipanayis G C, Niarchos D, Barandiaran J M, Cuesta-López S 2016 Phys. Status Solidi C 13 942

Google Scholar

Google Scholar

[26] Xia W Y, Sakurai M, Balasubramanian B, Liao T, Wang R H, Zhang C, Sun H J, Ho K M, Chelikowsky J R, Sellmyer D J, Wang C Z 2022 Proc. Natl. Acad. Sci. 119 2204485119

Google Scholar

Google Scholar

[27] Zhang B, Zheng X Q, Zhao T Y, Hu F X, Sun J R, Shen B G 2018 Chin. Phys. B 27 067503

Google Scholar

Google Scholar

[28] 张博 2018 博士学位论文 (北京: 中国科学院大学)

Zhang B 2018 Ph. D. Dissertation (Beijing: University of Chinese Academy of Sciences

[29] Ucar H, Paudyal D, Choudhary K 2022 Comp. Mater. Sci. 209 111414

Google Scholar

Google Scholar

[30] Alqahtani A 2024 Sustainability 16 1542

Google Scholar

Google Scholar

[31] Shamsah S M I 2024 Int. J. Refrig. 168 122

Google Scholar

Google Scholar

[32] Zhao Q, Yan K L, Cui Z, Wen B Y, Xue F, Li J T, Guo J N, Xu A, Qiao K M, Ye R C, Long Y, Zhang D W, Luo H, Taskaev S, Zhang H 2023 Corros. Sci. 216 111115

Google Scholar

Google Scholar

[33] Gong J H, Zhang Z M, Zhang C L, Hu P Q, Zhou C, Wang D H, Yang S 2024 Rare Met. 43 2251

Google Scholar

Google Scholar

[34] Hu P Q, Zhou C, Zhang R S, Ding S D, Guo Y J, Wang B, Xue D Z, Ma Y Z, Dai Z Y, Zhang Y, Tian F H, Yang S 2025 Mater. Design 252 113799

Google Scholar

Google Scholar

[35] Foggiatto A L, Mizutori Y, Yamazaki T, Sato S, Masuzawa K, Nagaoka R, Taniwaki M, Fujieda S, Suzuki S, Ishiyama K, Fukuda T, Igarashi Y, Mitsumata C, Kotsugi M 2023 IEEE T. Magn. 59 2501604

[36] 黎威, 龙连春, 刘静毅, 杨洋 2022 71 060202

Google Scholar

Google Scholar

Li W, Long L C, Liu J Y, Yang Y 2022 Acta Phys. Sin. 71 060202

Google Scholar

Google Scholar

[37] Liu D, Liu Z X, Zhang J E, Yin Y N, Xi J F, Wang L C, Xiong J F, Zhang M, Zhao T Y, Jin J Y, Sun J R, Hu F X, Shen J, Shen B G 2023 Research 6 0082

Google Scholar

Google Scholar

[38] Liu D, Song J H, Liu Z X, Zhang J E, Chen W Q, Yin Y N, Xi J F, Zheng X Q, Hao J Z, Zhao T Y, Hu F X, Sun J R, Shen B G 2025 Mater. Design 251 113710

Google Scholar

Google Scholar

[39] Li X, Shek C H, Liaw P K, Shan G C 2024 Prog. Mater. Sci. 146 101332

Google Scholar

Google Scholar

计量

- 文章访问数: 562

- PDF下载量: 17

- 被引次数: 0

下载:

下载: