-

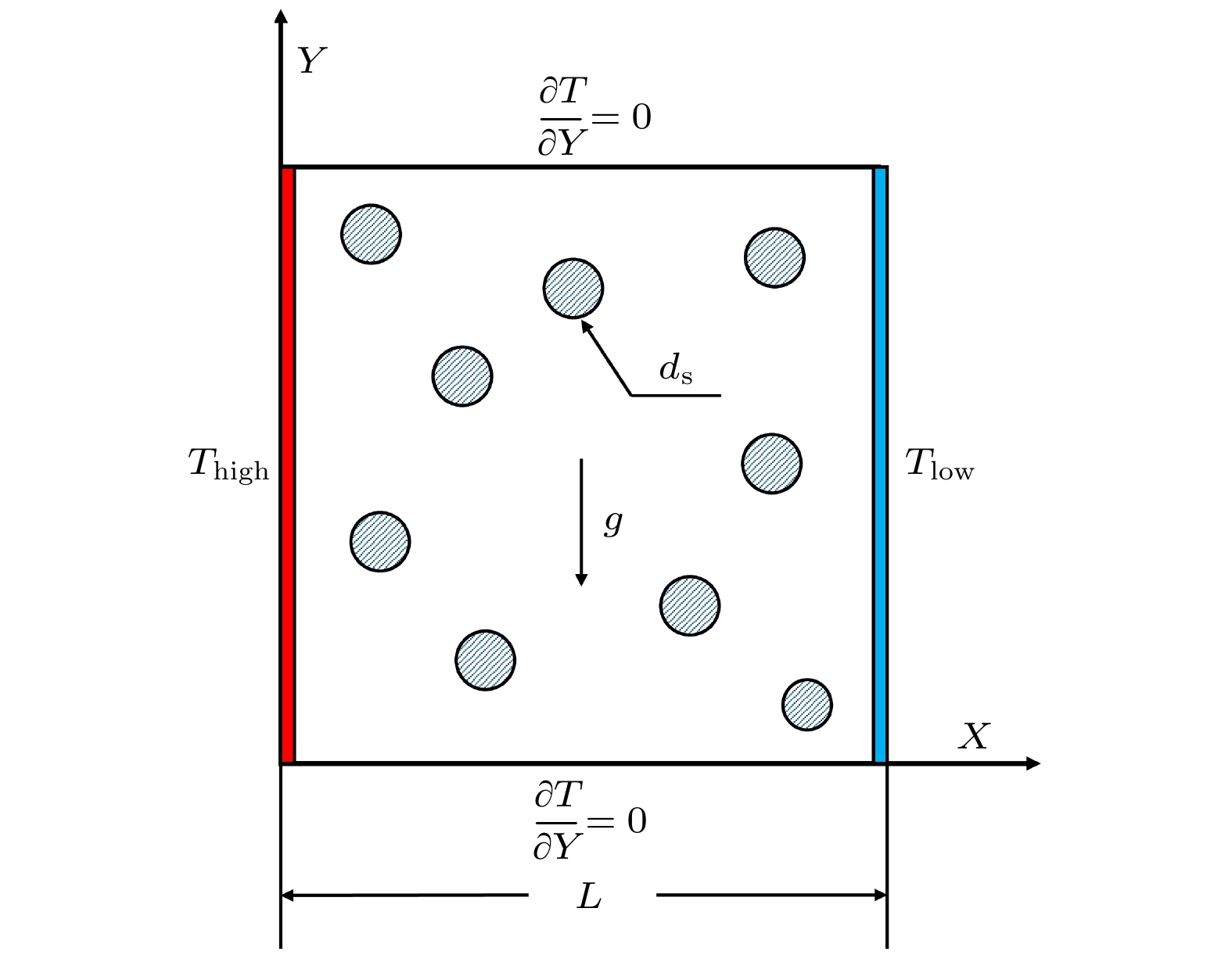

采用无量纲格子玻尔兹曼(non-dimensional lattice Boltzmann method, NDLBM)对方腔内纳米流体的自然对流进行数值模拟, 讨论克努森数($10^{-6} \leqslant Kn_{{\rm{f}},{\rm{s}}} \leqslant 10^4$)、瑞利数($10^3 \leqslant Ra_{{\rm{f}},{\rm{L}}} \leqslant 10^6$)、颗粒体积分数($10^{-2} \leqslant $$ \phi_{\rm{s}} \leqslant 10^{-1}$)等参数对纳米流体流动和传热的影响. 结果表明: 在不同$Ra_{{\rm{f}},{\rm{L}}}$下, 颗粒粒径对传热效率的影响是不同的. 在低$Ra_{{\rm{f}},{\rm{L}}}$的热传导区间, 颗粒粒径对传热影响较小; 在高$Ra_{{\rm{f}},{\rm{L}}}$的热对流区间, 较大的颗粒粒径显著提升了流动强度和传热效率. 若保持$Ra_{{\rm{f}},{\rm{L}}}$和$\phi_{\rm{s}}$不变, 随着颗粒粒径的减小, 纳米流体的传热方式由热传导转变为热对流. 此外, 针对高$Ra_{{\rm{f}},{\rm{L}}}$的热对流区间, 在兼顾了导热和流动性的情况下, 最大传热效率所对应的颗粒体积分数为$\phi_{\rm{s}} = 8 {\text{%}}$. 最后, 通过分析平均努塞尔数$\overline {Nu}_{{\rm{f}},{\rm{L}}}$和纳米流体相较于基液增加传热率$Re_{{\rm{n}},{\rm{f}}}$随不同无量纲参数变化的三维等值面图, 发现$\overline {Nu}_{{\rm{f}},{\rm{L}}}$和$Re_{{\rm{n}},{\rm{f}}}$的极值均出现在颗粒粒径为$Kn_{{\rm{f}},{\rm{s}}} = 10^{-1}$. 基于数值结果, 构建$\overline {Nu}_{{\rm{f}},{\rm{L}}}$与$Kn_{\rm{f},\rm{s}} $, $Ra_{\rm{f},\rm{L}}$, $\phi_{\rm{s}}$之间的函数关系式, 揭示了这些无量纲参数对传热性能的影响.In this work, numerical simulation of natural convection of nanofluids within a square enclosure are conducted by using the non-dimensional lattice Boltzmann method (NDLBM). The effects of key governing parameters Knudsen number ($10^{-6} \leqslant Kn_{{\rm{f}},{\rm{s}}} \leqslant 10^4$), Rayleigh number ($10^3 \leqslant Ra_{{\rm{f}},{\rm{L}}} \leqslant 10^6$), and nanoparticle volume fraction ($10^{-2} \leqslant \phi_{\rm{s}} \leqslant 10^{-1}$) on the heat and mass transfer of nanofluids are discussed. The results show that in the low $Ra_{{\rm{f}},{\rm{L}}}$ conduction dominated regime, the nanoparticle size has little effect on heat transfer, whereas in the high $Ra_{{\rm{f}},{\rm{L}}}$ convection dominated regime, larger nanoparticle size significantly enhances flow intensity and heat transfer efficiency. For fixed $Ra_{{\rm{f}},{\rm{L}}}$ and $\phi_{\rm{s}}$, the heat transfer patterns change from conduction to convection dominated regime with $Kn_{{\rm{f}},{\rm{s}}}$ increasing. The influence of nanoparticle volume fraction is also investigated, and in the convection-dominated regime, the maximum heat transfer efficiency is achieved when $\phi_{\rm{s}} = 8 {\text{%}}$, balancing thermal conduction and drag fore of nanofluid. Additionally, by analyzing the full maps of mean Nusselt number ($\overline {Nu}_{{\rm{f}},{\rm{L}}}$) and the enhancement ratio related to the base fluid ($Re_{{\rm{n}},{\rm{f}}}$), the maximum value of $\overline {Nu}_{{\rm{f}},{\rm{L}}}$ and $Re_{{\rm{n}},{\rm{f}}}$ occur when the nanoparticle size is $Kn_{{\rm{f}},{\rm{s}}} = 10^{-1}$ for both conductive and convection dominated regime. To ascertain the effects of all key governing parameters on $\overline {Nu}_{{\rm{f}},{\rm{L}}}$, a new empirical correlation is derived from the numerical results, providing a more in-depth insight into how these parameters influence on heat transfer performance.

-

Keywords:

- Knudsen number /

- nanofluid /

- natural convection /

- lattice Boltzmann method

[1] Wang X, Song Y, Li C, Zhang Y, Ali H M, Sharma S, Li R, Yang M, Gao T, Liu M, Cui X, Said Z, Zhou Z 2024 Int. J. Adv. Manuf. Technol. 131 3113

Google Scholar

Google Scholar

[2] Sandhya M, Ramasamy D, Sudhakar K, Kadirgama K, Samykano M, Harun W S W, Najafi G, Mofijur M, Mazlan M 2021 Sustainable Energy Technol. Assess. 44 101058

Google Scholar

Google Scholar

[3] Said Z, Sundar L S, Tiwari A K, Ali H M, Sheikholeslami M, Bellos E, Babar H 2022 Phys. Rep. 946 1

Google Scholar

Google Scholar

[4] Smaisim G F, Mohammed D B, Abdulhadi A M, Uktamov K F, Alsultany F H, Izzat S E, Ansari M J, Kzar H H, Al-Gazally M E, Kianfar E 2022 J. Sol-Gel Sci. Technol. 104 1

Google Scholar

Google Scholar

[5] 肖波齐, 范金土, 蒋国平, 陈玲霞 2012 61 317

Google Scholar

Google Scholar

Xiao B Q, Fan J T, Jiang G P, Chen L X 2012 Acta Phys. Sin. 61 317

Google Scholar

Google Scholar

[6] Azmi W H, Sharma K V, Mamat R, Najafi G, Mohamad M S 2016 Renewable Sustainable Energy Rev. 53 1046

Google Scholar

Google Scholar

[7] Wang X, Xu X, Choi S U S 1999 J. Thermophys. Heat Transfer 13 474

Google Scholar

Google Scholar

[8] Das S K, Putra N, Thiesen P, Roetzel W 2003 J. Heat Transfer 125 567

Google Scholar

Google Scholar

[9] Nguyen C T, Desgranges F, Galanis N, Roy G, Mare T, Boucher S, Minsta H A 2008 Int. J. Therm. Sci. 47 103

Google Scholar

Google Scholar

[10] Maxwell J C 1982 A Treatise on Electricity and Magnetism (Vol. 2) (London: Oxford University Press) pp173–215

[11] Nan C W, Shi Z, Lin Y 2003 Chem. Phys. Lett. 375 666

Google Scholar

Google Scholar

[12] Mintsa H A, Roy G, Nguyen C T, Doucet D 2009 Int. J. Therm. Sci. 48 363

Google Scholar

Google Scholar

[13] Brinkman H C 1952 J. Chem. Phys. 20 571

Google Scholar

Google Scholar

[14] Batchelor G K 1977 J. Fluid Mech. 83 97

Google Scholar

Google Scholar

[15] Nguyen C T, Desgranges F, Roy G, Galanis N, Mare T, Boucher S, Minsta H A 2007 Int. J. Heat Fluid Flow 28 1492

Google Scholar

Google Scholar

[16] Majumdar A 1993 J. Heat Transfer 115 7

Google Scholar

Google Scholar

[17] Mazumder S, Majumdar A 2001 J. Heat Transfer 123 749

Google Scholar

Google Scholar

[18] Su Y, Davidson J H 2018 Int. J. Heat Mass Transfer 127 303

Google Scholar

Google Scholar

[19] Chambre P A, Schaaf S A 1961 Flow of Rarefied Gases (Princeton: Princeton University Press) pp78–146

[20] Sui P, Su Y, Sin V, Davidson J H 2022 Int. J. Heat Mass Transfer 187 122541

Google Scholar

Google Scholar

[21] Zarki A, Ghalambaz M, Chamkha A J, Ghalambaz M, Rossi D D 2015 Adv. Powder Technol. 26 935

Google Scholar

Google Scholar

[22] Sabour M, Ghalambaz M, Chamkha A 2017 Int. J. Numer. Methods Heat Fluid Flow 27 1504

Google Scholar

Google Scholar

[23] Paul T C, Morshed A, Fox E B, Khan J A 2017 Int. J. Heat Mass Transfer 28 753

[24] Liu F, Wang L 2009 Int. J. Heat Mass Transfer 52 5849

Google Scholar

Google Scholar

[25] Zahmatkesh I, Sheremet M, Yang L, Heris S Z, Sharifpur M, Meyer J P, Ghalambaz M, Wongwises S, Jing D, Mahian O 2021 J. Mol. Liq. 321 114430

Google Scholar

Google Scholar

[26] Trodi A, Benhamza M E H 2017 Chem. Eng. Commun. 204 158

Google Scholar

Google Scholar

[27] Sheikhzadeh G A, Aghaei A, Soleimani S 2018 Challenges Nano Micro Scale Sci. Technol. 6 27

[28] Dogonchi A S, Hashemi-Tilehnoee M, Waqas M, Seyyedi S M, Animasaun I L, Ganji D D 2020 Phys. A 540 123034

Google Scholar

Google Scholar

[29] 张贝豪, 郑林 2020 69 164401

Google Scholar

Google Scholar

Zhang B H, Zheng L 2020 Acta Phys. Sin. 69 164401

Google Scholar

Google Scholar

[30] Su Y, Sui P, Davidson J H 2022 Renew. Energy 184 712

Google Scholar

Google Scholar

[31] Lai F, Yang Y 2011 Int. J. Therm. Sci. 50 1930

Google Scholar

Google Scholar

[32] Sheikholeslami M, Gorji-Bandpy M, Domairry G 2013 Appl. Math. Mech. 34 833

Google Scholar

Google Scholar

[33] 齐聪, 何光艳, 李意民, 何玉荣 2015 64 328

Google Scholar

Google Scholar

Qi C, He G Y, Li Y M, He Y R 2015 Acta Phys. Sin. 64 328

Google Scholar

Google Scholar

[34] Taher M A, Kim H D, Lee Y W 2017 Heat Transfer Res. 48 1025

Google Scholar

Google Scholar

[35] 袁俊杰, 叶欣, 单彦广 2021 计算物理 38 57

Yuan J J, Ye X, Shan Y G 2021 Chinese Journal of Computational Physics 38 57

[36] Ganji D D, Malvandi A 2014 Powder Technol. 263 50

Google Scholar

Google Scholar

[37] Hwang K S, Lee J H, Jang S P 2009 Int. J. Heat Mass Transfer 50 4003

[38] Wang D, Cheng P, Quan X 2019 Int. J. Heat Mass Transfer 130 1358

Google Scholar

Google Scholar

[39] Hua Y C, Cao B Y 2016 Int. J. Heat Mass Transfer 92 995

Google Scholar

Google Scholar

[40] Tarokh A, Mohamad A, Jiang L 2013 Numer. Heat Transfer, Part A 63 159

Google Scholar

Google Scholar

[41] Ho C J, Chen M W, Li Z W 2008 Int. J. Heat Mass Transfer 51 4506

Google Scholar

Google Scholar

[42] Li C H, Peterson G P 2007 J. Appl. Phys. 101 044312

Google Scholar

Google Scholar

[43] Chon C H, Kihm K D, Lee S P 2005 Appl. Phys. Lett. 87 153107

Google Scholar

Google Scholar

-

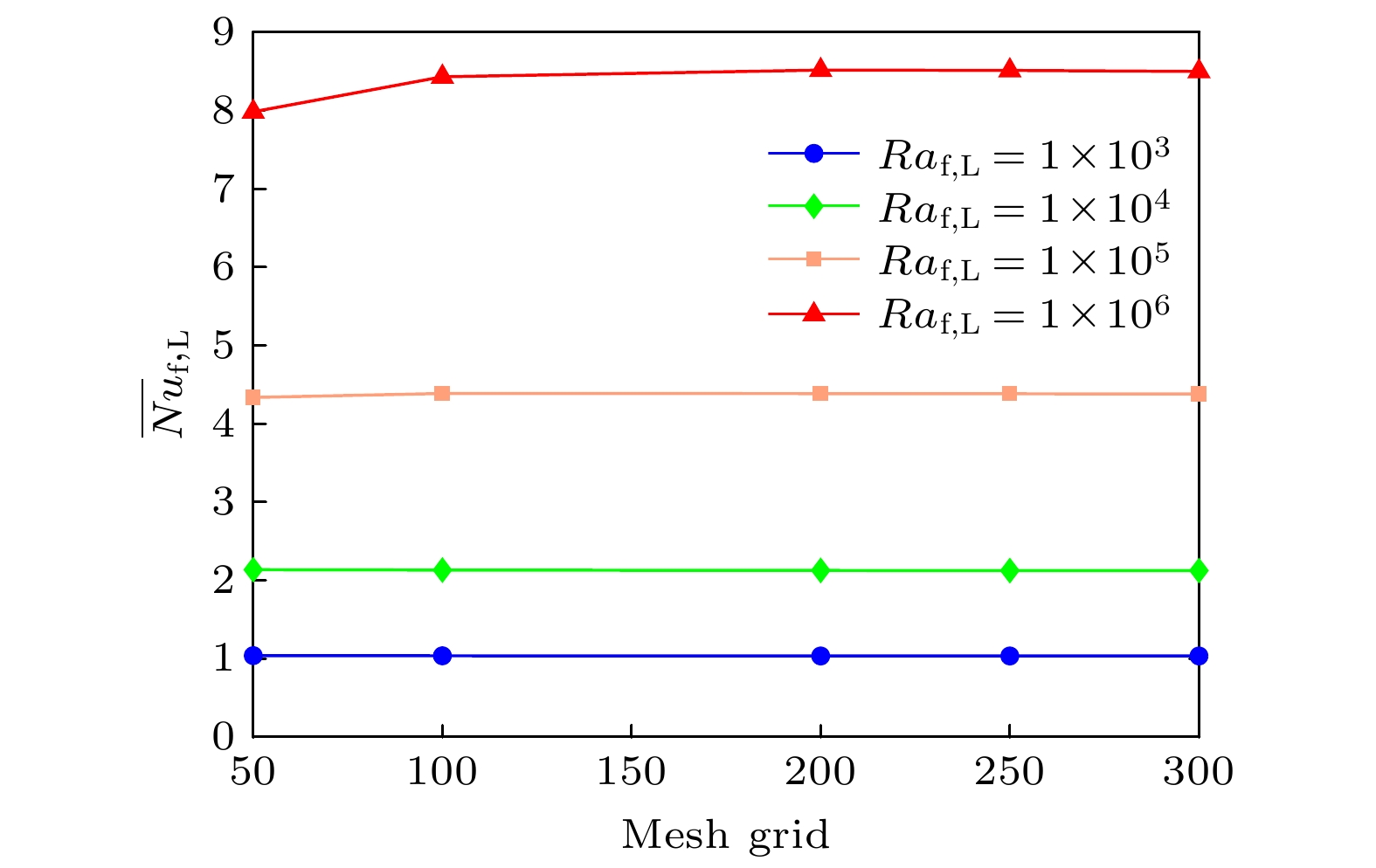

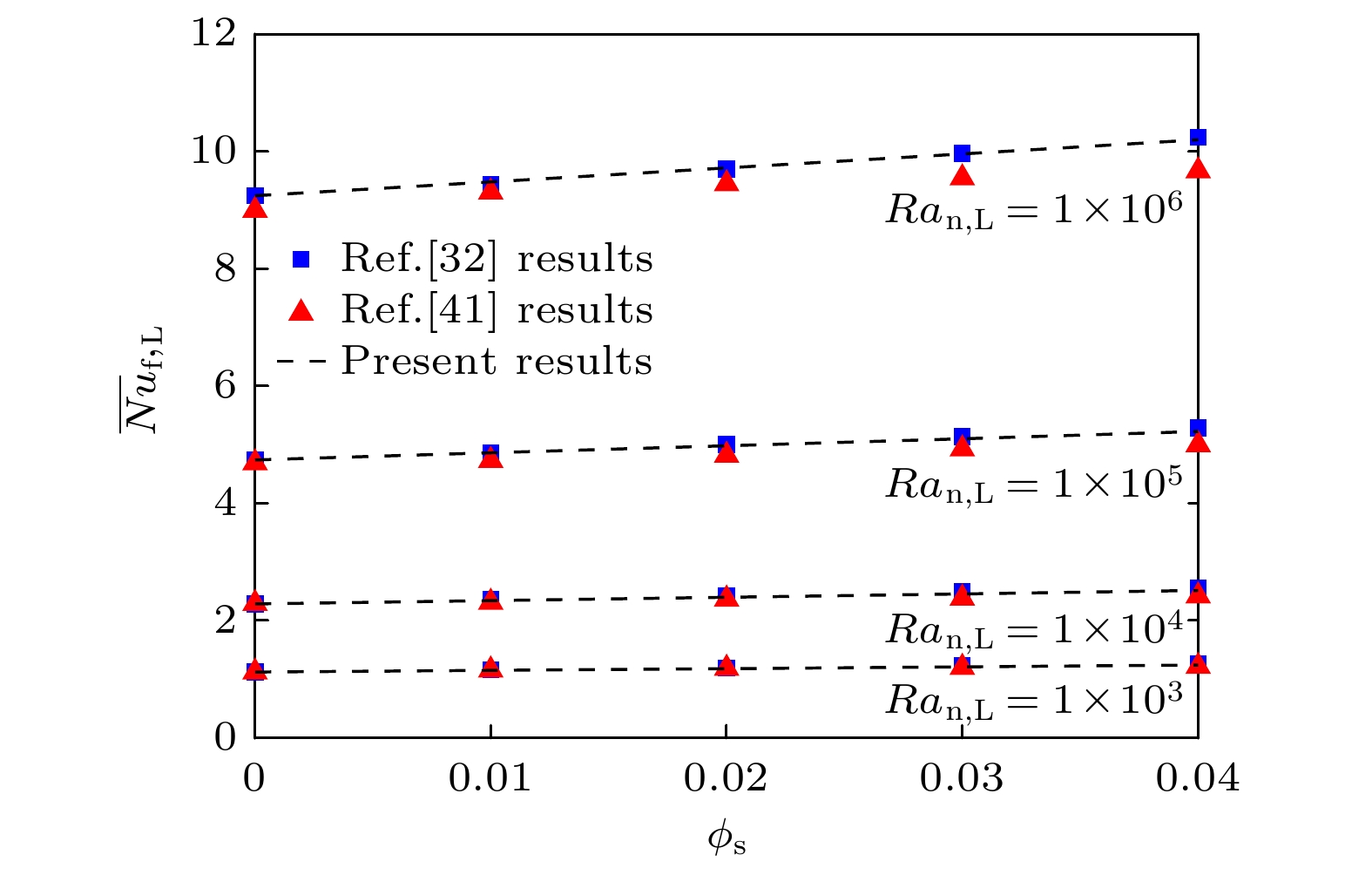

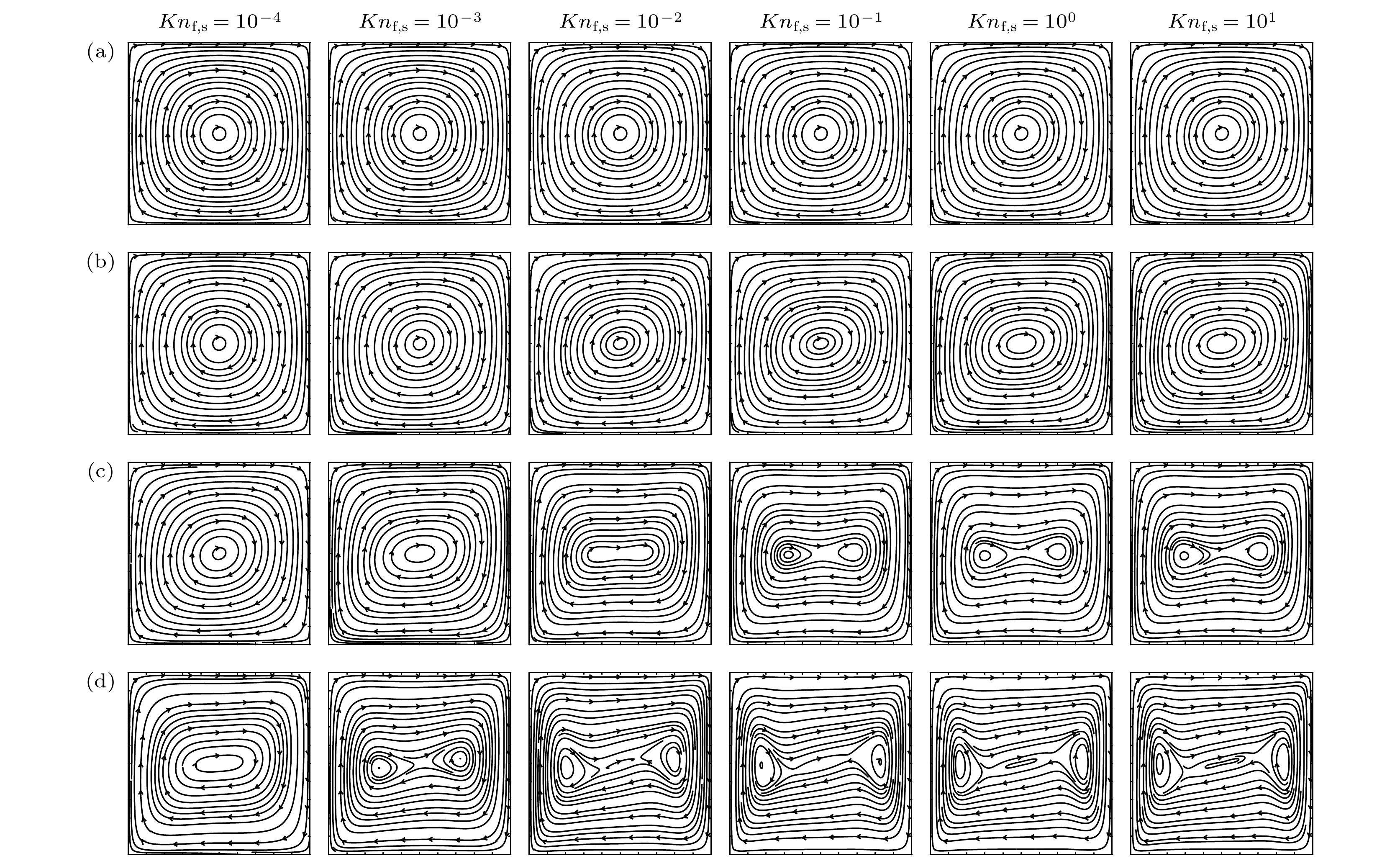

图 4 在固定颗粒体积分数$ \phi_{\rm{s}} = 8 {\text{%}} $, 不同颗粒粒径$ 1 \times 10^{-4} \leqslant Kn_{{\rm{f}}, {\rm{s}}} \leqslant 1 \times 10^2 $和瑞利数$ 1 \times 10^{3} \leqslant Ra_{{{\rm{f}}, {\rm{L}}}} \leqslant 1 \times 10^6 $下的无量纲速度场流线分布图像 (a) $ Ra_{{{\rm{f}}, {\rm{L}}}} = 1 \times 10^{3} $; (b) $ Ra_{{{\rm{f}}, {\rm{L}}}} = 1 \times 10^{4} $; (c) $ Ra_{{{\rm{f}}, {\rm{L}}}} = 1 \times 10^{5} $; (d) $ Ra_{{{\rm{f}}, {\rm{L}}}} = 1 \times 10^{6} $

Fig. 4. Dimensionless streamlines for different nanoparticle size $ 1 \times 10^{-4} \leqslant Kn_{{\rm{f}}, {\rm{s}}} \leqslant 1 \times 10^2 $ and Rayleigh number $ 1 \times 10^{3}\leqslant $$ Ra_{{{\rm{f}}, {\rm{L}}}} \leqslant 1 \times 10^6 $ with fixed $ \phi_{\mathrm{s}} = 8 {\text{%}} $: (a) $ Ra_{{{\rm{f}}, {\rm{L}}}} = 1 \times 10^{3} $; (b) $ Ra_{{{\rm{f}}, {\rm{L}}}} = 1 \times 10^{4} $; (c) $ Ra_{{{\rm{f}}, {\rm{L}}}} = 1 \times 10^{5} $; (d) $ Ra_{{{\rm{f}}, {\rm{L}}}} = 1 \times 10^{6} $

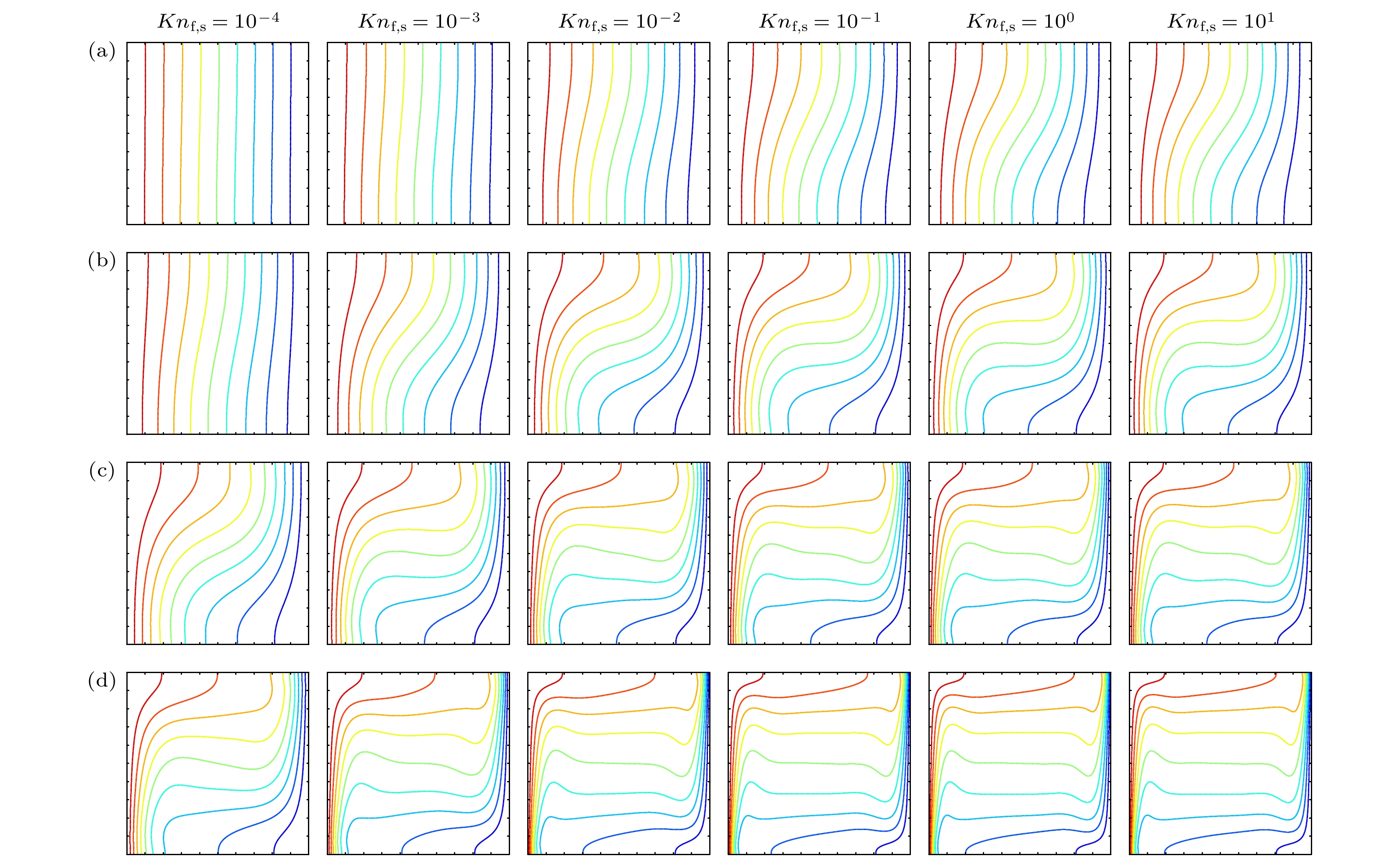

图 5 在固定颗粒体积分数$ \phi_{\rm{s}} = 8 {\text{%}} $, 不同颗粒粒径$ 1 \times 10^{-4} \leqslant Kn_{{\rm{f}}, {\rm{s}}} \leqslant 1 \times 10^2 $和瑞利数$ 1 \times 10^{3} \leqslant Ra_{{{\rm{f}}, {\rm{L}}}} \leqslant 1 \times 10^6 $下的无量纲温度场等温线分布图像 (a) $ Ra_{{{\rm{f}}, {\rm{L}}}} = 1 \times 10^{3} $; (b) $ Ra_{{{\rm{f}}, {\rm{L}}}} = 1 \times 10^{4} $; (c) $ Ra_{{{\rm{f}}, {\rm{L}}}} = 1 \times 10^{5} $; (d) $ Ra_{{{\rm{f}}, {\rm{L}}}} = 1 \times 10^{6} $

Fig. 5. Dimensionless isotherms for different nanoparticle size $ 1 \times 10^{-4} \leqslant Kn_{{\rm{f}}, {\rm{s}}} \leqslant 1 \times 10^2 $ and Rayleigh number $ 1 \times 10^{3} \leqslant $$ Ra_{{{\rm{f}}, {\rm{L}}}} \leqslant 1 \times 10^6 $ with fixed $ \phi_{\mathrm{s}} = 8 {\text{%}} $: (a) $ Ra_{{{\rm{f}}, {\rm{L}}}} = 1 \times 10^{3} $; (b) $ Ra_{{{\rm{f}}, {\rm{L}}}} = 1 \times 10^{4} $; (c) $ Ra_{{{\rm{f}}, {\rm{L}}}} = 1 \times 10^{5} $; (d) $ Ra_{{{\rm{f}}, {\rm{L}}}} = 1 \times 10^{6} $.

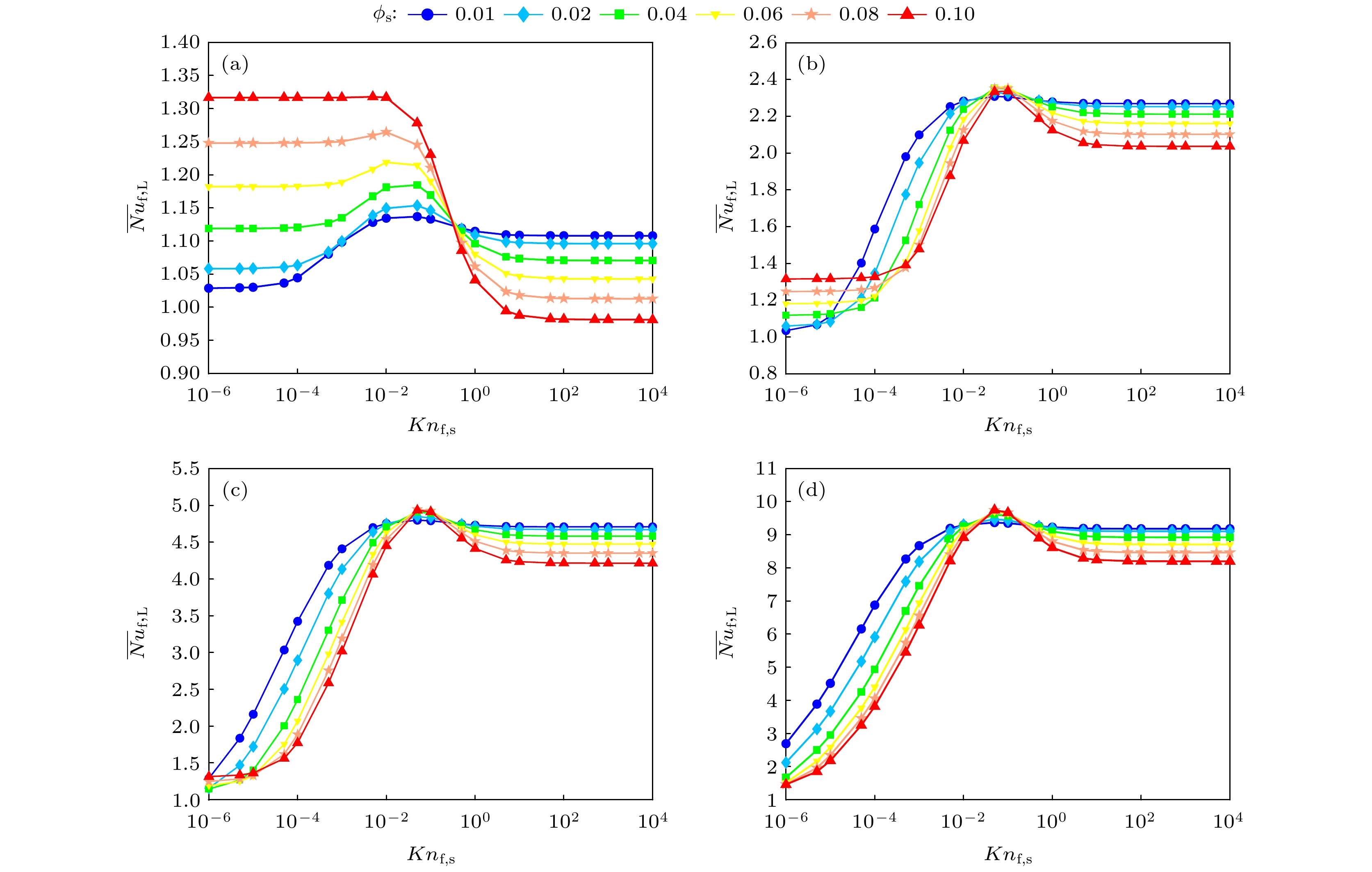

图 6 不同颗粒体积分数和瑞利数下, 平均努塞尔数$ \overline {Nu}_{{{\rm{f}}, {\rm{L}}}} $与克努森数$ 1 \times 10^{-6} \leqslant Kn_{{\rm{f}}, {\rm{s}}} \leqslant 1 \times 10^4 $关系 (a) $ Ra_{{{\rm{f}}, {\rm{L}}}} = 1 \times 10^3 $; (b) $ Ra_{{{\rm{f}}, {\rm{L}}}} = 1 \times 10^4 $; (c) $ Ra_{{{\rm{f}}, {\rm{L}}}} = 1 \times 10^5 $; (d) $ Ra_{{{\rm{f}}, {\rm{L}}}} = 1 \times 10^6 $

Fig. 6. The mean Nusselt number $ \overline {Nu}_{{{\rm{f}}, {\rm{L}}}} $ versus Knudsen number $ 1 \times 10^{-6} \leqslant Kn_{{\rm{f}}, {\rm{s}}} \leqslant 1 \times 10^4 $ with different volume fraction and Rayleigh number: (a) $ Ra_{{{\rm{f}}, {\rm{L}}}} = 1 \times 10^3 $; (b) $ Ra_{{{\rm{f}}, {\rm{L}}}} = 1 \times 10^4 $; (c) $ Ra_{{{\rm{f}}, {\rm{L}}}} = 1 \times 10^5 $; (d) $ Ra_{{{\rm{f}}, {\rm{L}}}} = 1 \times 10^6 $.

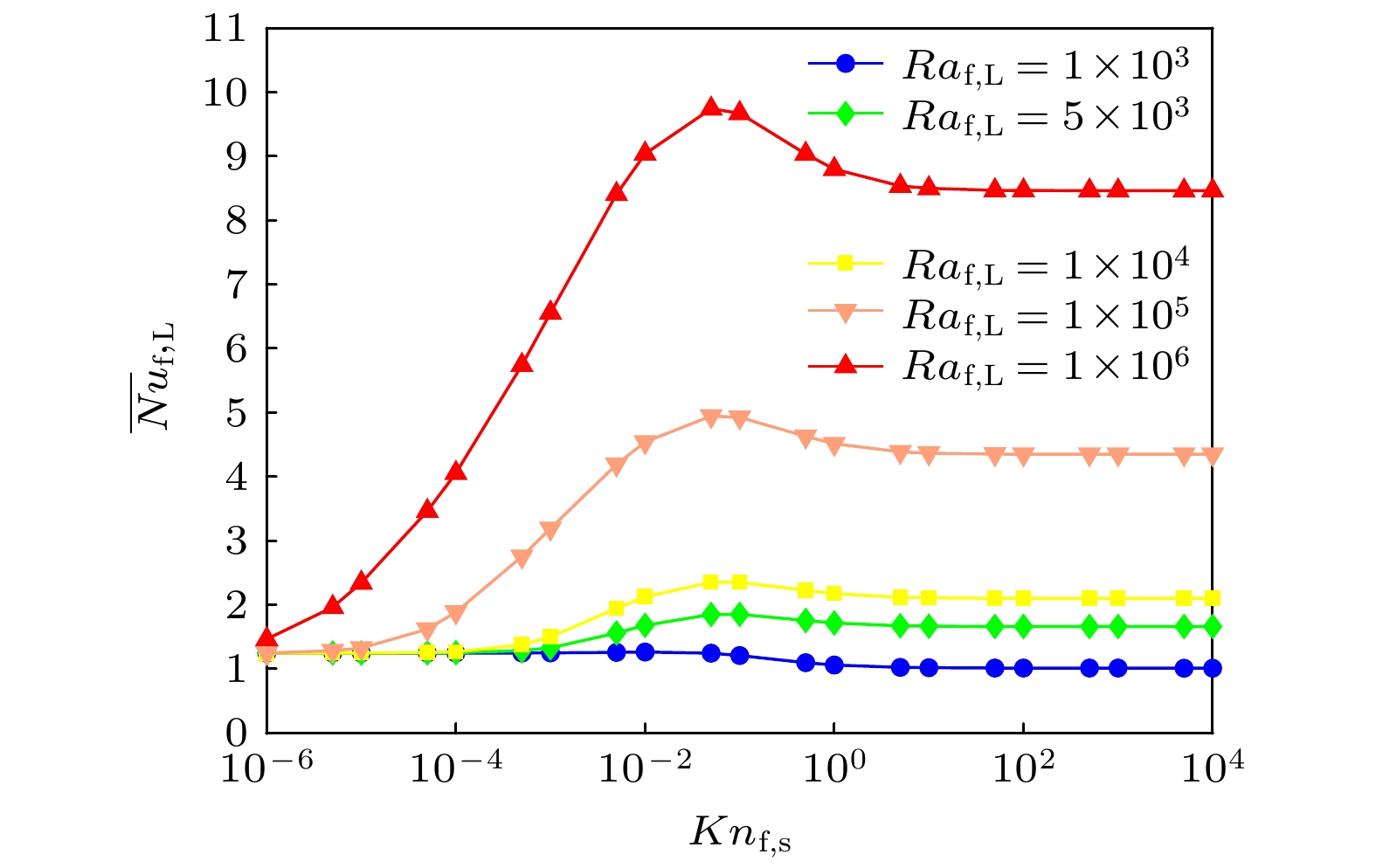

图 7 不同瑞利数$ 1 \times 10^{3} \leqslant Ra_{{{\rm{f}}, {\rm{L}}}} \leqslant 1 \times 10^6 $和固定颗粒体积分数$ \phi_{\rm{s}} = 8{\text{%}} $下, 平均努塞尔数$ \overline {Nu}_{{{\rm{f}}, {\rm{L}}}} $与克努森数关系

Fig. 7. The mean Nusselt number $ \overline {Nu}_{{{\rm{f}}, {\rm{L}}}} $ versus Knudsen number with different Rayleigh number $ 1 \times 10^{3} \leqslant Ra_{{{\rm{f}}, {\rm{L}}}} \leqslant $$ 1 \times 10^6 $ and fixed nanoparticle volume fraction $ \phi_{\rm{s}} = 8{\text{%}} $.

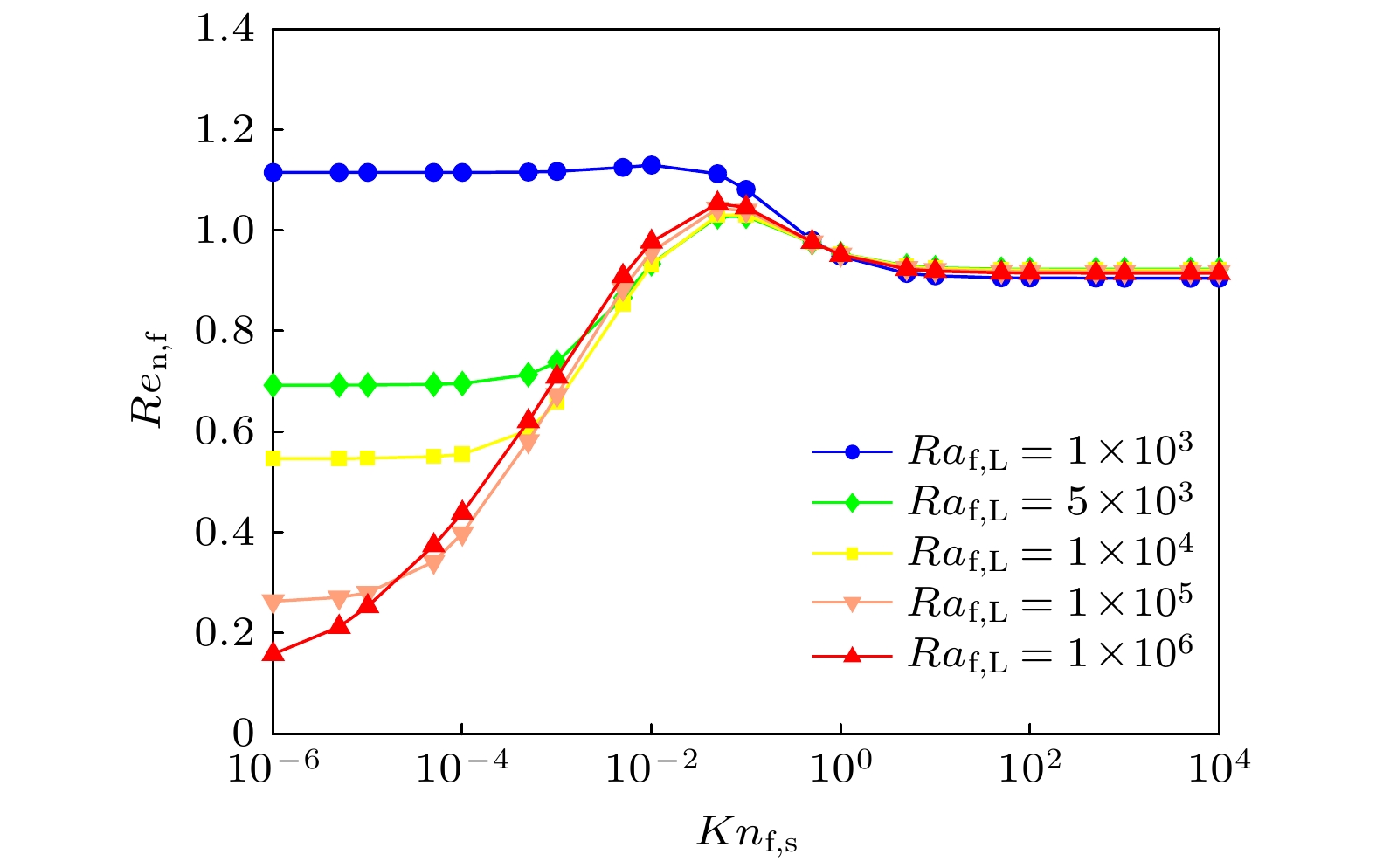

图 8 不同瑞利数$ 1 \times 10^{3} \leqslant Ra_{{{\rm{f}}, {\rm{L}}}} \leqslant 1 \times 10^6 $和固定颗粒体积分数$ \phi_{\rm{s}} = 8{\text{%}} $下, 纳米流体相较于基液传热增加率$ Re_{{\rm{n}}, {\rm{f}}} $与克努森数关系

Fig. 8. The enhancement ratio $ Re_{{\rm{n}}, {\rm{f}}} $ versus Knudsen number with different Rayleigh number $ 1 \times 10^{3} \leqslant Ra_{{{\rm{f}}, {\rm{L}}}} \leqslant $$ 1 \times 10^6 $ and fixed nanoparticle volume fraction $ \phi_{\rm{s}} = 8{\text{%}} $.

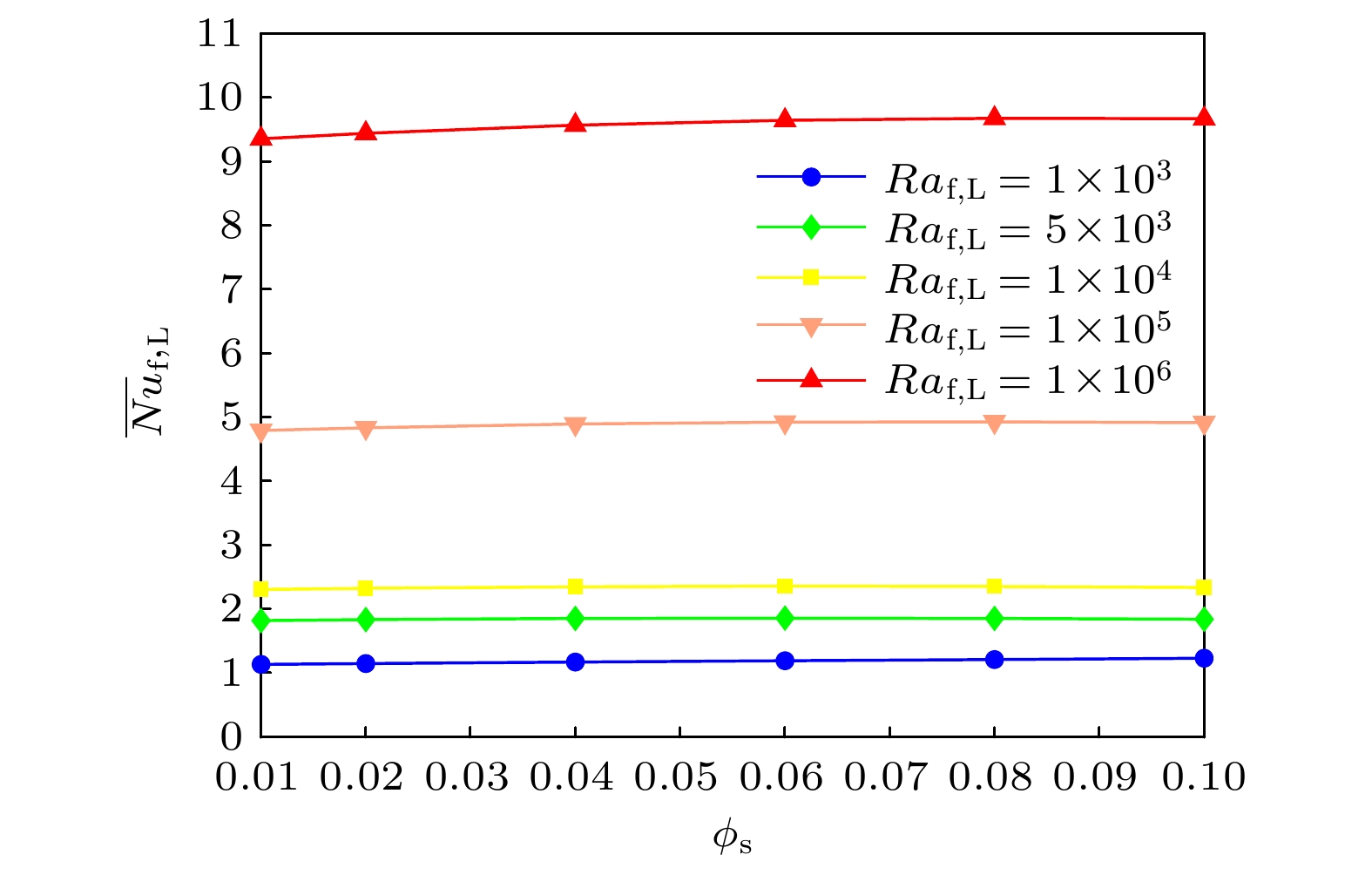

图 9 不同瑞利数$ 1 \times 10^{3} \leqslant Ra_{{{\rm{f}}, {\rm{L}}}} \leqslant 1 \times 10^6 $和固定颗粒粒径$ Kn_{{\rm{f}}, {\rm{s}}} = 10^{-1} $下, 平均努塞尔数$ \overline {Nu}_{{{\rm{f}}, {\rm{L}}}} $与颗粒体积分数关系

Fig. 9. The mean Nusselt number $ \overline {Nu}_{{{\rm{f}}, {\rm{L}}}} $ versus nanoparticle volume fraction with different Rayleigh number $ 1 \times 10^{3} \leqslant Ra_{{{\rm{f}}, {\rm{L}}}} \leqslant 1 \times 10^6 $ and fixed nanoparticle size $ Kn_{{\rm{f}}, {\rm{s}}} = 10^{-1} $.

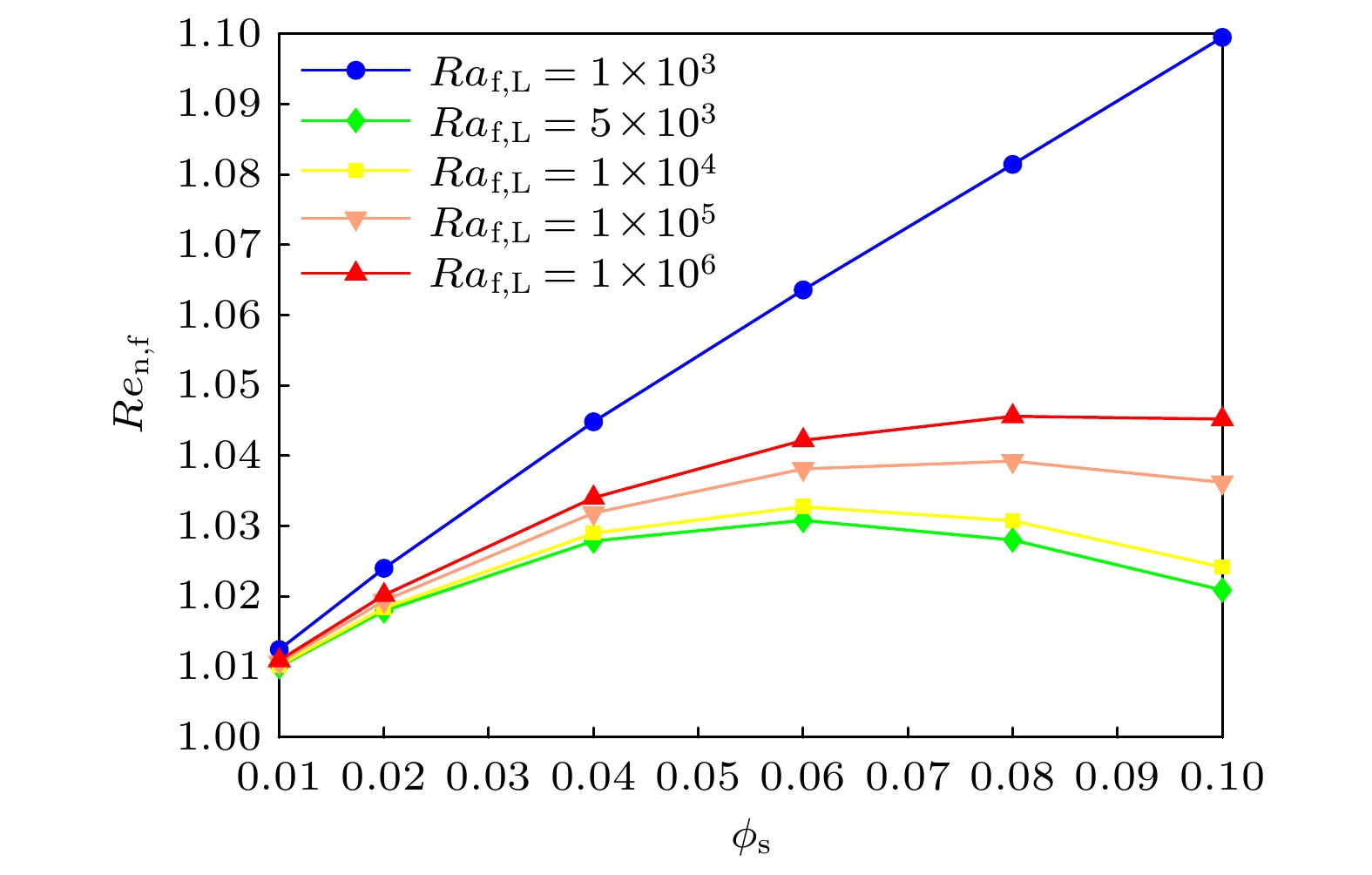

图 10 不同瑞利数$ 1 \times 10^{3} \leqslant Ra_{{{\rm{f}}, {\rm{L}}}} \leqslant 1 \times 10^6 $和固定颗粒粒径$ Kn_{{\rm{f}}, {\rm{s}}} = 10^{-1} $下, 纳米流体相较于基液传热增加率$ Re_{{\rm{n}}, {\rm{f}}} $与颗粒体积分数关系

Fig. 10. The enhancement ratio $ Re_{{\rm{n}}, {\rm{f}}} $ versus nanoparticle volume fraction with different Rayleigh number $ 1 \times 10^{3} \leqslant $$ Ra_{{{\rm{f}}, {\rm{L}}}} \leqslant 1 \times 10^6 $ and fixed nanoparticle size $ Kn_{{\rm{f}}, {\rm{s}}} = 10^{-1} $.

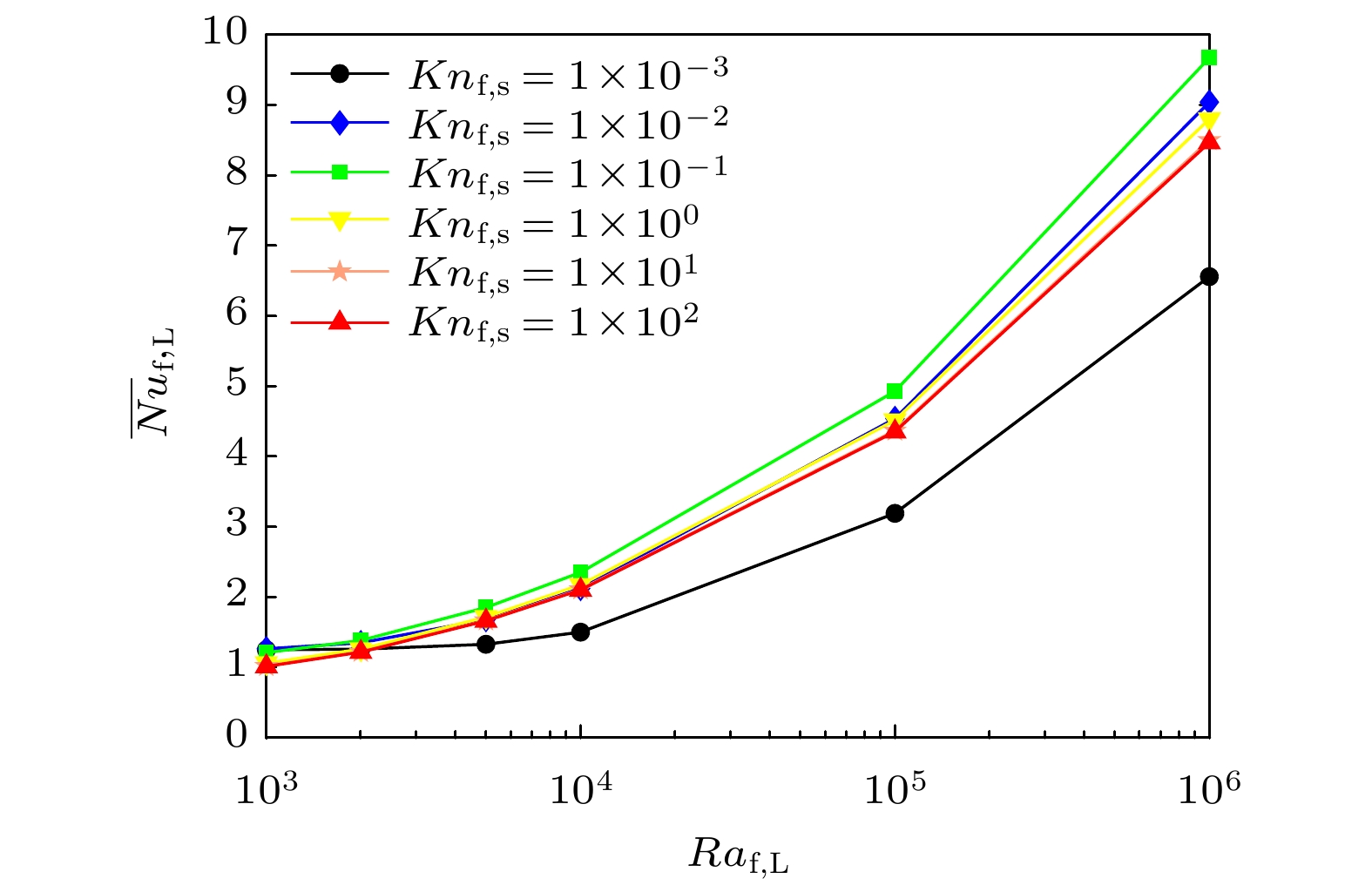

图 11 不同克努森数$ 1 \times 10^{-3} \leqslant Kn_{{\rm{f}}, {\rm{s}}} \leqslant 1 \times 10^2 $和固定颗粒体积分数$ \phi_{\rm{s}} = 8 {\text{%}} $下, 平均努塞尔数$ \overline {Nu}_{{{\rm{f}}, {\rm{L}}}} $与瑞利数关系

Fig. 11. The mean Nusselt number $ \overline {Nu}_{{{\rm{f}}, {\rm{L}}}} $ versus Rayleigh number with different Knudsen number $ 1 \times 10^{-3} \leqslant Kn_{{\rm{f}}, {\rm{s}}} \leqslant $$ 1 \times 10^2 $ and fixed nanoparticle volume fraction $ \phi_{\rm{s}} = 8 {\text{%}} $.

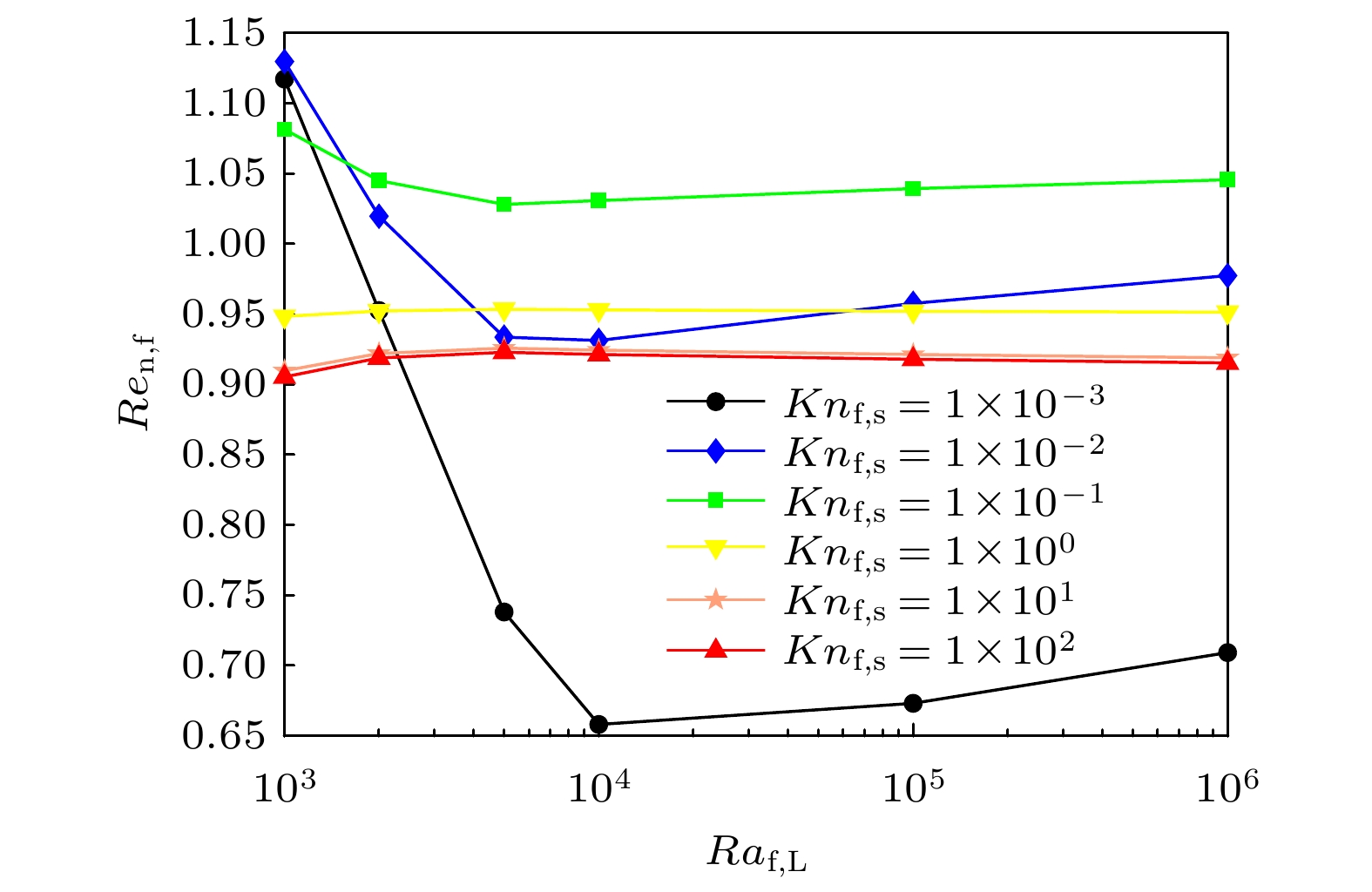

图 12 不同克努森数$ 1 \times 10^{-3} \leqslant Kn_{{\rm{f}}, {\rm{s}}} \leqslant 1 \times 10^2 $和固定颗粒体积分数$ \phi_{\rm{s}} = 8 {\text{%}} $下, 纳米流体相较于基液传热增加率$ Re_{{\rm{n}}, {\rm{f}}} $与瑞利数关系

Fig. 12. The enhancement ratio $ Re_{{\rm{n}}, {\rm{f}}} $ versus Rayleigh number with different Knudsen number $ 1 \times 10^{-3} \leqslant Kn_{{\rm{f}}, {\rm{s}}} \leqslant $$ 1 \times 10^2 $ and fixed nanoparticle volume fraction $ \phi_{\rm{s}} = 8 {\text{%}} $.

图 13 全参数范围下(a)平均努塞尔数的对数函数$ \lg (\overline {Nu}_{{{\rm{f}}, {\rm{L}}}}) = $$ l \lg \Big(\dfrac{{{k_{\rm{n}}}}}{{{k_{\rm{f}}}}}\overline {Nu}_{{{\rm{n}}, {\rm{L}}}}\Big) $和(b)纳米流体相较基液传热增加率$ Re_{{\rm{n}}, {\rm{f}}} $随不同克努森数$ Kn_{{\rm{f}}, {\rm{s}}} $、瑞利数$ Ra_{{{\rm{f}}, {\rm{L}}}} $、颗粒体积分数$ \phi_{\rm{s}} $变化的三维等值面图

Fig. 13. The three dimensional isosurfaces of (a) logarithmic function of mean Nusselt number $ \lg (\overline {Nu}_{{{\rm{f}}, {\rm{L}}}}) = $$ \lg \Big(\dfrac{{{k_{\rm{n}}}}}{{{k_{\rm{f}}}}}\overline {Nu}_{{{\rm{n}}, {\rm{L}}}}\Big) $ and (b) enhancement ratio $ Re_{{\rm{n}}, {\rm{f}}} $ over the full parameter range as a function of Knudsen number $ Kn_{{\rm{f}}, {\rm{s}}} $, Rayleigh number $ Ra_{{{\rm{f}}, {\rm{L}}}} $, and nanoparticle volume fraction $ \phi_{\rm{s}} $.

-

[1] Wang X, Song Y, Li C, Zhang Y, Ali H M, Sharma S, Li R, Yang M, Gao T, Liu M, Cui X, Said Z, Zhou Z 2024 Int. J. Adv. Manuf. Technol. 131 3113

Google Scholar

Google Scholar

[2] Sandhya M, Ramasamy D, Sudhakar K, Kadirgama K, Samykano M, Harun W S W, Najafi G, Mofijur M, Mazlan M 2021 Sustainable Energy Technol. Assess. 44 101058

Google Scholar

Google Scholar

[3] Said Z, Sundar L S, Tiwari A K, Ali H M, Sheikholeslami M, Bellos E, Babar H 2022 Phys. Rep. 946 1

Google Scholar

Google Scholar

[4] Smaisim G F, Mohammed D B, Abdulhadi A M, Uktamov K F, Alsultany F H, Izzat S E, Ansari M J, Kzar H H, Al-Gazally M E, Kianfar E 2022 J. Sol-Gel Sci. Technol. 104 1

Google Scholar

Google Scholar

[5] 肖波齐, 范金土, 蒋国平, 陈玲霞 2012 61 317

Google Scholar

Google Scholar

Xiao B Q, Fan J T, Jiang G P, Chen L X 2012 Acta Phys. Sin. 61 317

Google Scholar

Google Scholar

[6] Azmi W H, Sharma K V, Mamat R, Najafi G, Mohamad M S 2016 Renewable Sustainable Energy Rev. 53 1046

Google Scholar

Google Scholar

[7] Wang X, Xu X, Choi S U S 1999 J. Thermophys. Heat Transfer 13 474

Google Scholar

Google Scholar

[8] Das S K, Putra N, Thiesen P, Roetzel W 2003 J. Heat Transfer 125 567

Google Scholar

Google Scholar

[9] Nguyen C T, Desgranges F, Galanis N, Roy G, Mare T, Boucher S, Minsta H A 2008 Int. J. Therm. Sci. 47 103

Google Scholar

Google Scholar

[10] Maxwell J C 1982 A Treatise on Electricity and Magnetism (Vol. 2) (London: Oxford University Press) pp173–215

[11] Nan C W, Shi Z, Lin Y 2003 Chem. Phys. Lett. 375 666

Google Scholar

Google Scholar

[12] Mintsa H A, Roy G, Nguyen C T, Doucet D 2009 Int. J. Therm. Sci. 48 363

Google Scholar

Google Scholar

[13] Brinkman H C 1952 J. Chem. Phys. 20 571

Google Scholar

Google Scholar

[14] Batchelor G K 1977 J. Fluid Mech. 83 97

Google Scholar

Google Scholar

[15] Nguyen C T, Desgranges F, Roy G, Galanis N, Mare T, Boucher S, Minsta H A 2007 Int. J. Heat Fluid Flow 28 1492

Google Scholar

Google Scholar

[16] Majumdar A 1993 J. Heat Transfer 115 7

Google Scholar

Google Scholar

[17] Mazumder S, Majumdar A 2001 J. Heat Transfer 123 749

Google Scholar

Google Scholar

[18] Su Y, Davidson J H 2018 Int. J. Heat Mass Transfer 127 303

Google Scholar

Google Scholar

[19] Chambre P A, Schaaf S A 1961 Flow of Rarefied Gases (Princeton: Princeton University Press) pp78–146

[20] Sui P, Su Y, Sin V, Davidson J H 2022 Int. J. Heat Mass Transfer 187 122541

Google Scholar

Google Scholar

[21] Zarki A, Ghalambaz M, Chamkha A J, Ghalambaz M, Rossi D D 2015 Adv. Powder Technol. 26 935

Google Scholar

Google Scholar

[22] Sabour M, Ghalambaz M, Chamkha A 2017 Int. J. Numer. Methods Heat Fluid Flow 27 1504

Google Scholar

Google Scholar

[23] Paul T C, Morshed A, Fox E B, Khan J A 2017 Int. J. Heat Mass Transfer 28 753

[24] Liu F, Wang L 2009 Int. J. Heat Mass Transfer 52 5849

Google Scholar

Google Scholar

[25] Zahmatkesh I, Sheremet M, Yang L, Heris S Z, Sharifpur M, Meyer J P, Ghalambaz M, Wongwises S, Jing D, Mahian O 2021 J. Mol. Liq. 321 114430

Google Scholar

Google Scholar

[26] Trodi A, Benhamza M E H 2017 Chem. Eng. Commun. 204 158

Google Scholar

Google Scholar

[27] Sheikhzadeh G A, Aghaei A, Soleimani S 2018 Challenges Nano Micro Scale Sci. Technol. 6 27

[28] Dogonchi A S, Hashemi-Tilehnoee M, Waqas M, Seyyedi S M, Animasaun I L, Ganji D D 2020 Phys. A 540 123034

Google Scholar

Google Scholar

[29] 张贝豪, 郑林 2020 69 164401

Google Scholar

Google Scholar

Zhang B H, Zheng L 2020 Acta Phys. Sin. 69 164401

Google Scholar

Google Scholar

[30] Su Y, Sui P, Davidson J H 2022 Renew. Energy 184 712

Google Scholar

Google Scholar

[31] Lai F, Yang Y 2011 Int. J. Therm. Sci. 50 1930

Google Scholar

Google Scholar

[32] Sheikholeslami M, Gorji-Bandpy M, Domairry G 2013 Appl. Math. Mech. 34 833

Google Scholar

Google Scholar

[33] 齐聪, 何光艳, 李意民, 何玉荣 2015 64 328

Google Scholar

Google Scholar

Qi C, He G Y, Li Y M, He Y R 2015 Acta Phys. Sin. 64 328

Google Scholar

Google Scholar

[34] Taher M A, Kim H D, Lee Y W 2017 Heat Transfer Res. 48 1025

Google Scholar

Google Scholar

[35] 袁俊杰, 叶欣, 单彦广 2021 计算物理 38 57

Yuan J J, Ye X, Shan Y G 2021 Chinese Journal of Computational Physics 38 57

[36] Ganji D D, Malvandi A 2014 Powder Technol. 263 50

Google Scholar

Google Scholar

[37] Hwang K S, Lee J H, Jang S P 2009 Int. J. Heat Mass Transfer 50 4003

[38] Wang D, Cheng P, Quan X 2019 Int. J. Heat Mass Transfer 130 1358

Google Scholar

Google Scholar

[39] Hua Y C, Cao B Y 2016 Int. J. Heat Mass Transfer 92 995

Google Scholar

Google Scholar

[40] Tarokh A, Mohamad A, Jiang L 2013 Numer. Heat Transfer, Part A 63 159

Google Scholar

Google Scholar

[41] Ho C J, Chen M W, Li Z W 2008 Int. J. Heat Mass Transfer 51 4506

Google Scholar

Google Scholar

[42] Li C H, Peterson G P 2007 J. Appl. Phys. 101 044312

Google Scholar

Google Scholar

[43] Chon C H, Kihm K D, Lee S P 2005 Appl. Phys. Lett. 87 153107

Google Scholar

Google Scholar

计量

- 文章访问数: 3779

- PDF下载量: 118

- 被引次数: 0

下载:

下载: