-

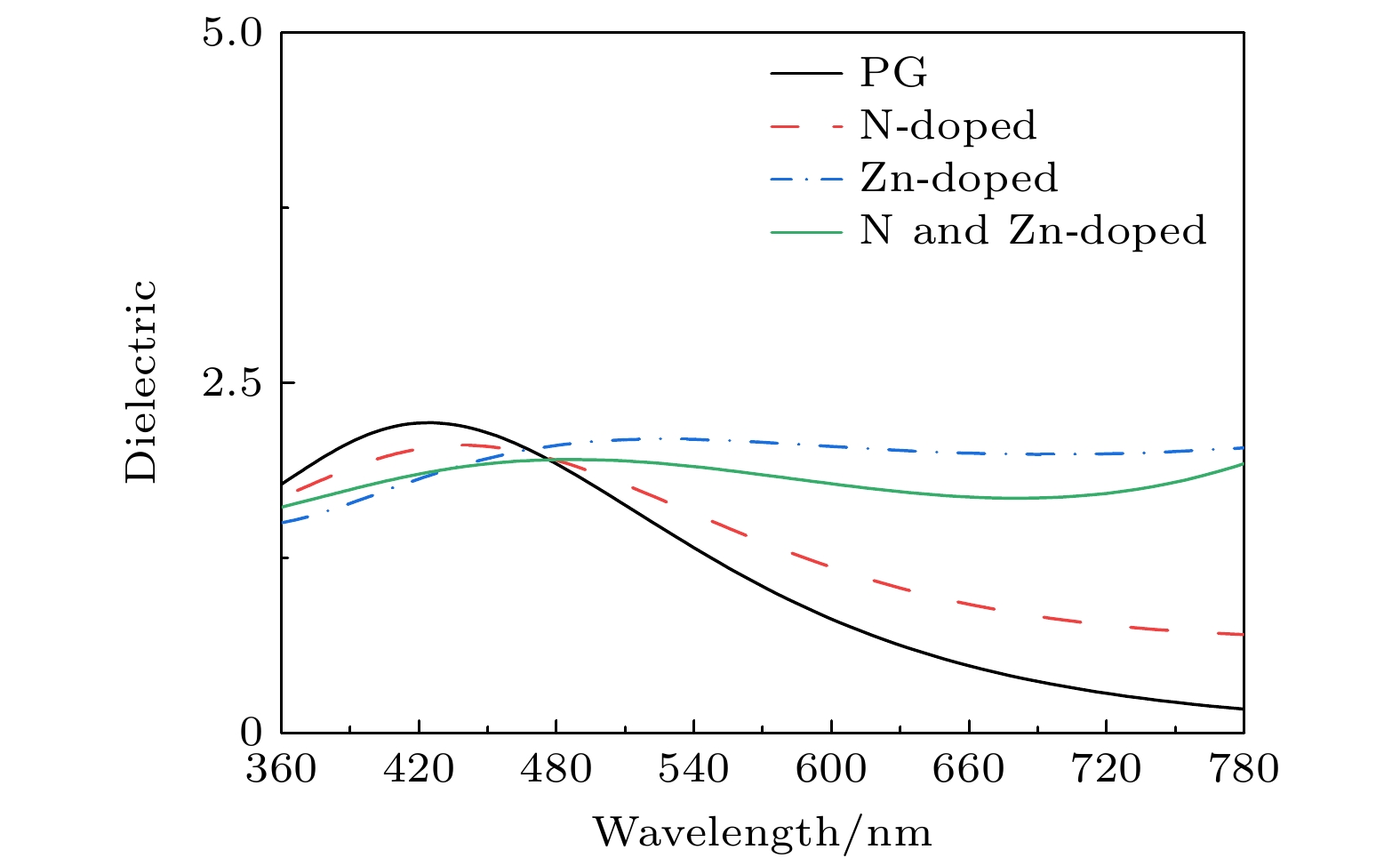

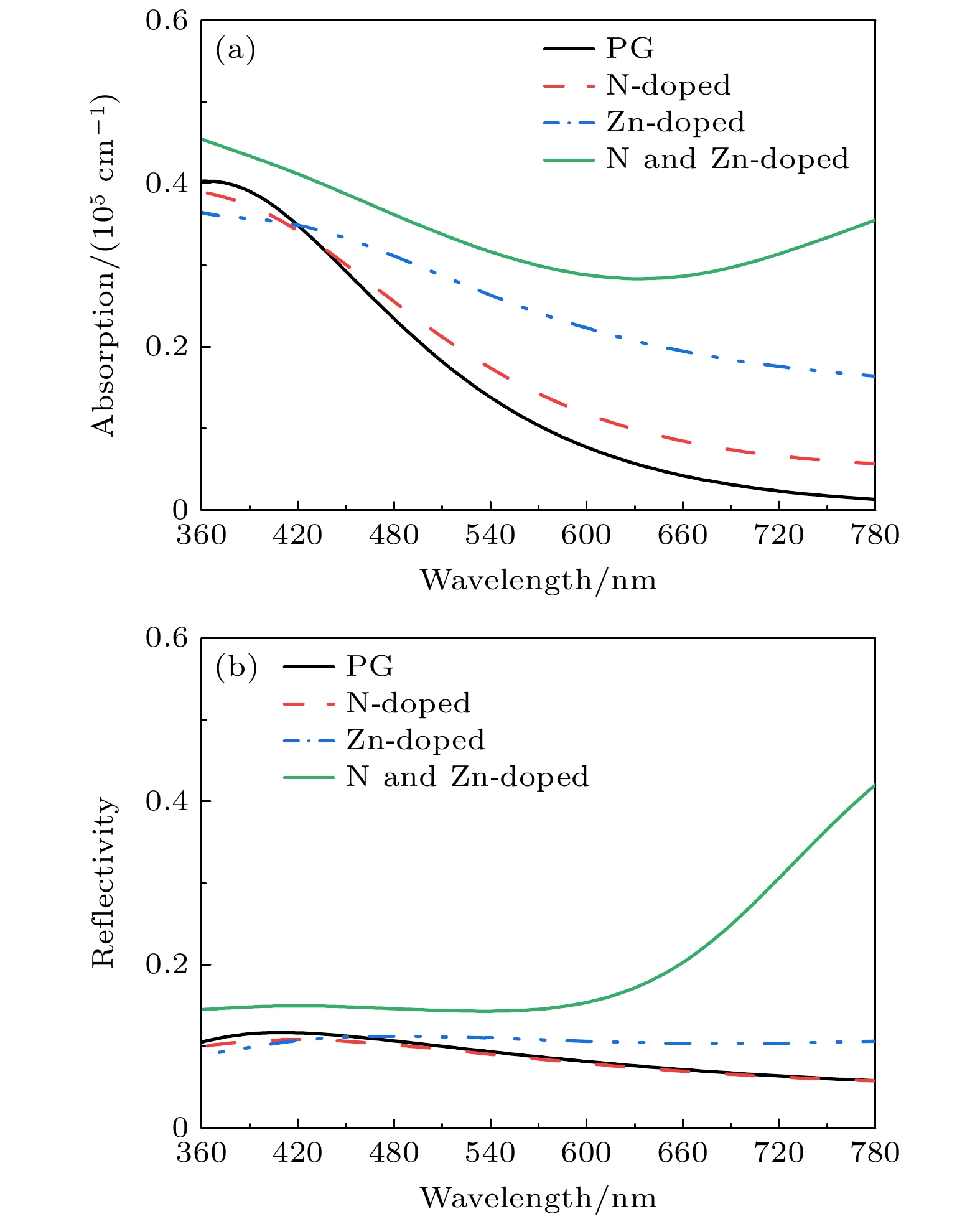

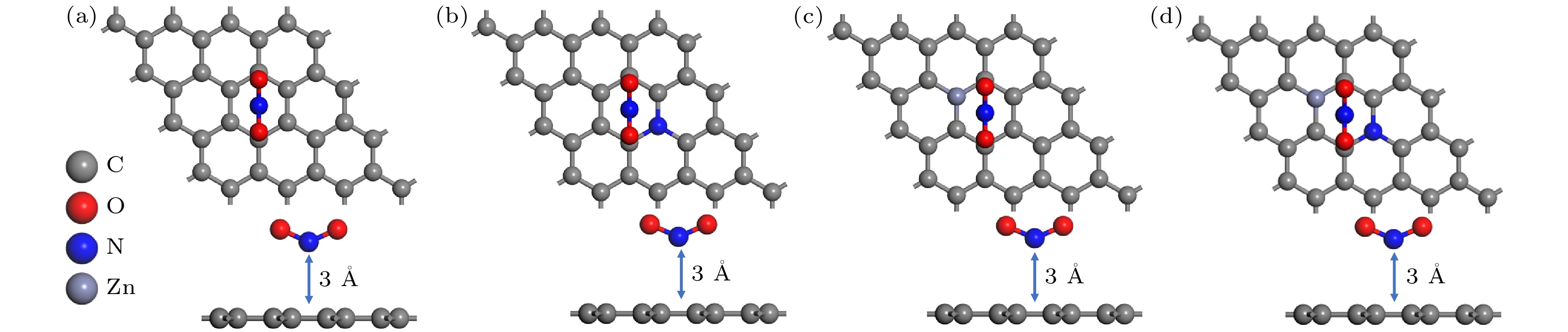

为了研究NO2在未掺杂石墨烯和掺杂石墨烯(N掺杂、Zn掺杂、N-Zn双掺杂)上的吸附, 本工作采用密度泛函理论的第一性原理平面波超软赝势对其吸附过程进行模拟. 计算了石墨烯表面吸附NO2分子的吸附能、Mulliken分布、差分电荷密度、态密度和光学性质. 研究结果表明, 与未掺杂石墨烯表面相比, 掺杂石墨烯表面对吸附NO2表现出了更高的敏感性, 吸附能大小顺序为: N-Zn双掺杂表面 > Zn掺杂表面 > N掺杂表面 > 未掺杂表面. 未掺杂石墨烯和N掺杂石墨烯表面与NO2的相互作用较弱, 是物理吸附. Zn掺杂和N-Zn双掺杂石墨烯表面与NO2之间形成了化学键, 是化学吸附. 在可见光范围内, 3种掺杂方式中 N-Zn双掺杂表面对于提高石墨烯光学性能效果最佳, 其吸收系数和反射系数的峰值较未掺杂石墨烯表明分别提高了约1.12倍和3.42倍. N-Zn双掺杂石墨烯不但能增强表面与NO2的相互作用, 同时也能提高材料的光学性能, 这为基于石墨烯基底的NO2气体检测传感提供了理论支撑和实验指导.In order to study the adsorption of NO2 on pristine graphene and doped graphene (N-doped, Zn-doped, and N-Zn co-doped), we simulate the adsorption process by applying the first-principles plane-wave ultrasoft pseudopotentials of the density-functional theory in this work. The adsorption energy, Mulliken distribution, differential charge density, density of states, and optical properties of NO2 molecules adsorbed on the graphene surface are calculated. The results show that the doped graphene surface exhibits higher sensitivity to the adsorption of NO2 compared with the pristine graphene surface, and the order of adsorption energy is as follows: N-Zn co-doped surface > Zn-doped surface > N-doped surface > pristine surface. Pristine graphene surface and N-doped graphene surface have weak interactions with and physical adsorption of NO2. Zn-doped graphene surfac and N-Zn co-doped graphene surface form chemical bonds with NO2 and are chemisorbed. In the visible range, among the three doping modes, the N-Zn co-doped surface is the most effective for improving the optical properties of graphene, with the peak absorption and reflection coefficients improved by about 1.12 and 3.42 times, respectively, compared with pristine graphene. The N-Zn co-doped graphene not only enhances the interaction between the surface and NO2, but also improves the optical properties of the material, which provides theoretical support and experimental guidance for NO2 gas detection and sensing based on graphene substrate.

-

Keywords:

- NO2 /

- graphene /

- adsorption /

- first principles

[1] Cooper M J, Martin R V, Hammer M S, Levelt P F, Veefkind P, Lamsal L N, Krotkov N A, Brook J R, McLinden C A 2022 Nature 601 380

Google Scholar

Google Scholar

[2] Gholami F, Tomas M, Gholami Z, Vakili M 2020 Sci. Total. Environ. 714 136712

Google Scholar

Google Scholar

[3] Wang S, Liu J, Yi H, Tang X L, Yu Q J, Zhao S Z, Gao F Y, Zhou Y S, Zhong T T, Wang Y X 2022 Chemosphere 291 132917

Google Scholar

Google Scholar

[4] Lim H, Kwon H, Kang H, Jang J E, Kwon H J 2023 Nat. Commun. 14 3114

Google Scholar

Google Scholar

[5] Gao Z Y, Li L L, Huang H Y, Xu S P, Yan G, Zhao M L, Ding Z 2020 Appl. Surf. Sci. 527 146939

Google Scholar

Google Scholar

[6] Geng X, Li S W, Mawella-Vithanage L, Ma T, Kilani M, Wang B W, Ma L, Hewa-Rahinduwage C C, Shafikova A, Nikolla E, Mao G Z, Brock S L, Zhang L, Luo L 2021 Nat. Commun. 12 4895

Google Scholar

Google Scholar

[7] 熊枫, 彭志敏, 丁艳军, 杜艳君 2022 71 203302

Google Scholar

Google Scholar

Xiong F, Peng Z M, Ding Y J, Du Y J 2022 Acta Phys. Sin. 71 203302

Google Scholar

Google Scholar

[8] Zhao S K, Shen Y B, Zhou P F, Zhong X X, Han C, Zhao Q, Wei D Z 2019 Sens. Actuat. B-Chem. 282 917

Google Scholar

Google Scholar

[9] Choi M S, Kim M Y, Mirzaei A, Kim S I, Baek S H, Chun D W, Jin C H, Lee K H 2021 Appl. Surf. Sci. 568 150910

Google Scholar

Google Scholar

[10] Brophy R E, Junker B, Fakhri E A, Arnason H Ö, Svavarsson H G, Weimar U, Bârsan N, Manolescu A 2024 Sens. Actuat. B-Chem. 410 135648

Google Scholar

Google Scholar

[11] Rani S, Kumar M, Garg P, Rani S, Kumar M, Garg P, Parmar R, Kumar A, Singh Y, Baloria V, Deshpande U, Singh V N 2022 ACS Appl. Mater. Interfaces 14 15381

Google Scholar

Google Scholar

[12] Yu W, Sisi L, Haiyan Y, Luo J 2020 Rsc Adv. 10 15328

Google Scholar

Google Scholar

[13] Dong Q C, Xiao M, Chu Z Y, Li G C, Zhang Y 2021 Sensors 21 3386

Google Scholar

Google Scholar

[14] Gui Y G, Peng X, Liu K Ding Z Y 2020 Physicas E 119 113959

Google Scholar

Google Scholar

[15] Zhu P C, Tang F, Wang S F, Cao W, Wang Q 2022 Mater. Today Commun. 33 104280

Google Scholar

Google Scholar

[16] Li Q F, Chen W L, Liu W H, Sun M L, Xu M H, Peng H L, Wu H Y, Song S X, Li T H, Tang X H 2022 Appl. Surf. Sci. 586 152689

Google Scholar

Google Scholar

[17] Hong H S, Ha N H, Thinh, D D, Nam N H, Huong N T, Hue N T, Hoang T V 2021 Nano Energy 87 106165

Google Scholar

Google Scholar

[18] Zhang T, Sun H, Wang F D, Zhang W D, Tang S W, Ma J M, Gong H W, Zhang J P 2017 Appl. Surf. Sci. 425 340

Google Scholar

Google Scholar

[19] Choudhuri I, Patra N, Mahata A, Ahuja R, Pathak B 2015 J. Phys. Chem. C 119 24827

Google Scholar

Google Scholar

[20] Shukri M S M, Saimin M N S, Yaakob M K, Yahya M Z A, Taib M F M 2019 Appl. Surf. Sci. 494 817

Google Scholar

Google Scholar

[21] Shamim S U D, Roy D, Alam S, Piya A A, Rahman M S, Hossain M K, Ahmed F 2022 Appl. Surf. Sci. 596 153603

Google Scholar

Google Scholar

[22] Zhang X X, Yu L, Gui Y G, Hu W H 2016 Appl. Surf. Sci. 367 259

Google Scholar

Google Scholar

[23] Jia X, An L 2019 Mod. Phys. Lett. B 33 1950044

Google Scholar

Google Scholar

[24] Segall M D, Lindan P J D, Probert M J, Pickard C J, Hasnip P J, Clark S J, Payne M C 2002 J. Phys. Condens. Mat. 14 2717

Google Scholar

Google Scholar

[25] Yang Z H, Wang Z Y, Su X P 2012 J. Cent. South Univ. 19 1796

Google Scholar

Google Scholar

[26] Basiuk V A, Henao-Holguin L V 2014 J. Comput. Theor. Nanosci. 11 1609

Google Scholar

Google Scholar

[27] 朱洪强, 冯庆 2014 63 133101

Google Scholar

Google Scholar

Zhu H Q, Feng Q 2014 Acta Phys. Sin. 63 133101

Google Scholar

Google Scholar

[28] Gao X, Zhou Q, Wang J X, Xu L N, Zeng W 2020 Appl. Surf. Sci. 517 146180

Google Scholar

Google Scholar

[29] Zheng T, Traian D, Thomas F 2021 Phys. Chem. Chem. Phys. 23 19627

Google Scholar

Google Scholar

[30] Ping L K, Mohamed M A, Mondal A K, Taib M F M, Samat M H, Berhanuddin D D, Menon P S, Bahru R 2021 Micromachines 12 348

Google Scholar

Google Scholar

-

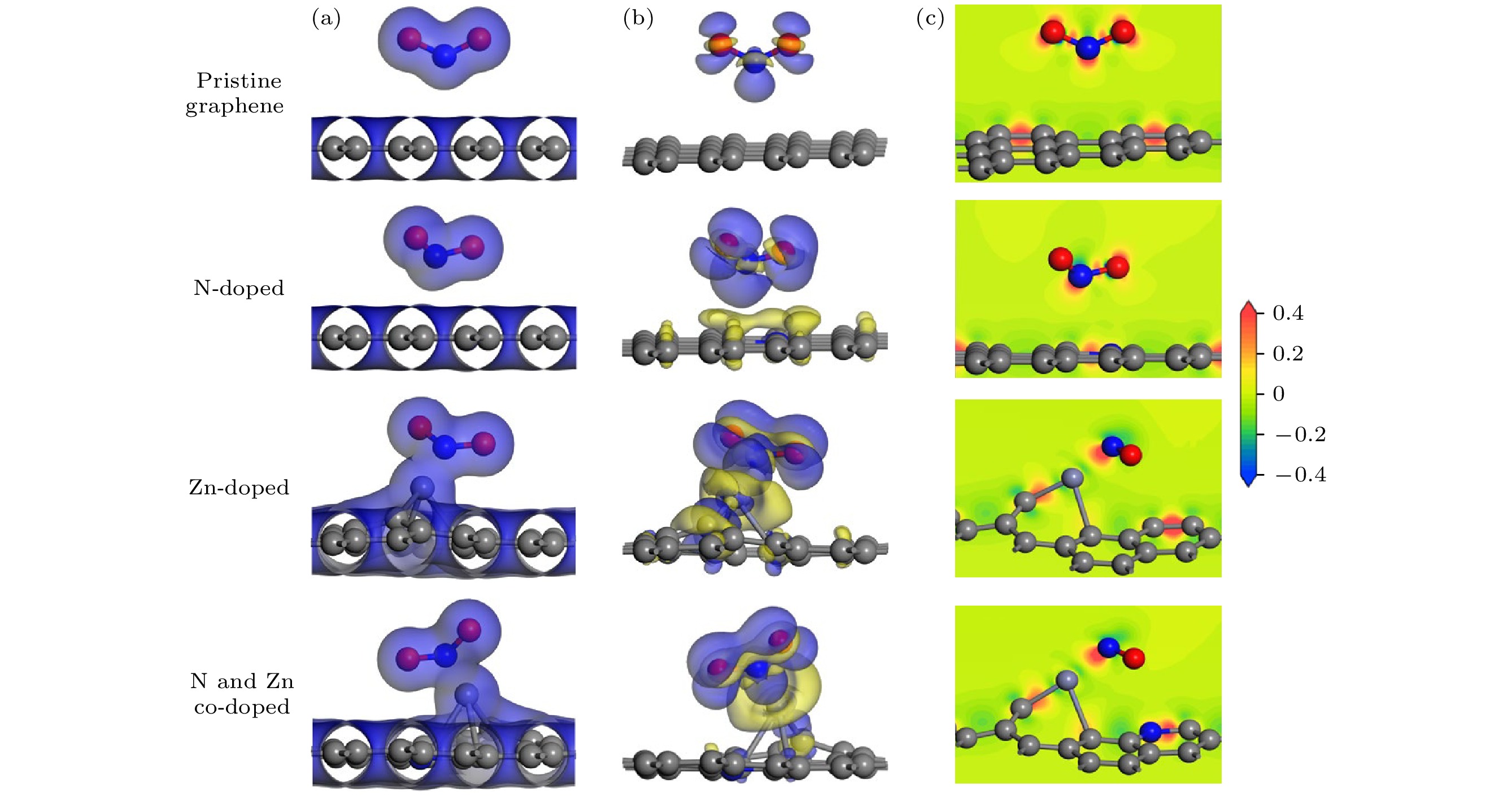

图 3 石墨烯表面吸附NO2分子 (a) 总电子密度等面图(TCD)、(b) 电荷密度差图(CDD)和(c)电子密度差图(ECD). TCD图等面设为0.02 e/Å3; CDD图等面设为0.01 e/Å3, 蓝色代表电子积累, 黄色代表电子耗尽; ECD图红色代表电荷聚集, 蓝色代表电荷耗尽

Fig. 3. (a) Charge density difference (CDD), (b) total charge density (TCD), and (c) electron density difference (EDD) plots of NO2 molecules adsorbed on different graphene surfaces. The isosurfaces of TCD plots are set to 0.02 e/Å3; the isosurfaces of CDD plots are set to 0.01 e/Å3, blue represents electron accumulation and yellow represents electron depletion; in EDD plots, red represents charge accumulation and blue represents charge depletion.

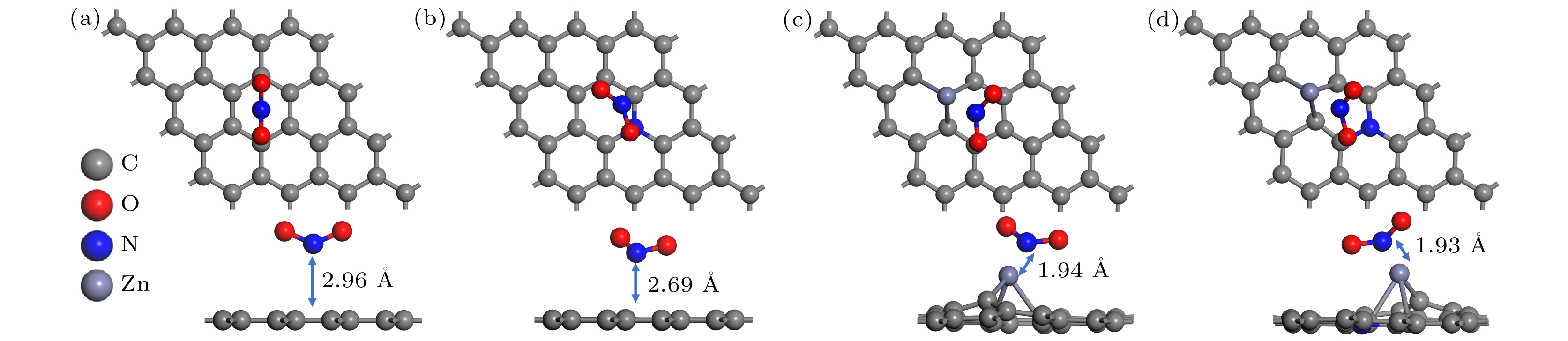

表 1 石墨烯表面吸附NO2的距离和吸附能

Table 1. The distance and adsorption energy of NO2 adsorption on graphene surface.

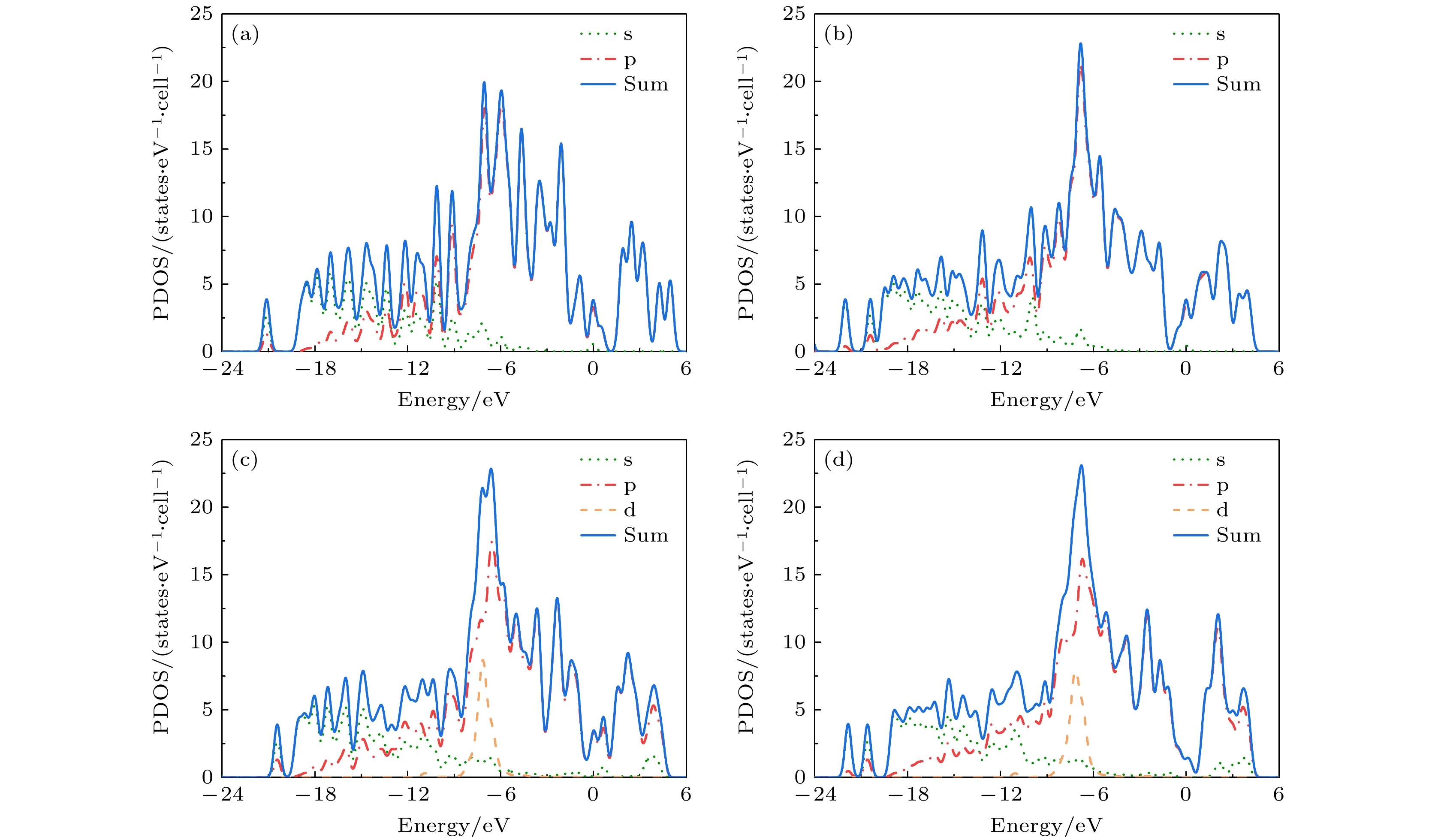

模型 初始距离/Å 优化后距离/Å 吸附能/eV 未掺杂石墨烯 3.00 2.96 –0.22 N掺杂 3.00 2.73 –0.69 Zn掺杂 3.00 1.94 –4.80 N-Zn双掺杂 3.00 1.93 –4.97 表 2 NO2分子的Mulliken的电荷分布

Table 2. Mulliken charge distribution of NO2.

模型 种类 s电子 p电子 总电子 电荷/e 分子带电荷/e 布居数 键长/Å NO2 N 1.39 3.18 4.57 0.44 0 0.68 1.23 O 1.85 4.36 6.22 –0.22 O 1.85 4.36 6.22 –0.22 未掺杂石墨烯 N 1.46 3.21 4.67 0.33 –0.25 0.63 1.24 O 1.86 4.44 6.29 –0.29 O 1.86 4.44 6.29 –0.29 N掺杂 N 1.51 3.23 4.74 0.26 –0.48 0.60 1.25 O 1.86 4.53 6.39 –0.38 O 1.86 4.51 6.36 –0.36 Zn掺杂 N 1.48 3.40 4.88 0.12 –0.59 0.67 1.26 O 1.86 4.50 6.36 –0.36 O 1.86 4.49 6.35 –0.35 N-Zn

双掺杂N 1.49 3.40 4.88 0.11 –0.60 0.67 1.27 O 1.86 4.51 6.37 –0.37 O 1.86 4.48 6.34 –0.34 -

[1] Cooper M J, Martin R V, Hammer M S, Levelt P F, Veefkind P, Lamsal L N, Krotkov N A, Brook J R, McLinden C A 2022 Nature 601 380

Google Scholar

Google Scholar

[2] Gholami F, Tomas M, Gholami Z, Vakili M 2020 Sci. Total. Environ. 714 136712

Google Scholar

Google Scholar

[3] Wang S, Liu J, Yi H, Tang X L, Yu Q J, Zhao S Z, Gao F Y, Zhou Y S, Zhong T T, Wang Y X 2022 Chemosphere 291 132917

Google Scholar

Google Scholar

[4] Lim H, Kwon H, Kang H, Jang J E, Kwon H J 2023 Nat. Commun. 14 3114

Google Scholar

Google Scholar

[5] Gao Z Y, Li L L, Huang H Y, Xu S P, Yan G, Zhao M L, Ding Z 2020 Appl. Surf. Sci. 527 146939

Google Scholar

Google Scholar

[6] Geng X, Li S W, Mawella-Vithanage L, Ma T, Kilani M, Wang B W, Ma L, Hewa-Rahinduwage C C, Shafikova A, Nikolla E, Mao G Z, Brock S L, Zhang L, Luo L 2021 Nat. Commun. 12 4895

Google Scholar

Google Scholar

[7] 熊枫, 彭志敏, 丁艳军, 杜艳君 2022 71 203302

Google Scholar

Google Scholar

Xiong F, Peng Z M, Ding Y J, Du Y J 2022 Acta Phys. Sin. 71 203302

Google Scholar

Google Scholar

[8] Zhao S K, Shen Y B, Zhou P F, Zhong X X, Han C, Zhao Q, Wei D Z 2019 Sens. Actuat. B-Chem. 282 917

Google Scholar

Google Scholar

[9] Choi M S, Kim M Y, Mirzaei A, Kim S I, Baek S H, Chun D W, Jin C H, Lee K H 2021 Appl. Surf. Sci. 568 150910

Google Scholar

Google Scholar

[10] Brophy R E, Junker B, Fakhri E A, Arnason H Ö, Svavarsson H G, Weimar U, Bârsan N, Manolescu A 2024 Sens. Actuat. B-Chem. 410 135648

Google Scholar

Google Scholar

[11] Rani S, Kumar M, Garg P, Rani S, Kumar M, Garg P, Parmar R, Kumar A, Singh Y, Baloria V, Deshpande U, Singh V N 2022 ACS Appl. Mater. Interfaces 14 15381

Google Scholar

Google Scholar

[12] Yu W, Sisi L, Haiyan Y, Luo J 2020 Rsc Adv. 10 15328

Google Scholar

Google Scholar

[13] Dong Q C, Xiao M, Chu Z Y, Li G C, Zhang Y 2021 Sensors 21 3386

Google Scholar

Google Scholar

[14] Gui Y G, Peng X, Liu K Ding Z Y 2020 Physicas E 119 113959

Google Scholar

Google Scholar

[15] Zhu P C, Tang F, Wang S F, Cao W, Wang Q 2022 Mater. Today Commun. 33 104280

Google Scholar

Google Scholar

[16] Li Q F, Chen W L, Liu W H, Sun M L, Xu M H, Peng H L, Wu H Y, Song S X, Li T H, Tang X H 2022 Appl. Surf. Sci. 586 152689

Google Scholar

Google Scholar

[17] Hong H S, Ha N H, Thinh, D D, Nam N H, Huong N T, Hue N T, Hoang T V 2021 Nano Energy 87 106165

Google Scholar

Google Scholar

[18] Zhang T, Sun H, Wang F D, Zhang W D, Tang S W, Ma J M, Gong H W, Zhang J P 2017 Appl. Surf. Sci. 425 340

Google Scholar

Google Scholar

[19] Choudhuri I, Patra N, Mahata A, Ahuja R, Pathak B 2015 J. Phys. Chem. C 119 24827

Google Scholar

Google Scholar

[20] Shukri M S M, Saimin M N S, Yaakob M K, Yahya M Z A, Taib M F M 2019 Appl. Surf. Sci. 494 817

Google Scholar

Google Scholar

[21] Shamim S U D, Roy D, Alam S, Piya A A, Rahman M S, Hossain M K, Ahmed F 2022 Appl. Surf. Sci. 596 153603

Google Scholar

Google Scholar

[22] Zhang X X, Yu L, Gui Y G, Hu W H 2016 Appl. Surf. Sci. 367 259

Google Scholar

Google Scholar

[23] Jia X, An L 2019 Mod. Phys. Lett. B 33 1950044

Google Scholar

Google Scholar

[24] Segall M D, Lindan P J D, Probert M J, Pickard C J, Hasnip P J, Clark S J, Payne M C 2002 J. Phys. Condens. Mat. 14 2717

Google Scholar

Google Scholar

[25] Yang Z H, Wang Z Y, Su X P 2012 J. Cent. South Univ. 19 1796

Google Scholar

Google Scholar

[26] Basiuk V A, Henao-Holguin L V 2014 J. Comput. Theor. Nanosci. 11 1609

Google Scholar

Google Scholar

[27] 朱洪强, 冯庆 2014 63 133101

Google Scholar

Google Scholar

Zhu H Q, Feng Q 2014 Acta Phys. Sin. 63 133101

Google Scholar

Google Scholar

[28] Gao X, Zhou Q, Wang J X, Xu L N, Zeng W 2020 Appl. Surf. Sci. 517 146180

Google Scholar

Google Scholar

[29] Zheng T, Traian D, Thomas F 2021 Phys. Chem. Chem. Phys. 23 19627

Google Scholar

Google Scholar

[30] Ping L K, Mohamed M A, Mondal A K, Taib M F M, Samat M H, Berhanuddin D D, Menon P S, Bahru R 2021 Micromachines 12 348

Google Scholar

Google Scholar

计量

- 文章访问数: 2619

- PDF下载量: 72

- 被引次数: 0

下载:

下载: