-

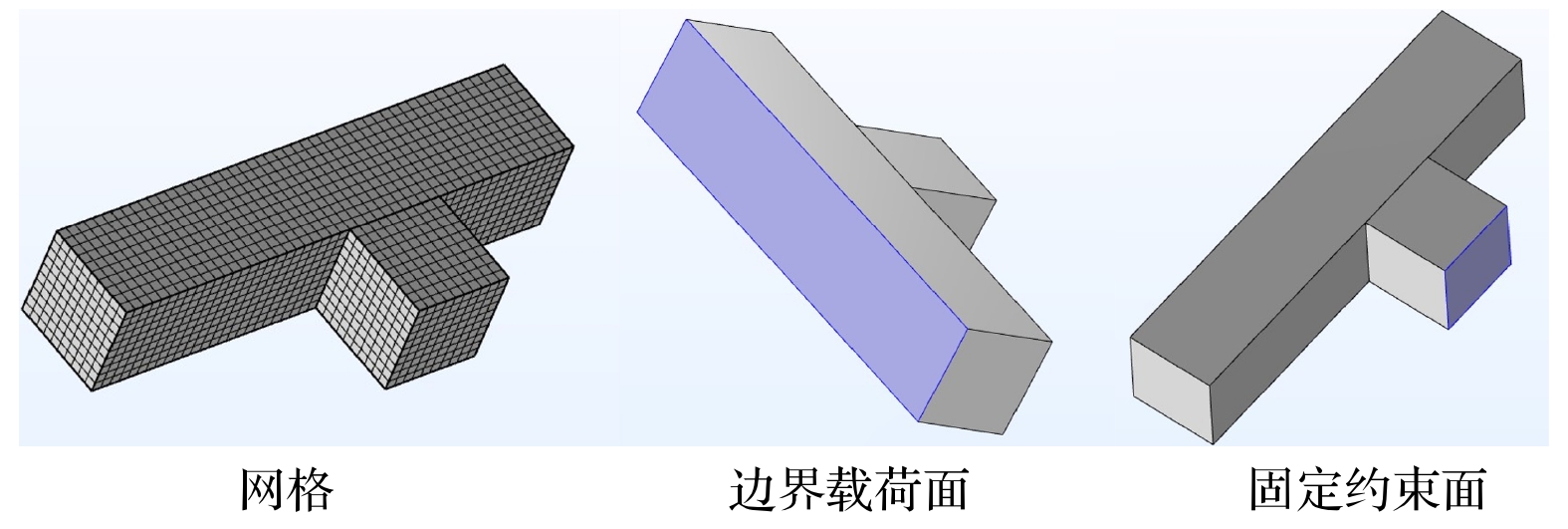

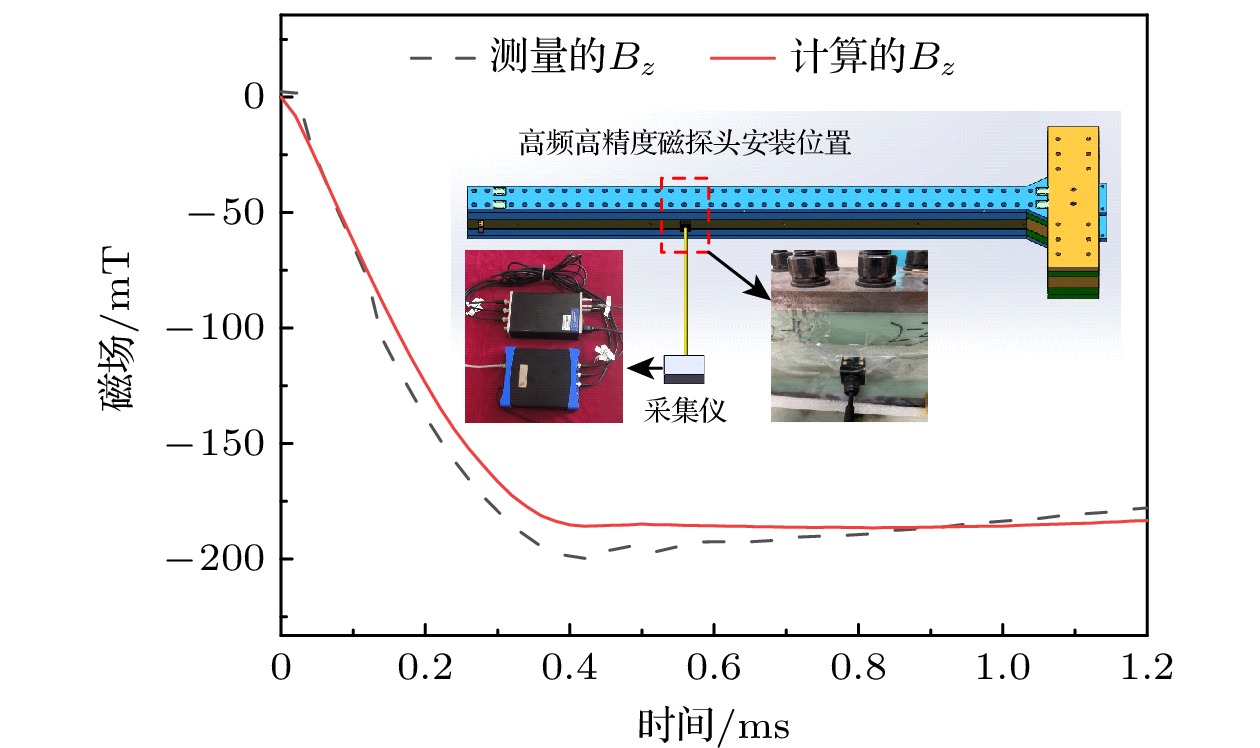

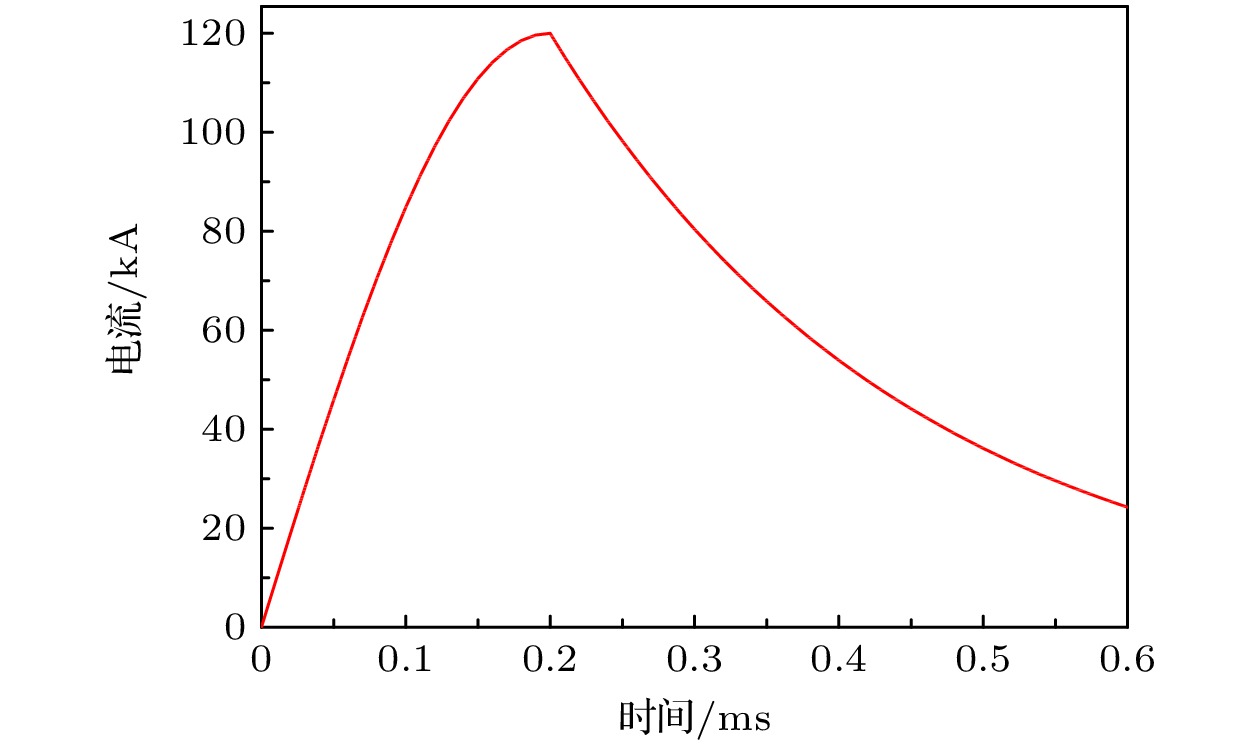

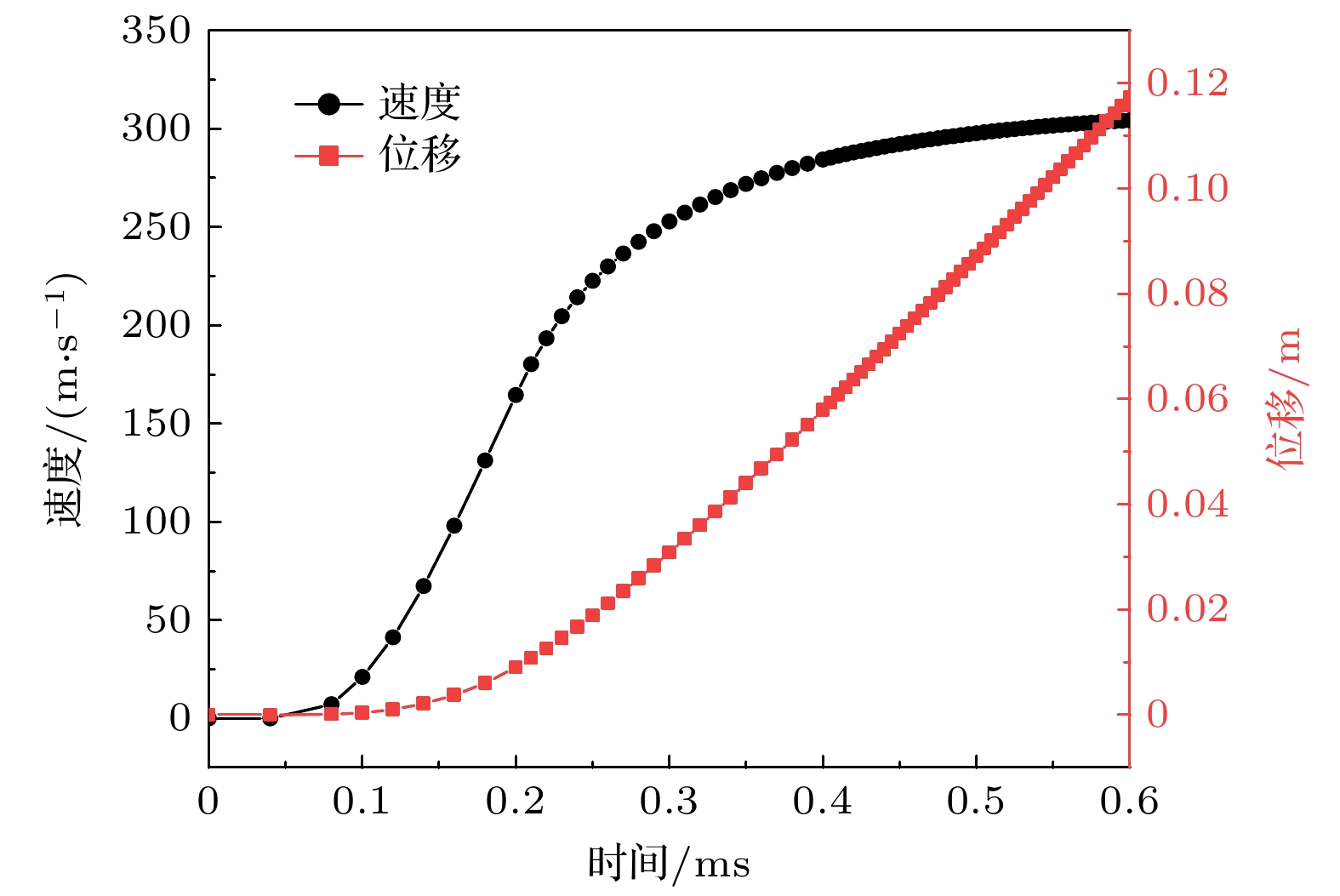

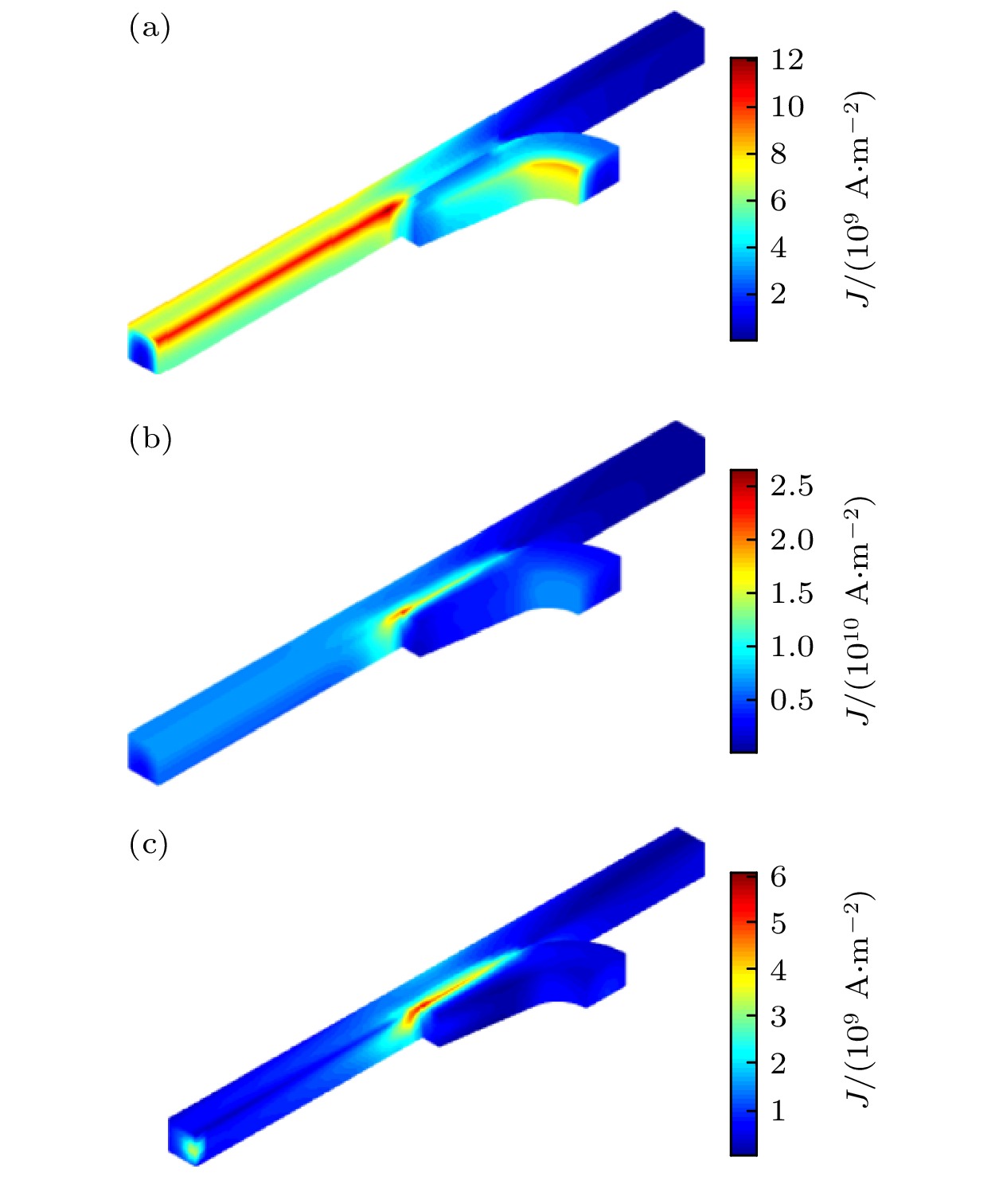

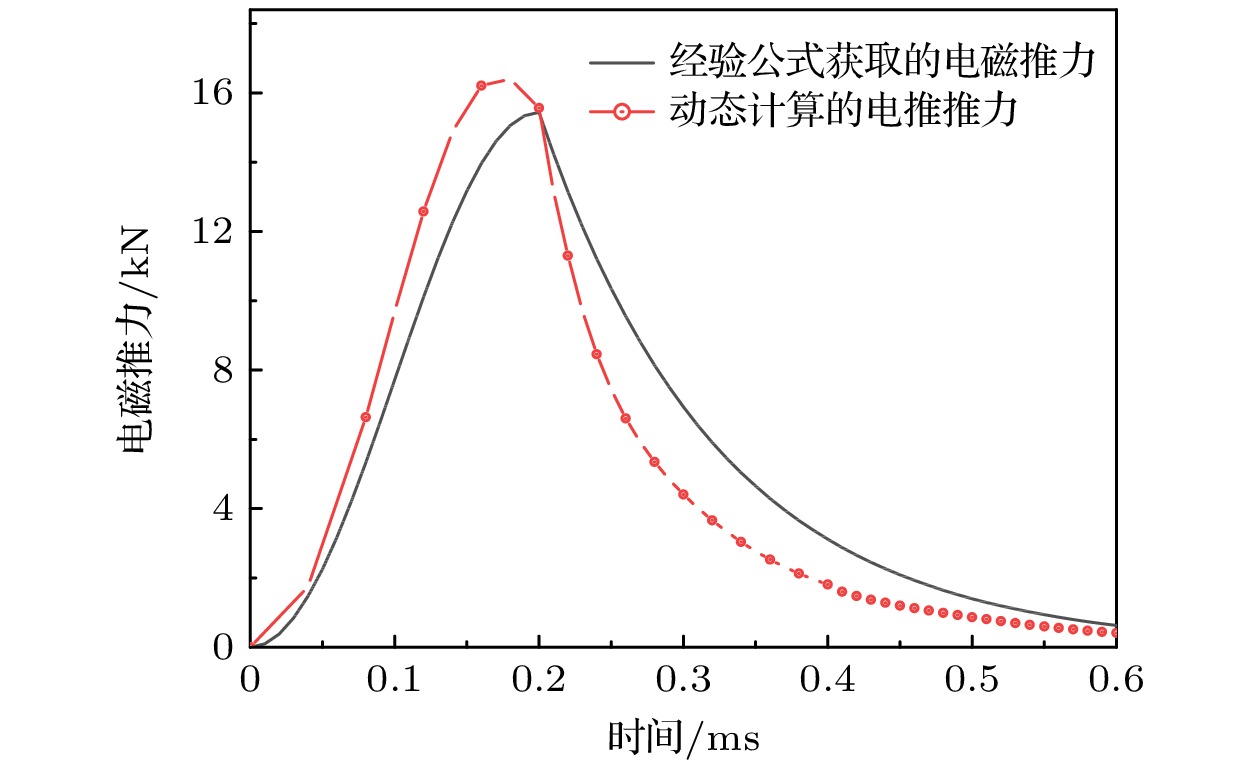

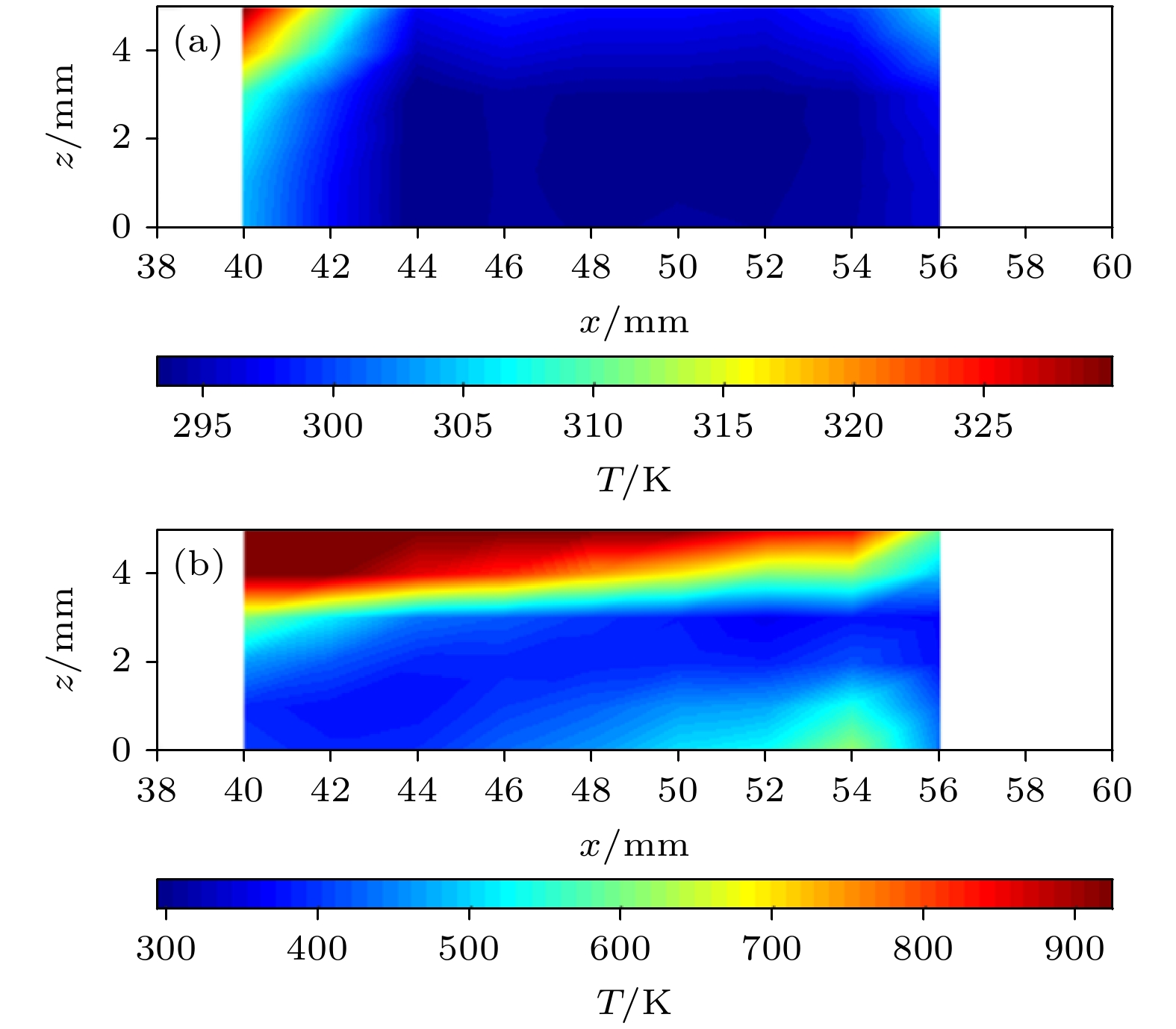

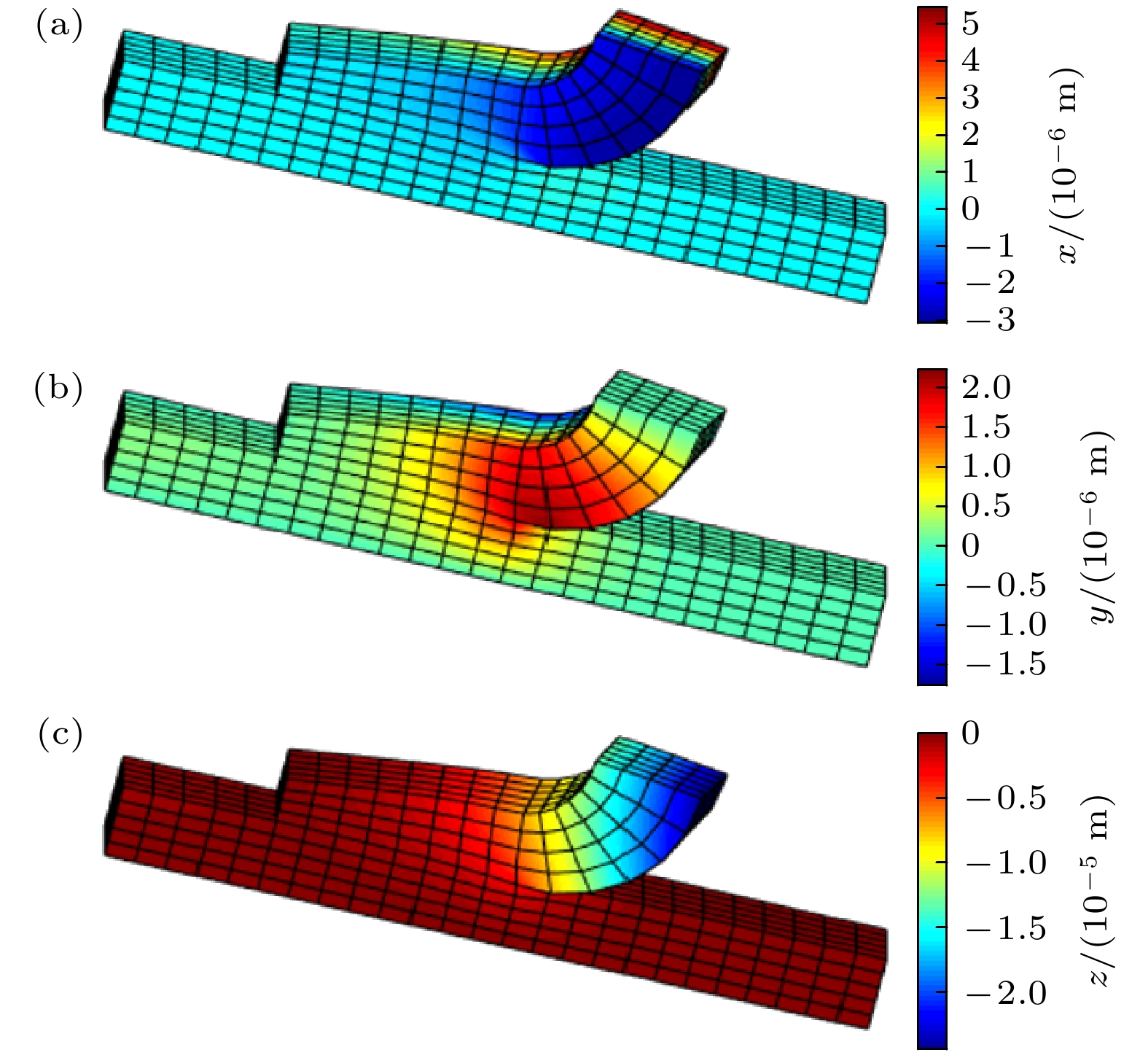

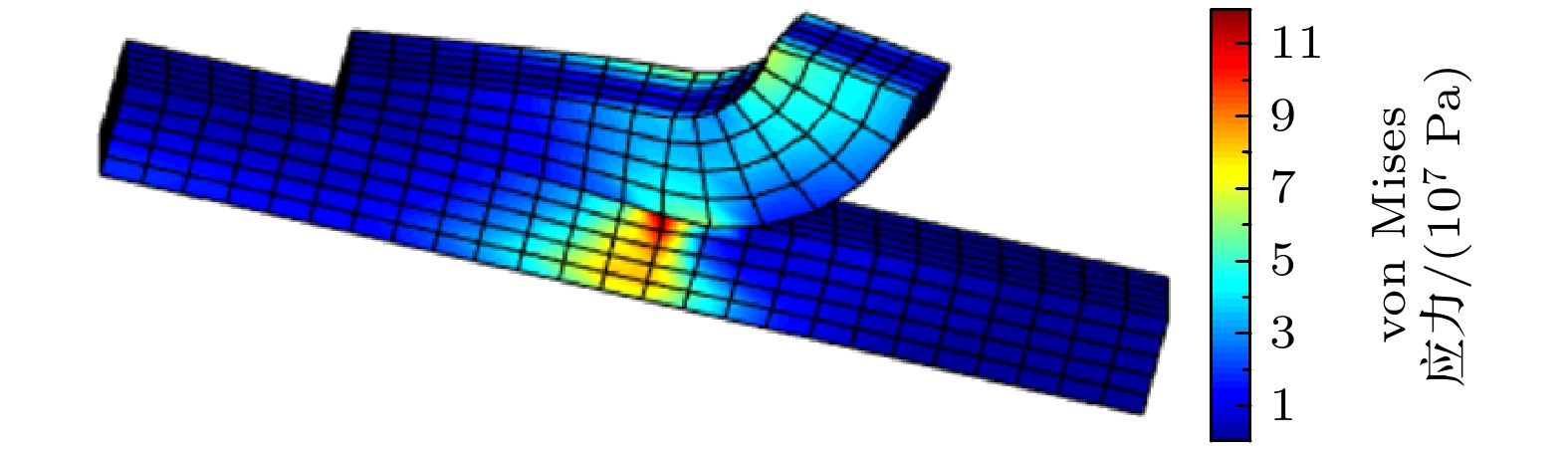

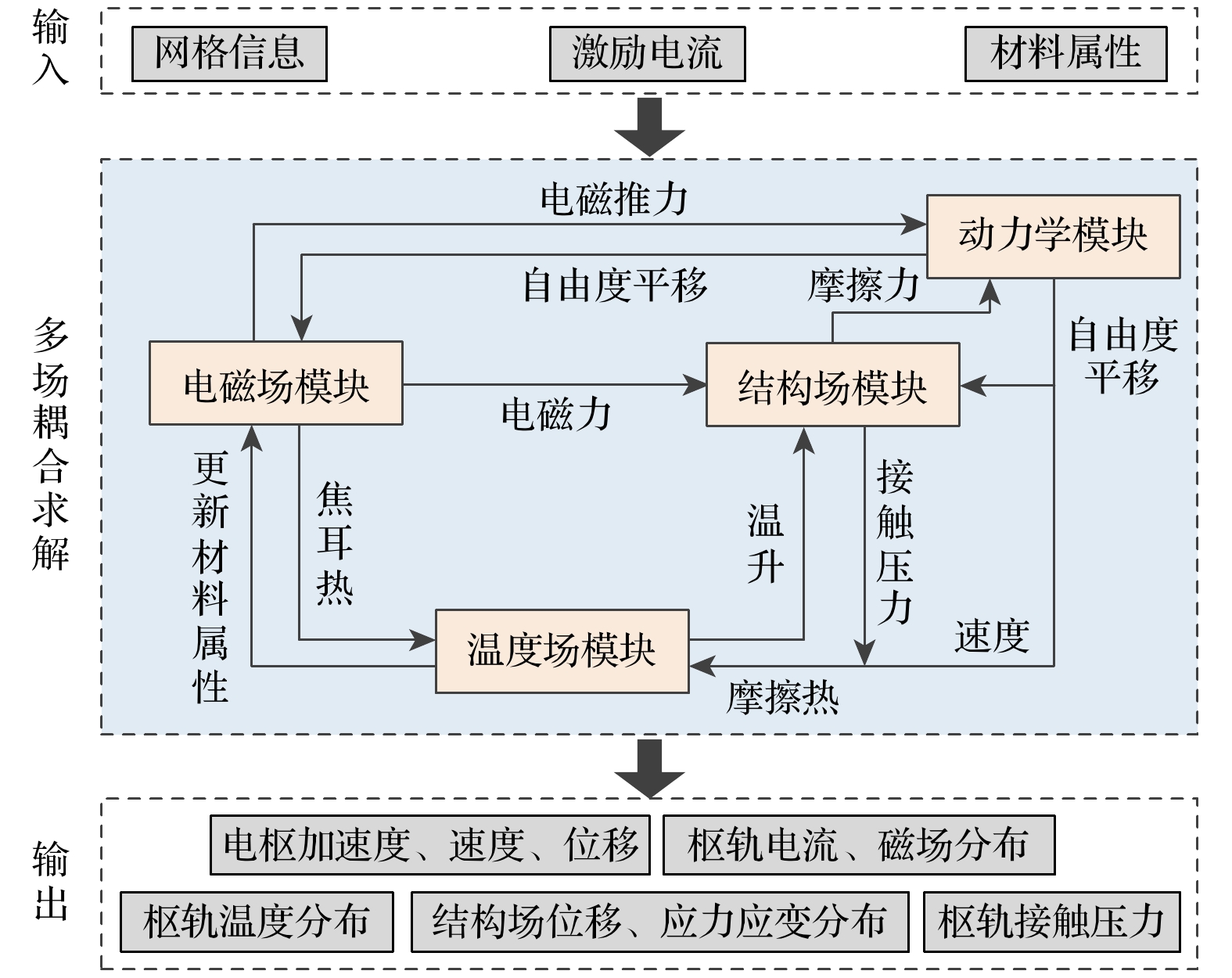

脉冲大电流直线驱动装置运行过程中产生的极端工况导致多种损伤形式. 为了研究多场耦合过程并分析多物理参量作用机理, 建立了动态下的电磁场、温度场、结构场数学物理模型. 利用轨道反向运动及接触远端物理量渐进平移不变的特性进行局域求解. 模型还考虑了材料属性温度依赖性, 热应力, 接触面摩擦热等实际因素. 各个物理场采用同一套网格体系, 电磁场以及温度场的有限元离散格式采用欧拉向后差分形式求解, 结构场则采用Newmark法进行求解, 完成多场耦合下的数值模拟. 通过与数值工具EMAP3D、Comsolol在相同模型和输入条件下的计算结果以及相关实验比较, 验证了该模型的可靠性. 本文采用一种C型电枢进行案例计算, 得到了多参量的典型演化过程, 并对速度趋肤效应下的场分布进行了讨论.The pulsed high current linear driving device operates under extreme conditions, and various forms of metal damages will reduce the service life of the device. At present, the multi-physics coupling mechanism of pulsed high current linear driving device is still unclear, and the multi-parameter diagnosis method in the laboratory environment is limited. Therefore, it is urgent to clarify the evolution process of multiple physical parameters through numerical modeling methods, in order to guide the optimization of the overall performance and improve the service life of the device. In this work, mathematical and physical models of electromagnetic field, temperature field and structural field under dynamic conditions are established. The local solution is carried out by using the characteristics of rail reverse motion and the invariant physical quantities at the distal end of the contact. The constraint equations of the non-equipotential surface of the rail entrance and the armature-rail interface conditions under the technical framework are derived. The constraint equations are applied by the penalty function method. The model also takes into account the practical factors such as the temperature dependence of the material properties, thermal stresses, and the frictional heat of the contact surface. The finite element discrete format of the electromagnetic field and the temperature field is solved in the form of Euler’s backward differentiation, and the structural field is solved by the Newmark method. The reliability of the model is verified by comparing the calculation results with the numerical tools EMAP3D and Comsol under the same configuration and input conditions, as well as related experiments. Through the numerical simulation of the C-type armature, the typical evolution process of the corresponding multi-parameter is obtained. During sliding electrical contact, the velocity skin effect becomes more pronounced with velocity increasing. The current is gradually concentrated on the surface of the rail, and the highest current density is found at the rear edge of the contact surface and at the edge of the outer arm of the armature. Moreover, the magnetic induction intensity at the tail of the contact surface continues to shrink over time. The heat-concentrated region appears at the top edge of the contact surface, and with time going by, it extends along the sliding direction and bottom direction of the armature. In addition, there is peak stress in the front of the rail contact and significant stress at the armature throat. When the local stress at the throat of the armature exceeds the corresponding yield strength, it can cause serious deformation or even fracture of the armature.

-

Keywords:

- finite element numerical simulation /

- sliding electrical contact /

- friction heat /

- local modeling

[1] Fair H D 2001 IEEE Trans. Magn. 37 25

Google Scholar

Google Scholar

[2] 马伟明, 鲁军勇 2023 电工技术学报 38 3943

Google Scholar

Google Scholar

Ma W M, Lu J Y 2023 Trans. Chin. Electrotech. Soc. 38 3943

Google Scholar

Google Scholar

[3] Sun J, Cheng J, Wang Q 2021 IEEE Trans. Plasma Sci. 49 3988

Google Scholar

Google Scholar

[4] Stefani F, Parker J V 1999 IEEE Trans. Magn. 35 312

Google Scholar

Google Scholar

[5] Li S, Li J, Xia S, Zhang Q, Liu P 2019 IEEE Trans. Plasma Sci. 47 2399

Google Scholar

Google Scholar

[6] Sun J, Cheng J, Wang Q 2022 IEEE Trans. Plasma Sci. 50 1032

Google Scholar

Google Scholar

[7] 殷强, 张合, 李豪杰, 史云雷 2016 强激光与粒子束 28 025008

Google Scholar

Google Scholar

Yin Q, Zhang H, Li H J, Shi Y L 2016 High Power Laser Part. Beams 28 025008

Google Scholar

Google Scholar

[8] 李昕, 翁春生 2009 火炮发射与控制学报 2009 1

Google Scholar

Google Scholar

Li X, Weng C S 2009 J. Gun Launch Control 2009 1

Google Scholar

Google Scholar

[9] Li X, Weng C S 2008 Prog. Nat. Sci. 18 1565

Google Scholar

Google Scholar

[10] Tang B, Xu Y, Lin Q, Li B 2017 IEEE Trans. Plasma Sci. 45 1361

Google Scholar

Google Scholar

[11] 郑杜成, 徐蓉, 成文凭, 赵伟康, 袁伟群, 严萍 2019 电工电能新技术 38 33

Google Scholar

Google Scholar

Zheng D C, Xu R, Cheng W P, Zhao W K, Yuan W Q, Yan P 2019 Adv. Technol. Electr. Eng. Energy 38 33

Google Scholar

Google Scholar

[12] 翟小飞, 杨帆, 张晓, 刘华 2021 海军工程大学学报 33 19

Google Scholar

Google Scholar

Zhai X F, Yang F, Zhang X, Liu H 2021 J. Naval Univ. Eng. 33 19

Google Scholar

Google Scholar

[13] Hsieh K T 1995 IEEE Trans. Magn. 31 604

Google Scholar

Google Scholar

[14] Hsieh K T, Kim B K 1999 IEEE Trans. Magn. 35 166

Google Scholar

Google Scholar

[15] Hsieh K T 2007 IEEE Trans. Magn. 43 1131

Google Scholar

Google Scholar

[16] Lin Q H, Li B M 2020 IEEE Trans. Plasma Sci. 48 2287

Google Scholar

Google Scholar

[17] Lin Q H, Li B M 2016 Defence Technol. 12 101

Google Scholar

Google Scholar

[18] 林庆华, 栗保明 2020 兵工学报 41 1697

Google Scholar

Google Scholar

Lin Q H, Li B M 2020 Acta Armamentarii 41 1697

Google Scholar

Google Scholar

[19] Shatoff H, Pearson D A, Kull A E 2005 IEEE Pulsed Power Conference Monterey, CA, USA, June 13–17, 2005 p253

[20] Wang G H, Xie L, He Y, Song S Y, Gao J J 2016 IEEE Trans. Plasma Sci. 44 1424

Google Scholar

Google Scholar

[21] 王刚华, 谢龙, 赵海龙 2021 爆炸与冲击 41 111

Google Scholar

Google Scholar

Wang G H, Xie L, Zhao H L 2021 Explosion and Shock Waves 41 111

Google Scholar

Google Scholar

-

表 1 仿真模型电磁场参数

Table 1. Electromagnetic field parameters of simulation model.

参数 初始电导率

σ0/(MS·m–1)磁导率

μ/(10–6 H·m–1)质量密度

ρ/(kg·m–3)比热容

c/(J·kg–1·K–1)热导率

λ/(W·m–1·K–1)电阻率温度系数

α/K熔化温度

Tm/K铜 58.8 1.2566 8960 385 385 0.0039 1356.15 铝 25 1.2566 2700 896 167 0.0041 924.85 表 2 仿真模型热场及结构场参数

Table 2. Thermal field and structural field parameters of simulation model.

参数 弹性模量

E/GPa线膨胀系数

β/(µm·m–1·K–1)泊松比 μPoisson 铜 110 16.5 0.34 铝 68.9 23.6 0.33 -

[1] Fair H D 2001 IEEE Trans. Magn. 37 25

Google Scholar

Google Scholar

[2] 马伟明, 鲁军勇 2023 电工技术学报 38 3943

Google Scholar

Google Scholar

Ma W M, Lu J Y 2023 Trans. Chin. Electrotech. Soc. 38 3943

Google Scholar

Google Scholar

[3] Sun J, Cheng J, Wang Q 2021 IEEE Trans. Plasma Sci. 49 3988

Google Scholar

Google Scholar

[4] Stefani F, Parker J V 1999 IEEE Trans. Magn. 35 312

Google Scholar

Google Scholar

[5] Li S, Li J, Xia S, Zhang Q, Liu P 2019 IEEE Trans. Plasma Sci. 47 2399

Google Scholar

Google Scholar

[6] Sun J, Cheng J, Wang Q 2022 IEEE Trans. Plasma Sci. 50 1032

Google Scholar

Google Scholar

[7] 殷强, 张合, 李豪杰, 史云雷 2016 强激光与粒子束 28 025008

Google Scholar

Google Scholar

Yin Q, Zhang H, Li H J, Shi Y L 2016 High Power Laser Part. Beams 28 025008

Google Scholar

Google Scholar

[8] 李昕, 翁春生 2009 火炮发射与控制学报 2009 1

Google Scholar

Google Scholar

Li X, Weng C S 2009 J. Gun Launch Control 2009 1

Google Scholar

Google Scholar

[9] Li X, Weng C S 2008 Prog. Nat. Sci. 18 1565

Google Scholar

Google Scholar

[10] Tang B, Xu Y, Lin Q, Li B 2017 IEEE Trans. Plasma Sci. 45 1361

Google Scholar

Google Scholar

[11] 郑杜成, 徐蓉, 成文凭, 赵伟康, 袁伟群, 严萍 2019 电工电能新技术 38 33

Google Scholar

Google Scholar

Zheng D C, Xu R, Cheng W P, Zhao W K, Yuan W Q, Yan P 2019 Adv. Technol. Electr. Eng. Energy 38 33

Google Scholar

Google Scholar

[12] 翟小飞, 杨帆, 张晓, 刘华 2021 海军工程大学学报 33 19

Google Scholar

Google Scholar

Zhai X F, Yang F, Zhang X, Liu H 2021 J. Naval Univ. Eng. 33 19

Google Scholar

Google Scholar

[13] Hsieh K T 1995 IEEE Trans. Magn. 31 604

Google Scholar

Google Scholar

[14] Hsieh K T, Kim B K 1999 IEEE Trans. Magn. 35 166

Google Scholar

Google Scholar

[15] Hsieh K T 2007 IEEE Trans. Magn. 43 1131

Google Scholar

Google Scholar

[16] Lin Q H, Li B M 2020 IEEE Trans. Plasma Sci. 48 2287

Google Scholar

Google Scholar

[17] Lin Q H, Li B M 2016 Defence Technol. 12 101

Google Scholar

Google Scholar

[18] 林庆华, 栗保明 2020 兵工学报 41 1697

Google Scholar

Google Scholar

Lin Q H, Li B M 2020 Acta Armamentarii 41 1697

Google Scholar

Google Scholar

[19] Shatoff H, Pearson D A, Kull A E 2005 IEEE Pulsed Power Conference Monterey, CA, USA, June 13–17, 2005 p253

[20] Wang G H, Xie L, He Y, Song S Y, Gao J J 2016 IEEE Trans. Plasma Sci. 44 1424

Google Scholar

Google Scholar

[21] 王刚华, 谢龙, 赵海龙 2021 爆炸与冲击 41 111

Google Scholar

Google Scholar

Wang G H, Xie L, Zhao H L 2021 Explosion and Shock Waves 41 111

Google Scholar

Google Scholar

计量

- 文章访问数: 5667

- PDF下载量: 94

- 被引次数: 0

下载:

下载: