-

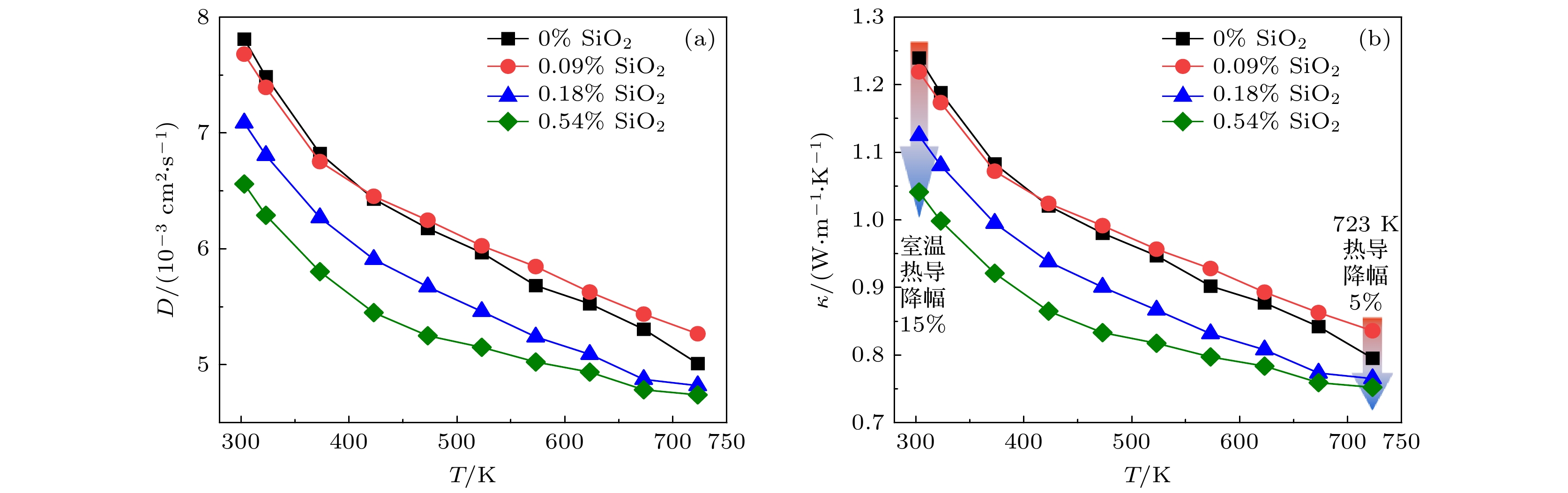

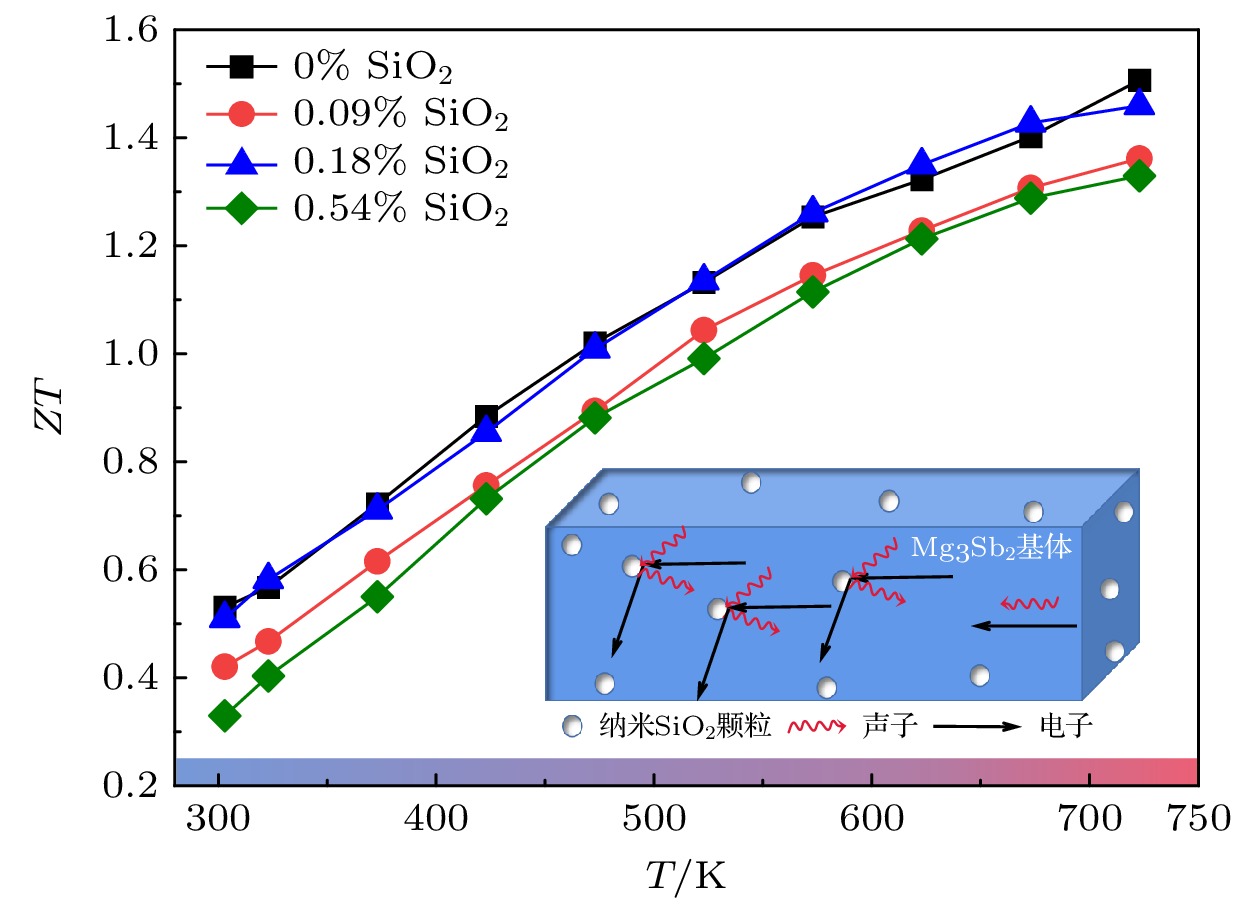

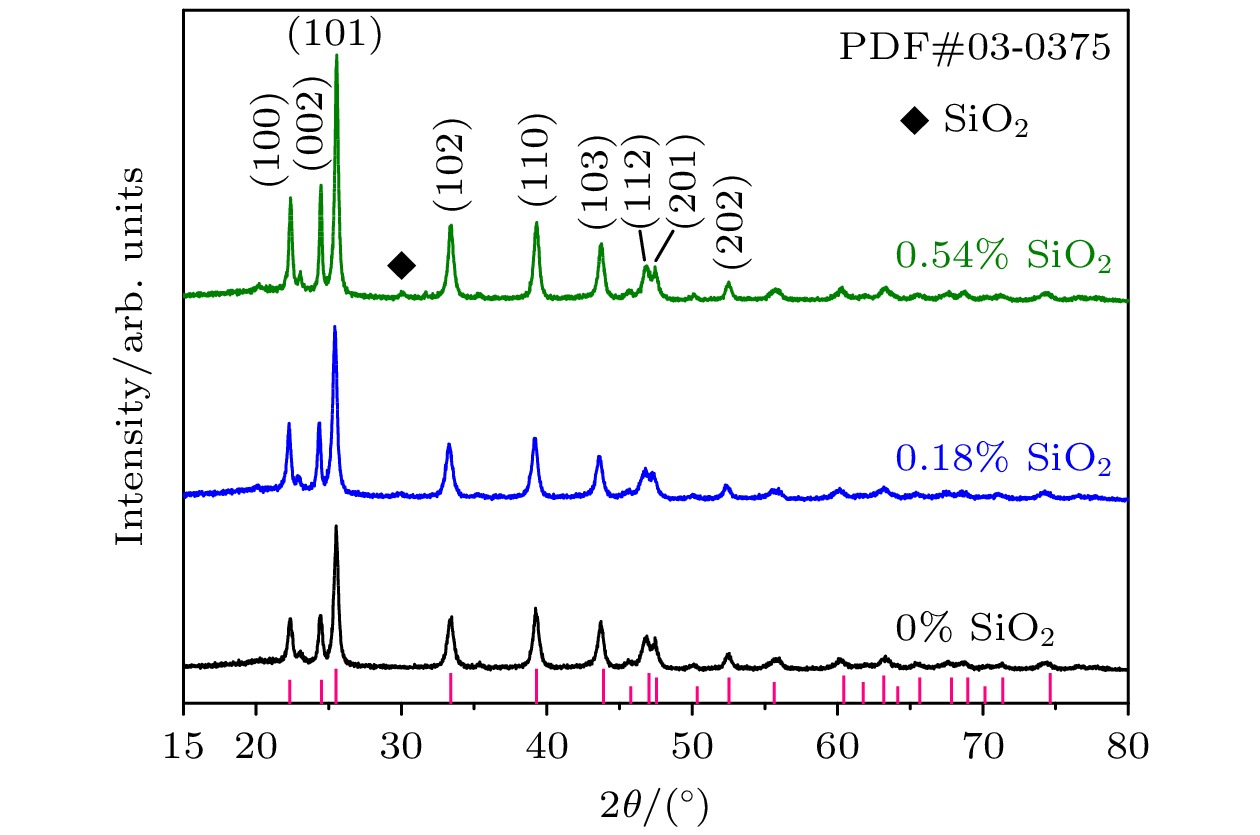

Mg3(Sb, Bi)2基热电材料由于其优异的热电性能和较低的成本近来受到广泛的关注. 本研究通过将纳米SiO2复合进成分为Mg3.275Mn0.025Sb1.49Bi0.5Te0.01的基体相中, 考察其热电输运性能的变化及机制. 结果表明, 当SiO2复合进Mg3Sb2基材料中时, 由于引进大量的微小晶界, 能有效地散射声子, 促使晶格热导率降低, 优化热输运性能, 如SiO2体积含量为0.54%时, 室温时热导率由复合前的1.24 W/(m·K)降至1.04 W/(m·K), 降幅达到15%; 同时其对电子也产生强烈的散射作用, 导致迁移率和电导率大幅下滑, 结果表现为近室温区功率因子剧烈衰减, 恶化了电输运性能. 电性能相对于热性能较大降低幅度使得材料在整个测试温区的热电优值没有得到改善. 纳米SiO2作为Mg3Sb2基热电材料复合物来调控热电性能是有效的备选物质, 可结合其他手段改善输运特性, 如在晶界处适当修饰, 降低载流子传输的晶界势垒, 能够提升该体系的综合热电性能.Recently, Mg3(Sb,Bi)2-based thermoelectric materials have received extensive attention owing to excellent thermoelectric properties and the low cost. This study investigates the change and mechanism of thermoelectric transport properties of Mg3.275Mn0.025Sb1.49Bi0.5Te0.01/SiO2 nanocomposite. The results show that nano-SiO2 can effectively scatter phonons, promote the reduction of lattice thermal conductivity, and optimize the heat transport performance owing to the introduction of a large number of tiny grain boundaries. For example, when SiO2 content is 0.54%, the thermal conductivity decreases by 15% from 1.24 W/(m·K) to 1.04 W/(m·K) compared with that of 0% SiO2 sample at room temperature. At the same time, the material system also has a strong scattering effect on electrons. This leads to a sharp attenuation of power factor and electrical transport performance with decline of mobility and conductivity in the room temperature area. Nano SiO2 is an effective candidate for regulating thermoelectric properties of Mg3Sb2 based thermoelectric material. The thermoelectric transport performance of the material will be improved by combining with other methods, such as appropriate grain boundary modification to reduce the potential barrier of charge carrier transport.

-

Keywords:

- nano-SiO2 /

- Mg3Sb2-based materials /

- composite /

- thermoelectric transport properties

[1] Mao J, Liu Z, Zhou J, Zhu H, Zhang Q, Chen G, Ren Z 2018 Adv. Phys. 67 69

Google Scholar

Google Scholar

[2] Kim S I, Lee K H, Mun H A, Kim H S, Hwang S W, Roh J W, Yang D J, Shin W H, Li X S, Lee Y H 2015 Science 348 109

Google Scholar

Google Scholar

[3] Pei Y, Shi X, LaLonde A, Wang H, Chen L, Snyder G J 2011 Nature 473 66

Google Scholar

Google Scholar

[4] He J, Tritt T M 2017 Science 357 eaak9997

Google Scholar

Google Scholar

[5] Boona S R, Myers R C, Heremans J P 2014 Energy Environ. Sci. 7 885

Google Scholar

Google Scholar

[6] Zheng Y, Lu T, Polash M M, Rasoulianboroujeni M, Liu N, Manley M E, Deng Y, Sun P, Chen X, Hermann R P, Vashaee D, Heremans J P, Zhao H 2019 Sci. Adv. 5 eaat9461

Google Scholar

Google Scholar

[7] Imasato K, Kang S D, Snyder G J 2019 Energy Environ. Sci. 12 965

Google Scholar

Google Scholar

[8] Ren Z, Shuai J, Mao J, Zhu Q, Song S, Ni Y, Chen S 2018 Acta Mater. 143 265

Google Scholar

Google Scholar

[9] Imasato K, Kang S D, Ohno S, Snyder G J 2018 Mater. Horiz. 5 59

Google Scholar

Google Scholar

[10] Tamaki H, Sato H K, Kanno T 2016 Adv. Mater. 28 10182

Google Scholar

Google Scholar

[11] Shuai J, Ge B, Mao J, Song S, Wang Y, Ren Z 2018 J. Am. Chem. Soc. 140 1910

Google Scholar

Google Scholar

[12] Imasato K, Ohno S, Kang S D, Snyder G J 2018 APL Mater. 6 016106

Google Scholar

Google Scholar

[13] Wood M, Kuo J J, Imasato K, Snyder G J 2019 Adv. Mater. 31 1902337

Google Scholar

Google Scholar

[14] Mao J, Zhu H, Ding Z, Liu Z, Gamage G A, Chen G, Ren Z 2019 Science 365 495

[15] Yang J, Li G, Zhu H, Chen N, Lu T, Gao J, Guo L, Xiang J, Sun P, Yao Y 2022 Joule 6 193

Google Scholar

Google Scholar

[16] Ren P, Liu Y, He J, Lv T, Gao J, Xu G 2018 Inorg. Chem. Front. 5 2380

Google Scholar

Google Scholar

[17] Shi X, Wang X, Li W, Pei Y 2018 Small Methods 2 1800022

Google Scholar

Google Scholar

[18] Brod M K, Anand S, Snyder G J 2023 Mater. Today Phys. 31 100959

Google Scholar

Google Scholar

[19] Imasato K, Wood M, Anand S, Kuo J J, Snyder G J 2022 Adv. Energy Sustainability Res. 3 2100208

Google Scholar

Google Scholar

[20] Sharp J W, Volckmann E H, Goldsmid H J 2001 Phys. Status Solidi A 185 257

Google Scholar

Google Scholar

[21] Sharp J W, Goldsmid H J 1999 Proceedings of the 18th International Conference on Thermoelectrics Baltimore, USA, August 29–September 2, 1999 p709

[22] Jin H, Heremans J P 2018 Phys. Rev. Mater. 2 115401

Google Scholar

Google Scholar

[23] Kuo J J, Kang S D, Imasato K, Tamaki H, Ohno S, Kanno T, Snyder G J 2018 Energy Environ. Sci. 11 429

Google Scholar

Google Scholar

[24] Kanno T, Tamaki H, Sato H K, Kang S D, Ohno S, Imasato K, Kuo J J, Snyder G J, Miyazaki Y 2018 Appl. Phys. Lett. 112 033903

Google Scholar

Google Scholar

[25] Mao T, Qiu P, Liu J, Du X, Hu P, Zhao K, Ren D, Shi X, Chen L 2020 Phys. Chem. Chem. Phys. 22 7374

Google Scholar

Google Scholar

-

图 2 (a), (b), (d)不同SiO2含量的Mg3.275Mn0.025Sb1.49Bi0.5Te0.01电性能温度依赖曲线; (c)室温和723 K时样品的简约费米能级变化趋势图

Fig. 2. (a), (b) and (d) are temperature dependence curves of electrical properties of Mg3.275Mn0.025Sb1.49Bi0.5Te0.01 with different SiO2 content; (c) change trend of reduced Fermi level of samples at room temperature and 723 K.

图 7 不同纳米SiO2含量的Mg3.3Sb1.5Bi0.49Te0.01样品ZT值温度依赖曲线; 插图为纳米SiO2复合的Mg3Sb2基材料样品电子和声子输运过程中的散射原理图

Fig. 7. Temperature dependence curve of ZT value of Mg3.3Sb1.5Bi0.49Te0.01 samples with different nano-SiO2 content; the illustration shows the scattering schematic diagram of the electron and phonon transport process of the composite with Mg3Sb2-based material and nano-SiO2.

-

[1] Mao J, Liu Z, Zhou J, Zhu H, Zhang Q, Chen G, Ren Z 2018 Adv. Phys. 67 69

Google Scholar

Google Scholar

[2] Kim S I, Lee K H, Mun H A, Kim H S, Hwang S W, Roh J W, Yang D J, Shin W H, Li X S, Lee Y H 2015 Science 348 109

Google Scholar

Google Scholar

[3] Pei Y, Shi X, LaLonde A, Wang H, Chen L, Snyder G J 2011 Nature 473 66

Google Scholar

Google Scholar

[4] He J, Tritt T M 2017 Science 357 eaak9997

Google Scholar

Google Scholar

[5] Boona S R, Myers R C, Heremans J P 2014 Energy Environ. Sci. 7 885

Google Scholar

Google Scholar

[6] Zheng Y, Lu T, Polash M M, Rasoulianboroujeni M, Liu N, Manley M E, Deng Y, Sun P, Chen X, Hermann R P, Vashaee D, Heremans J P, Zhao H 2019 Sci. Adv. 5 eaat9461

Google Scholar

Google Scholar

[7] Imasato K, Kang S D, Snyder G J 2019 Energy Environ. Sci. 12 965

Google Scholar

Google Scholar

[8] Ren Z, Shuai J, Mao J, Zhu Q, Song S, Ni Y, Chen S 2018 Acta Mater. 143 265

Google Scholar

Google Scholar

[9] Imasato K, Kang S D, Ohno S, Snyder G J 2018 Mater. Horiz. 5 59

Google Scholar

Google Scholar

[10] Tamaki H, Sato H K, Kanno T 2016 Adv. Mater. 28 10182

Google Scholar

Google Scholar

[11] Shuai J, Ge B, Mao J, Song S, Wang Y, Ren Z 2018 J. Am. Chem. Soc. 140 1910

Google Scholar

Google Scholar

[12] Imasato K, Ohno S, Kang S D, Snyder G J 2018 APL Mater. 6 016106

Google Scholar

Google Scholar

[13] Wood M, Kuo J J, Imasato K, Snyder G J 2019 Adv. Mater. 31 1902337

Google Scholar

Google Scholar

[14] Mao J, Zhu H, Ding Z, Liu Z, Gamage G A, Chen G, Ren Z 2019 Science 365 495

[15] Yang J, Li G, Zhu H, Chen N, Lu T, Gao J, Guo L, Xiang J, Sun P, Yao Y 2022 Joule 6 193

Google Scholar

Google Scholar

[16] Ren P, Liu Y, He J, Lv T, Gao J, Xu G 2018 Inorg. Chem. Front. 5 2380

Google Scholar

Google Scholar

[17] Shi X, Wang X, Li W, Pei Y 2018 Small Methods 2 1800022

Google Scholar

Google Scholar

[18] Brod M K, Anand S, Snyder G J 2023 Mater. Today Phys. 31 100959

Google Scholar

Google Scholar

[19] Imasato K, Wood M, Anand S, Kuo J J, Snyder G J 2022 Adv. Energy Sustainability Res. 3 2100208

Google Scholar

Google Scholar

[20] Sharp J W, Volckmann E H, Goldsmid H J 2001 Phys. Status Solidi A 185 257

Google Scholar

Google Scholar

[21] Sharp J W, Goldsmid H J 1999 Proceedings of the 18th International Conference on Thermoelectrics Baltimore, USA, August 29–September 2, 1999 p709

[22] Jin H, Heremans J P 2018 Phys. Rev. Mater. 2 115401

Google Scholar

Google Scholar

[23] Kuo J J, Kang S D, Imasato K, Tamaki H, Ohno S, Kanno T, Snyder G J 2018 Energy Environ. Sci. 11 429

Google Scholar

Google Scholar

[24] Kanno T, Tamaki H, Sato H K, Kang S D, Ohno S, Imasato K, Kuo J J, Snyder G J, Miyazaki Y 2018 Appl. Phys. Lett. 112 033903

Google Scholar

Google Scholar

[25] Mao T, Qiu P, Liu J, Du X, Hu P, Zhao K, Ren D, Shi X, Chen L 2020 Phys. Chem. Chem. Phys. 22 7374

Google Scholar

Google Scholar

计量

- 文章访问数: 5282

- PDF下载量: 80

- 被引次数: 0

下载:

下载: