-

半导体型气体传感器对还原性气体普遍存在特异性识别不强的问题, 单个传感器很难实现识别混合气体的功能. 为了解决这一系列问题, 本文利用纳米气体传感器矩阵来增强对不同气体的特异性识别和混合气体识别. 首先利用水热法制备4种纳米气敏结构, 然后结合微机电系统制成传感器矩阵, 对石化领域中几种关键气体及其混合气体进行了气敏响应测试, 最后利用主成分分析算法进行了气体成分分析. 研究发现, 混合气体会对单个传感器的识别产生很大干扰, 而通过纳米传感器矩阵识别和主成分分析算法处理后, 不同气体会呈现不同的区域分布, 并随浓度呈现一定的方向性. 由此, 不同气体及其浓度的变化可以被准确地区分开来. 而对于混合气体识别同样满足这样的规律, 且混合气体将会分布在所组成的单一气体围成的扇形区域内. 实验表明, 纳米传感器矩阵和主成分分析方法为复杂气体种类和浓度识别提供了方向.

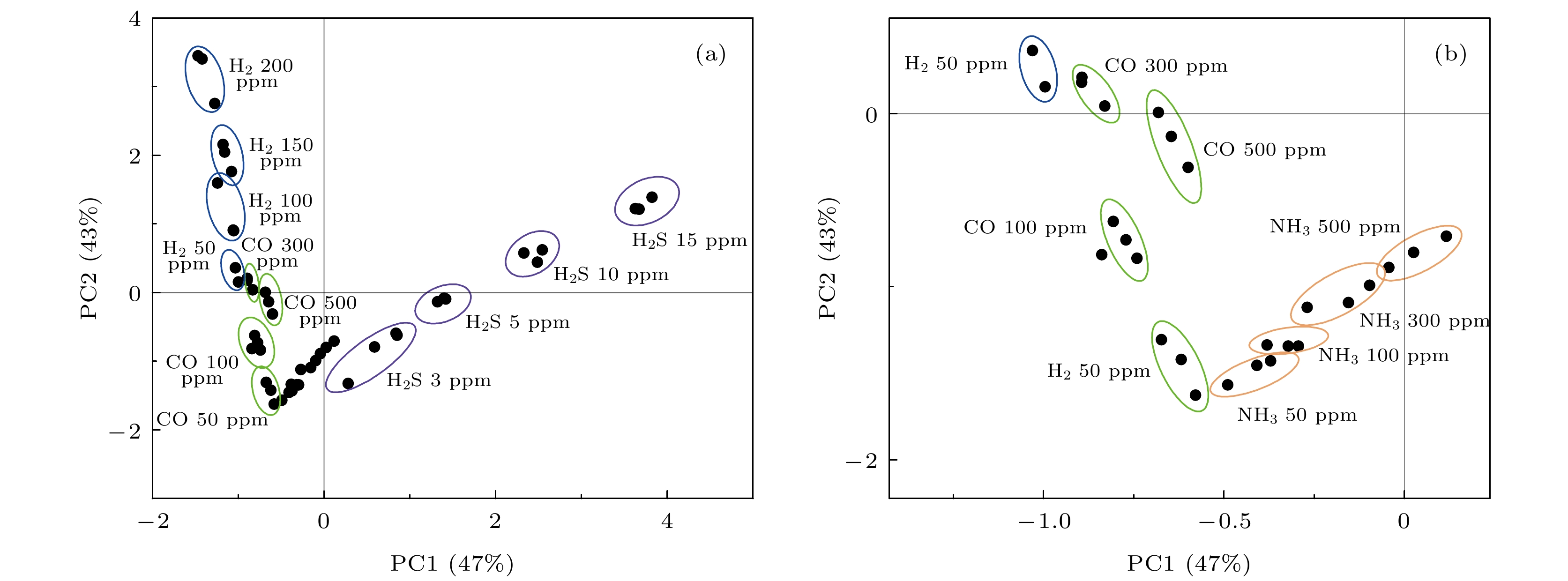

In recent years, quite a few production safety accidents caused by hazardous gas leakage have occurred in the petrochemical industry, causing great potential safety hazards and huge economic losses. Therefore, it is necessary to develop gas sensors with high sensitivity and accurate identification. Semiconductor gas sensor, which has the advantages of high sensitivity, fast response and high integration, is one of the most popular types in the sensing field. However, the semiconductor gas sensor has low specific recognition to reducing gases (such as H2S, CO, H2, etc.), and it is difficult to accurately achieve mixed-gas identification with a single sensor. With the development of micro-electromechanical systems (MEMS), the size of semiconductor sensor can be reduced to millimeters with high integration. In order to solve the cross-sensitivity problem, the concept of sensor array has been proposed and widely studied. Through the principal component analysis, the data having the most characteristic information can be selected from among the acquired data while preserving the original data information as much as possible, and they are projected onto the new orthogonal vector by linear transformation. This method can maximize data dispersion and minimize information loss after dimensionality reduction. Therefore, it is an effective way to identify the gas species by combining sensor array. In this work, we synthesize four types of tungsten trioxide sensing materials with different morphologies or compositions by the hydrothermal method. The sensor array is fabricated by MEMS-based nano sensors. The gas sensitivities to the four single gases (H2S, CO, H2, NH3) and their mixed gas are measured by sensor array, which can acquire four groups of data at the same time. Compared with single sensor, the sensor array has different responses to pure gas and mixed gas, which is the basis for gas identification. Furthermore, we use principal component analysis method to process the response of sensor array. The results show that different gases will occupy different areas in the diagram for pure gas, and show certain directionality according to different concentration distributions. By determining the position of the detected gas, the composition and concentration of the measured gas can be inferred. For mixed gas, the distributions of single gases show the same tendency. And the points of mixed gas always occupy the area between the fans formed by the two gas components, and each region keeps independent. Therefore, this method can also identify the compositions and the concentrations of gas species contained in mixed gas. These results prove that nano sensor array can provide direction and guidance for semiconductor sensor to identify the gas species and concentration. -

Keywords:

- gas sensor /

- sensor array /

- principal component analysis

[1] Wang F, Hu K, Liu H, Zhao Q, Wang K, Zhang Y 2020 Int. J. Hydrogen Energy 45 7234

Google Scholar

Google Scholar

[2] Zhu Z, Xing X, Feng D, Li Z, Tian Y, Yang D 2021 Nanoscale 13 12669

Google Scholar

Google Scholar

[3] Zhou Q, Sussman A, Chang J, Dong J, Zettl A, Mickelson W 2015 Sens. Actuators A 223 67

Google Scholar

Google Scholar

[4] Mickelson W, Sussman A, Zettl A 2012 Appl. Phys. Lett. 100 173110

Google Scholar

Google Scholar

[5] Wang J, Yang J, Chen D, Jin L, Li Y, Zhang Y, Xu L, Guo Y, Lin F, Wu F 2018 IEEE Sens. J. 18 6765

Google Scholar

Google Scholar

[6] Chen D, Hou X, Li T, Yin L, Fan B, Wang H, Li X, Xu H, Lu H, Zhang R, Sun J 2011 Sens. Actuators B 153 373

Google Scholar

Google Scholar

[7] Luo X, Lou Z, Wang L, Zheng X, Zhang T 2014 New J. Chem. 38 84

Google Scholar

Google Scholar

[8] Su Y, Chen P, Wang P, Ge J, Hu S, Zhao Y, Xie G, Liang W, Song P 2019 RSC Adv. 9 5987

Google Scholar

Google Scholar

[9] Shi J, Cheng Z, Gao L, Zhang Y, Xu J, Zhao H 2016 Sens. Actuators B 230 736

Google Scholar

Google Scholar

[10] Shobin L R, Manivannan S 2018 Sens. Actuators B 256 7

Google Scholar

Google Scholar

[11] Chen H, Zhao Y, Shi L, Li G D, Sun L, Zou X 2018 ACS Appl. Mater. Interfaces 10 29795

Google Scholar

Google Scholar

[12] Zhu L Y, Yuan K P, Yang J H, Hang C Z, Ma H P, Ji X M, Devi A, Lu H L, Zhang D W 2020 Microsyst. Nanoeng. 6 30

Google Scholar

Google Scholar

[13] Li W, Liu H, Xie D, He Z, Pi X 2017 Sci. Rep. 7 1969

Google Scholar

Google Scholar

[14] Gabrieli G, Hu R, Matsumoto K, Temiz Y, Bissig S, Cox A, Heller R, Lopez A, Barroso J, Kaneda K, Orii Y, Ruch P W 2021 Anal. Chem. 93 16853

Google Scholar

Google Scholar

[15] Rullich C C, Kiefer J 2019 Analyst 144 2080

Google Scholar

Google Scholar

[16] Jolliffe I T, Cadima J 2016 Philos Trans. A Math. Phys. Eng. Sci. 374 20150202

Google Scholar

Google Scholar

[17] Li Z H, Xie J, Hu X B, Chen C, Xie L L, Zhu Z G, Zheng L Y 2018 Mater. Sci. Forum 939 133

Google Scholar

Google Scholar

[18] Bai S, Chen S, Zhao Y, Guo T, Luo R, Li D, Chen A 2014 J. Mater. Chem. A 2 16697

Google Scholar

Google Scholar

[19] Wang Q, Wu H, Wang Y, Li J, Yang Y, Cheng X, Luo Y, An B, Pan X, Xie E 2021 J Hazard. Mater. 412 125175

Google Scholar

Google Scholar

[20] Zhou Q, Xu L, Umar A, Chen W, Kumar R 2018 Sens. Actuators B 256 656

Google Scholar

Google Scholar

[21] Wang L, Wang Y, Yu K, Wang S, Zhang Y, Wei C 2016 Sens. Actuators B 232 91

Google Scholar

Google Scholar

[22] Brun M, Berthet A, Bertolini J C 1999 J Electron. Spectros. Relat. Phenomena. 104 55

Google Scholar

Google Scholar

[23] Schipani F, Miller D R, Ponce M A, Aldao C M, Akbar S A, Morris P A, Xu J C 2017 Sens. Actuators B 241 99

Google Scholar

Google Scholar

[24] Hua Z, Yuasa M, Kida T, Yamazoe N, Shimanoe K 2014 Chem. Lett. 43 1435

Google Scholar

Google Scholar

[25] Rong Q, Xiao B, Zeng J, Yu R, Zi B, Zhang G, Zhu Z, Zhang J, Wu J, Liu Q 2022 ACS Sens. 7 199

Google Scholar

Google Scholar

[26] Wang C, Zhang Y, Sun X, Sun Y, Liu F, Yan X, Wang C, Sun P, Lu G 2020 Sens. Actuators B 321 128629

Google Scholar

Google Scholar

[27] Kim M H, Jang B, Kim W, Lee W 2019 Sens. Actuators B 283 890

Google Scholar

Google Scholar

[28] 胡云鹏, 陈焕新, 周诚, 杨小双, 徐荣吉 2012 化工学报 63 85

Google Scholar

Google Scholar

Hu Y P, Chen H X, Zhou C Yang X S, Xu R J 2012 CIESC J. 63 85

Google Scholar

Google Scholar

[29] Lu Y, Partridge C, Meyyappan M, Li J 2006 J. Electroanal. Chem. 593 105

Google Scholar

Google Scholar

[30] 谢前朋, 潘小义, 陈吉源, 肖顺平 2021 70 044302

Google Scholar

Google Scholar

Xie Q P, Pan X Y, Chen J Y, Xiao S P 2021 Acta Phys. Sin. 70 044302

Google Scholar

Google Scholar

[31] Zeng H, Li Q, Gu Y 2016 Chin. Phys. B 25 024201

Google Scholar

Google Scholar

[32] Lee J, Jung Y, Sung S H, Lee G, Kim J, Seong J, Shim Y S, Jun S C, Jeon S 2021 J. Mater. Chem. A 9 1159

Google Scholar

Google Scholar

-

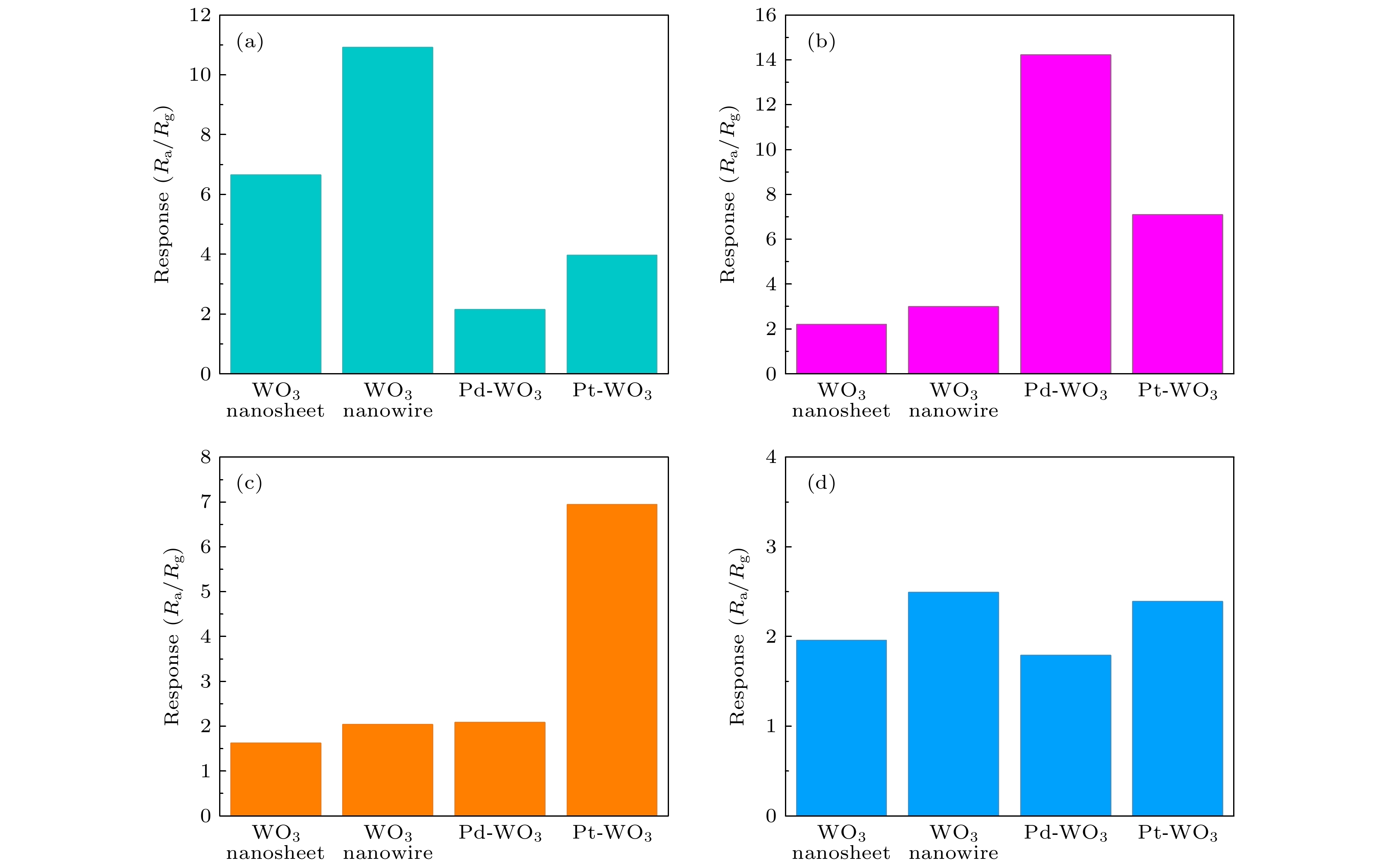

图 5 传感器矩阵对4种纯气体的响应对比 (a) 体积分数为5 × 10–6的H2S; (b) 体积分数为10–4的H2; (c) 体积分数为3 × 10–4的CO; (d) 体积分数为10–4的NH3

Fig. 5. Response comparison of sensor array to four pure gas: (a) H2S with the volume fraction of 5 × 10–6; (b) H2 with the volume fraction of 10–4; (c) CO with the volume fraction of 3 × 10–4; (d) NH3 with the volume fraction of 10–4.

图 6 传感器矩阵对H2S和不同混合气体的响应对比图 (a) H2S/H2; (b) H2S/CO; (c) H2S/NH3; (d) H2/CO. 10 ppm H2S表示H2S的体积分数为1 × 10–5, 其他符号的含义类似, 1 ppm = 10–6

Fig. 6. Response comparison of sensor array for H2S and different mixed gas: (a) H2S/H2; (b) H2S/CO; (c) H2S/NH3; (d) H2/CO. 10 ppm H2S represents that the volume fraction of H2S is 1 × 10–5. 1 ppm = 10–6. Other symbols have similar meanings.

-

[1] Wang F, Hu K, Liu H, Zhao Q, Wang K, Zhang Y 2020 Int. J. Hydrogen Energy 45 7234

Google Scholar

Google Scholar

[2] Zhu Z, Xing X, Feng D, Li Z, Tian Y, Yang D 2021 Nanoscale 13 12669

Google Scholar

Google Scholar

[3] Zhou Q, Sussman A, Chang J, Dong J, Zettl A, Mickelson W 2015 Sens. Actuators A 223 67

Google Scholar

Google Scholar

[4] Mickelson W, Sussman A, Zettl A 2012 Appl. Phys. Lett. 100 173110

Google Scholar

Google Scholar

[5] Wang J, Yang J, Chen D, Jin L, Li Y, Zhang Y, Xu L, Guo Y, Lin F, Wu F 2018 IEEE Sens. J. 18 6765

Google Scholar

Google Scholar

[6] Chen D, Hou X, Li T, Yin L, Fan B, Wang H, Li X, Xu H, Lu H, Zhang R, Sun J 2011 Sens. Actuators B 153 373

Google Scholar

Google Scholar

[7] Luo X, Lou Z, Wang L, Zheng X, Zhang T 2014 New J. Chem. 38 84

Google Scholar

Google Scholar

[8] Su Y, Chen P, Wang P, Ge J, Hu S, Zhao Y, Xie G, Liang W, Song P 2019 RSC Adv. 9 5987

Google Scholar

Google Scholar

[9] Shi J, Cheng Z, Gao L, Zhang Y, Xu J, Zhao H 2016 Sens. Actuators B 230 736

Google Scholar

Google Scholar

[10] Shobin L R, Manivannan S 2018 Sens. Actuators B 256 7

Google Scholar

Google Scholar

[11] Chen H, Zhao Y, Shi L, Li G D, Sun L, Zou X 2018 ACS Appl. Mater. Interfaces 10 29795

Google Scholar

Google Scholar

[12] Zhu L Y, Yuan K P, Yang J H, Hang C Z, Ma H P, Ji X M, Devi A, Lu H L, Zhang D W 2020 Microsyst. Nanoeng. 6 30

Google Scholar

Google Scholar

[13] Li W, Liu H, Xie D, He Z, Pi X 2017 Sci. Rep. 7 1969

Google Scholar

Google Scholar

[14] Gabrieli G, Hu R, Matsumoto K, Temiz Y, Bissig S, Cox A, Heller R, Lopez A, Barroso J, Kaneda K, Orii Y, Ruch P W 2021 Anal. Chem. 93 16853

Google Scholar

Google Scholar

[15] Rullich C C, Kiefer J 2019 Analyst 144 2080

Google Scholar

Google Scholar

[16] Jolliffe I T, Cadima J 2016 Philos Trans. A Math. Phys. Eng. Sci. 374 20150202

Google Scholar

Google Scholar

[17] Li Z H, Xie J, Hu X B, Chen C, Xie L L, Zhu Z G, Zheng L Y 2018 Mater. Sci. Forum 939 133

Google Scholar

Google Scholar

[18] Bai S, Chen S, Zhao Y, Guo T, Luo R, Li D, Chen A 2014 J. Mater. Chem. A 2 16697

Google Scholar

Google Scholar

[19] Wang Q, Wu H, Wang Y, Li J, Yang Y, Cheng X, Luo Y, An B, Pan X, Xie E 2021 J Hazard. Mater. 412 125175

Google Scholar

Google Scholar

[20] Zhou Q, Xu L, Umar A, Chen W, Kumar R 2018 Sens. Actuators B 256 656

Google Scholar

Google Scholar

[21] Wang L, Wang Y, Yu K, Wang S, Zhang Y, Wei C 2016 Sens. Actuators B 232 91

Google Scholar

Google Scholar

[22] Brun M, Berthet A, Bertolini J C 1999 J Electron. Spectros. Relat. Phenomena. 104 55

Google Scholar

Google Scholar

[23] Schipani F, Miller D R, Ponce M A, Aldao C M, Akbar S A, Morris P A, Xu J C 2017 Sens. Actuators B 241 99

Google Scholar

Google Scholar

[24] Hua Z, Yuasa M, Kida T, Yamazoe N, Shimanoe K 2014 Chem. Lett. 43 1435

Google Scholar

Google Scholar

[25] Rong Q, Xiao B, Zeng J, Yu R, Zi B, Zhang G, Zhu Z, Zhang J, Wu J, Liu Q 2022 ACS Sens. 7 199

Google Scholar

Google Scholar

[26] Wang C, Zhang Y, Sun X, Sun Y, Liu F, Yan X, Wang C, Sun P, Lu G 2020 Sens. Actuators B 321 128629

Google Scholar

Google Scholar

[27] Kim M H, Jang B, Kim W, Lee W 2019 Sens. Actuators B 283 890

Google Scholar

Google Scholar

[28] 胡云鹏, 陈焕新, 周诚, 杨小双, 徐荣吉 2012 化工学报 63 85

Google Scholar

Google Scholar

Hu Y P, Chen H X, Zhou C Yang X S, Xu R J 2012 CIESC J. 63 85

Google Scholar

Google Scholar

[29] Lu Y, Partridge C, Meyyappan M, Li J 2006 J. Electroanal. Chem. 593 105

Google Scholar

Google Scholar

[30] 谢前朋, 潘小义, 陈吉源, 肖顺平 2021 70 044302

Google Scholar

Google Scholar

Xie Q P, Pan X Y, Chen J Y, Xiao S P 2021 Acta Phys. Sin. 70 044302

Google Scholar

Google Scholar

[31] Zeng H, Li Q, Gu Y 2016 Chin. Phys. B 25 024201

Google Scholar

Google Scholar

[32] Lee J, Jung Y, Sung S H, Lee G, Kim J, Seong J, Shim Y S, Jun S C, Jeon S 2021 J. Mater. Chem. A 9 1159

Google Scholar

Google Scholar

计量

- 文章访问数: 6486

- PDF下载量: 148

- 被引次数: 0

下载:

下载: