-

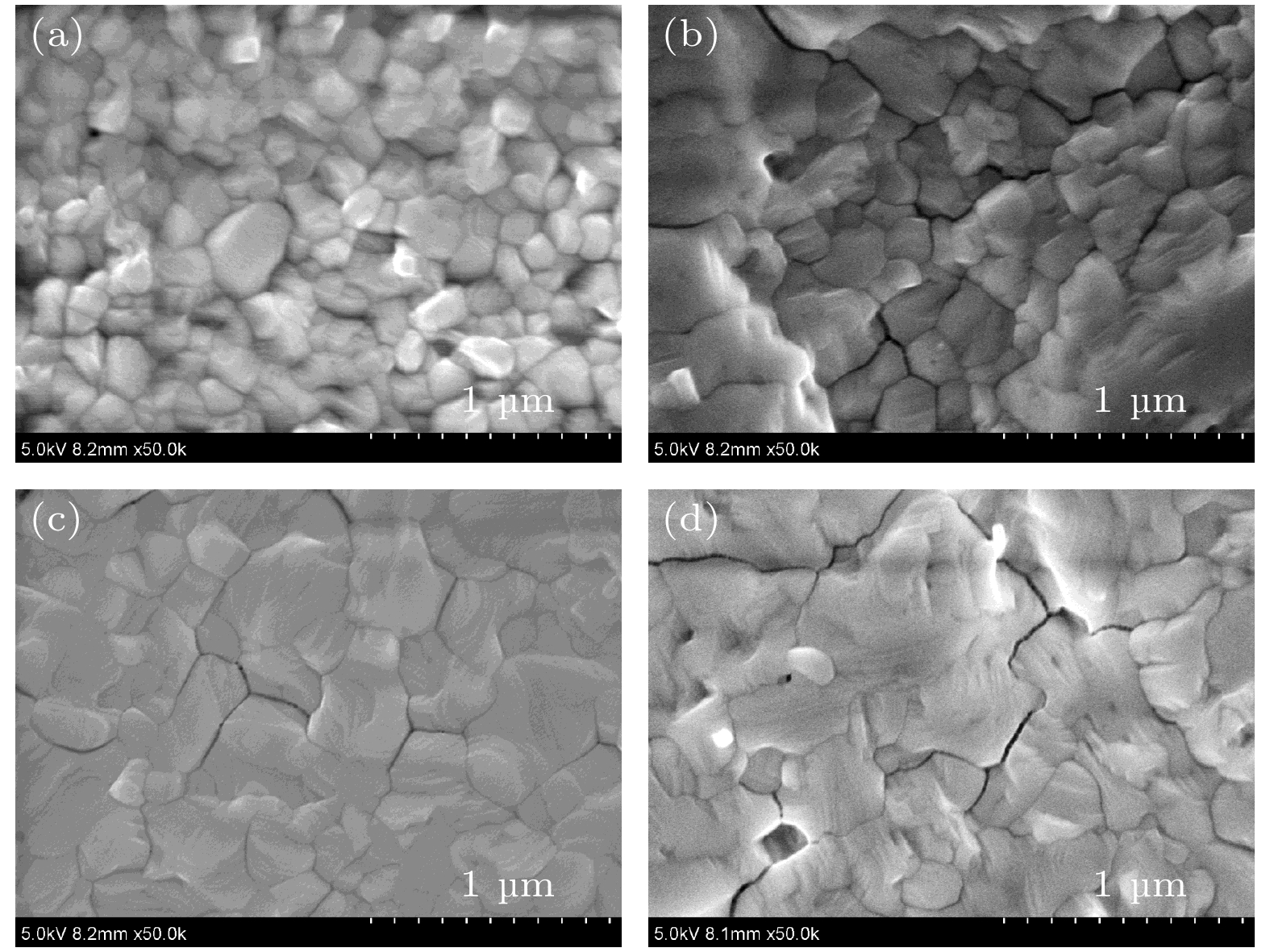

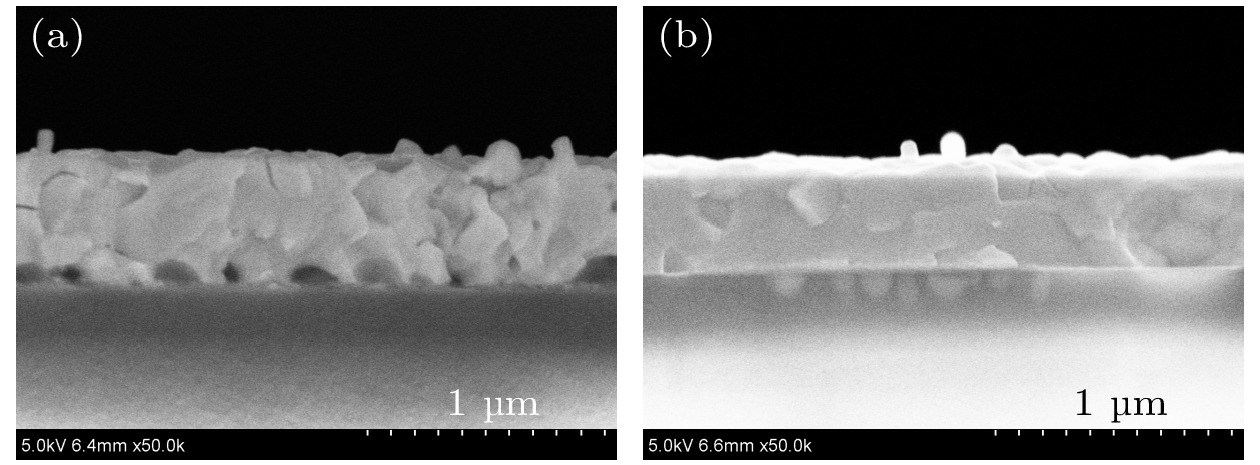

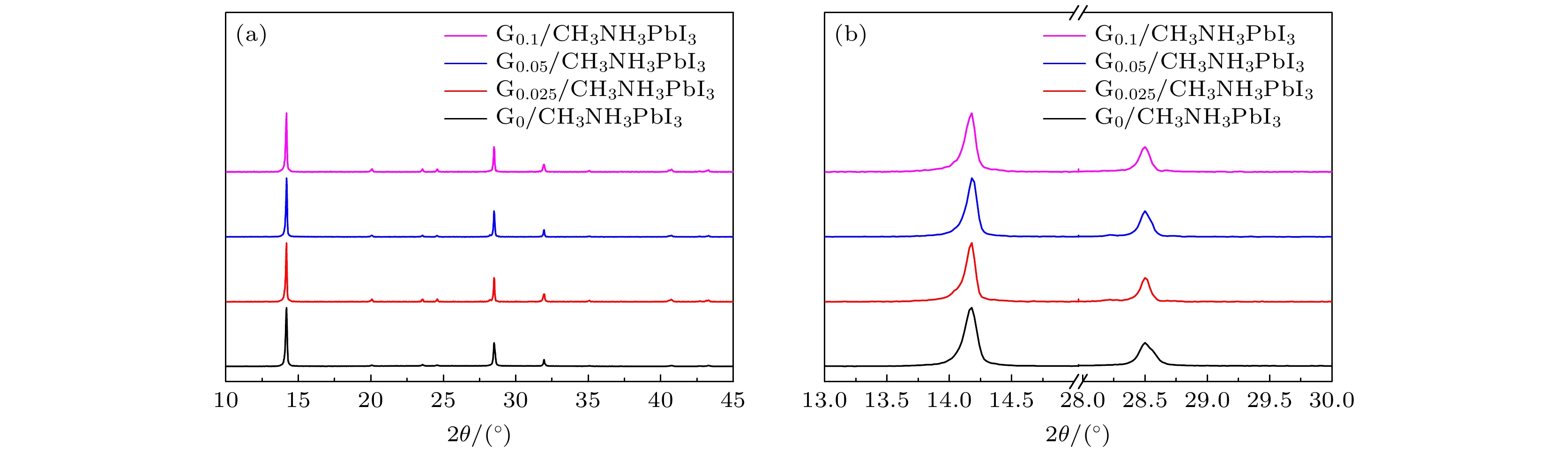

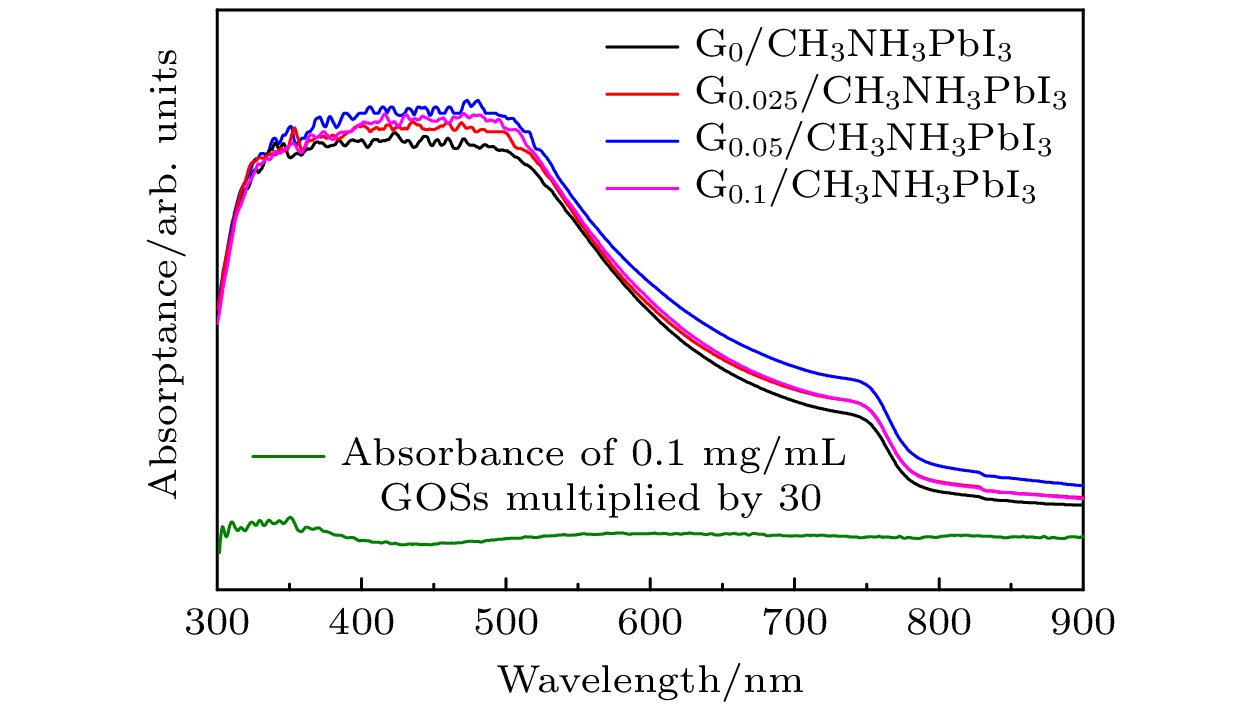

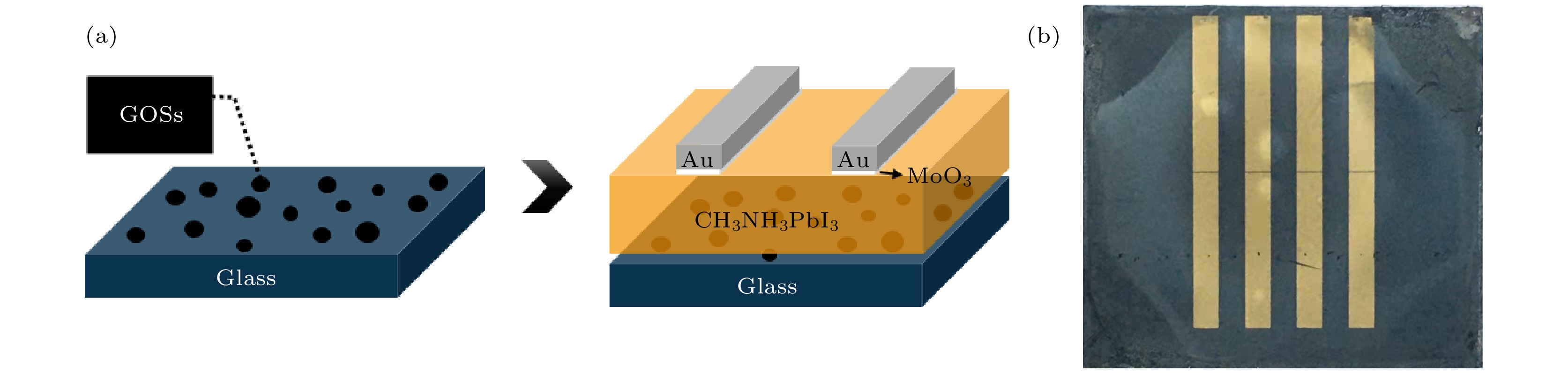

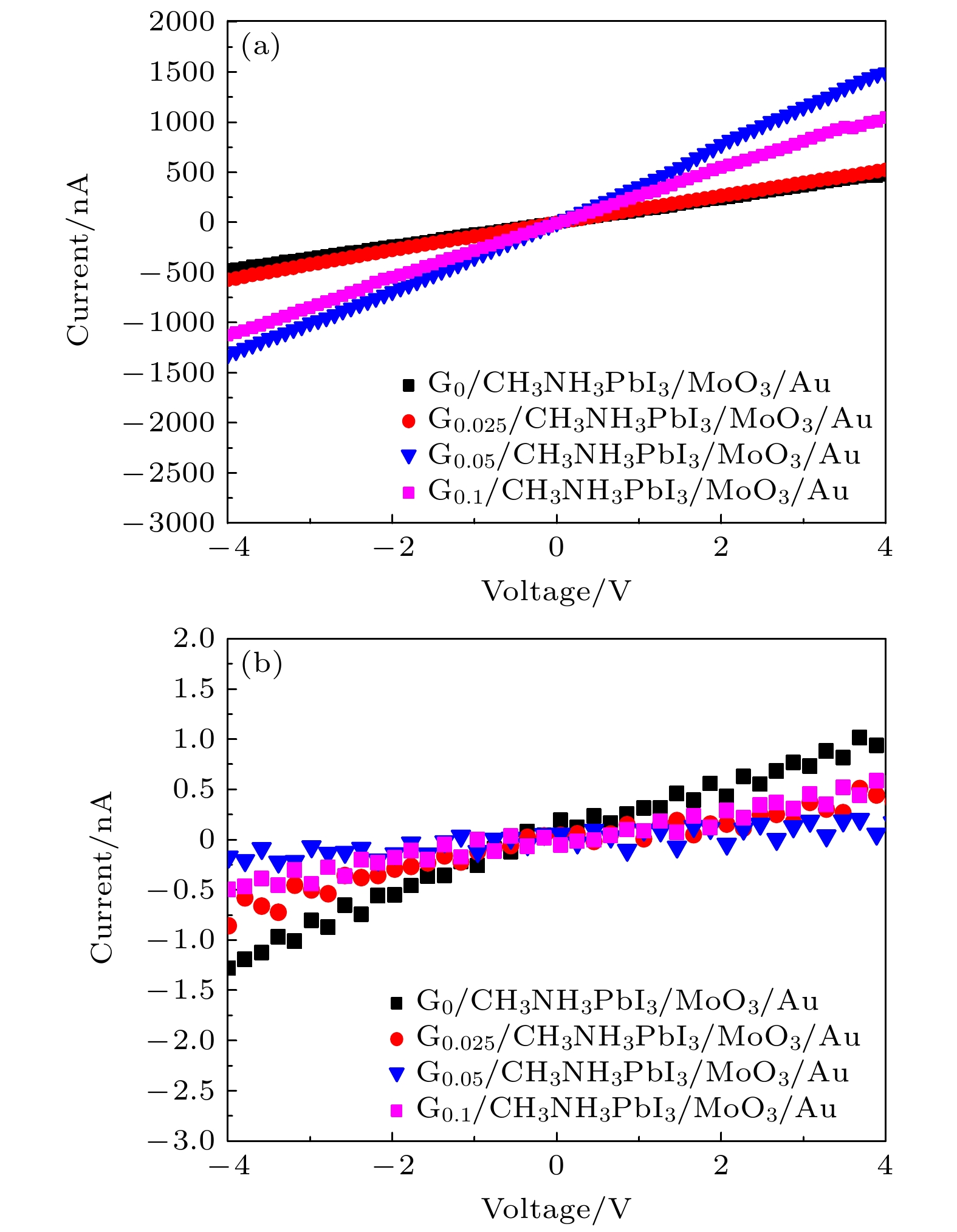

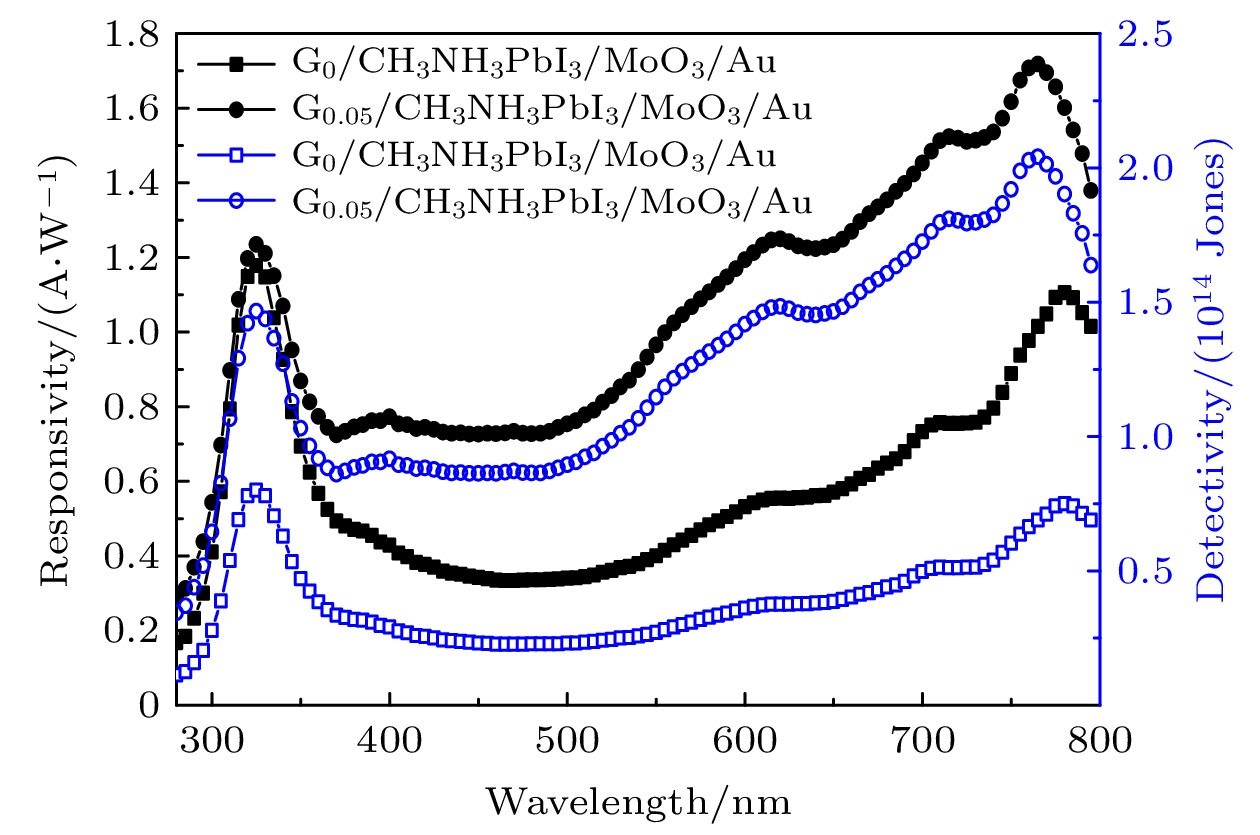

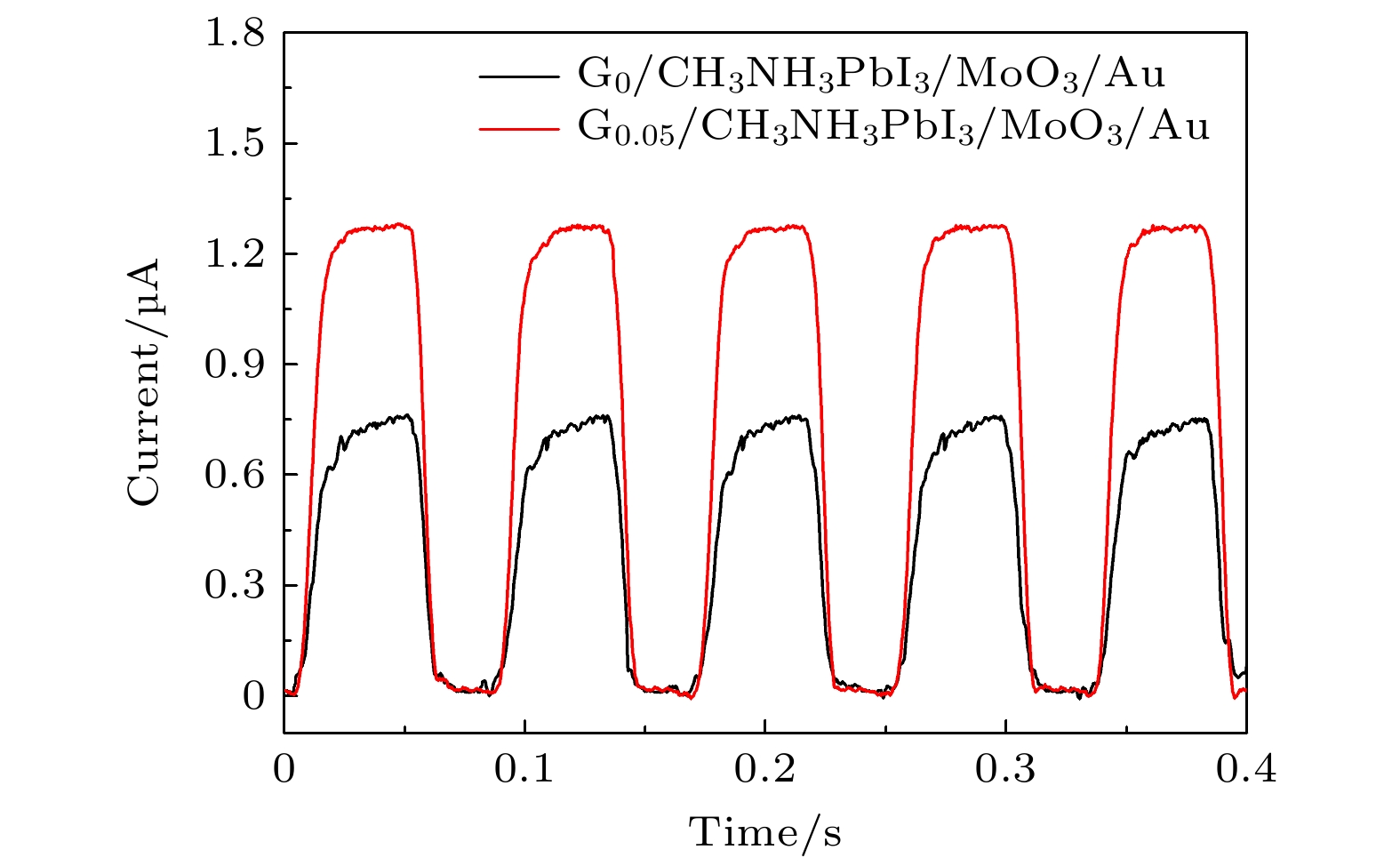

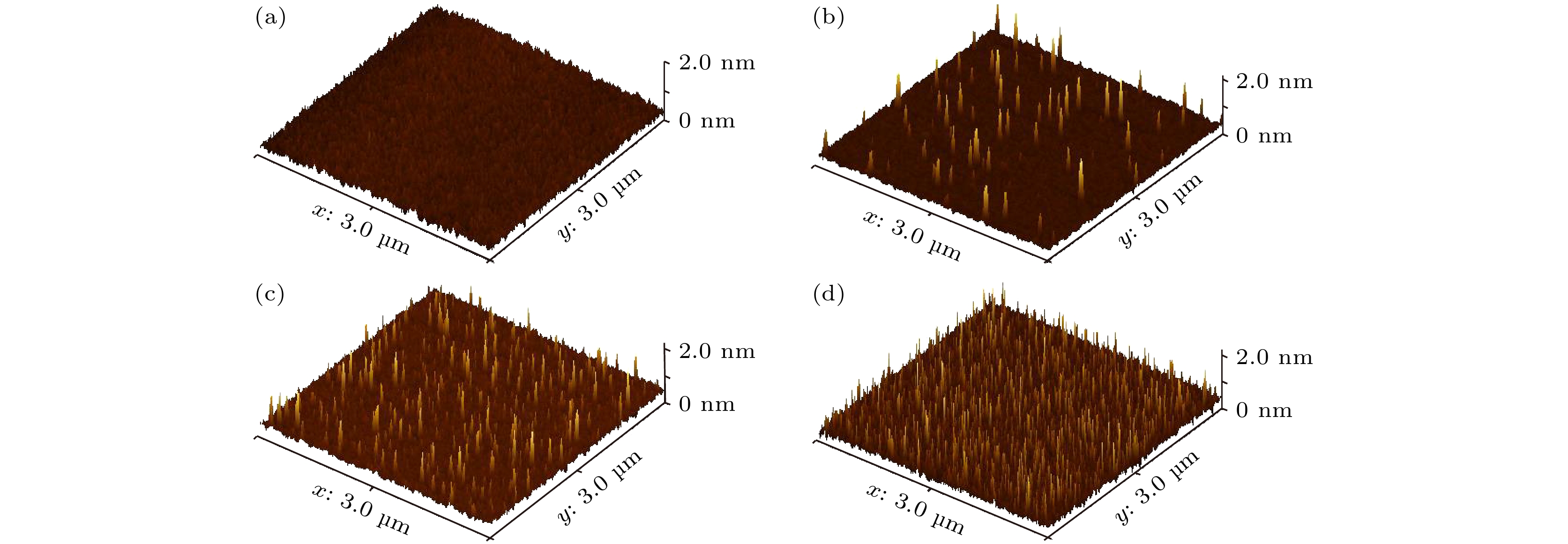

有机无机杂化钙钛矿材料因具有可调节的带隙宽度、优异的载流子传输性能、可低温溶液法制备等优点, 近年来在光电器件的应用研究上受到了广泛的关注. 对于平面光电导型探测器, 电荷在两电极之间需横穿钙钛矿层, 由于钙钛矿晶体的形成能较低, 在晶界和薄膜表面易产生缺陷, 光生载流子被缺陷阻挡而加剧激子的非辐射复合, 造成器件光电性能下降. 本文通过在钙钛矿界面层下方引入微量的氧化石墨烯纳米片作为钙钛矿晶体的有效成核点, 使得钙钛矿晶体可依附于氧化石墨烯形核, 降低钙钛矿晶体成核势垒的同时与钙钛矿形成铅-氧键, 最终获得晶体颗粒增大、晶界数量减少、薄膜致密的钙钛矿层. 由于氧化石墨烯在玻璃基底上的含量极低, 大片玻璃基底裸露并与钙钛矿直接接触, 因此钙钛矿层应视为制备在玻璃基底上. 在氧化石墨烯纳米片的影响下钙钛矿与玻璃基底的接触更为紧密, 有效降低界面间的激子非辐射复合概率, 提高了界面间电荷传输性能. 最终, 在氧化石墨烯纳米片最优制备参数的影响下, 钙钛矿光电探测器光电流相比空白对照器件提高了1个数量级, 在3 V偏压下的开关电流比为5.22 × 103, 并且最优的光电探测器的光响应速度明显提高, 上升时间为9.6 ms, 下降时间为6.6 ms.

Photodetector occupies an important position in the sensor family, but most of the photoelectric conversion materials of photodetectors are inorganic semiconductors, such as GaAs, GaN, Ge and Si, these inorganic semiconductors are usually prepared by complicated methods and high cost, and furthermore, they have poor mechanical flexibility. Organic-inorganic hybrid perovskite materials serving as visible-light sensitizers have the advantages of balanced electron and hole mobilities, adjustable bandgaps, high absorption coefficients, low temperature solution preparation, which make the materials a suitable candidate for inorganic semiconductors. For planar photodetectors, carriers have greater probabilities to be trapped by the defects in the perovskite films, therefore it is important to fabricate a high-quality perovskite film. However, owing to the low formation energy of perovskite crystals, defects prove to occur on the film surface and grain boundaries, which aggravate the performance of perovskite optoelectronic devices. In this work, we introduce a small quantity of graphene oxide nanosheets (GOSs) on bare glass substrate as effective nucleation sites of perovskite crystals. Owing to the extremely low density of GOSs and large exposed glass basement, the GOSs cannot be regarded as an interface layer. The existence of GOSs on smooth substance reduces the perovskite nucleation barrier, leading to a more preferential crystal growth in these locations, and binds tightly with glass substrate, which passivates the defects efficiently. Meanwhile, the element of O in the GOSs can create Pb–O bond with Pb in the CH3NH3PbI3, further improving the crystal of perovskite. On this basis, planner perovskite photodetector with a structure of glass/GOSs/CH3NH3PbI3/MoO3/Au is fabricated. By adjusting the concentration of GOSs deionized water dispersion under the same spin-coating condition, the photoelectric conversion performance of perovskite photodetector is enhanced. Under the influence of the optimal concentration of GOSs, photocurrent of the champion photodetector (1.15 × 10–6 A) is an order of magnitude higher than that of reference device without GOSs modified (3.58 × 10–7 A) at 3 V bias, leading to a high ON/OFF current ratio of 5.22 × 103. Besides, improved photoresponse speed is also found in the champion device, with a rise time of 9.6 ms and a decay time of 6.6 ms, respectively. The enhanced performance of GOSs modified perovskite photodetector can be attributed to the significantly reduced defects bringing about an enhanced charge separation and collection performance in the CH3NH3PbI3 films. By introducing extremely low quantity GOSs as the effective perovskite crystal nucleation sites, the perovskite crystallization and thin film can be effectively improved, leading to a positive effect on the performance of perovskite photodetector. This method has a certain universality, and therefore it has a reference value for other structures of perovskite photoelectric devices. [1] Šagátová A, Zaťko B, Nečas V, Dubecký F, Anh T L, Sedlačková K, Boháček P, Zápražný Z 2018 Appl. Surf. Sci. 461 3

Google Scholar

Google Scholar

[2] Tian H J, Hu A Q, Liu Q L, He X Y, Guo X 2020 Adv. Opt. Mater. 8 1901741

Google Scholar

Google Scholar

[3] Wu J H, Yang Z W, Qiu C Y, Zhang Y J, Wu Z Q, Yang J L, Lu Y H, Li J F, Yang D X, Hao R, Li E P, Yu G L, Lin S S 2018 Nanoscale 10 8023

Google Scholar

Google Scholar

[4] Gundimeda A, Krishna S, Aggarwal N, Sharma A, Sharma N D, Maurya K K, Husale S, Gupta G 2017 Appl. Phys. Lett. 110 103507

Google Scholar

Google Scholar

[5] Liu L, Yang C, Patanè A, Yu Z, Yan F G, Wang K Y, Lu H X, Li J M, Zhao L X 2017 Nanoscale 9 8142

Google Scholar

Google Scholar

[6] Takenaka M, Morii K, Sugiyama M, Nakano Y, Takagi S 2012 Opt. Express 20 8718

Google Scholar

Google Scholar

[7] Hössbacher C, Salamin Y, Fedoryshyn Y, et al. 2017 IEEE Photonics Technol. Lett. 29 1760

Google Scholar

Google Scholar

[8] Berencén Y, Prucnal S, Liu F, Skorupa I, Hübner R, Rebohle L, Zhou S Q, Schneider H, Helm M, Skorupa W 2017 Sci. Rep. 7 1

Google Scholar

Google Scholar

[9] Vivien L, Polzer A, Marris-Morini D, Osmond J, Hartmann J M, Crozat P, Cassan E, Kopp C, Zimmermann H, Fédéli J M 2012 Opt. Express 20 1096

Google Scholar

Google Scholar

[10] Yang J, Pi M Y, Zhang D K, Tang X S, Du J 2021 Chin. J. Lumin. 42 755

Google Scholar

Google Scholar

[11] Gayen R N, Paul R, Biswas S 2020 Appl. Surf. Sci. 533 147149

Google Scholar

Google Scholar

[12] Ozel K, Yildiz A 2021 Phys. Status. Solidi RRL 15 2100085

Google Scholar

Google Scholar

[13] Chen W, Tang H, Chen Y, Heger J E, Li N, Kreuzer L P, Xie Y, Li D P, Anthony C, Pikramenou Z, Ng W K, Sun X W, Wang K, Müller-Buschbaum, P 2020 Nano Energy 78 105254

Google Scholar

Google Scholar

[14] Wang Y D, Liu Y L, Cao S K, Wang J Z 2021 J. Mater. Chem. C 9 5302

Google Scholar

Google Scholar

[15] 柴磊, 钟敏 2016 65 237902

Google Scholar

Google Scholar

Chai L, Zhong M 2016 Acta Phys. Sin. 65 237902

Google Scholar

Google Scholar

[16] Qu Z H, Ma F, Zhao Y, Chu X B, Yu S Q, You J B 2021 Chin. Phys. Lett. 38 107801

Google Scholar

Google Scholar

[17] Wang H, Kim D H 2017 Chem. Soc. Rev. 46 5204

Google Scholar

Google Scholar

[18] 张钰, 周欢萍 2019 68 158804

Google Scholar

Google Scholar

Zhang Y, Zhou H P 2019 Acta Phys. Sin. 68 158804

Google Scholar

Google Scholar

[19] Zhu H L, Liang Z, Huo Z, Ng W K, Mao J, Wong K S, Yin W J, Choy W C H 2018 Adv. Funct. Mater. 28 1706068

Google Scholar

Google Scholar

[20] Li Y, Li Y, Shi J, Zhang H Y, Wu J H, Li D M, Luo Y H, Wu H J, Meng Q B 2018 Adv. Funct. Mater. 28 1705220

Google Scholar

Google Scholar

[21] Wang T, Lian G, Huang L P, Zhu F, Cui D L, Wang Q L, Meng Q B, Jiang H H, Zhou G J, Wong C P 2019 Nano Energy 64 103914

Google Scholar

Google Scholar

[22] Li D, Müller M B, Gilje S, Kaner R B, Wallace G G 2008 Nat. Nanotechnol. 3 101

Google Scholar

Google Scholar

[23] Yang X, Qiu L, Cheng C, Wu Y Z, Ma Z F, Li D 2011 Angew. Chem. Int. Ed. 50 7325

Google Scholar

Google Scholar

[24] Georgakilas V, Tiwari J N, Kemp K C, Perman J A, Bourlinos A B, Kim K S, Zboril R 2016 Chem. Rev. 116 5464

Google Scholar

Google Scholar

[25] Ye S Y, Rao H X, Yan W B, Li Y H, Sun W H, Peng H T, Liu Z W, Bian Z Q, Li Y F, Huang C H 2016 Adv. Mater. 28 9648

Google Scholar

Google Scholar

[26] Jeon N J, Noh J H, Kim Y C, Yang W S, Ryu S, Seol S I 2014 Nat. Mater. 13 897

Google Scholar

Google Scholar

[27] Wang Z K, Li M, Yuan D X, Shi X B, Ma H, Liao L S 2015 ACS Appl. Mater. Interfaces 7 9645

Google Scholar

Google Scholar

[28] Liu L, Xi Q Y, Gao G, Yang W, Zhou H, Zhao Y X, Wu C Q, Wang L D, Xu J W 2016 Sol. Energy Mater. Sol. Cells 157 937

Google Scholar

Google Scholar

[29] Li W Z, Dong H P, Guo X D, Li N, Li J W, Niu G D, Wang L D 2014 J. Mater. Chem. A 2 20105

Google Scholar

Google Scholar

[30] Kröger M, Hamwi S, Meyer J, Riedl T, Kowalsky W, Kahn A 2009 Appl. Phys. Lett. 95 251

[31] Greiner M T, Helander M G, Tang W M, Wang Z B, Qiu J, Lu Z H 2012 Nat. Mater. 11 76

Google Scholar

Google Scholar

[32] Wang Y, Song Q G, Lin T, Fu Y, Sun X, Chu B, Jin F M, Zhao H F, Li W L, Su Z S, Li Y T 2017 Org. Electron. 49 355

Google Scholar

Google Scholar

[33] Afzal A M, Bae I G, Aggarwal Y, Park J, Jeong H R, Choi E H, Park B 2021 Sci. Rep. 11 1

Google Scholar

Google Scholar

[34] Hamilton M C, Martin S, Kanicki J 2004 IEEE Trans. Electron. Devices 51 887

[35] Khan A A, Azam M, Eric D, Liang G X, Yu Z N 2020 J. Mater. Chem. C 8 2880

Google Scholar

Google Scholar

[36] Wei Y Z, Feng G T, Mao P, Luan Y G, Zhuang J, Chen N L, Yang H X, Li W W, Yang S Y, Wang J Z 2020 ACS Appl. Mater. Interfaces 12 8826

Google Scholar

Google Scholar

[37] Shan C W, Meng F, Yu J H, Wang Z X, Li W H, Fan D Y, Chen R, Ma H B, Li G Q, Kyaw A K K 2021 J. Mater. Chem. C 9 7632

Google Scholar

Google Scholar

[38] Srivastava A, Jit S, Tripathi S 2021 IEEE Trans. Electron. Devices 68 IEEE Trans. Electron. Devices

[39] Reddy K C S, Selamneni V, Rao M G S, Meza-Arroyo J, Sahatiya P, Ramirez-Bon R 2021 Appl. Surf. Sci. 568 150944

Google Scholar

Google Scholar

[40] Dutta A, Medda A, Bera R, Sarkar K, Sain S, Kumar P, Patra A 2020 ACS Appl. Nano Mater. 3 4717

[41] Bristow H, Jacoutot P, Scaccabarozzi A D, et al. 2020 ACS Appl. Mater. Interfaces 12 48836

Google Scholar

Google Scholar

-

表 1 不同基底上生长的钙钛矿薄膜XRD衍射峰半峰宽

Table 1. FWHM of the CH3NH3PbI3 XRD diffraction peaks deposited on different substrates.

FWHM/(°) 14.2 28.5 G0/CH3NH3PbI3 0.133 0.146 G0.025/CH3NH3PbI3 0.113 0.104 G0.05/CH3NH3PbI3 0.112 0.099 G0.1/CH3NH3PbI3 0.121 0.115 表 2 溶液法制备的可见光探测器性能

Table 2. Performance of visible light detector prepared by solution method.

材料 制备方法 开关比/103 响应度/(A·W–1) 探测率/Jones 响应时间 Ref. Cs0.1FA0.2MA0.7Pb(I0.9Cl0.1)3-F4TCNQ 旋涂 6.94 5.4 — 530 ms/600 ms [35] (BA)2(MA)n1PbnI3n+1 旋涂 1.38 27.06 — 3.53 ms/3.78 ms [36] CH3NH3PbI3 旋涂 — 0.47 8.2 × 1012 18 ns [37] CH3NH3PbI3 旋涂 5.22 1.71 2.04 × 1014 9.6 ms/6.6 ms This work ZnO/pentacene 旋涂 — 0.36 2.17 × 1014 — [38] p-NiO/n-CdS 水热法/旋涂 ~0.005 2.60 × 10–2 9.21 × 109 3.5 s [39] CdSe 旋涂 4.7 0.16 4 × 1011 107 ms/110 ms [40] PTQ10∶O-IDTBR 刮刀涂布 — 0.03 3.3 × 1011 20 μs/25 μs [41] PTQ10∶O-FBR 0.34 9.6 × 1012 12 μs/15 μs -

[1] Šagátová A, Zaťko B, Nečas V, Dubecký F, Anh T L, Sedlačková K, Boháček P, Zápražný Z 2018 Appl. Surf. Sci. 461 3

Google Scholar

Google Scholar

[2] Tian H J, Hu A Q, Liu Q L, He X Y, Guo X 2020 Adv. Opt. Mater. 8 1901741

Google Scholar

Google Scholar

[3] Wu J H, Yang Z W, Qiu C Y, Zhang Y J, Wu Z Q, Yang J L, Lu Y H, Li J F, Yang D X, Hao R, Li E P, Yu G L, Lin S S 2018 Nanoscale 10 8023

Google Scholar

Google Scholar

[4] Gundimeda A, Krishna S, Aggarwal N, Sharma A, Sharma N D, Maurya K K, Husale S, Gupta G 2017 Appl. Phys. Lett. 110 103507

Google Scholar

Google Scholar

[5] Liu L, Yang C, Patanè A, Yu Z, Yan F G, Wang K Y, Lu H X, Li J M, Zhao L X 2017 Nanoscale 9 8142

Google Scholar

Google Scholar

[6] Takenaka M, Morii K, Sugiyama M, Nakano Y, Takagi S 2012 Opt. Express 20 8718

Google Scholar

Google Scholar

[7] Hössbacher C, Salamin Y, Fedoryshyn Y, et al. 2017 IEEE Photonics Technol. Lett. 29 1760

Google Scholar

Google Scholar

[8] Berencén Y, Prucnal S, Liu F, Skorupa I, Hübner R, Rebohle L, Zhou S Q, Schneider H, Helm M, Skorupa W 2017 Sci. Rep. 7 1

Google Scholar

Google Scholar

[9] Vivien L, Polzer A, Marris-Morini D, Osmond J, Hartmann J M, Crozat P, Cassan E, Kopp C, Zimmermann H, Fédéli J M 2012 Opt. Express 20 1096

Google Scholar

Google Scholar

[10] Yang J, Pi M Y, Zhang D K, Tang X S, Du J 2021 Chin. J. Lumin. 42 755

Google Scholar

Google Scholar

[11] Gayen R N, Paul R, Biswas S 2020 Appl. Surf. Sci. 533 147149

Google Scholar

Google Scholar

[12] Ozel K, Yildiz A 2021 Phys. Status. Solidi RRL 15 2100085

Google Scholar

Google Scholar

[13] Chen W, Tang H, Chen Y, Heger J E, Li N, Kreuzer L P, Xie Y, Li D P, Anthony C, Pikramenou Z, Ng W K, Sun X W, Wang K, Müller-Buschbaum, P 2020 Nano Energy 78 105254

Google Scholar

Google Scholar

[14] Wang Y D, Liu Y L, Cao S K, Wang J Z 2021 J. Mater. Chem. C 9 5302

Google Scholar

Google Scholar

[15] 柴磊, 钟敏 2016 65 237902

Google Scholar

Google Scholar

Chai L, Zhong M 2016 Acta Phys. Sin. 65 237902

Google Scholar

Google Scholar

[16] Qu Z H, Ma F, Zhao Y, Chu X B, Yu S Q, You J B 2021 Chin. Phys. Lett. 38 107801

Google Scholar

Google Scholar

[17] Wang H, Kim D H 2017 Chem. Soc. Rev. 46 5204

Google Scholar

Google Scholar

[18] 张钰, 周欢萍 2019 68 158804

Google Scholar

Google Scholar

Zhang Y, Zhou H P 2019 Acta Phys. Sin. 68 158804

Google Scholar

Google Scholar

[19] Zhu H L, Liang Z, Huo Z, Ng W K, Mao J, Wong K S, Yin W J, Choy W C H 2018 Adv. Funct. Mater. 28 1706068

Google Scholar

Google Scholar

[20] Li Y, Li Y, Shi J, Zhang H Y, Wu J H, Li D M, Luo Y H, Wu H J, Meng Q B 2018 Adv. Funct. Mater. 28 1705220

Google Scholar

Google Scholar

[21] Wang T, Lian G, Huang L P, Zhu F, Cui D L, Wang Q L, Meng Q B, Jiang H H, Zhou G J, Wong C P 2019 Nano Energy 64 103914

Google Scholar

Google Scholar

[22] Li D, Müller M B, Gilje S, Kaner R B, Wallace G G 2008 Nat. Nanotechnol. 3 101

Google Scholar

Google Scholar

[23] Yang X, Qiu L, Cheng C, Wu Y Z, Ma Z F, Li D 2011 Angew. Chem. Int. Ed. 50 7325

Google Scholar

Google Scholar

[24] Georgakilas V, Tiwari J N, Kemp K C, Perman J A, Bourlinos A B, Kim K S, Zboril R 2016 Chem. Rev. 116 5464

Google Scholar

Google Scholar

[25] Ye S Y, Rao H X, Yan W B, Li Y H, Sun W H, Peng H T, Liu Z W, Bian Z Q, Li Y F, Huang C H 2016 Adv. Mater. 28 9648

Google Scholar

Google Scholar

[26] Jeon N J, Noh J H, Kim Y C, Yang W S, Ryu S, Seol S I 2014 Nat. Mater. 13 897

Google Scholar

Google Scholar

[27] Wang Z K, Li M, Yuan D X, Shi X B, Ma H, Liao L S 2015 ACS Appl. Mater. Interfaces 7 9645

Google Scholar

Google Scholar

[28] Liu L, Xi Q Y, Gao G, Yang W, Zhou H, Zhao Y X, Wu C Q, Wang L D, Xu J W 2016 Sol. Energy Mater. Sol. Cells 157 937

Google Scholar

Google Scholar

[29] Li W Z, Dong H P, Guo X D, Li N, Li J W, Niu G D, Wang L D 2014 J. Mater. Chem. A 2 20105

Google Scholar

Google Scholar

[30] Kröger M, Hamwi S, Meyer J, Riedl T, Kowalsky W, Kahn A 2009 Appl. Phys. Lett. 95 251

[31] Greiner M T, Helander M G, Tang W M, Wang Z B, Qiu J, Lu Z H 2012 Nat. Mater. 11 76

Google Scholar

Google Scholar

[32] Wang Y, Song Q G, Lin T, Fu Y, Sun X, Chu B, Jin F M, Zhao H F, Li W L, Su Z S, Li Y T 2017 Org. Electron. 49 355

Google Scholar

Google Scholar

[33] Afzal A M, Bae I G, Aggarwal Y, Park J, Jeong H R, Choi E H, Park B 2021 Sci. Rep. 11 1

Google Scholar

Google Scholar

[34] Hamilton M C, Martin S, Kanicki J 2004 IEEE Trans. Electron. Devices 51 887

[35] Khan A A, Azam M, Eric D, Liang G X, Yu Z N 2020 J. Mater. Chem. C 8 2880

Google Scholar

Google Scholar

[36] Wei Y Z, Feng G T, Mao P, Luan Y G, Zhuang J, Chen N L, Yang H X, Li W W, Yang S Y, Wang J Z 2020 ACS Appl. Mater. Interfaces 12 8826

Google Scholar

Google Scholar

[37] Shan C W, Meng F, Yu J H, Wang Z X, Li W H, Fan D Y, Chen R, Ma H B, Li G Q, Kyaw A K K 2021 J. Mater. Chem. C 9 7632

Google Scholar

Google Scholar

[38] Srivastava A, Jit S, Tripathi S 2021 IEEE Trans. Electron. Devices 68 IEEE Trans. Electron. Devices

[39] Reddy K C S, Selamneni V, Rao M G S, Meza-Arroyo J, Sahatiya P, Ramirez-Bon R 2021 Appl. Surf. Sci. 568 150944

Google Scholar

Google Scholar

[40] Dutta A, Medda A, Bera R, Sarkar K, Sain S, Kumar P, Patra A 2020 ACS Appl. Nano Mater. 3 4717

[41] Bristow H, Jacoutot P, Scaccabarozzi A D, et al. 2020 ACS Appl. Mater. Interfaces 12 48836

Google Scholar

Google Scholar

计量

- 文章访问数: 5614

- PDF下载量: 95

- 被引次数: 0

下载:

下载: