-

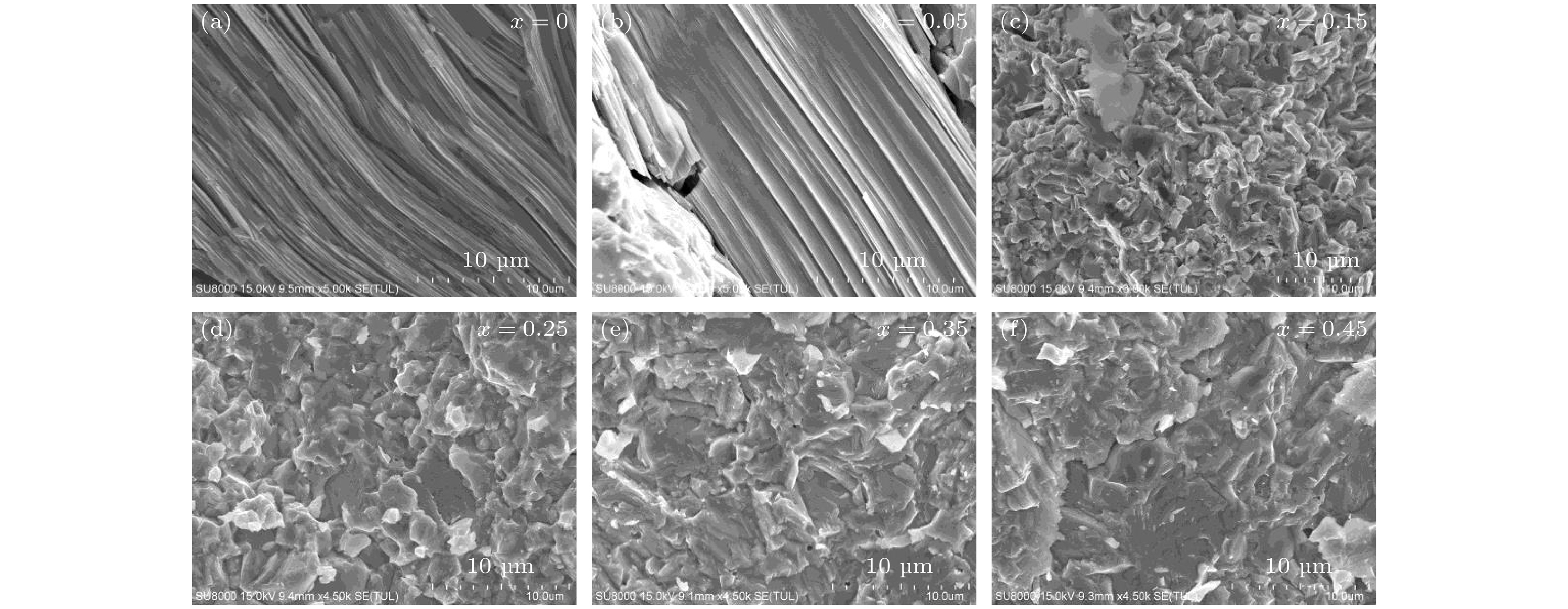

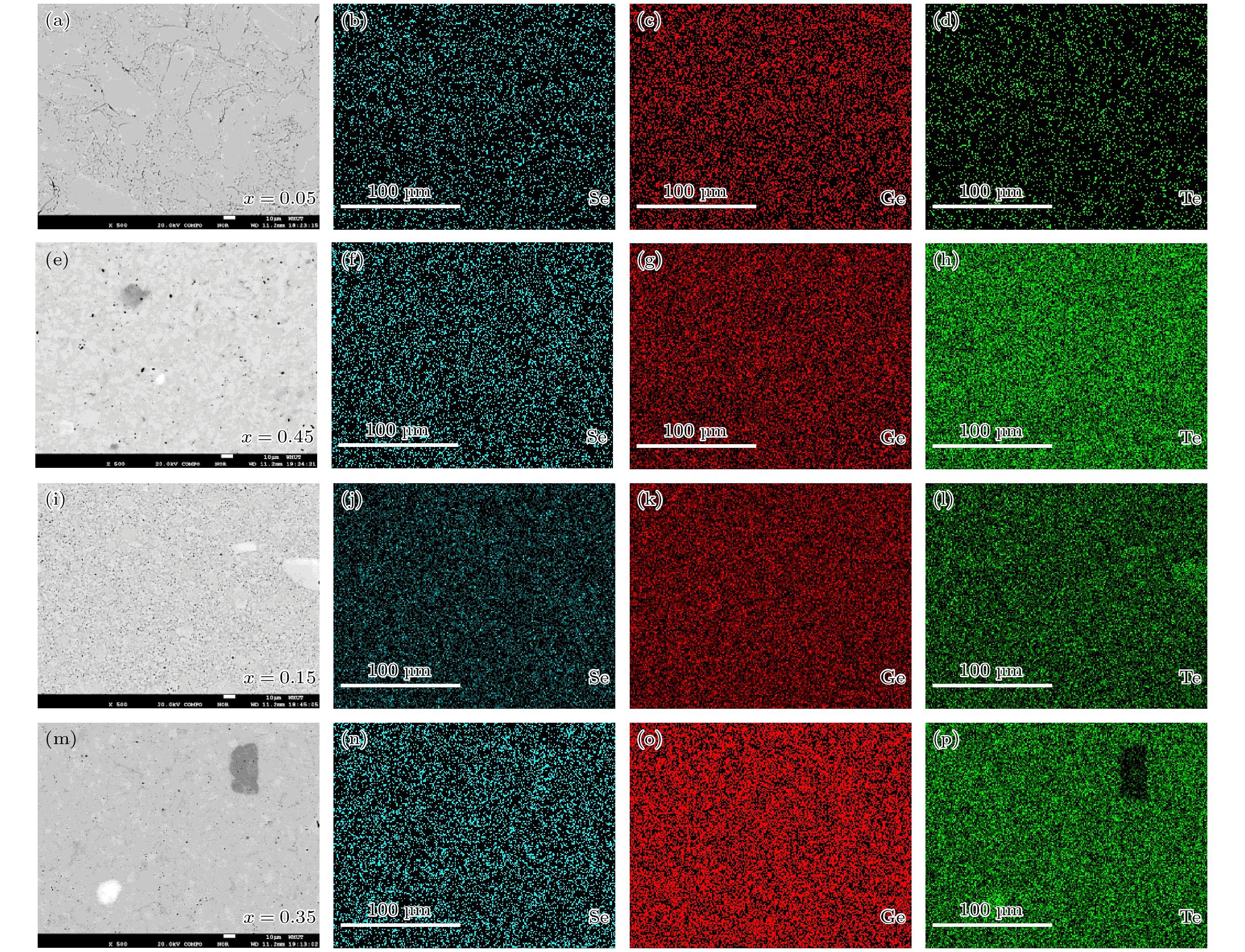

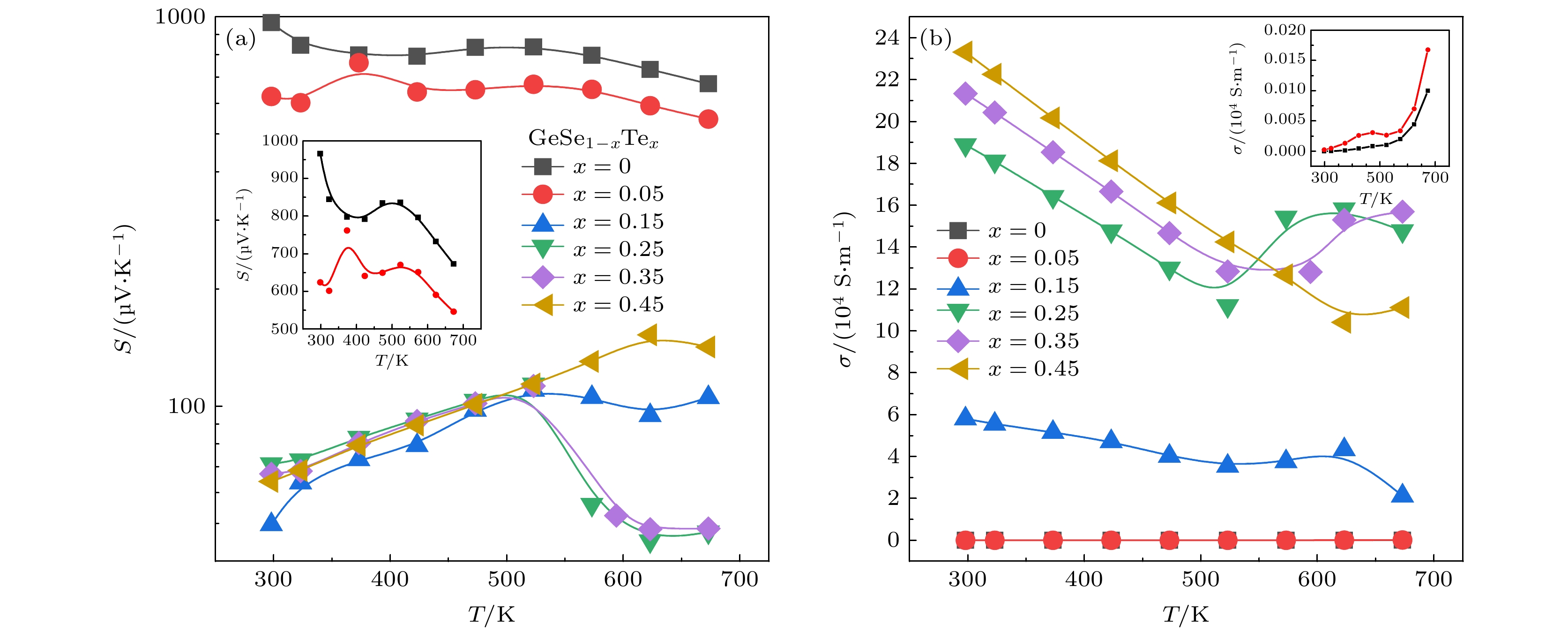

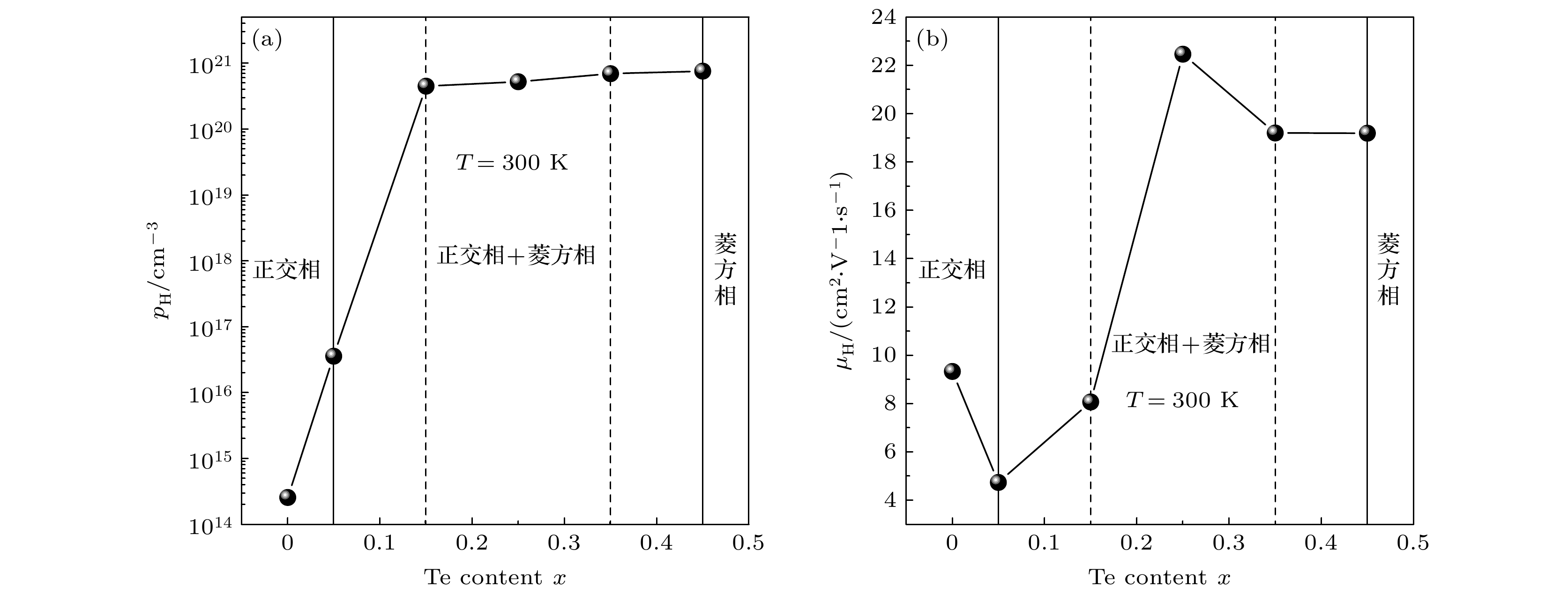

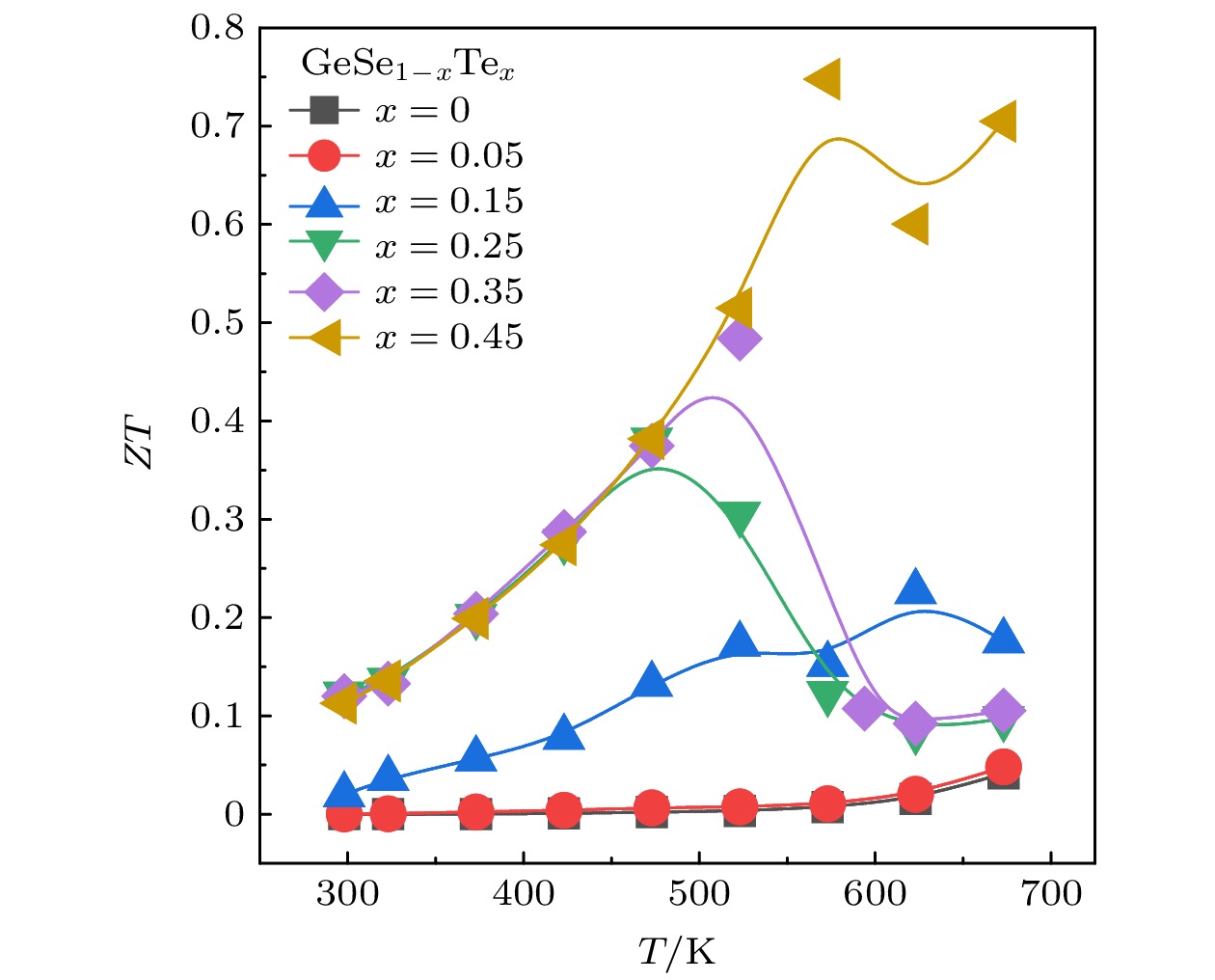

在热电研究领域, GeSe是一种二维层状结构具有较大带隙的半导体, 本征载流子浓度低, 热电性能差. 在本工作中, 采用熔融淬火结合放电等离子活化烧结工艺制备了一系列的GeSe1–xTex (x = 0, 0.05, 0.15, 0.25, 0.35, 0.45)多晶样品, 研究了Te含量对GeSe化合物物相结构和热电输运性能的影响规律. 结果表明: 随着Te含量的增加, GeSe的晶体结构逐渐由正交相向菱方相转变, 使得材料的带隙降低, 载流子浓度和迁移率同步增加; 同时, 晶体对称性的提高增加了化合物的能带简并度, 有效提高了载流子有效质量. 在这些因素的共同作用下, 菱方相GeSe的功率因子比正交相GeSe提高约2—3个数量级. 此外, 菱方相GeSe具有丰富的阳离子空位缺陷以及铁电特性所导致的声子软化现象, 这导致其晶格热导率比正交相GeSe降低近60%. 当Te含量为0.45时, 样品在573 K取得最大热电优值ZT为0.75, 是本征GeSe样品的19倍. 晶体结构工程是提升GeSe化合物热电性能的有效途径.In the thermoelectric field, GeSe is a two-dimensional layered semiconductor with a large band gap, intrinsically low carrier concentration and poor thermoelectric figure of merit ZT. In this work, a series of GeSe1–xTex (x = 0, 0.05, 0.15, 0.25, 0.35, 0.45) polycrystalline samples is prepared by melting and quenching combined with spark plasma activation sintering process. The influences of Te content on the phase structure and thermoelectric transport properties of GeSe are systematically studied. The results indicate that with the increase of Te content, the crystal structure of GeSe gradually changes from orthorhombic to rhombohedral structure. This reduces the band gap of the material, and simultaneously increases the carrier concentration and mobility. Meanwhile, the energy band degeneracy of the compound increases significantly because of enhanced crystal symmetry in this process, thereby considerably improving the effective mass of carriers. Altogether, the power factor of the rhombohedral GeSe is increased by about 2 to 3 orders of magnitude compared with that of the orthorhombic phase GeSe. In addition, the rhombohedral phase GeSe has abundant cationic vacancy defects and softened phonons arising from its ferroelectric feature, leading the lattice thermal conductivity to be 60% lower than orthorhombic one. The GeSe0.55Te0.45 sample achieves a peak ZT of 0.75 at 573 K, which is 19 times that of pristine GeSe. Crystal structure engineering could be considered as an effective way of improving the thermoelectric performance of GeSe compounds.

-

Keywords:

- GeSe /

- crystal structure engineering /

- thermoelectric properties /

- semiconductors

[1] Wang Y, Shi Y, Mei D, Chen Z 2017 Appl. Energy 205 710

Google Scholar

Google Scholar

[2] Kim Y J, Gu H M, Kim C S, Choi H, Lee G, Kim S, Yi K K, Lee S G, Cho B J 2018 Energy 162 526

Google Scholar

Google Scholar

[3] Tan G, Zhao L D, Kanatzidis M G 2016 Chem. Rev. 116 12123

Google Scholar

Google Scholar

[4] Okazaki A 1958 J. Phys. Soc. Jpn. 13 1151

Google Scholar

Google Scholar

[5] Sist M, Gatti C, Norby P, Cenedese S, Kasai H, Kato K, Iversen B B 2017 Chem. Eur. J. 23 6888

Google Scholar

Google Scholar

[6] Kim Y, Choi I-H 2018 J. Korean Phys. Soc. 72 238

Google Scholar

Google Scholar

[7] Hao S, Shi F, Dravid V P, Kanatzidis M G, Wolverton C 2016 Chem. Mater. 28 3218

Google Scholar

Google Scholar

[8] Fan Q, Yang J, Cao J, Liu C 2021 R. Soc. Open Sci. 8 201980

Google Scholar

Google Scholar

[9] Yuan K, Sun Z, Zhang X, Tang D 2019 Sci. Rep. 9 9490

Google Scholar

Google Scholar

[10] Roychowdhury S, Ghosh T, Arora R, Waghmare U V, Biswas K 2018 Angew. Chem. Int. Ed. 57 15167

Google Scholar

Google Scholar

[11] Yan M, Geng H, Jiang P, Bao X 2020 J. Energy Chem. 45 83

Google Scholar

Google Scholar

[12] Zhang X, Shen J, Lin S, Li J, Chen Z, Li W, Pei Y 2016 J. Materiomics 2 331

Google Scholar

Google Scholar

[13] Huang Z, Miller S A, Ge B, Yan M, Anand S, Wu T, Nan P, Zhu Y, Zhuang W, Snyder G J, Jiang P, Bao X 2017 Angew. Chem. Int. Ed. 56 14113

Google Scholar

Google Scholar

[14] Yan M, Tan X, Huang Z, Liu G, Jiang P, Bao X 2018 J. Mater. Chem. A 6 8215

Google Scholar

Google Scholar

[15] Sarkar D, Ghosh T, Roychowdhury S, Arora R, Sajan S, Sheet G, Waghmare U V, Biswas K 2020 J. Am. Chem. Soc. 142 12237

Google Scholar

Google Scholar

[16] Li J, Zhang X, Lin S, Chen Z, Pei Y 2017 Chem. Mater. 29 605

Google Scholar

Google Scholar

[17] Wang Z, Wu H, Xi M, Zhu H, Dai L, Xiong Q, Wang G, Han G, Lu X, Zhou X, Wang G 2020 ACS Appl. Mater. Interfaces 12 41381

Google Scholar

Google Scholar

[18] Sidharth D, Alagar Nedunchezhian A S, Akilan R, Srivastava A, Srinivasan B, Immanuel P, Rajkumar R, Yalini Devi N, Arivanandhan M, Liu C J, Anbalagan G, Shankar R, Jayavel R 2021 Sustain. Energy Fuels 5 1734

Google Scholar

Google Scholar

[19] Shaabani L, Aminorroaya-Yamini S, Byrnes J, Akbar Nezhad A, Blake G R 2017 ACS Omega 2 9192

Google Scholar

Google Scholar

[20] 范人杰, 江先燕, 陶奇睿, 梅期才, 唐颖菲, 陈志权, 苏贤礼, 唐新峰 2021 70 137102

Google Scholar

Google Scholar

Fan R J, Jiang X Y, Tao Q R, Mei Q C, Tang Y F, Chen Z Q, Su X L, Tang X F 2021 Acta Phys. Sin. 70 137102

Google Scholar

Google Scholar

[21] Cao Y, Su X, Meng F, Bailey T P, Zhao J, Xie H, He J, Uher C, Tang X 2020 Adv. Funct. Mater. 30 2005861

Google Scholar

Google Scholar

[22] 黄平, 游理, 梁星, 张继业, 骆军 2019 68 077201

Google Scholar

Google Scholar

Huang P, You L, Liang X, Zhang J Y, Luo J 2019 Acta Phys. Sin. 68 077201

Google Scholar

Google Scholar

[23] 苏贤礼, 唐新峰, 李涵, 邓书康 2008 57 6488

Google Scholar

Google Scholar

Su X L, Tang X F, Li H, Deng S G 2008 Acta Phys. Sin. 57 6488

Google Scholar

Google Scholar

[24] Sun J, Su X, Yan Y, Liu W, Tan G, Tang X 2020 ACS Appl. Energy Mater. 3 2

Google Scholar

Google Scholar

[25] Zhang W, Chen C, Yao H, Xue W, Li S, Bai F, Huang Y, Li X, Lin X, Cao F, Sui J, Wang S, Yu B, Wang Y, Liu X, Zhang Q 2020 Chem. Mater. 32 6983

Google Scholar

Google Scholar

[26] Nshimyimana E, Hao S, Su X, Zhang C, Liu W, Yan Y, Uher C, Wolverton C, Kanatzidis M G, Tang X 2020 J. Mater. Chem. A 8 1193

Google Scholar

Google Scholar

[27] Zheng Z, Su X, Deng R, Stoumpos C, Xie H, Liu W, Yan Y, Hao S, Uher C, Wolverton C, Kanatzidis M G, Tang X 2018 J. Am. Chem. Soc. 140 2673

Google Scholar

Google Scholar

[28] Chen S, Bai H, Li J, Pan W, Jiang X, Li Z, Chen Z, Yan Y, Su X, Wu J, Uher C, Tang X 2020 ACS Appl. Mater. Interfaces 12 19664

Google Scholar

Google Scholar

[29] Franz R, Wiedemann G 1853 Ann. Phys. 165 497

[30] Pietrak K, Wisniewski T S 2015 J. Power Technol. 95 14

[31] Banik A, Ghosh T, Arora R, Dutta M, Pandey J, Acharya S, Soni A, Waghmare U V, Biswas K 2019 Energy Environ. Sci. 12 589

Google Scholar

Google Scholar

-

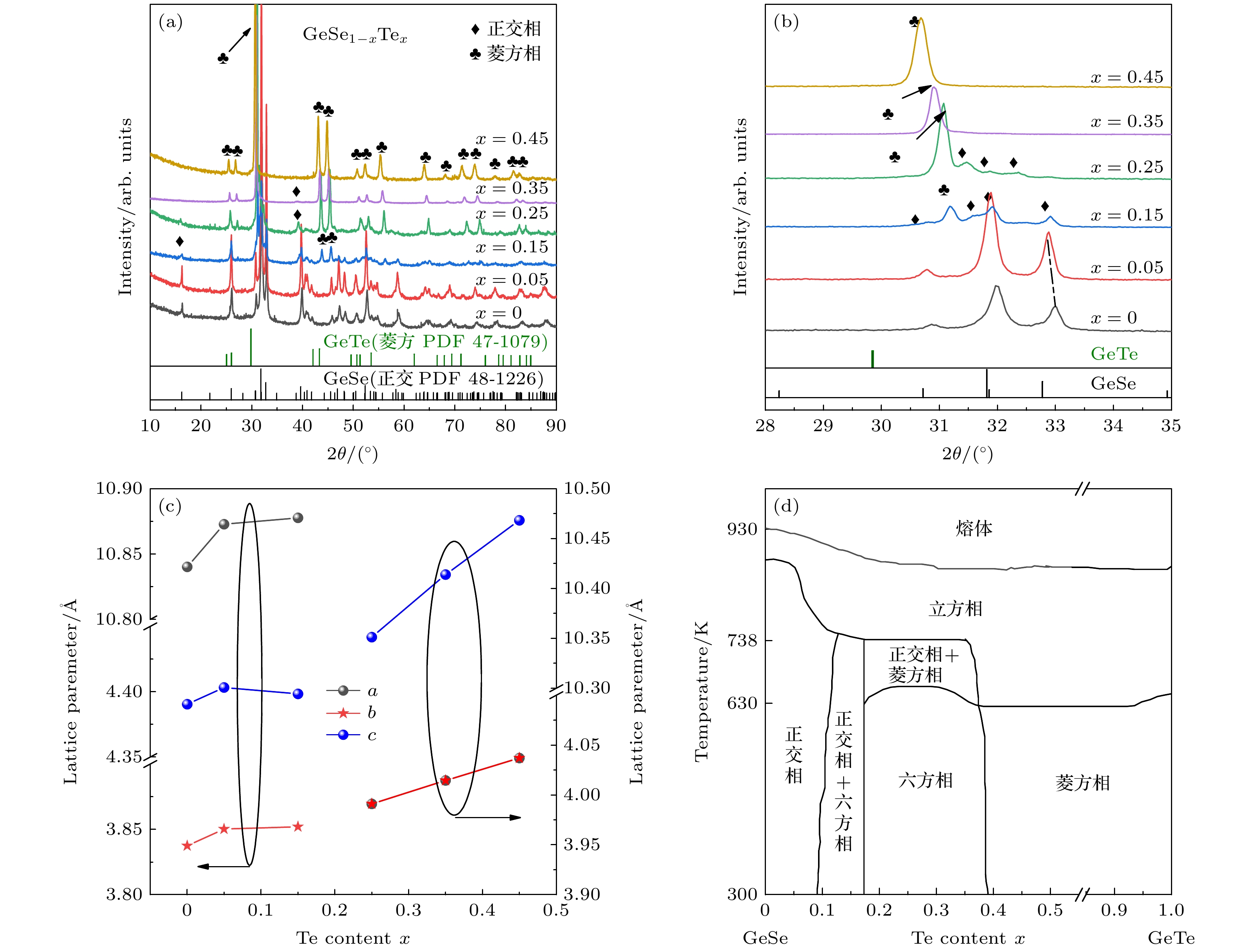

图 2 GeSe1–xTex (x = 0—0.45)样品的 (a)粉末XRD图谱; (b) 28°—35°粉末XRD图谱; (c)晶胞参数; (d) GeSe-GeTe赝二元相图

Fig. 2. (a) Powder XRD patterns of GeSe1–xTex samples (x = 0–0.45); (b) enlarged view of XRD patterns (2θ = 28°–35°); (c) the a, b and c lattice parameters of GeSe1–xTex samples (x = 0–0.45); (d) GeSe-GeTe pseudo-binary phase diagram.

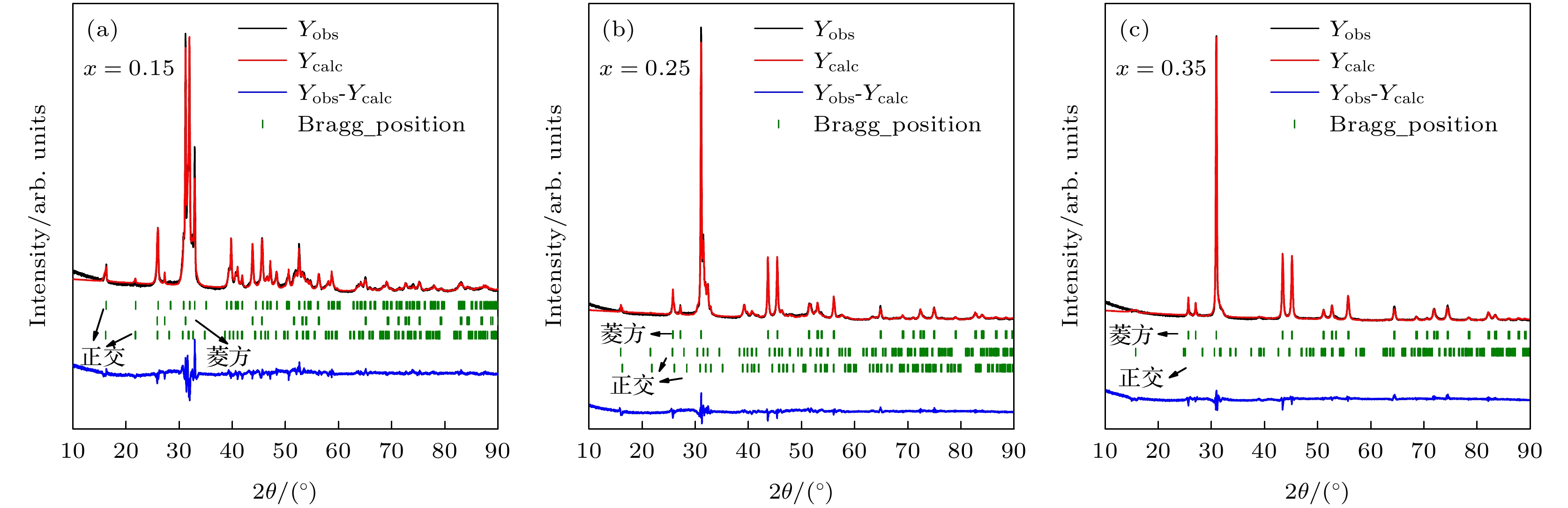

表 1 室温下GeSe1–xTex样品中各种物相的质量分数

Table 1. Mass fractions of various phases in GeSe1–xTex (x = 0.15, 0.25, 0.35) samples at room temperature.

样品组分(GeSe1–xTex) 质量分数/% 正交相 菱方相 x = 0.15 80.9 19.1 x = 0.25 58.5 41.5 x = 0.35 11.2 88.8 -

[1] Wang Y, Shi Y, Mei D, Chen Z 2017 Appl. Energy 205 710

Google Scholar

Google Scholar

[2] Kim Y J, Gu H M, Kim C S, Choi H, Lee G, Kim S, Yi K K, Lee S G, Cho B J 2018 Energy 162 526

Google Scholar

Google Scholar

[3] Tan G, Zhao L D, Kanatzidis M G 2016 Chem. Rev. 116 12123

Google Scholar

Google Scholar

[4] Okazaki A 1958 J. Phys. Soc. Jpn. 13 1151

Google Scholar

Google Scholar

[5] Sist M, Gatti C, Norby P, Cenedese S, Kasai H, Kato K, Iversen B B 2017 Chem. Eur. J. 23 6888

Google Scholar

Google Scholar

[6] Kim Y, Choi I-H 2018 J. Korean Phys. Soc. 72 238

Google Scholar

Google Scholar

[7] Hao S, Shi F, Dravid V P, Kanatzidis M G, Wolverton C 2016 Chem. Mater. 28 3218

Google Scholar

Google Scholar

[8] Fan Q, Yang J, Cao J, Liu C 2021 R. Soc. Open Sci. 8 201980

Google Scholar

Google Scholar

[9] Yuan K, Sun Z, Zhang X, Tang D 2019 Sci. Rep. 9 9490

Google Scholar

Google Scholar

[10] Roychowdhury S, Ghosh T, Arora R, Waghmare U V, Biswas K 2018 Angew. Chem. Int. Ed. 57 15167

Google Scholar

Google Scholar

[11] Yan M, Geng H, Jiang P, Bao X 2020 J. Energy Chem. 45 83

Google Scholar

Google Scholar

[12] Zhang X, Shen J, Lin S, Li J, Chen Z, Li W, Pei Y 2016 J. Materiomics 2 331

Google Scholar

Google Scholar

[13] Huang Z, Miller S A, Ge B, Yan M, Anand S, Wu T, Nan P, Zhu Y, Zhuang W, Snyder G J, Jiang P, Bao X 2017 Angew. Chem. Int. Ed. 56 14113

Google Scholar

Google Scholar

[14] Yan M, Tan X, Huang Z, Liu G, Jiang P, Bao X 2018 J. Mater. Chem. A 6 8215

Google Scholar

Google Scholar

[15] Sarkar D, Ghosh T, Roychowdhury S, Arora R, Sajan S, Sheet G, Waghmare U V, Biswas K 2020 J. Am. Chem. Soc. 142 12237

Google Scholar

Google Scholar

[16] Li J, Zhang X, Lin S, Chen Z, Pei Y 2017 Chem. Mater. 29 605

Google Scholar

Google Scholar

[17] Wang Z, Wu H, Xi M, Zhu H, Dai L, Xiong Q, Wang G, Han G, Lu X, Zhou X, Wang G 2020 ACS Appl. Mater. Interfaces 12 41381

Google Scholar

Google Scholar

[18] Sidharth D, Alagar Nedunchezhian A S, Akilan R, Srivastava A, Srinivasan B, Immanuel P, Rajkumar R, Yalini Devi N, Arivanandhan M, Liu C J, Anbalagan G, Shankar R, Jayavel R 2021 Sustain. Energy Fuels 5 1734

Google Scholar

Google Scholar

[19] Shaabani L, Aminorroaya-Yamini S, Byrnes J, Akbar Nezhad A, Blake G R 2017 ACS Omega 2 9192

Google Scholar

Google Scholar

[20] 范人杰, 江先燕, 陶奇睿, 梅期才, 唐颖菲, 陈志权, 苏贤礼, 唐新峰 2021 70 137102

Google Scholar

Google Scholar

Fan R J, Jiang X Y, Tao Q R, Mei Q C, Tang Y F, Chen Z Q, Su X L, Tang X F 2021 Acta Phys. Sin. 70 137102

Google Scholar

Google Scholar

[21] Cao Y, Su X, Meng F, Bailey T P, Zhao J, Xie H, He J, Uher C, Tang X 2020 Adv. Funct. Mater. 30 2005861

Google Scholar

Google Scholar

[22] 黄平, 游理, 梁星, 张继业, 骆军 2019 68 077201

Google Scholar

Google Scholar

Huang P, You L, Liang X, Zhang J Y, Luo J 2019 Acta Phys. Sin. 68 077201

Google Scholar

Google Scholar

[23] 苏贤礼, 唐新峰, 李涵, 邓书康 2008 57 6488

Google Scholar

Google Scholar

Su X L, Tang X F, Li H, Deng S G 2008 Acta Phys. Sin. 57 6488

Google Scholar

Google Scholar

[24] Sun J, Su X, Yan Y, Liu W, Tan G, Tang X 2020 ACS Appl. Energy Mater. 3 2

Google Scholar

Google Scholar

[25] Zhang W, Chen C, Yao H, Xue W, Li S, Bai F, Huang Y, Li X, Lin X, Cao F, Sui J, Wang S, Yu B, Wang Y, Liu X, Zhang Q 2020 Chem. Mater. 32 6983

Google Scholar

Google Scholar

[26] Nshimyimana E, Hao S, Su X, Zhang C, Liu W, Yan Y, Uher C, Wolverton C, Kanatzidis M G, Tang X 2020 J. Mater. Chem. A 8 1193

Google Scholar

Google Scholar

[27] Zheng Z, Su X, Deng R, Stoumpos C, Xie H, Liu W, Yan Y, Hao S, Uher C, Wolverton C, Kanatzidis M G, Tang X 2018 J. Am. Chem. Soc. 140 2673

Google Scholar

Google Scholar

[28] Chen S, Bai H, Li J, Pan W, Jiang X, Li Z, Chen Z, Yan Y, Su X, Wu J, Uher C, Tang X 2020 ACS Appl. Mater. Interfaces 12 19664

Google Scholar

Google Scholar

[29] Franz R, Wiedemann G 1853 Ann. Phys. 165 497

[30] Pietrak K, Wisniewski T S 2015 J. Power Technol. 95 14

[31] Banik A, Ghosh T, Arora R, Dutta M, Pandey J, Acharya S, Soni A, Waghmare U V, Biswas K 2019 Energy Environ. Sci. 12 589

Google Scholar

Google Scholar

计量

- 文章访问数: 9781

- PDF下载量: 199

- 被引次数: 0

下载:

下载: