-

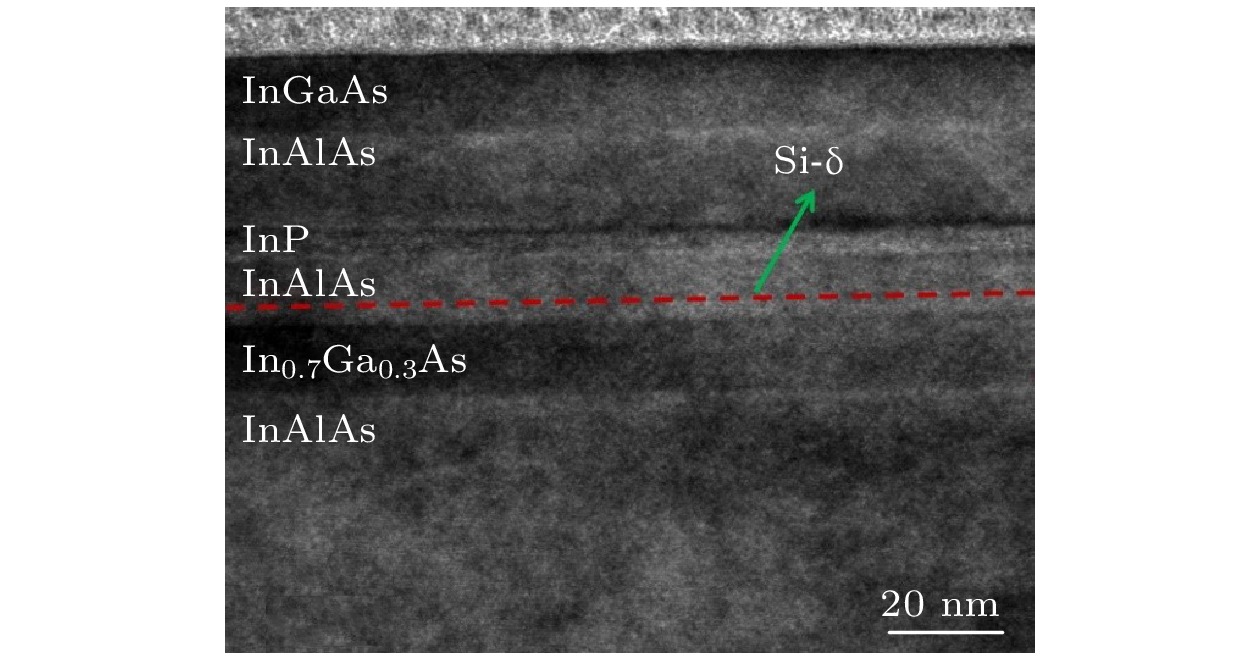

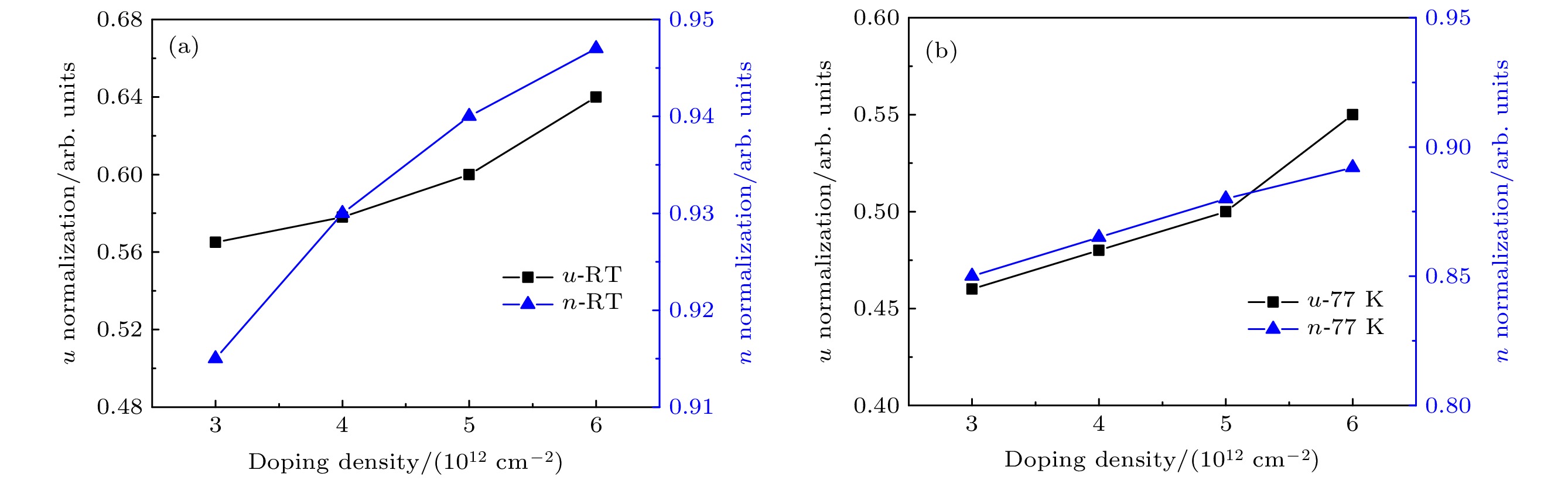

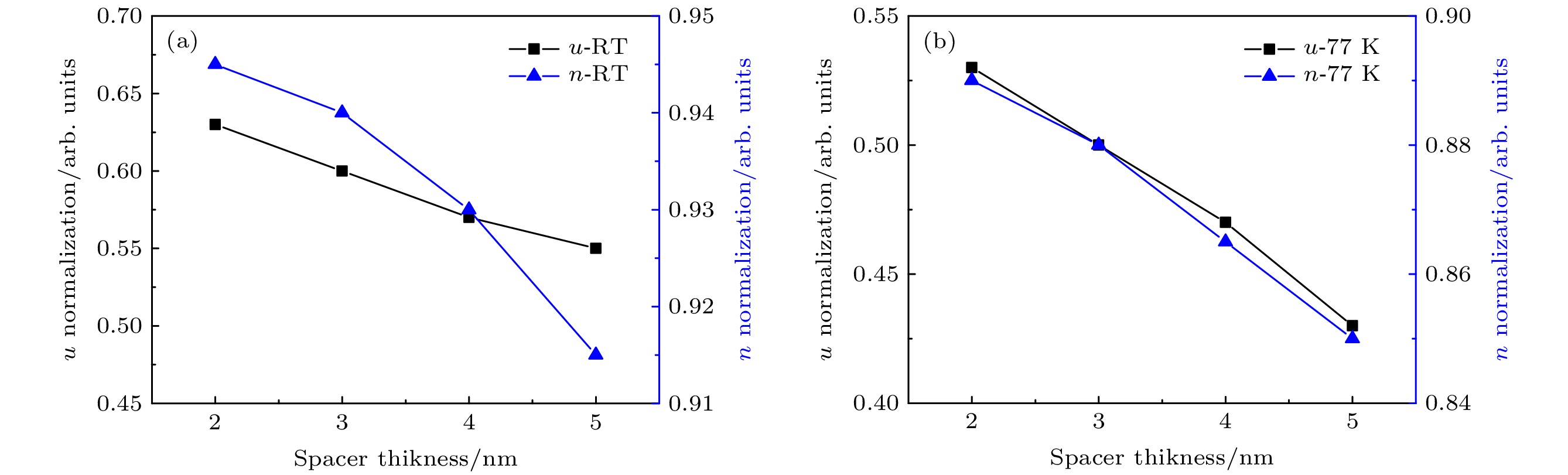

为研究磷化铟高电子迁移率晶体管(InP HEMT)外延结构材料的抗电子辐照加固设计的效果, 本文采用气态源分子束外延法制备了系列InP HEMT外延结构材料. 针对不同外延结构材料开展了1.5 MeV电子束辐照试验, 在辐照注量为2 × 1015 cm–2条件下, 并测试了InP HEMT外延结构材料二维电子气辐照前后的电学特性, 获得了辐照前后不同外延结构InP HEMT材料二维电子气归一化浓度和电子迁移率随外延参数的变化规律, 分析了InP HEMT二维电子气辐射损伤与Si-δ掺杂浓度、InGaAs 沟道厚度和沟道In组分以及隔离层厚度等结构参数的关系. 结果表明: Si-δ掺杂浓度越大, 隔离层厚度较薄, InGaAs 沟道厚度较大, 沟道In组分低的InP HEMT外延结构二维电子气辐射损伤相对较低, 具有更强的抗电子辐照能力. 经分析原因如下: 1)电子束与材料晶格发生能量传递, 破坏晶格完整性, 且在沟道异质界面引入辐射诱导缺陷, 增加复合中心密度, 散射增强导致二维电子气迁移率和浓度降低; 2)高浓度Si-δ掺杂和薄隔离层有利于提高量子阱二维电子气浓度, 降低二维电子气受辐射损伤的影响; 3)高In组分应变沟道有利于提高二维电子气迁移率, 但辐照后更容易应变弛豫产生位错缺陷, 导致二维电子气迁移率显著下降.

-

关键词:

- 磷化铟高电子迁移率晶体管 /

- 二维电子气 /

- 电子束辐照 /

- 辐射加固

In order to improve the radiation-resistance ability of the InP based high electron mobility transistor (InP HEMT) by optimizing the epitaxial structure design, a series of InP HEMT epitaxial structure materials with different structure parameters is grown by gas source molecular beam epitaxy. These samples are irradiated at room temperature by a 1.5-MeV electron beam at the same irradiation fluence of 2 × 1015 cm–2. The electrical properties of the two-dimensional electron gas (2DEG) for InP HEMT epitaxial materials before and after irradiation are measured by Hall measurements to obtain the changes of the normalized 2DEG density and electron mobility along with the epitaxial structure parameters. The relation between 2DEG radiation damage and epitaxial structure parameters (such as Si-δ-doping density, spacer thickness, channel thickness and channel In content) of InP HEMT epitaxial structure materials is analyzed. The results show that the 2DEG of the InP HEMT epitaxial structure material with higher Si-δ-doping density, thinner spacer thickness, thicker channel thickness and lower channel In content has lower radiation damage, which possesses the stronger radiation-resistance ability.-

Keywords:

- InP based high electron mobility transistor /

- two-dimensional electron gas /

- electron beam irradiation /

- radiation-resistance

[1] Cha E, Wadefalk N, Moschetti G, Pourkabirian A, Stenarson J, Grahn J 2020 IEEE Electron Device Lett. 41 1005

Google Scholar

Google Scholar

[2] Hamada H, Tsutsumi T, Matsuzaki H, Fujimura T, Abdo I, Shirane A, Okada K, Itami G, Song H J, Sugiyama H, Nosaka H 2020 IEEE J. Solid-State Circuits 55 2316

Google Scholar

Google Scholar

[3] Sato M, Niida Y, Suzuki T, Nakasha Y, Kawano Y, Iwai T, Hara N, Joshin K 2017 IEICE Trans. Electron. E100C 417

Google Scholar

Google Scholar

[4] Tang J J, Liu G P, Zhao G J, Xing S, Malik S A 2020 J. Vac. Sci. Technol. B 38 023202

Google Scholar

Google Scholar

[5] Tang J J, Liu G P, Song J Y, Zhao G J, Yang J H 2021 Chin. Phys. B 30 027303

Google Scholar

Google Scholar

[6] 谷文萍, 张进城, 王冲, 冯倩, 马晓华, 郝跃 2009 58 1161

Google Scholar

Google Scholar

Gu W, Zhang J C, Wang C, Feng Q, Ma X H, Hao Y 2009 Acta Phys. Sin. 58 1161

Google Scholar

Google Scholar

[7] Ives N E, Chen J, Witulski A F, Schrimpf R D, Fleetwood D M, Bruce R W, McCurdy M W, Zhang E X, Massengill L W 2015 IEEE Trans. Nucl. Sci. 62 2417

Google Scholar

Google Scholar

[8] Fleetwood D M 2015 IEEE Trans. Nucl. Sci. 62 1462

Google Scholar

Google Scholar

[9] Sun S X, Ding P, Jin Z, Zhong Y H, Li Y X, Wei Z C 2019 Nanomaterials 9 967

Google Scholar

Google Scholar

[10] Daoudi M, Kaouach H, Hosni F 2016 Optik 127 7188

Google Scholar

Google Scholar

[11] 陈睿, 梁亚楠, 韩建伟, 王璇, 杨涵, 陈钱, 袁润杰, 马英起, 上官士鹏 2021 70 116102

Google Scholar

Google Scholar

Chen R, Liang Y N, Han J W, Wang X, Yang H, Chen Q, Yuan R J, Ma Y Q, Shangguan S P 2021 Acta Phys. Sin. 70 116102

Google Scholar

Google Scholar

[12] Sun S X, Yang B, Zhong Y H, Li Y X, Ding P, Jin Z, Wei Z C 2020 J. Phys. D: Appl. Phys. 53 175107

Google Scholar

Google Scholar

[13] Warner J H, McMorrow D, Buchner S, Boos J B, Roche N, Paillet P, Gaillardin M, Blackmore E, Trinczek M, Ramachandran V, Reed R A, Schrimpf R D 2013 IEEE Trans. Nucl. Sci. 60 2651

Google Scholar

Google Scholar

[14] Pearton S J, Ren F, Patrick E, Law M E, Polyakov A Y 2016 ECS J. Solid State Sci. Technol. 5 Q35

Google Scholar

Google Scholar

[15] Lin L B, Liao Z, Liu Q, Lu T, Feng X 2002 Surf. Coat. Technol. 158 737

Google Scholar

Google Scholar

[16] 林理彬, 李有梅, 陈卫东, 蒋锦江, 孔梅影 1995 四川大学学报 (自然科学版) 32 39

Lin L B, Li Y M, Chen W D, Jiang J J, Kong M Y 1995 J. Sichuan Univ. (Nat. Sci. Ed.) 32 39

[17] Tang J J, Liu G P, Mao B Y, Ali S, Zhao G J, Yang J H 2021 Phys. Lett. A 410 127527

Google Scholar

Google Scholar

[18] Zhang Z, Cardwell D, Sasikumar A, Kyle E C H, Chen J, Zhang E X, Fleetwood D M, Schrimpf R D, Speck J S, Arehart A R, Ringel S A 2016 J. Appl. Phys. 119 165704

Google Scholar

Google Scholar

[19] Smith M D, O'Mahony D, Vitobello F, Muschitiello M, Costantino A, Barnes A R, Parbrook P J 2016 Semicond. Sci. Technol. 31 025008

Google Scholar

Google Scholar

[20] Zhong Y H, Yang B, Chang M M, Ding P, Ma L H, Li M K, Duan Z Y, Yang J, Jin Z, Wei Z C 2020 Chin. Phys. B 29 038502

Google Scholar

Google Scholar

[21] Zhou S X, Qi M, Ai L K, Xu A H, Wang L D, Ding P, Jin Z 2015 Chin. Phys. Lett. 32 097101

Google Scholar

Google Scholar

[22] Klaassen D B M 1992 Solid-State Electron. 35 961

Google Scholar

Google Scholar

[23] 玛丽娅, 李豫东, 郭旗, 艾尔肯, 王海娇, 汪波, 曾骏哲 2015 64 154217

Google Scholar

Google Scholar

Ma L Y, Li Y D, Guo Q, Ai E, Wang H J, Zeng J 2015 Acta Phys. Sin. 64 154217

Google Scholar

Google Scholar

[24] Anderson N G, Laidig W D, Kolbas R M, Lo Y C 1986 J. Appl. Phys. 60 2361

Google Scholar

Google Scholar

-

表 1 InP HEMT外延结构表(S.I.InP sub, 半绝缘InP衬底)

Table 1. Structure parameters of the InP HEMT (S.I.InP sub, semi-insulating InP substrate)

Layer Material Doping Thickness/nm Cap layer 1 In0.65Ga0.35As n+ 10 Cap layer 2 In0.53Ga0.47As n+ 15 Cap layer 3 In0.52Al0.48As n+ 15 Etch-stopper InP un 4 Barrier layer In0.52Al0.48As un 8 δ-doping Si (3—6)×1012 cm–2 Spacer layer In0.52Al0.48As un hw Channel InxGa1–xAs un tw Buffer layer In0.52Al0.48As un 300 S.I.InP sub 表 2 InP HEMT外延结构样品辐照前霍尔测试数据

Table 2. Hall data of the InP HEMT structures before irradiation

Sample

No.RT 77 K n/

(1012 cm–2)u/

(cm2·V–1·s–1)n/

(1012 cm–2)u/

(cm2·V–1·s–1)A1 1.851 8010 1.858 17100 A2 2.201 7920 2.205 16500 A3 2.394 7810 2.402 15900 A4 2.695 7530 2.700 14800 B1 2.557 7870 2.557 15100 B2 2.394 7810 2.402 15900 B3 2.272 7980 2.270 16700 B4 2.105 8110 2.085 17600 C1 2.408 8310 2.410 18400 C2 2.420 8960 2.421 22600 C3 2.431 9510 2.430 26200 C4 2.444 10500 2.445 32100 D1 2.387 7780 2.357 15600 D2 2.394 7810 2.402 15900 D3 2.398 7820 2.404 16000 D4 2.340 7810 2.405 16100 -

[1] Cha E, Wadefalk N, Moschetti G, Pourkabirian A, Stenarson J, Grahn J 2020 IEEE Electron Device Lett. 41 1005

Google Scholar

Google Scholar

[2] Hamada H, Tsutsumi T, Matsuzaki H, Fujimura T, Abdo I, Shirane A, Okada K, Itami G, Song H J, Sugiyama H, Nosaka H 2020 IEEE J. Solid-State Circuits 55 2316

Google Scholar

Google Scholar

[3] Sato M, Niida Y, Suzuki T, Nakasha Y, Kawano Y, Iwai T, Hara N, Joshin K 2017 IEICE Trans. Electron. E100C 417

Google Scholar

Google Scholar

[4] Tang J J, Liu G P, Zhao G J, Xing S, Malik S A 2020 J. Vac. Sci. Technol. B 38 023202

Google Scholar

Google Scholar

[5] Tang J J, Liu G P, Song J Y, Zhao G J, Yang J H 2021 Chin. Phys. B 30 027303

Google Scholar

Google Scholar

[6] 谷文萍, 张进城, 王冲, 冯倩, 马晓华, 郝跃 2009 58 1161

Google Scholar

Google Scholar

Gu W, Zhang J C, Wang C, Feng Q, Ma X H, Hao Y 2009 Acta Phys. Sin. 58 1161

Google Scholar

Google Scholar

[7] Ives N E, Chen J, Witulski A F, Schrimpf R D, Fleetwood D M, Bruce R W, McCurdy M W, Zhang E X, Massengill L W 2015 IEEE Trans. Nucl. Sci. 62 2417

Google Scholar

Google Scholar

[8] Fleetwood D M 2015 IEEE Trans. Nucl. Sci. 62 1462

Google Scholar

Google Scholar

[9] Sun S X, Ding P, Jin Z, Zhong Y H, Li Y X, Wei Z C 2019 Nanomaterials 9 967

Google Scholar

Google Scholar

[10] Daoudi M, Kaouach H, Hosni F 2016 Optik 127 7188

Google Scholar

Google Scholar

[11] 陈睿, 梁亚楠, 韩建伟, 王璇, 杨涵, 陈钱, 袁润杰, 马英起, 上官士鹏 2021 70 116102

Google Scholar

Google Scholar

Chen R, Liang Y N, Han J W, Wang X, Yang H, Chen Q, Yuan R J, Ma Y Q, Shangguan S P 2021 Acta Phys. Sin. 70 116102

Google Scholar

Google Scholar

[12] Sun S X, Yang B, Zhong Y H, Li Y X, Ding P, Jin Z, Wei Z C 2020 J. Phys. D: Appl. Phys. 53 175107

Google Scholar

Google Scholar

[13] Warner J H, McMorrow D, Buchner S, Boos J B, Roche N, Paillet P, Gaillardin M, Blackmore E, Trinczek M, Ramachandran V, Reed R A, Schrimpf R D 2013 IEEE Trans. Nucl. Sci. 60 2651

Google Scholar

Google Scholar

[14] Pearton S J, Ren F, Patrick E, Law M E, Polyakov A Y 2016 ECS J. Solid State Sci. Technol. 5 Q35

Google Scholar

Google Scholar

[15] Lin L B, Liao Z, Liu Q, Lu T, Feng X 2002 Surf. Coat. Technol. 158 737

Google Scholar

Google Scholar

[16] 林理彬, 李有梅, 陈卫东, 蒋锦江, 孔梅影 1995 四川大学学报 (自然科学版) 32 39

Lin L B, Li Y M, Chen W D, Jiang J J, Kong M Y 1995 J. Sichuan Univ. (Nat. Sci. Ed.) 32 39

[17] Tang J J, Liu G P, Mao B Y, Ali S, Zhao G J, Yang J H 2021 Phys. Lett. A 410 127527

Google Scholar

Google Scholar

[18] Zhang Z, Cardwell D, Sasikumar A, Kyle E C H, Chen J, Zhang E X, Fleetwood D M, Schrimpf R D, Speck J S, Arehart A R, Ringel S A 2016 J. Appl. Phys. 119 165704

Google Scholar

Google Scholar

[19] Smith M D, O'Mahony D, Vitobello F, Muschitiello M, Costantino A, Barnes A R, Parbrook P J 2016 Semicond. Sci. Technol. 31 025008

Google Scholar

Google Scholar

[20] Zhong Y H, Yang B, Chang M M, Ding P, Ma L H, Li M K, Duan Z Y, Yang J, Jin Z, Wei Z C 2020 Chin. Phys. B 29 038502

Google Scholar

Google Scholar

[21] Zhou S X, Qi M, Ai L K, Xu A H, Wang L D, Ding P, Jin Z 2015 Chin. Phys. Lett. 32 097101

Google Scholar

Google Scholar

[22] Klaassen D B M 1992 Solid-State Electron. 35 961

Google Scholar

Google Scholar

[23] 玛丽娅, 李豫东, 郭旗, 艾尔肯, 王海娇, 汪波, 曾骏哲 2015 64 154217

Google Scholar

Google Scholar

Ma L Y, Li Y D, Guo Q, Ai E, Wang H J, Zeng J 2015 Acta Phys. Sin. 64 154217

Google Scholar

Google Scholar

[24] Anderson N G, Laidig W D, Kolbas R M, Lo Y C 1986 J. Appl. Phys. 60 2361

Google Scholar

Google Scholar

计量

- 文章访问数: 7469

- PDF下载量: 115

- 被引次数: 0

下载:

下载: