-

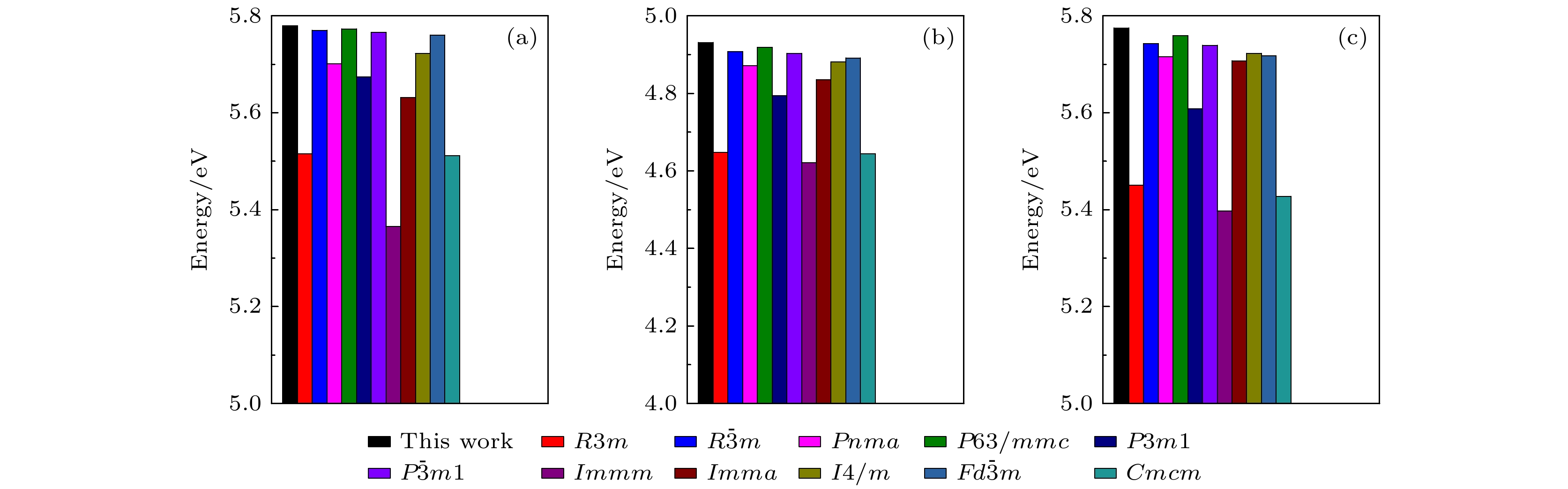

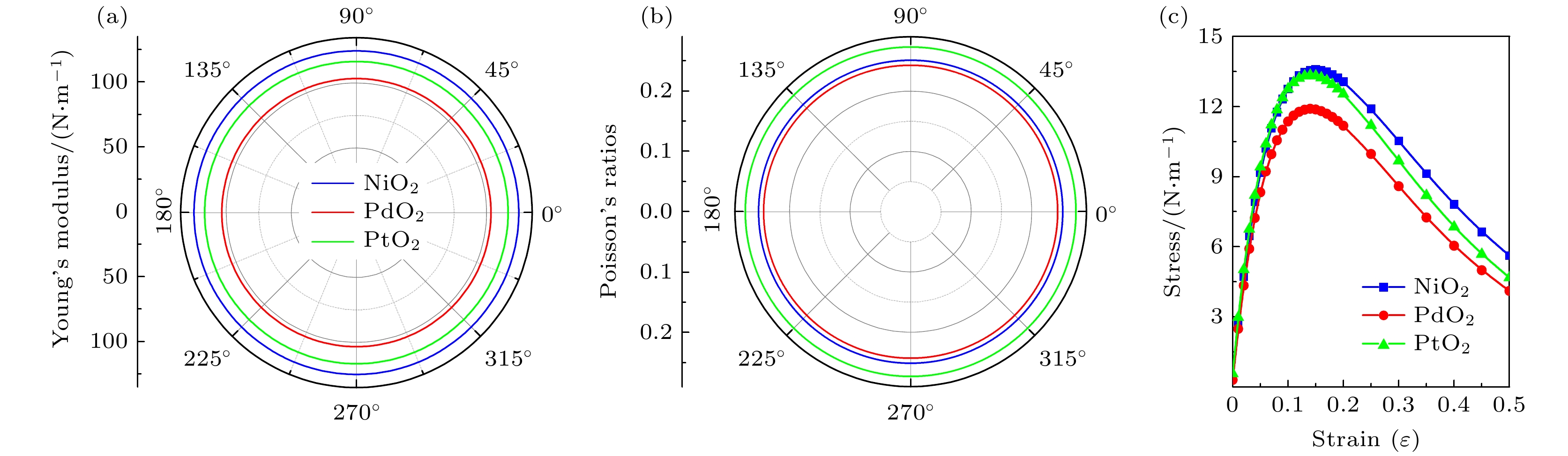

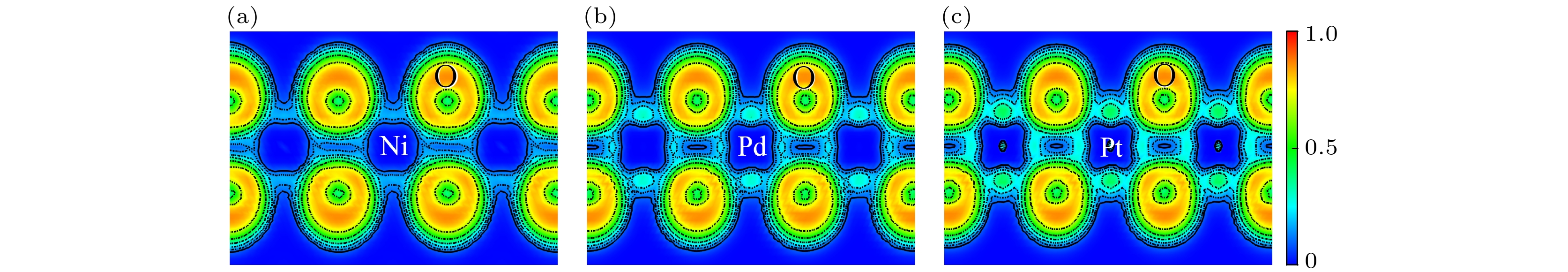

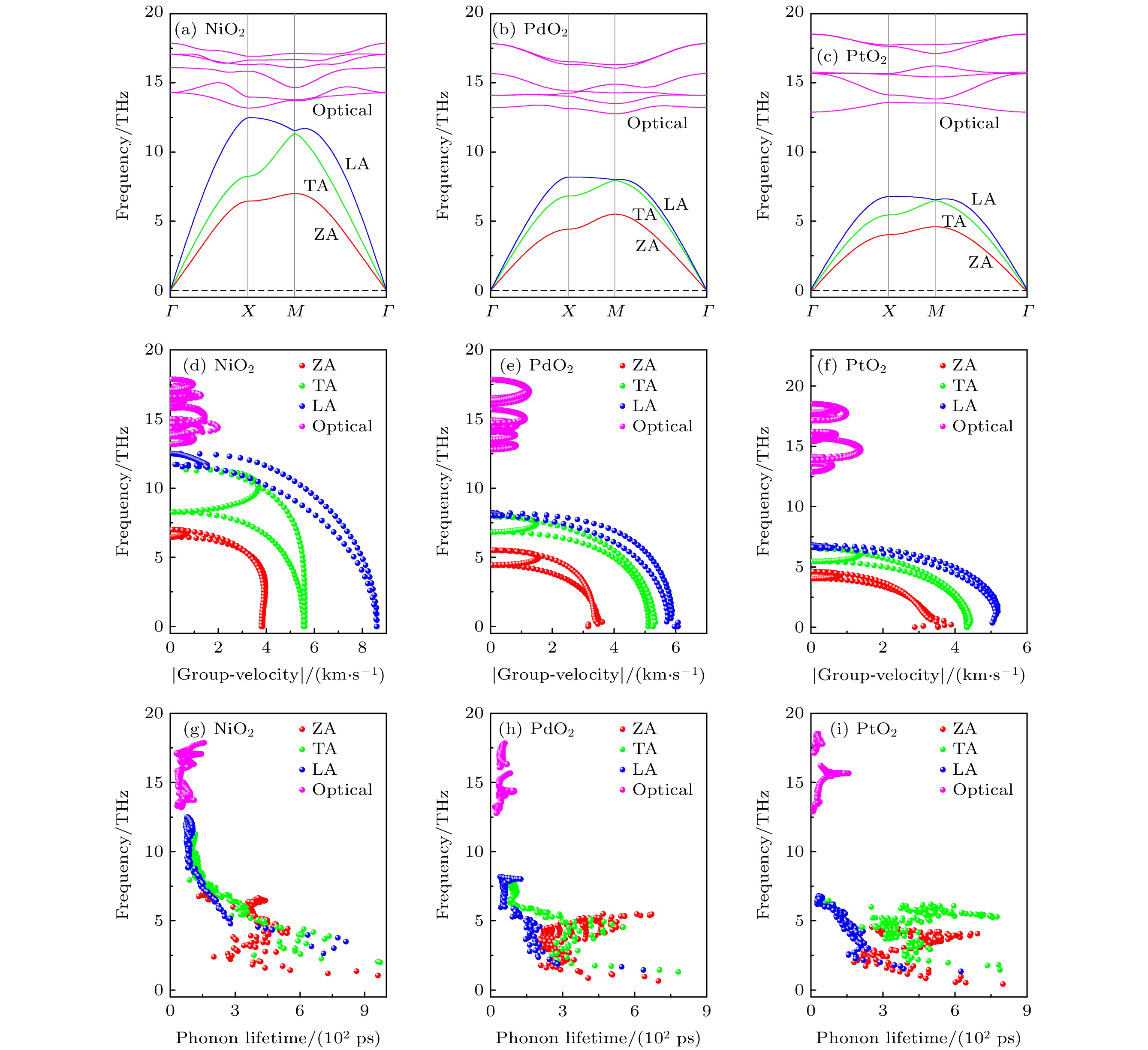

基于第一性原理计算方法, 研究了二维XO2 (X = Ni, Pd, Pt)的稳定性、弹性、电子结构和热导率. 计算结果显示, 二维XO2同时具备较好的机械和动力学稳定性. 此外, 二维NiO2, PdO2和PtO2的杨氏模量分别为124.69 N/m, 103.31 N/m和116.51 N/m, 泊松比分别为0.25, 0.24和0.27, 并呈现各向同性. 电子能带结构表明, 二维XO2 (X = Ni, Pd, Pt)为间接带隙半导体, 计算能隙分别为2.95 eV, 3.00 eV和3.34 eV, 且价带顶和导带底的能级主要由Ni-3d, Pd-4d, Pt-5d和O-2p轨道电子组成. 通过畸变势理论计算载流子迁移率, 结果显示二维XO2 (X = Ni, Pd, Pt)沿armchair和zigzag方向的有效质量和形变势表现出明显的各向异性, 电子/空穴的迁移率最高分别为13707.96/53.25 cm2·V–1·s–1, 1288.12/19.18 cm2·V–1·s–1和404.71/270.60 cm2·V–1·s–1. 此外, 在300 K温度下, 二维XO2 (X = Ni, Pd, Pt)的晶格热导率分别为53.55 W·m–1·K–1, 19.06 W·m–1·K–1和17.43 W·m–1·K–1, 这表明二维XO2 (X = Ni, Pd, Pt)在纳米电子材料和导热器件方面具备应用潜力.

-

关键词:

- 二维XO2 (X = Ni, Pd, Pt) /

- 电子结构 /

- 载流子迁移率 /

- 热导率

Based on the first-principles calculations, the stability, elastic constants, electronic structure, and lattice thermal conductivity of monolayer XO2 (X = Ni, Pd, Pt) are investigated in this work. The results show that XO2 (X = Ni, Pd, Pt) have mechanical and dynamic stability at the same time. In addition, the Young’s modulus of monolayer NiO2, PdO2 and PtO2 are 124.69 N·m–1, 103.31 N·m–1 and 116.51 N·m–1, Poisson’s ratio of monolayer NiO2, PdO2 and PtO2 are 0.25, 0.24 and 0.27, respectively, and each of them possesses high isotropy. The band structures show that monolayer XO2 (X = Ni, Pd, Pt) are indirect band-gap semiconductors with energy gap of 2.95 eV, 3.00 eV and 3.34 eV, respectively, and the energy levels near the valence band maximum and conduction band minimum are mainly composed of Ni-3d/Pd-4d/Pt-5d and O-2p orbital electrons. Based on deformation potential theory, the carrier mobility of each monolayer is calculated, and the results show that the effective mass and deformation potential of monolayer XO2 (X = Ni, Pd, Pt) along the armchair and zigzag directions show obvious anisotropy, and the highest electron and hole mobility are 13707.96 and 53.25 cm2·V–1·s–1, 1288.12 and 19.18 cm2·V–1·s–1, and 404.71 and 270.60 cm2·V–1·s–1 for NiO2, PdO2 and PtO2, respectively. Furthermore, the lattice thermal conductivity of monolayer XO2 (X = Ni, Pd, Pt) at 300 K are 53.55 W·m–1·K–1, 19.06 W·m–1·K–1 and 17.43 W·m–1·K–1, respectively. These properties indicate that monolayer XO2 (X = Ni, Pd, Pt) have potential applications in nanometer electronic materials and thermal conductivity devices.-

Keywords:

- monolayer XO2 (X = Ni, Pd, Pt) /

- electronic structure /

- carrier mobility /

- lattice thermal conductivity

[1] Novoselov K S, Geim A K, Morozov S V, Jiang D, Zhang Y, Dubonos S V, Grigorieva I V, Firsov A A 2004 Science 306 666

Google Scholar

Google Scholar

[2] Wang D, Song X L, Li P, Gao X J J, Gao X F 2020 J. Mater. Chem. B 8 9028

Google Scholar

Google Scholar

[3] Halo M, Casassa S, Maschio L, Pisani C, Dovesi R, Ehinon D, Baraille I, Rerat M, Usvyat D 2011 Phys. Chem. Chem. Phys. 13 4434

Google Scholar

Google Scholar

[4] Zhou M F, Wang W H, Lu J P, Ni Z H 2021 Nano Res. 14 29

Google Scholar

Google Scholar

[5] Fang W Y, Kang W B, Zhao J, Zhang P C 2020 Chin. Phys. B 29 096301

Google Scholar

Google Scholar

[6] Yeoh K H, Yoon T L, Rusi, Ong D S, Lim T L 2018 Appl. Surf. Sci. 445 161

Google Scholar

Google Scholar

[7] Yuan J H, Yu N N, Xue K H, Miao X S 2017 Appl. Surf. Sci. 409 85

Google Scholar

Google Scholar

[8] Lalmi B, Oughaddou H, Enriquez H, Kara A, Vizzini S, Ealet B, Aufray B 2010 Appl. Phys. Lett. 97 223109

Google Scholar

Google Scholar

[9] Yang Y, Zhang H, Song L H, Liu Z L 2021 Appl. Surf. Sci. 542 148691

Google Scholar

Google Scholar

[10] Li X B, Guo P, Cao T F, Liu H, Lau W M, Liu L M 2015 Sci. Rep. 5 10848

Google Scholar

Google Scholar

[11] Sharma S, Kumar S, Schwingenschlögl U 2017 Phys. Rev. Appl. 8 044013

Google Scholar

Google Scholar

[12] Shi Z Q, Li H, Xue C L, Yuan Q Q, Lv Y Y, Xu Y J, Jia Z Y, Gao L, Chen Y, Zhu W, Li S C 2020 Nano Lett. 20 8408

Google Scholar

Google Scholar

[13] Li T S 2012 Phys. Rev. B 85 235407

Google Scholar

Google Scholar

[14] Peng R, Ma Y, He Z, Huang B, Kou L, Dai Y 2019 Nano Lett. 19 1227

Google Scholar

Google Scholar

[15] Yan P, Gao G Y, Ding G Q, Qin D 2019 Rsc Adv. 9 12394

Google Scholar

Google Scholar

[16] Naghavi S S, He J, Xia Y, Wolverton C 2018 Chem. Mater. 30 5639

Google Scholar

Google Scholar

[17] Hu Z Y, Li K Y, Lu Y, Huang Y, Shao X H 2017 Nanoscale 9 16093

Google Scholar

Google Scholar

[18] Fang W Y, Li P A, Yuan J H, Xue K H, Wang J F 2019 J. Electron. Mater. 49 959

Google Scholar

Google Scholar

[19] Chen Z Y, Xiong M, Zeng Z Y, Chen X R, Chen Q F 2021 Solid State Commun. 326 114163

Google Scholar

Google Scholar

[20] Rajput K, Roy D R 2019 Appl. Nanosci. 9 1845

Google Scholar

Google Scholar

[21] Qu L H, Yu J, Mu Y L, Fu X L, Zhong C G, Min Y, Zhou P X, Zhang J M, Zou Y Q, Lu T S 2019 Mater. Res. Bull. 119 110533

Google Scholar

Google Scholar

[22] Chaurasiya R, Dixit A, Pandey R 2019 J. Appl. Phys. 125 082540

Google Scholar

Google Scholar

[23] Ersan F, Ozaydin H D, Gokoglu G, Akturk E 2017 Appl. Surf. Sci. 425 301

Google Scholar

Google Scholar

[24] Cakir D, Peeters F M, Sevik C 2014 Appl. Phys. Lett. 104 203110

Google Scholar

Google Scholar

[25] Shukla A, Gaur N K 2020 Chem. Phys. Lett. 754 137717

Google Scholar

Google Scholar

[26] Shang J, Li C, Tang X, Du A J, Liao T, Gu Y T, Ma Y D, Kou L Z, Chen C F 2020 Nanoscale 12 14847

Google Scholar

Google Scholar

[27] Chaouche A C, Lachebi A, Abid H, Benchehima M, Driz M 2019 Superlattices Microstruct. 130 249

Google Scholar

Google Scholar

[28] Zhu Y Y, Ji X, Cheng S, Chern Z Y, Jia J, Yang L F, Luo H W, Yu J Y, Peng X W, Wang J H, Zhou W J, Liu M L 2019 Acs Nano 13 9091

Google Scholar

Google Scholar

[29] Wang Y J, Li F F, Zheng H L, Han X F, Yan Y 2018 Phys. Chem. Chem. Phys. 20 28162

Google Scholar

Google Scholar

[30] Huang Q J, Ma J L, Xu D W, Hu R, Luo X B 2020 J. Appl. Phys. 128 185111

Google Scholar

Google Scholar

[31] Song Y Q, Yuan J H, Li L H, Xu M, Wang J F, Xue K H, Miao X S 2019 Nanoscale 11 1131

Google Scholar

Google Scholar

[32] Yuan J H, Song Y Q, Chen Q, Xue K H, Miao X S 2019 Appl. Surf. Sci. 469 456

Google Scholar

Google Scholar

[33] Ho T H, Dong H C, Bui V Q, Kawazoe Y, Le H M 2020 Phys. Chem. Chem. Phys. 22 18149

Google Scholar

Google Scholar

[34] Yuan H, Li Z Y, Yang J L 2018 J. Mater. Chem. C 6 9055

Google Scholar

Google Scholar

[35] Mohammed H A H, Dongho-Nguimdo G M, Joubert D P 2021 Physica E 127 114514

Google Scholar

Google Scholar

[36] Lei Z H, Wang W L, She J C 2021 Chin. Phys. B 30 047102

Google Scholar

Google Scholar

[37] Shimazaki T, Suzuki T, Kubo M 2011 Theor. Chem. Acc. 130 1031

Google Scholar

Google Scholar

[38] Shokri A, Yazdani A, Rahimi K 2020 Mater. Chem. Phys. 255 123617

Google Scholar

Google Scholar

[39] Hafner J 2008 J. Comput. Chem. 29 2044

Google Scholar

Google Scholar

[40] Perdew J P, Burke K, Ernzerhof M 1997 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[41] Blochl P E 1994 Phys. Rev. B 50 17953

Google Scholar

Google Scholar

[42] Krukau A V, Vydrov O A, Izmaylov A F, Scuseria G E 2006 J. Chem. Phys. 125 224106

Google Scholar

Google Scholar

[43] Blochl P E, Jepsen O, Andersen O K 1994 Phys. Rev. B 49 16223

Google Scholar

Google Scholar

[44] Eriksson F, Fransson E, Erhart P 2019 Adv. Theor. Simul. 2 1800184

Google Scholar

Google Scholar

[45] Togo A, Tanaka I 2015 Scr. Mater. 108 1

Google Scholar

Google Scholar

[46] Togo A, Chaput L, Tanaka I 2015 Phys. Rev. B 91 094306

Google Scholar

Google Scholar

[47] Zhang C Z, Liu J Y, Shen H M, Lo X Z, Sun Q 2017 Chem. Mater. 29 8588

Google Scholar

Google Scholar

[48] Shin H, Kang S, Koo J, Lee H, Kim J, Kwon Y 2014 J. Chem. Phys. 140 114702

Google Scholar

Google Scholar

[49] Qin Y, Zha X H, Bai X, Luo K, Huang Q, Wang Y, Du S 2020 J. Phys.: Condens. Matter 32 135302

Google Scholar

Google Scholar

[50] Xiong W Q, Huang K X, Yuan S J 2019 J. Mater. Chem. C 7 13518

Google Scholar

Google Scholar

[51] Lajevardipour A, Neek-Amal M, Peeters F M 2012 J. Phys-Condens. Mat. 24 175303

Google Scholar

Google Scholar

[52] Hess P 2017 Nanotechnology 28 064002

Google Scholar

Google Scholar

[53] Efetov D K, Kim P 2010 Phys. Rev. Lett. 105 256805

Google Scholar

Google Scholar

[54] Jain A, McGaughey A J 2015 Sci. Rep. 5 8501

Google Scholar

Google Scholar

[55] Hossain M T, Rahman M A 2020 J. Mol. Model. 26 40

Google Scholar

Google Scholar

[56] Min K, Aluru N R 2011 Appl. Phys. Lett. 98 013113

Google Scholar

Google Scholar

[57] Kudin K N, Scuseria G E, Yakobson B I 2001 Phys. Rev. B 64 235406

Google Scholar

Google Scholar

[58] Jing Y, Ma Y D, Li Y F, Heine T 2017 Nano Lett. 17 1833

Google Scholar

Google Scholar

[59] Pu C Y, Yu J H, Yu R M, Tang X, Zhou D W 2019 J. Mater. Chem. C 7 12231

Google Scholar

Google Scholar

[60] Zha X H, Zhou J, Luo K, Lang J J, Huang Q, Zhou X, Francisco J S, He J, Du S 2017 J. Phys.: Condens. Matter. 29 165701

Google Scholar

Google Scholar

[61] Xu Y, Liu G, Xing S A, Zhao G, Yang J 2020 J. Mater. Chem. C 8 14902

Google Scholar

Google Scholar

[62] Fei R X, Li Y 2014 Nano Lett. 14 2884

Google Scholar

Google Scholar

[63] Fang R H, Cui X Y, Stampfl C, Ringer S P, Zheng R K 2020 Phys. Chem. Chem. Phys. 22 2276

Google Scholar

Google Scholar

[64] Zeng L, Xin Z, Chen S W, Du G, Kang J F, Liu X Y 2014 Chinese Phys. Lett. 31 027301

Google Scholar

Google Scholar

[65] Nemec H, Kratochvilova I, Kuzel P, Sebera J, Kochalska A, Nozar J, Nespurek S 2011 Phys. Chem. Chem. Phys. 13 2850

Google Scholar

Google Scholar

[66] Hong Y, Zhang J, Huang X, Zeng X C 2015 Nanoscale 7 18716

Google Scholar

Google Scholar

[67] Zhu L Y, Zhang G, Li B W 2014 Phys. Rev. B 90 214302

Google Scholar

Google Scholar

[68] Peng B, Zhang H, Shao H Z, Xu Y C, Zhang X C, Zhu H Y 2016 Sci. Rep-Uk 6 20225

Google Scholar

Google Scholar

[69] Gu X K, Yang R G 2015 J. Appl. Phys. 117 025102

Google Scholar

Google Scholar

[70] Cai Y Q, Lan J H, Zhang G, Zhang Y W 2014 Phys. Rev. B 89 035438

Google Scholar

Google Scholar

[71] Zulfiqar M, Zhao Y C, Li G, Li Z C, Ni J 2019 Sci. Rep-Uk 9 4571

Google Scholar

Google Scholar

[72] Feng T, Ruan X 2018 Phys. Rev. B 97 045202

Google Scholar

Google Scholar

[73] Zeng Y J, Feng Y X, Tang L M, Chen K Q 2021 Appl. Phys. Lett. 118 183103

Google Scholar

Google Scholar

[74] Chen X K, Chen K Q 2020 J. Phys.: Condens. Matter. 32 153002

Google Scholar

Google Scholar

-

图 6 二维XO2 (X = Ni, Pd, Pt)平面刚度和形变势拟合曲线 (a)−(c) NiO2; (d)−(f) PdO2; (g)−(i) PtO2. (a), (d), (g)能量对单轴应变的二次项拟合来计算平面刚度; (b)和(c), (e)和(f), (h)和(i) 沿扶手椅和之字形方向价带顶和导带底的能量对应变量的线性拟合, 用于计算变形势

Fig. 6. Schematic diagram of plane stiffness and deformation potential of monolayer XO2 (X = Ni, Pd, Pt): (a)−(c) NiO2; (d)−(f) PdO2; (g)−(i) PtO2. (a), (d), (g) Quadratic fitting of the energy difference to the uniaxial strain are used to calculate the plane stiffness. (b) and (c), (e) and (f), (h) and (i) Linear fitting of the energy of VBM and CBM relative to the uniaxial strain along armchair and zigzag direction, which are used to calculate the deformation potential.

表 1 二维XO2 (X = Ni, Pd, Pt)结构参数和结合能

Table 1. Structure parameters and binding energies of monolayer XO2 (X = Ni, Pd, Pt).

Monolayers a/b /Å l /Å θ1/(°) θ2/(°) h /Å Ef/(eV·atom–1) Band gap/eV PBE PBE + SOC HSE06 NiO2 2.82 1.88 96.84 83.16 1.90 5.78 1.39 1.21 2.95 PdO2 3.07 2.03 98.54 81.46 1.96 4.93 1.50 1.40 3.00 PtO2 3.13 2.05 99.64 80.34 1.93 5.77 1.83 1.73 3.34 表 2 在300 K下, 二维XO2 (X = Ni, Pd, Pt)的有效质量(m*)、弹性模量(C 2D)、形变势(El)、电子和空穴迁移率(μ)

Table 2. Calculated effective mass (m*), elastic modulus (C 2D), deformation-potential constant (El), electron and hole mobility (μ) of monolayer XO2 (X = Ni, Pd, Pt) at 300 K.

Materials Direction Carrier type m*/m0 C 2D/(N·m–1) El/eV μ/(cm2·V–1·s–1) NiO2 Armchair Electron 0.63 134.81 0.56 13707.96 Hole 2.00 2.29 53.25 Zigzag Electron 1.80 135.21 0.88 1944.53 Hole 13.19 2.26 8.32 PdO2 Armchair Electron 0.81 113.38 1.28 1288.12 Hole 2.52 3.02 19.18 Zigzag Electron 2.42 114.25 2.10 162.17 Hole 11.81 3.01 4.16 PtO2 Armchair Electron 0.80 122.60 4.27 404.71 Hole 1.17 1.51 270.60 Zigzag Electron 2.51 123.25 4.27 40.46 Hole 8.77 1.51 40.86 BP a-axis Electron 0.17 24.81 1.59 2652.06 Hole 0.16 2.66 495.37 b-axis Electron 1.25 105.45 5.27 140.35 Hole 5.71 0.13 24469.72 -

[1] Novoselov K S, Geim A K, Morozov S V, Jiang D, Zhang Y, Dubonos S V, Grigorieva I V, Firsov A A 2004 Science 306 666

Google Scholar

Google Scholar

[2] Wang D, Song X L, Li P, Gao X J J, Gao X F 2020 J. Mater. Chem. B 8 9028

Google Scholar

Google Scholar

[3] Halo M, Casassa S, Maschio L, Pisani C, Dovesi R, Ehinon D, Baraille I, Rerat M, Usvyat D 2011 Phys. Chem. Chem. Phys. 13 4434

Google Scholar

Google Scholar

[4] Zhou M F, Wang W H, Lu J P, Ni Z H 2021 Nano Res. 14 29

Google Scholar

Google Scholar

[5] Fang W Y, Kang W B, Zhao J, Zhang P C 2020 Chin. Phys. B 29 096301

Google Scholar

Google Scholar

[6] Yeoh K H, Yoon T L, Rusi, Ong D S, Lim T L 2018 Appl. Surf. Sci. 445 161

Google Scholar

Google Scholar

[7] Yuan J H, Yu N N, Xue K H, Miao X S 2017 Appl. Surf. Sci. 409 85

Google Scholar

Google Scholar

[8] Lalmi B, Oughaddou H, Enriquez H, Kara A, Vizzini S, Ealet B, Aufray B 2010 Appl. Phys. Lett. 97 223109

Google Scholar

Google Scholar

[9] Yang Y, Zhang H, Song L H, Liu Z L 2021 Appl. Surf. Sci. 542 148691

Google Scholar

Google Scholar

[10] Li X B, Guo P, Cao T F, Liu H, Lau W M, Liu L M 2015 Sci. Rep. 5 10848

Google Scholar

Google Scholar

[11] Sharma S, Kumar S, Schwingenschlögl U 2017 Phys. Rev. Appl. 8 044013

Google Scholar

Google Scholar

[12] Shi Z Q, Li H, Xue C L, Yuan Q Q, Lv Y Y, Xu Y J, Jia Z Y, Gao L, Chen Y, Zhu W, Li S C 2020 Nano Lett. 20 8408

Google Scholar

Google Scholar

[13] Li T S 2012 Phys. Rev. B 85 235407

Google Scholar

Google Scholar

[14] Peng R, Ma Y, He Z, Huang B, Kou L, Dai Y 2019 Nano Lett. 19 1227

Google Scholar

Google Scholar

[15] Yan P, Gao G Y, Ding G Q, Qin D 2019 Rsc Adv. 9 12394

Google Scholar

Google Scholar

[16] Naghavi S S, He J, Xia Y, Wolverton C 2018 Chem. Mater. 30 5639

Google Scholar

Google Scholar

[17] Hu Z Y, Li K Y, Lu Y, Huang Y, Shao X H 2017 Nanoscale 9 16093

Google Scholar

Google Scholar

[18] Fang W Y, Li P A, Yuan J H, Xue K H, Wang J F 2019 J. Electron. Mater. 49 959

Google Scholar

Google Scholar

[19] Chen Z Y, Xiong M, Zeng Z Y, Chen X R, Chen Q F 2021 Solid State Commun. 326 114163

Google Scholar

Google Scholar

[20] Rajput K, Roy D R 2019 Appl. Nanosci. 9 1845

Google Scholar

Google Scholar

[21] Qu L H, Yu J, Mu Y L, Fu X L, Zhong C G, Min Y, Zhou P X, Zhang J M, Zou Y Q, Lu T S 2019 Mater. Res. Bull. 119 110533

Google Scholar

Google Scholar

[22] Chaurasiya R, Dixit A, Pandey R 2019 J. Appl. Phys. 125 082540

Google Scholar

Google Scholar

[23] Ersan F, Ozaydin H D, Gokoglu G, Akturk E 2017 Appl. Surf. Sci. 425 301

Google Scholar

Google Scholar

[24] Cakir D, Peeters F M, Sevik C 2014 Appl. Phys. Lett. 104 203110

Google Scholar

Google Scholar

[25] Shukla A, Gaur N K 2020 Chem. Phys. Lett. 754 137717

Google Scholar

Google Scholar

[26] Shang J, Li C, Tang X, Du A J, Liao T, Gu Y T, Ma Y D, Kou L Z, Chen C F 2020 Nanoscale 12 14847

Google Scholar

Google Scholar

[27] Chaouche A C, Lachebi A, Abid H, Benchehima M, Driz M 2019 Superlattices Microstruct. 130 249

Google Scholar

Google Scholar

[28] Zhu Y Y, Ji X, Cheng S, Chern Z Y, Jia J, Yang L F, Luo H W, Yu J Y, Peng X W, Wang J H, Zhou W J, Liu M L 2019 Acs Nano 13 9091

Google Scholar

Google Scholar

[29] Wang Y J, Li F F, Zheng H L, Han X F, Yan Y 2018 Phys. Chem. Chem. Phys. 20 28162

Google Scholar

Google Scholar

[30] Huang Q J, Ma J L, Xu D W, Hu R, Luo X B 2020 J. Appl. Phys. 128 185111

Google Scholar

Google Scholar

[31] Song Y Q, Yuan J H, Li L H, Xu M, Wang J F, Xue K H, Miao X S 2019 Nanoscale 11 1131

Google Scholar

Google Scholar

[32] Yuan J H, Song Y Q, Chen Q, Xue K H, Miao X S 2019 Appl. Surf. Sci. 469 456

Google Scholar

Google Scholar

[33] Ho T H, Dong H C, Bui V Q, Kawazoe Y, Le H M 2020 Phys. Chem. Chem. Phys. 22 18149

Google Scholar

Google Scholar

[34] Yuan H, Li Z Y, Yang J L 2018 J. Mater. Chem. C 6 9055

Google Scholar

Google Scholar

[35] Mohammed H A H, Dongho-Nguimdo G M, Joubert D P 2021 Physica E 127 114514

Google Scholar

Google Scholar

[36] Lei Z H, Wang W L, She J C 2021 Chin. Phys. B 30 047102

Google Scholar

Google Scholar

[37] Shimazaki T, Suzuki T, Kubo M 2011 Theor. Chem. Acc. 130 1031

Google Scholar

Google Scholar

[38] Shokri A, Yazdani A, Rahimi K 2020 Mater. Chem. Phys. 255 123617

Google Scholar

Google Scholar

[39] Hafner J 2008 J. Comput. Chem. 29 2044

Google Scholar

Google Scholar

[40] Perdew J P, Burke K, Ernzerhof M 1997 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[41] Blochl P E 1994 Phys. Rev. B 50 17953

Google Scholar

Google Scholar

[42] Krukau A V, Vydrov O A, Izmaylov A F, Scuseria G E 2006 J. Chem. Phys. 125 224106

Google Scholar

Google Scholar

[43] Blochl P E, Jepsen O, Andersen O K 1994 Phys. Rev. B 49 16223

Google Scholar

Google Scholar

[44] Eriksson F, Fransson E, Erhart P 2019 Adv. Theor. Simul. 2 1800184

Google Scholar

Google Scholar

[45] Togo A, Tanaka I 2015 Scr. Mater. 108 1

Google Scholar

Google Scholar

[46] Togo A, Chaput L, Tanaka I 2015 Phys. Rev. B 91 094306

Google Scholar

Google Scholar

[47] Zhang C Z, Liu J Y, Shen H M, Lo X Z, Sun Q 2017 Chem. Mater. 29 8588

Google Scholar

Google Scholar

[48] Shin H, Kang S, Koo J, Lee H, Kim J, Kwon Y 2014 J. Chem. Phys. 140 114702

Google Scholar

Google Scholar

[49] Qin Y, Zha X H, Bai X, Luo K, Huang Q, Wang Y, Du S 2020 J. Phys.: Condens. Matter 32 135302

Google Scholar

Google Scholar

[50] Xiong W Q, Huang K X, Yuan S J 2019 J. Mater. Chem. C 7 13518

Google Scholar

Google Scholar

[51] Lajevardipour A, Neek-Amal M, Peeters F M 2012 J. Phys-Condens. Mat. 24 175303

Google Scholar

Google Scholar

[52] Hess P 2017 Nanotechnology 28 064002

Google Scholar

Google Scholar

[53] Efetov D K, Kim P 2010 Phys. Rev. Lett. 105 256805

Google Scholar

Google Scholar

[54] Jain A, McGaughey A J 2015 Sci. Rep. 5 8501

Google Scholar

Google Scholar

[55] Hossain M T, Rahman M A 2020 J. Mol. Model. 26 40

Google Scholar

Google Scholar

[56] Min K, Aluru N R 2011 Appl. Phys. Lett. 98 013113

Google Scholar

Google Scholar

[57] Kudin K N, Scuseria G E, Yakobson B I 2001 Phys. Rev. B 64 235406

Google Scholar

Google Scholar

[58] Jing Y, Ma Y D, Li Y F, Heine T 2017 Nano Lett. 17 1833

Google Scholar

Google Scholar

[59] Pu C Y, Yu J H, Yu R M, Tang X, Zhou D W 2019 J. Mater. Chem. C 7 12231

Google Scholar

Google Scholar

[60] Zha X H, Zhou J, Luo K, Lang J J, Huang Q, Zhou X, Francisco J S, He J, Du S 2017 J. Phys.: Condens. Matter. 29 165701

Google Scholar

Google Scholar

[61] Xu Y, Liu G, Xing S A, Zhao G, Yang J 2020 J. Mater. Chem. C 8 14902

Google Scholar

Google Scholar

[62] Fei R X, Li Y 2014 Nano Lett. 14 2884

Google Scholar

Google Scholar

[63] Fang R H, Cui X Y, Stampfl C, Ringer S P, Zheng R K 2020 Phys. Chem. Chem. Phys. 22 2276

Google Scholar

Google Scholar

[64] Zeng L, Xin Z, Chen S W, Du G, Kang J F, Liu X Y 2014 Chinese Phys. Lett. 31 027301

Google Scholar

Google Scholar

[65] Nemec H, Kratochvilova I, Kuzel P, Sebera J, Kochalska A, Nozar J, Nespurek S 2011 Phys. Chem. Chem. Phys. 13 2850

Google Scholar

Google Scholar

[66] Hong Y, Zhang J, Huang X, Zeng X C 2015 Nanoscale 7 18716

Google Scholar

Google Scholar

[67] Zhu L Y, Zhang G, Li B W 2014 Phys. Rev. B 90 214302

Google Scholar

Google Scholar

[68] Peng B, Zhang H, Shao H Z, Xu Y C, Zhang X C, Zhu H Y 2016 Sci. Rep-Uk 6 20225

Google Scholar

Google Scholar

[69] Gu X K, Yang R G 2015 J. Appl. Phys. 117 025102

Google Scholar

Google Scholar

[70] Cai Y Q, Lan J H, Zhang G, Zhang Y W 2014 Phys. Rev. B 89 035438

Google Scholar

Google Scholar

[71] Zulfiqar M, Zhao Y C, Li G, Li Z C, Ni J 2019 Sci. Rep-Uk 9 4571

Google Scholar

Google Scholar

[72] Feng T, Ruan X 2018 Phys. Rev. B 97 045202

Google Scholar

Google Scholar

[73] Zeng Y J, Feng Y X, Tang L M, Chen K Q 2021 Appl. Phys. Lett. 118 183103

Google Scholar

Google Scholar

[74] Chen X K, Chen K Q 2020 J. Phys.: Condens. Matter. 32 153002

Google Scholar

Google Scholar

计量

- 文章访问数: 9129

- PDF下载量: 230

- 被引次数: 0

下载:

下载: