-

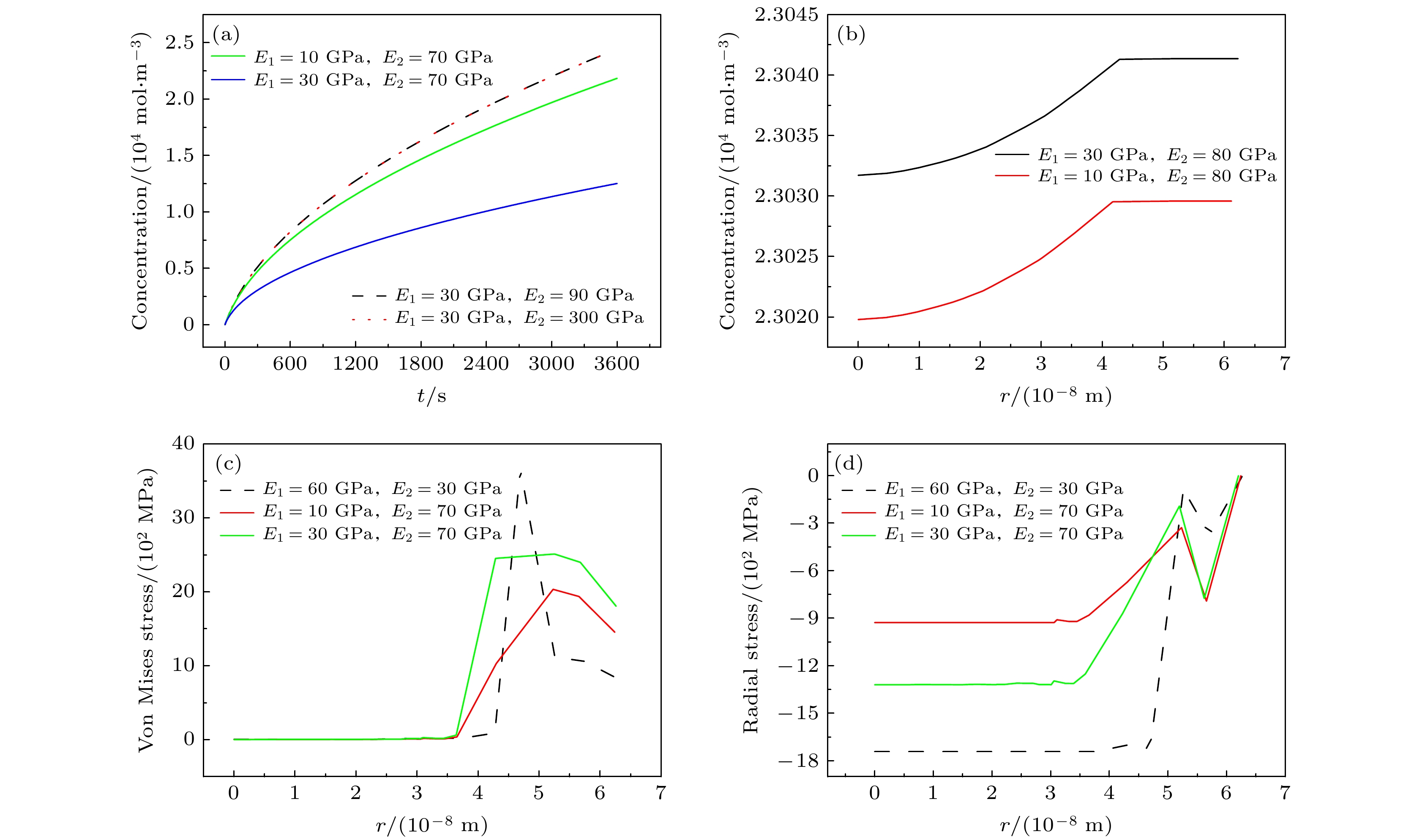

硅基电极材料在应用中的一个主要问题是巨大的体积膨胀, 以及由此带来的电极材料破裂、粉化. 本文在有限变形假设前提下, 基于电化学-力学耦合理论, 研究球形Si/C核壳结构在嵌锂过程中的浓度、应力场的演化, 并在此基础上讨论了核壳结构的优化设计. 计算结果显示: 壳层可以很好地保护硅颗粒的膨胀; 然而核内产生的较大的径向压缩应力可能导致核壳界面的脱黏, 而核壳界面处的切向拉伸应力可能会导致壳层的断裂. 进一步为有效提高核壳结构的电化学与力学性能, 从而实现锂离子电池更长的循环寿命, 考虑了两种结构的优化: 1)单层核壳结构; 2)双层核壳结构. 结果表明对于单层核壳结构应使用更软的包覆层材料; 而双层核壳结构中优化的材料布置方案为内软外硬, 对双层核壳结构的硬度分析表明, 内层材料的杨氏模量应低于10 GPa, 而外层材料的应不高于70 GPa. 本文的结论对球形材料颗粒电极的设计及优化具有一定的指导意义.Silicon is considered as a first candidate for ideal anode material of the next-generation lithium-ion battery due to its high theoretical capacity to meet the demand for higher energy density. On the other hand, high theoretical capacity is accompanied by massive volume expansion, which gives arise to high stress and crack and pulverization of anode particles. Finally, the capacity of the battery fades gradually. While some kinds of factors contribute to the failure of silicon-based electrodes, the most important one is the diffusion-induced stress generated in silicon-based electrode particles. The cyclic processes of lithiation and delithiation are accomplished by the intercalation into and deintercalation from the silicon particles of lithium ions. During the cycle, physical processes and chemical processes, such as diffusion of lithium ions, phase transition, and volume expansion, take place simultaneously, making the cyclic process a strong-coupling problem to be addressed. For example, the intercalation of lithium ions into the electrode results in volume expansion and phase transition of anodes, thereby inducing stress; in turn, stress affects the diffusion process of lithium ions. Aiming to probe this problem, with the finite deformation hypothesis, an electrochemical-mechanical coupling model is used to study the variation and distribution of concentration and stress of core-shell structure during lithiation. And more importantly, great emphasis is put on the optimal design of core-shell structure. The numerical results show that the shell is useful in prohibiting the volume expansion of silicon core, but large compressive radial stress in silicon core may cause the core and shell to be detached, while the tangential tensile stress at the core-shell interface leads the shell to fracture. To improve the electrochemical and mechanical performance and hence lengthen the cycle life of lithium-ion batteries, two kinds of optimal designs are considered: 1) single-layered core-shell structure and 2) double-layered core-shell structure. The numerical results suggest that the softer shell material is suitable for a single-layered core-shell structure and the inner-soft & outer-hard design is optimal for the double-layered core-shell structure. Furthermore, the effects of Young's modulus of the inner and outer carbon layer materials on the chemical and mechanical performance of anode are explored. The simulation shows that the optimal Young's modulus of the inner shell is less than 10 GPa, and that of the outer shell is not higher than 70 GPa. This research is helpful in designing and optimizing the silicon-based anode electrodes of lithium-ion batteries.

-

Keywords:

- lithium-ion battery /

- electrochemical-mechanical coupling /

- core-shell structure /

- finite deformation

[1] 程昀, 李劼, 贾明, 汤依伟, 杜双龙, 艾立华, 殷宝华, 艾亮 2015 64 210202

Google Scholar

Google Scholar

Cheng Y, Li J, Jia M, Tang Y W, Du S L, Ai L H, Yin B H, Ai L 2015 Acta Phys. Sin. 64 210202

Google Scholar

Google Scholar

[2] Li M, Lu J, Chen Z, Khalil A 2018 Adv. Mater. 30 1800561

Google Scholar

Google Scholar

[3] Xie Z, Ma Z, Wang Y, Zhou Y, Lu C 2016 RSC Adv. 6 22383

Google Scholar

Google Scholar

[4] Vetter J, Novák P, Wagner M R, Veit C, Möller K C, Besenhard J O, Winter M, Wohlfahrt-Mehrens M, Vogler C, Hammouche A 2005 J. Power Sources 147 269

Google Scholar

Google Scholar

[5] 孙凤楠, 冯露, 卜家贺, 张静, 李林安, 王世斌 2019 68 120201

Google Scholar

Google Scholar

Sun F N, Feng L, Bu J H, Zhang J, Li L A, Wang S B 2019 Acta Phys. Sin. 68 120201

Google Scholar

Google Scholar

[6] Baggetto L, Niessen R A H, Roozeboom F, Notten P H L 2008 Adv. Funct. Mater. 18 1057

Google Scholar

Google Scholar

[7] Panat R 2015 Thin Solid Films 596 174

Google Scholar

Google Scholar

[8] Zhao Y, Stein P, Bai Y, Al-Siraj M, Yang Y, Xu B X 2019 J. Power Sources 413 259

Google Scholar

Google Scholar

[9] Prussin S 1961 J. Appl. Phys. 32 1876

Google Scholar

Google Scholar

[10] Zhang X, Shyy W, Sastry A M 2007 J. Electrochem. Soc. 154 A910

Google Scholar

Google Scholar

[11] Song Y, Lu B, Ji X, Zhang J 2012 J. Electrochem. Soc. 159 A2060

Google Scholar

Google Scholar

[12] Bagheri A, Arghavani J, Naghdabadi R 2019 Mech. Mater. 137 103134

Google Scholar

Google Scholar

[13] Lu Y, Zhang P, Wang F, Zhang K, Zhao X 2018 Electrochim. Acta 274 359

Google Scholar

Google Scholar

[14] Christensen J 2010 J. Electrochem. Soc. 157 A366

Google Scholar

Google Scholar

[15] Zhang X Y, Hao F, Chen H S, Fang D N 2014 J. Electrochem. Soc. 161 A2243

Google Scholar

Google Scholar

[16] Cheng Y T, Verbrugge M W 2008 J. Appl. Phys. 104 1876

[17] Deluca C M, Maute K, Dunn M L 2011 J. Power Sources 196 9672

Google Scholar

Google Scholar

[18] Li Y, Zhang K, Zheng B, Zhang X Q, Wang Q 2015 J. Appl. Phys. 117 245103

[19] Hu B, Ma Z S, Lei W X, Zou Y L, Lu C S 2017 Theor. Appl. Mech. Lett. 7 199

Google Scholar

Google Scholar

[20] Zhao Y F, Lu B, Zhang J 2018 Acta. Mech. Solida. Sin. 31 290

Google Scholar

Google Scholar

[21] Gao X, Lu W, Xu J 2020 J. Power Sources 449 227501

Google Scholar

Google Scholar

[22] Hao F, Fang D 2013 J. Electrochem. Soc. 160 A595

Google Scholar

Google Scholar

[23] Zhao K J, Pharr M, Hartle L, Vlassak J J, Suo Z G 2012 J. Power Sources 218 6

Google Scholar

Google Scholar

[24] Wu B, Lu W 2017 J. Phys. Chem. C 121 19022

Google Scholar

Google Scholar

[25] Zhang Y, Zhu Z 2020 Int. J. Adv. Manuf. Technol. 108 499

Google Scholar

Google Scholar

[26] Bohn E, Eckl T, Kamlah M, McMeekingc R 2013 J. Electrochem. Soc. 160 A1638

Google Scholar

Google Scholar

[27] Zhang X, Chen H S, Fang D 2019 Int. J. Mech. Sci. 169 105323

[28] Xu C, Weng L, Chen B, Zhou J Q, Cai R 2019 Int. J. Mech. Sci. 157 87

[29] Zhao K, Pharr M, Cai S, Vlassak J J, Suo Z G 2011 J. Am. Ceram. Soc. 94 s226

Google Scholar

Google Scholar

[30] Zhang K, Zheng B, Yang F, Li Y 2020 Int. J. Mech. Sci. 177 105602

Google Scholar

Google Scholar

[31] Liu B H, Wang X, Chen H S, Chen S, Yang H X, Xu J, Jiang H Q, Fang D N 2019 J. Appl. Mech. 86 041005

Google Scholar

Google Scholar

[32] Ding N, Xu J, Yao Y X, Wegner G, Fang X, . Chen C.H, Lieberwirth I 2009 Solid State Ionics 180 222

Google Scholar

Google Scholar

[33] Sethuraman V A, Chon M J, Shimshak M, Winkle N V, Guduru P R 2010 Electrochem. Commun. 12 1614

Google Scholar

Google Scholar

[34] Wu B, Lu W 2017 J. Power Sources 360 360

Google Scholar

Google Scholar

[35] Deng Q, Hu R, Xu C, Chen B, Zhou J 2019 J. Solid State Electrochem. 23 2999

Google Scholar

Google Scholar

-

图 4 不同假设条件下充电过程中沿着半径方向的径向应力和切向应力 (a)小变形下的径向应力; (b)有限变形下的径向应力; (c)小变形下的切向应力; (d)有限变形下的切向应力

Fig. 4. Radial stress and tangential stress along the radial direction during charging under different hypothesis: (a) Radial stress under small deformation; (b) radial stress under finite deformation; (c) tangential stress under small deformation; (d) tangential stress under finite deformation.

参数 核 壳 饱和浓度 Cmax/(mol·m–3) 2.95 × 105 2.4 × 104 初始浓度C0/(mol·m–3) 0 0 扩散系数 D/(m2·s–1) 1.0 × 10–16 1.45 × 10–13 内径/外径 R/m 4 × 10–8 5 × 10–8 泊松比 ν 0.23 0.30 杨氏模量E/Pa 8 × 1010 6 × 1010 偏摩尔体积 Ω/(m3·mol–1) 3/Cmax 3.497 × 10–6 室温 T/K 298 表 2 包覆层碳的材料参数

Table 2. Material parameters of the outer shell.

-

[1] 程昀, 李劼, 贾明, 汤依伟, 杜双龙, 艾立华, 殷宝华, 艾亮 2015 64 210202

Google Scholar

Google Scholar

Cheng Y, Li J, Jia M, Tang Y W, Du S L, Ai L H, Yin B H, Ai L 2015 Acta Phys. Sin. 64 210202

Google Scholar

Google Scholar

[2] Li M, Lu J, Chen Z, Khalil A 2018 Adv. Mater. 30 1800561

Google Scholar

Google Scholar

[3] Xie Z, Ma Z, Wang Y, Zhou Y, Lu C 2016 RSC Adv. 6 22383

Google Scholar

Google Scholar

[4] Vetter J, Novák P, Wagner M R, Veit C, Möller K C, Besenhard J O, Winter M, Wohlfahrt-Mehrens M, Vogler C, Hammouche A 2005 J. Power Sources 147 269

Google Scholar

Google Scholar

[5] 孙凤楠, 冯露, 卜家贺, 张静, 李林安, 王世斌 2019 68 120201

Google Scholar

Google Scholar

Sun F N, Feng L, Bu J H, Zhang J, Li L A, Wang S B 2019 Acta Phys. Sin. 68 120201

Google Scholar

Google Scholar

[6] Baggetto L, Niessen R A H, Roozeboom F, Notten P H L 2008 Adv. Funct. Mater. 18 1057

Google Scholar

Google Scholar

[7] Panat R 2015 Thin Solid Films 596 174

Google Scholar

Google Scholar

[8] Zhao Y, Stein P, Bai Y, Al-Siraj M, Yang Y, Xu B X 2019 J. Power Sources 413 259

Google Scholar

Google Scholar

[9] Prussin S 1961 J. Appl. Phys. 32 1876

Google Scholar

Google Scholar

[10] Zhang X, Shyy W, Sastry A M 2007 J. Electrochem. Soc. 154 A910

Google Scholar

Google Scholar

[11] Song Y, Lu B, Ji X, Zhang J 2012 J. Electrochem. Soc. 159 A2060

Google Scholar

Google Scholar

[12] Bagheri A, Arghavani J, Naghdabadi R 2019 Mech. Mater. 137 103134

Google Scholar

Google Scholar

[13] Lu Y, Zhang P, Wang F, Zhang K, Zhao X 2018 Electrochim. Acta 274 359

Google Scholar

Google Scholar

[14] Christensen J 2010 J. Electrochem. Soc. 157 A366

Google Scholar

Google Scholar

[15] Zhang X Y, Hao F, Chen H S, Fang D N 2014 J. Electrochem. Soc. 161 A2243

Google Scholar

Google Scholar

[16] Cheng Y T, Verbrugge M W 2008 J. Appl. Phys. 104 1876

[17] Deluca C M, Maute K, Dunn M L 2011 J. Power Sources 196 9672

Google Scholar

Google Scholar

[18] Li Y, Zhang K, Zheng B, Zhang X Q, Wang Q 2015 J. Appl. Phys. 117 245103

[19] Hu B, Ma Z S, Lei W X, Zou Y L, Lu C S 2017 Theor. Appl. Mech. Lett. 7 199

Google Scholar

Google Scholar

[20] Zhao Y F, Lu B, Zhang J 2018 Acta. Mech. Solida. Sin. 31 290

Google Scholar

Google Scholar

[21] Gao X, Lu W, Xu J 2020 J. Power Sources 449 227501

Google Scholar

Google Scholar

[22] Hao F, Fang D 2013 J. Electrochem. Soc. 160 A595

Google Scholar

Google Scholar

[23] Zhao K J, Pharr M, Hartle L, Vlassak J J, Suo Z G 2012 J. Power Sources 218 6

Google Scholar

Google Scholar

[24] Wu B, Lu W 2017 J. Phys. Chem. C 121 19022

Google Scholar

Google Scholar

[25] Zhang Y, Zhu Z 2020 Int. J. Adv. Manuf. Technol. 108 499

Google Scholar

Google Scholar

[26] Bohn E, Eckl T, Kamlah M, McMeekingc R 2013 J. Electrochem. Soc. 160 A1638

Google Scholar

Google Scholar

[27] Zhang X, Chen H S, Fang D 2019 Int. J. Mech. Sci. 169 105323

[28] Xu C, Weng L, Chen B, Zhou J Q, Cai R 2019 Int. J. Mech. Sci. 157 87

[29] Zhao K, Pharr M, Cai S, Vlassak J J, Suo Z G 2011 J. Am. Ceram. Soc. 94 s226

Google Scholar

Google Scholar

[30] Zhang K, Zheng B, Yang F, Li Y 2020 Int. J. Mech. Sci. 177 105602

Google Scholar

Google Scholar

[31] Liu B H, Wang X, Chen H S, Chen S, Yang H X, Xu J, Jiang H Q, Fang D N 2019 J. Appl. Mech. 86 041005

Google Scholar

Google Scholar

[32] Ding N, Xu J, Yao Y X, Wegner G, Fang X, . Chen C.H, Lieberwirth I 2009 Solid State Ionics 180 222

Google Scholar

Google Scholar

[33] Sethuraman V A, Chon M J, Shimshak M, Winkle N V, Guduru P R 2010 Electrochem. Commun. 12 1614

Google Scholar

Google Scholar

[34] Wu B, Lu W 2017 J. Power Sources 360 360

Google Scholar

Google Scholar

[35] Deng Q, Hu R, Xu C, Chen B, Zhou J 2019 J. Solid State Electrochem. 23 2999

Google Scholar

Google Scholar

计量

- 文章访问数: 13597

- PDF下载量: 501

- 被引次数: 0

下载:

下载: