-

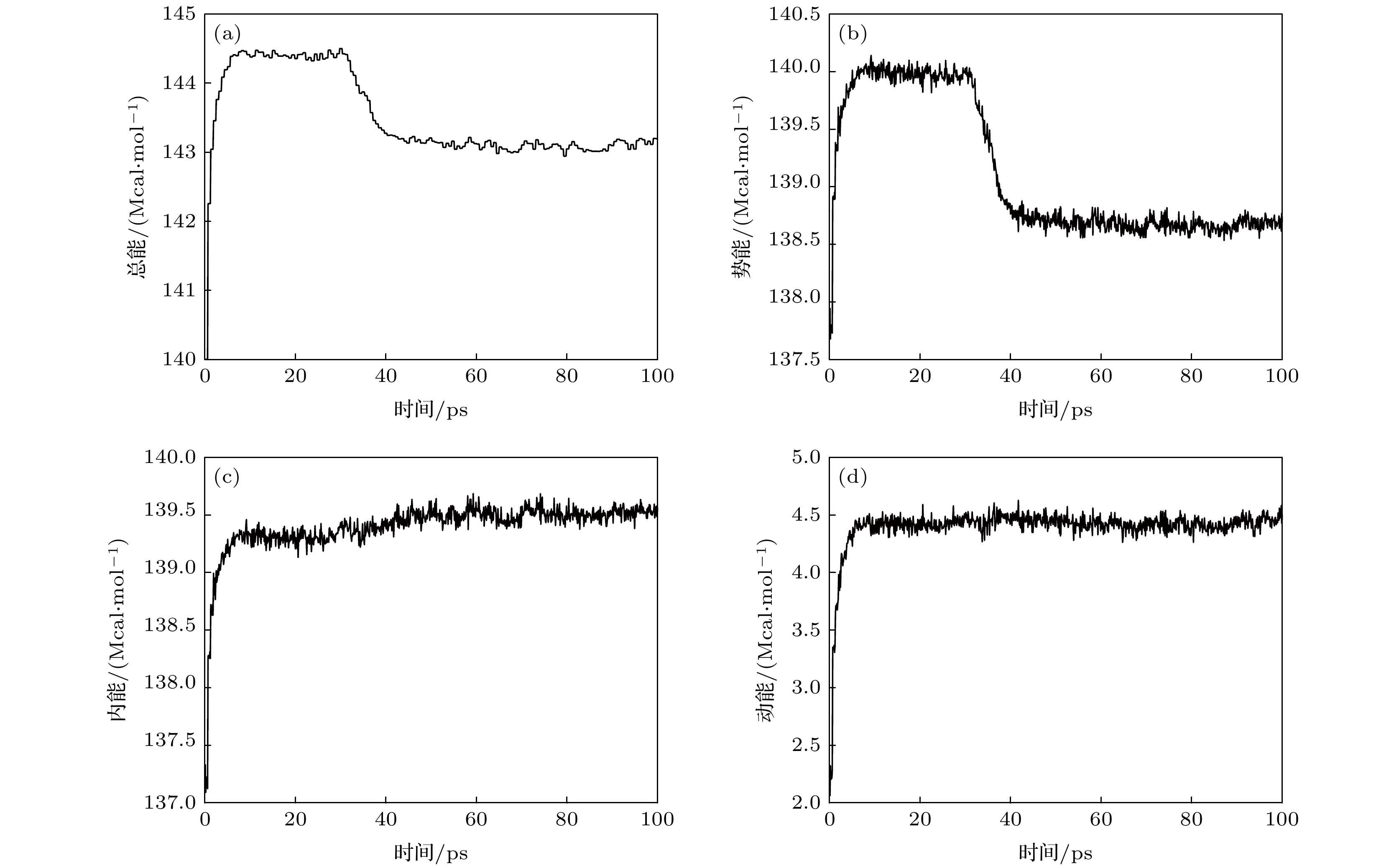

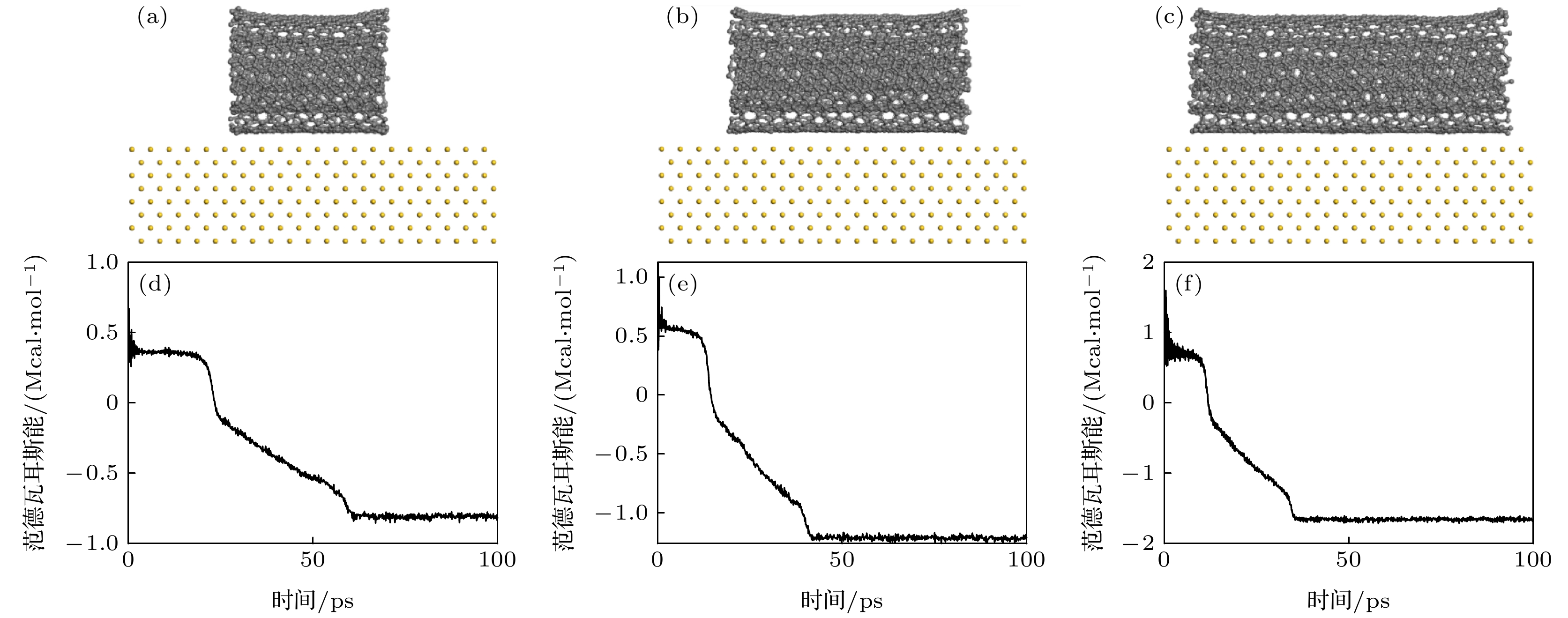

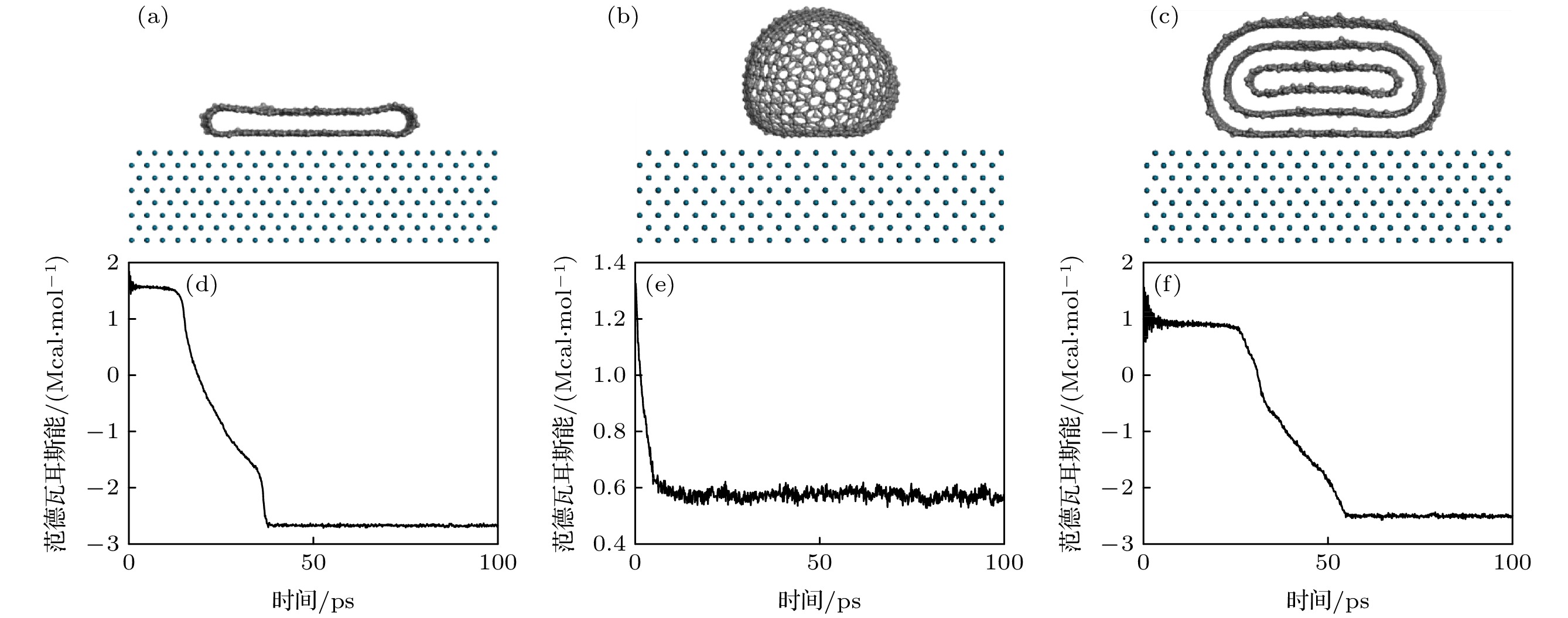

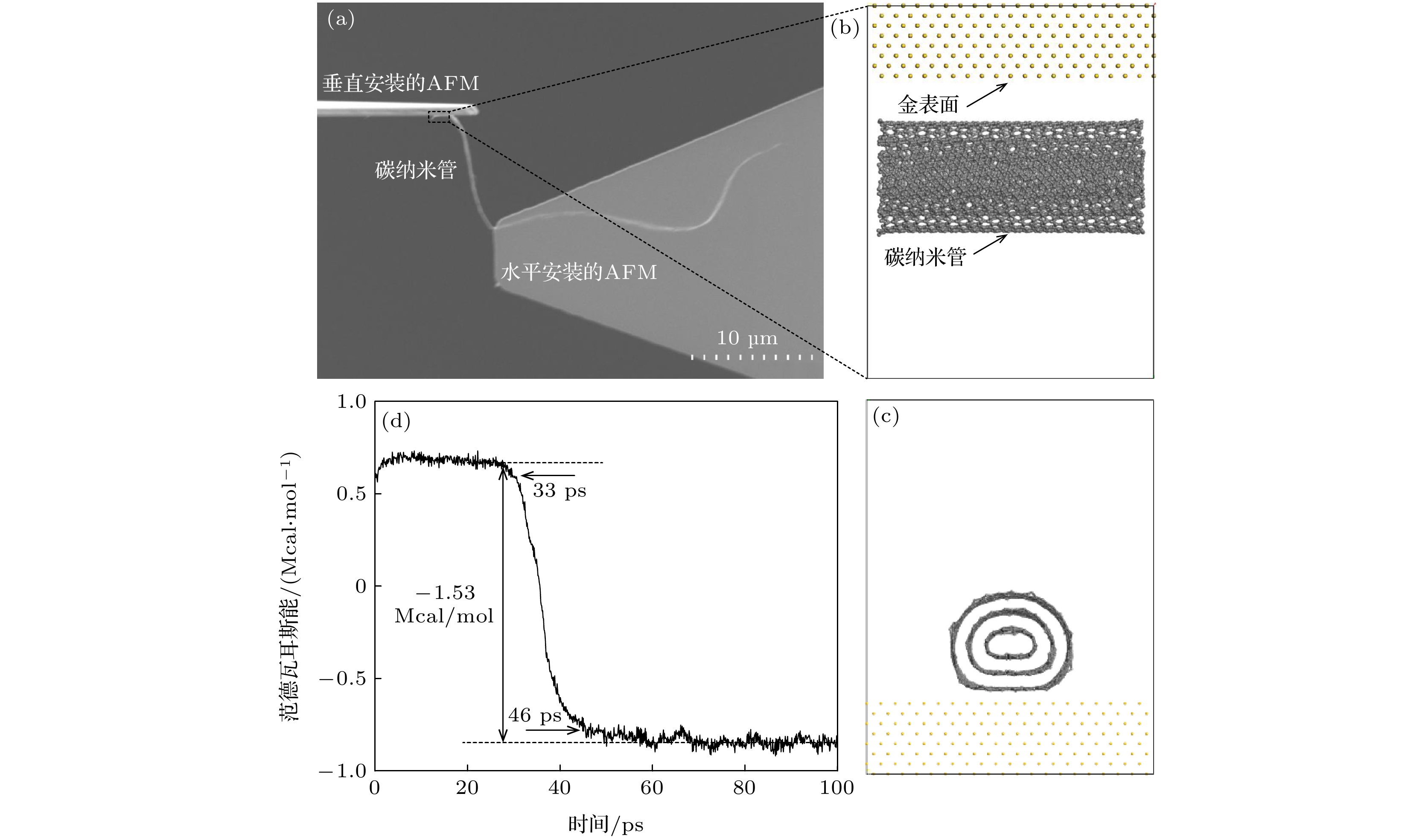

碳纳米管与金属表面间的界面接触行为对碳基电子器件的性能研究具有重要意义. 本文利用分子动力学模拟方法研究了端部开口和闭口的多壁碳纳米管与金属表面间的界面接触构型和粘着强度. 模拟结果表明, 多壁碳纳米管在金属表面上的位置和形状变化是因为减少的范德瓦耳斯能转变成碳纳米管的内能; 多壁碳纳米管与金属表面的结合能为负值, 表明两者存在粘着作用; 多壁碳纳米管水平地接触金属表面时的粘着强度受初始间距、接触长度和金属种类影响, 即范德瓦耳斯能作用的初始间距阈值约为1 nm且最终平衡状态时的两者间距约为0.3 nm; 随着两者接触长度增加, 粘着强度增大, 铂与碳纳米管的粘着强度比钨和铝的大; 端部开口和闭口的碳纳米管与金属表面垂直接触时的粘着强度都比水平接触时的小, 两端开口的碳纳米管在金属表面上发生径向压缩变形, 最终形成带状结构; 而两端封闭的碳纳米管在金属表面上发生轴向压缩变形; 在碳纳米管场效应晶体管中, 两端开口的多壁碳纳米管与单壁碳纳米管一样变形成带状结构, 并且各个管壁之间以及最外层管壁与金属电极之间的间距相当, 该原子尺度的间距(约0.34 nm)保证电子从金属隧穿到最外层管壁, 并在内层管壁之间径向迁移.The interfacial contact configuration and contact intensity between carbon nanotube and metal surface play an important role in the electrical performance of carbon nanotube field effect transistors and nanoscale carbon nanotube robotic manipulation. In this paper, we investigate numerically the contact configuration and the contact intensity between multiwall carbon nanotube with open ends or capped ends and various metal surfaces in carbon nanotube field effect transistor assembly by the molecular dynamics simulation. The simulation results show that the change in the position and shape of multiwall carbon nanotube on the metal surface are mainly due to the decrease of van der Waals energy reduction: the decrement of van der Waals energy is converted into the internal energy and kinetic energy of carbon nanotubes. Moreover, the binding energy between multiwall carbon nanotube and metal surface is negative, which indicates that multiwall carbon nanotube adheres to the metal surface. In addition, the contact intensity of multiwall carbon nanotube in horizontally contacting metal surface is influenced by initial distance, contact length and metal materials. The final equilibrium distance is around ~0.3 nm when the initial distance is less than ~1 nm. And the contact intensity increases with the augment of contact length between carbon nanotube and metal. The contact intensity between platinum and carbon nanotube is larger than that between tungsten and aluminum, therefore, platinum-coated probe is generally utilized for picking carbon nanotube up. The contact intensity of the carbon nanotubes with the open ends and closed ends in the vertical contact with the metal surface are both lower than those in the horizontal contact. The interfacial contact configuration of carbon nanotube and metal materials mainly include the displacement and geometric deformation of carbon nanotube. The displacement and geometric deformation of multiwall carbon nanotube with open ends on the metal surface finally result in its radial nanoscale ribbon structure. But the closed-end three-wall carbon nanotube has the small axial geometric deformation through comparing the concentration profiles between the initial carbon nanotube and the collapsed carbon nanotube. In a carbon nanotube field effect transistor, the collapsed multiwall carbon nanotube forms the ribbon structure like a single wall carbon nanotube. And the distance between carbon nanotube walls and between the outermost carbon nanotube wall and the metal electrode are both about ~0.34 nm. The atomic scale spacing ensures that electrons tunnel from the metal to the outermost carbon nanotube wall and migrate radially between the inner carbon nanotube walls.

-

Keywords:

- carbon nanotube /

- van der Waals energy /

- molecular dynamic

[1] Yu M F, Dyer M J, Skidmore G D, Rohrs H W, Lu X, Ausman K D, Ehr J R V, Ruoff R S 1999 Nanotechnology 10 244

Google Scholar

Google Scholar

[2] Yu M F, Lourie O, Dyer M J, Moloni K, Kelly T F, S. R R 2000 Science 287 637

Google Scholar

Google Scholar

[3] Ding H Y, Shi C Y, Li M, Zhan Y, Wang M Y, Wang Y Q, Tao C, Sun L N, Fukuda T 2018 Sensors 18 1137

Google Scholar

Google Scholar

[4] 王亚洲, 马立, 杨权, 耿松超, 林旖旎, 陈涛, 孙立宁 2020 69 068801

Google Scholar

Google Scholar

Wang Y Z, Ma L, Yang Q, Geng S C, Lin Y N, Chen T, Sun L N 2020 Acta Phys. Sin. 69 068801

Google Scholar

Google Scholar

[5] Zhang Z Y, Wang S, Ding L, Liang X L, Xu H L, Shen J, Chen Q, Cui R L, Li Y, Peng L M 2008 Appl. Phys. Lett. 92 133117

Google Scholar

Google Scholar

[6] Xie S, Jiao N, Tung S, Liu L 2015 Micromachines 6 1317

Google Scholar

Google Scholar

[7] Yu N, Shi Q, Nakajima M, Wang H P, Yang Z, Sun L N, Huang Q, Fukuda T 2017 J. Micromech. Microeng. 27 105007

Google Scholar

Google Scholar

[8] Fukuda T, Arai F, Dong L 2003 Proc. IEEE 91 1803

[9] Yang Z, Chen T, Wang Y Q, Sun L N, Fukuda T 2016 Micro-Nano Lett. 11 645

Google Scholar

Google Scholar

[10] 杨权, 马立, 杨斌, 丁汇洋, 陈涛, 杨湛, 孙立宁, 福田敏男 2018 67 136801

Google Scholar

Google Scholar

Yang Q, Ma L, Yang B, Ding H Y, Chen T, Yang Z, Sun L N, Toshio F 2018 Acta Phys. Sin. 67 136801

Google Scholar

Google Scholar

[11] Liu P, Nakajima M, Yang Z, Fukuda T, Arai F 2009 Proc. IMechE Part N: J. Nanoengineering and Nanosystems 222 33

[12] Yu N, Nakajima M, Shi Q, Yang Z, Wang H P, Sun L N, Huang Q, Fukuda T 2017 Scanning 2017 5910734

[13] Shi Q, Yang Z, Guo Y N, Wang H P, Sun L N, Huang Q, Fukuda T 2017 IEEE/ASME Trans. Mechatron. 22 845

Google Scholar

Google Scholar

[14] Chen Q, Wang S, Peng L M 2006 Nanotechnology 17 1087

Google Scholar

Google Scholar

[15] Martel R, Schmidt T, Shea H R, Hertel T, Avouris P 1998 Appl. Phys. Lett. 73 2447

Google Scholar

Google Scholar

[16] Cui J L, Zhang J W, He X Q, Mei X S, Wang W J, Yang X J, Xie H, Yang L J, Wang Y 2017 J. Nanopart. Res. 19 110

Google Scholar

Google Scholar

[17] Gao G H, Çagin T, Goddard W A 1998 Nanotechnology 9 184

Google Scholar

Google Scholar

[18] Yu M F, Dyer M J, Ruoff R S 2001 J. Appl. Phys. 89 4554

Google Scholar

Google Scholar

[19] Liu B, Yu M F, Huang Y G 2004 Phys. Rev. B 70 2806

[20] Xiao J, Liu B, Huang Y, Zuo J, Hwang K C, Yu M F 2007 Nanotechnology 18 395703

Google Scholar

Google Scholar

[21] Xiao S G, Liu S L, Song M M, Ang N, Zhang H L 2020 Multibody Sys. Dyn. 48 451

Google Scholar

Google Scholar

[22] Xiao S G, Liu S L, Wang H Z, Lin Y, Song M M, Zhang H L 2020 Nonlinear Dyn. 100 1203

Google Scholar

Google Scholar

[23] Zhang D H, Liu Z K, Yang H B, Liu A M 2018 Mol. Simul. 44 648

Google Scholar

Google Scholar

[24] Zhang D H, Yang H B, Liu Z K, Liu A M 2018 J. Alloys Compd. 765 140

Google Scholar

Google Scholar

[25] Andriotis A, Menon M, Gibson H 2008 IEEE Sens. J. 8 910

Google Scholar

Google Scholar

[26] Cui J L, Zhang J W, Wang X W, Theogene B, Wang W J, Tohmyoh H, He X Q, Mei X S 2019 J. Phys. Chem. C 123 19693

Google Scholar

Google Scholar

[27] Cui J L, Ren X Y, Mei H H, Wang X W, Zhang J W, Fan Z J, Wang W J, Tohmyoh H, Mei X S 2020 Appl. Surf. Sci. 512 145696

Google Scholar

Google Scholar

[28] Xie J, Xue Q, Yan K, Chen H, Xia D, Dong M 2009 J. Phys. Chem. C 113 14747

[29] Yan K Y, Xue Q Z, Xia D, Chen H J, Xie J, Dong M D 2009 ACS Nano 3 2235

Google Scholar

Google Scholar

[30] Yan K Y, Xue Q Z, Zheng Q B, Xia D, Xie J 2009 J. Phys. Chem. C 113 3120

Google Scholar

Google Scholar

[31] Ling C C, Xue Q Z, Jing N N, Xia D 2012 RSC Adv. 2 7549

Google Scholar

Google Scholar

[32] Mozos J, Ordejón P, Brandbyge M, Taylor J, Stokbro K 2003 Advances in Quantum Chemistry (Salt Lake City: Academic Press) pp299−314

[33] Chen W, Li H, He Y Z 2014 Phys. Chem. Chem. Phys. 16 7907

Google Scholar

Google Scholar

[34] 李瑞, 密俊霞 2017 66 046101

Google Scholar

Google Scholar

Li R, Mi J X 2017 Acta Phys. Sin. 66 046101

Google Scholar

Google Scholar

[35] Akita S, Nishijima H, Nakayama Y 2000 J. Phys. D: Appl. Phys. 33 2673

Google Scholar

Google Scholar

[36] Yang Q 2020 Micro-Nano Lett. 15 883

Google Scholar

Google Scholar

[37] Maiti A, Ricca A 2004 Chem. Phys. Lett. 395 7

Google Scholar

Google Scholar

[38] Frank S P, Poncharal P, Wang Z L, Heer W A D 1998 Science 280 1744

Google Scholar

Google Scholar

[39] Xiang L, Wang Y W, Zhang P P, Fong X Y, Wei X L, Hu Y F 2018 Nanoscale 10 21857

Google Scholar

Google Scholar

[40] Xiao M M, Lin Y X, Xu L, Deng B, Peng H L, Peng L M, Zhang Z Y 2020 Adv. Electron. Mater. 6 2000258

Google Scholar

Google Scholar

[41] Zhang Z Y, Liang X L, Wang S, Yao K, Hu Y F, Zhu Y Z, Chen Q, Zhou W W, Li Y, Yao Y G, Zhang J, Peng L M 2007 Nano Lett. 7 3603

Google Scholar

Google Scholar

[42] Park C J, Kim Y H, Chang K J 1999 Phys. Rev. B 60 10656

Google Scholar

Google Scholar

[43] Lu J Q, Wu J, Duan W H, Liu F, Zhu B F, Gu B L 2003 Phys. Rev. Lett. 90 156601

Google Scholar

Google Scholar

[44] Lu J Q, Wu J, Duan W H, Gu B L, Johnson H T 2005 J. Appl. Phys. 97 56

[45] Giusca C E, Tison Y, Silva S R P 2008 Nano Lett. 8 3350

Google Scholar

Google Scholar

-

图 4 碳纳米管与金表面在不同初始间距下的界面接触构型及范德瓦耳斯能差 初始间距: (a) 1.1999 nm; (b) 0.9489 nm; (c) 0.1378 nm; 平衡间距: (d) 1.16 nm; (e) 0.3081 nm; (f) 0.2933 nm; 范德瓦耳斯能差: (g) 1.1999 nm; (b) 0.9489 nm; (c) 0.1378 nm

Fig. 4. Contact configuration and Van der Waals energy of CNT with different initial gap: (a) Initial separate gap of 1.1999 nm; (b) 0.9489 nm; (c) 0.1378 nm; (d) final gap of 1.16 nm; (e) 0.3081 nm; (f) 0.2933 nm; Van der Waals energy at distance of (g) 1.1999 nm; (b) 0.9489 nm; (c) 0.1378 nm.

图 6 碳纳米管与金在不同接触长度下的接触构型和范德瓦耳斯能差值. 接触构型: (a) 2.46 nm; (b) 3.689 nm; (c) 4.919 nm; 范德瓦耳斯能差值: (d) 2.46 nm; (e) 3.689 nm; (f) 4.919 nm

Fig. 6. Contact behavior and VdW energy reduction with different contact length. Contact behavior: (a) 2.46 nm; (b) 3.689 nm; (c) 4.919 nm; and VdW energy reduction under contact length: (d) 2.46 nm; (e) 3.689 nm; (f) 4.919 nm.

图 7 碳纳米管与金表面垂直接触下的接触构型和范德瓦耳斯能差值 接触构型:(a) 两端开口; (b) 一端开口和闭口; (c) 两端闭口; 范德瓦耳斯能差值: (d) 两端开口; (e) 一端开口和闭口; (f) 两端闭口

Fig. 7. Contact behavior in vertical contact and VdW energy reduction: (a) 2 open ends; (b) capped and open end; (c) 2 capped ends; VdW energy reduction with: (d) 2 open ends; (e) capped and open end; (f) 2 capped ends.

图 13 两端开口或闭口碳纳米管与钯电极接触的构型和范德瓦耳斯能差值 接触构型:(a)单壁开口; (b)单壁闭口; (c)三壁开口; 范德瓦耳斯能差值: (d)单壁开口; (e)单壁闭口; (f)三壁开口

Fig. 13. Interface configuration and Van der Waals energy of CNTs contacting with palladium: (a) Single-walled open-ends CNT; (b) single-walled closed-ends CNT; (c) three-walled open-ends CNT; Van der Waals energy of (d) single-walled open-ends CNT; (e) single-walled closed-ends CNT; (f) three-walled open-ends CNT.

表 1 多壁碳纳米管与金表面接触系统径向压缩变形前后的能量组成

Table 1. The energy components of multi-walled CNT and gold surface before and after collapse.

能量组成 初始状态 稳定状态 能量差值 总能/Mcal/mol 144.3 约143 –1.3 势能/Mcal/mol 约140 约138.7 –1.3 动能/Mcal/mol 4.5 ± 0.03 4.5 ± 0.03 — 内能/Mcal/mol 约139.3 约139.5 0.2 范德瓦耳斯能/Mcal/mol 约0.7 约–0.83 –1.53 表 2 多壁碳纳米管与金表面上径向压缩变形前后的初始间距及其对应能量

Table 2. VDW energy of multi-walled CNT and gold surface at different original distance.

能量对应间距 初始状态 最终状态 范德瓦

耳斯

能差能量/

(Mcal/mol)

(间距/ nm)约0.7(1.1999) 约0.7(1.16) 0 约0.7(0.9489) –0.8(0.3081) 1.5 –3.6(0.1378) –3.6(0.2933) 0 表 3 多壁碳纳米管与金表面在不同金属种类、接触长度和接触模式下范德瓦耳斯能差

Table 3. VDW energy of MWCNT and gold surface with different metal, contact length and model.

能量/(Mcal/mol) 金属种类 水平接触长度/nm 垂直接触 铂 铝 钨 2.46 3.689 4.919 两端开口 开口封闭 两端封闭 范德瓦耳斯能差 2 1.15 1.05 1.2 1.8 2.4 0 0.5 0 表 4 多壁碳纳米管最外层管壁与金表面的接触距离

Table 4. Contacting distance of outmost layer of MWCNT with gold surface.

碳纳米

管结构源漏初始间距/nm 源漏最终

间距/nm栅极初始

间距/nm栅极最终

间距/nm三壁两

端闭口0.6374 0.29 0.9233 0.36 三壁两

端开口0.6729 0.3204 0.932 0.3235 单壁两

端开口0.67 0.3 0.93 0.34 -

[1] Yu M F, Dyer M J, Skidmore G D, Rohrs H W, Lu X, Ausman K D, Ehr J R V, Ruoff R S 1999 Nanotechnology 10 244

Google Scholar

Google Scholar

[2] Yu M F, Lourie O, Dyer M J, Moloni K, Kelly T F, S. R R 2000 Science 287 637

Google Scholar

Google Scholar

[3] Ding H Y, Shi C Y, Li M, Zhan Y, Wang M Y, Wang Y Q, Tao C, Sun L N, Fukuda T 2018 Sensors 18 1137

Google Scholar

Google Scholar

[4] 王亚洲, 马立, 杨权, 耿松超, 林旖旎, 陈涛, 孙立宁 2020 69 068801

Google Scholar

Google Scholar

Wang Y Z, Ma L, Yang Q, Geng S C, Lin Y N, Chen T, Sun L N 2020 Acta Phys. Sin. 69 068801

Google Scholar

Google Scholar

[5] Zhang Z Y, Wang S, Ding L, Liang X L, Xu H L, Shen J, Chen Q, Cui R L, Li Y, Peng L M 2008 Appl. Phys. Lett. 92 133117

Google Scholar

Google Scholar

[6] Xie S, Jiao N, Tung S, Liu L 2015 Micromachines 6 1317

Google Scholar

Google Scholar

[7] Yu N, Shi Q, Nakajima M, Wang H P, Yang Z, Sun L N, Huang Q, Fukuda T 2017 J. Micromech. Microeng. 27 105007

Google Scholar

Google Scholar

[8] Fukuda T, Arai F, Dong L 2003 Proc. IEEE 91 1803

[9] Yang Z, Chen T, Wang Y Q, Sun L N, Fukuda T 2016 Micro-Nano Lett. 11 645

Google Scholar

Google Scholar

[10] 杨权, 马立, 杨斌, 丁汇洋, 陈涛, 杨湛, 孙立宁, 福田敏男 2018 67 136801

Google Scholar

Google Scholar

Yang Q, Ma L, Yang B, Ding H Y, Chen T, Yang Z, Sun L N, Toshio F 2018 Acta Phys. Sin. 67 136801

Google Scholar

Google Scholar

[11] Liu P, Nakajima M, Yang Z, Fukuda T, Arai F 2009 Proc. IMechE Part N: J. Nanoengineering and Nanosystems 222 33

[12] Yu N, Nakajima M, Shi Q, Yang Z, Wang H P, Sun L N, Huang Q, Fukuda T 2017 Scanning 2017 5910734

[13] Shi Q, Yang Z, Guo Y N, Wang H P, Sun L N, Huang Q, Fukuda T 2017 IEEE/ASME Trans. Mechatron. 22 845

Google Scholar

Google Scholar

[14] Chen Q, Wang S, Peng L M 2006 Nanotechnology 17 1087

Google Scholar

Google Scholar

[15] Martel R, Schmidt T, Shea H R, Hertel T, Avouris P 1998 Appl. Phys. Lett. 73 2447

Google Scholar

Google Scholar

[16] Cui J L, Zhang J W, He X Q, Mei X S, Wang W J, Yang X J, Xie H, Yang L J, Wang Y 2017 J. Nanopart. Res. 19 110

Google Scholar

Google Scholar

[17] Gao G H, Çagin T, Goddard W A 1998 Nanotechnology 9 184

Google Scholar

Google Scholar

[18] Yu M F, Dyer M J, Ruoff R S 2001 J. Appl. Phys. 89 4554

Google Scholar

Google Scholar

[19] Liu B, Yu M F, Huang Y G 2004 Phys. Rev. B 70 2806

[20] Xiao J, Liu B, Huang Y, Zuo J, Hwang K C, Yu M F 2007 Nanotechnology 18 395703

Google Scholar

Google Scholar

[21] Xiao S G, Liu S L, Song M M, Ang N, Zhang H L 2020 Multibody Sys. Dyn. 48 451

Google Scholar

Google Scholar

[22] Xiao S G, Liu S L, Wang H Z, Lin Y, Song M M, Zhang H L 2020 Nonlinear Dyn. 100 1203

Google Scholar

Google Scholar

[23] Zhang D H, Liu Z K, Yang H B, Liu A M 2018 Mol. Simul. 44 648

Google Scholar

Google Scholar

[24] Zhang D H, Yang H B, Liu Z K, Liu A M 2018 J. Alloys Compd. 765 140

Google Scholar

Google Scholar

[25] Andriotis A, Menon M, Gibson H 2008 IEEE Sens. J. 8 910

Google Scholar

Google Scholar

[26] Cui J L, Zhang J W, Wang X W, Theogene B, Wang W J, Tohmyoh H, He X Q, Mei X S 2019 J. Phys. Chem. C 123 19693

Google Scholar

Google Scholar

[27] Cui J L, Ren X Y, Mei H H, Wang X W, Zhang J W, Fan Z J, Wang W J, Tohmyoh H, Mei X S 2020 Appl. Surf. Sci. 512 145696

Google Scholar

Google Scholar

[28] Xie J, Xue Q, Yan K, Chen H, Xia D, Dong M 2009 J. Phys. Chem. C 113 14747

[29] Yan K Y, Xue Q Z, Xia D, Chen H J, Xie J, Dong M D 2009 ACS Nano 3 2235

Google Scholar

Google Scholar

[30] Yan K Y, Xue Q Z, Zheng Q B, Xia D, Xie J 2009 J. Phys. Chem. C 113 3120

Google Scholar

Google Scholar

[31] Ling C C, Xue Q Z, Jing N N, Xia D 2012 RSC Adv. 2 7549

Google Scholar

Google Scholar

[32] Mozos J, Ordejón P, Brandbyge M, Taylor J, Stokbro K 2003 Advances in Quantum Chemistry (Salt Lake City: Academic Press) pp299−314

[33] Chen W, Li H, He Y Z 2014 Phys. Chem. Chem. Phys. 16 7907

Google Scholar

Google Scholar

[34] 李瑞, 密俊霞 2017 66 046101

Google Scholar

Google Scholar

Li R, Mi J X 2017 Acta Phys. Sin. 66 046101

Google Scholar

Google Scholar

[35] Akita S, Nishijima H, Nakayama Y 2000 J. Phys. D: Appl. Phys. 33 2673

Google Scholar

Google Scholar

[36] Yang Q 2020 Micro-Nano Lett. 15 883

Google Scholar

Google Scholar

[37] Maiti A, Ricca A 2004 Chem. Phys. Lett. 395 7

Google Scholar

Google Scholar

[38] Frank S P, Poncharal P, Wang Z L, Heer W A D 1998 Science 280 1744

Google Scholar

Google Scholar

[39] Xiang L, Wang Y W, Zhang P P, Fong X Y, Wei X L, Hu Y F 2018 Nanoscale 10 21857

Google Scholar

Google Scholar

[40] Xiao M M, Lin Y X, Xu L, Deng B, Peng H L, Peng L M, Zhang Z Y 2020 Adv. Electron. Mater. 6 2000258

Google Scholar

Google Scholar

[41] Zhang Z Y, Liang X L, Wang S, Yao K, Hu Y F, Zhu Y Z, Chen Q, Zhou W W, Li Y, Yao Y G, Zhang J, Peng L M 2007 Nano Lett. 7 3603

Google Scholar

Google Scholar

[42] Park C J, Kim Y H, Chang K J 1999 Phys. Rev. B 60 10656

Google Scholar

Google Scholar

[43] Lu J Q, Wu J, Duan W H, Liu F, Zhu B F, Gu B L 2003 Phys. Rev. Lett. 90 156601

Google Scholar

Google Scholar

[44] Lu J Q, Wu J, Duan W H, Gu B L, Johnson H T 2005 J. Appl. Phys. 97 56

[45] Giusca C E, Tison Y, Silva S R P 2008 Nano Lett. 8 3350

Google Scholar

Google Scholar

计量

- 文章访问数: 10941

- PDF下载量: 191

- 被引次数: 0

下载:

下载: