-

碳纳米管作为新一代热界面材料, 在天然材料中具有最高的热导率, 有望解决金刚石半导体超高热流密度的散热问题. 因此, 本文提出将金刚石和碳纳米管结合, 可大幅度提高器件性能及稳定性, 减小封装尺寸, 实现器件小型化设计. 采用非平衡分子动力学方法从微观层面探究了金刚石/碳纳米管异质结构界面热特性及影响因素. 研究发现碳纳米管层数增加使声子态密度峰值增大并向低频波段移动, 低频声子增多更有利于界面传热, 同时声子重叠能提高, 声子耦合振动增强提升了界面传热效率; 同时, 一定范围内体系温度的升高及碳纳米管长径比的增大可以提高近界面处金刚石和碳纳米管的态密度截止频率, 提升低频波段的峰值, 进一步增强两侧声子的耦合振动, 提高了界面热导. 最后, 采用正交试验模拟获得了金刚石/碳纳米管界面热导的最优值, 结果远优于目前一般半导体/金属的界面热导. 该工作为优化金刚石/碳纳米管异质界面的热输运提供了思路, 并将有利于器件热管理和芯片材料设计.

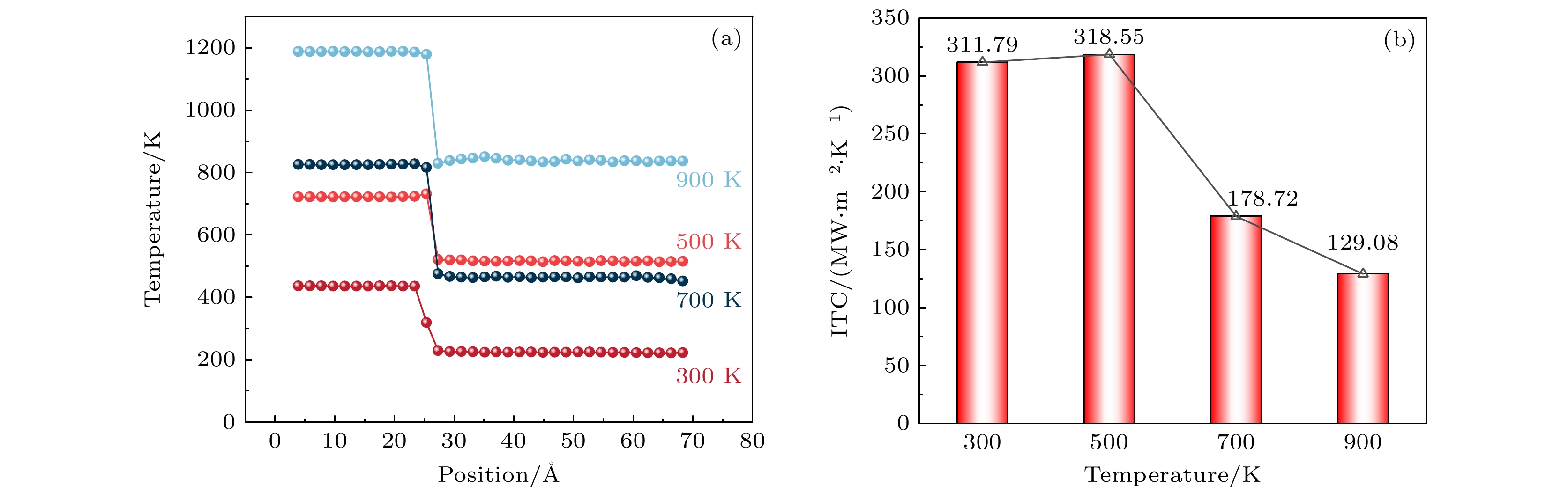

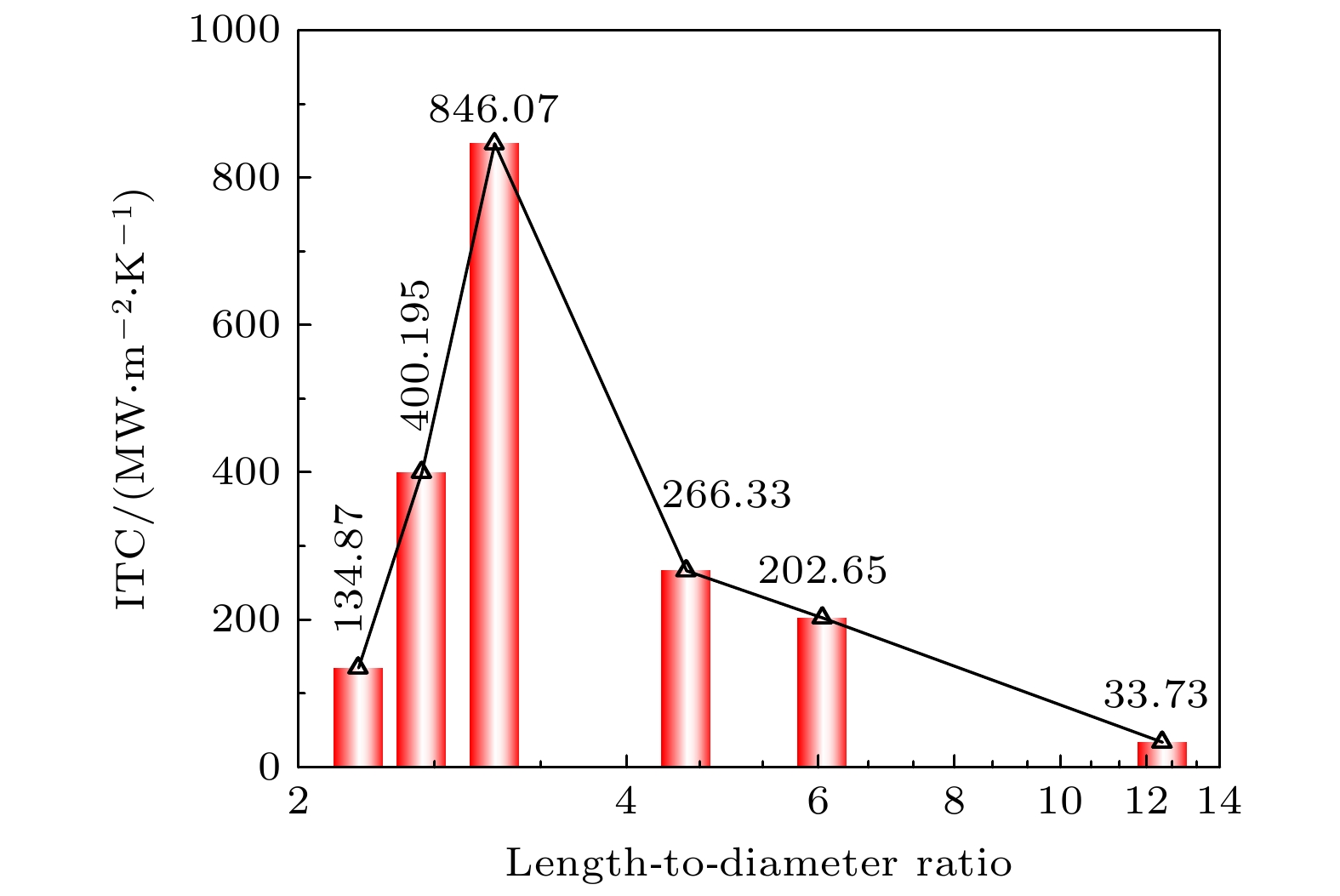

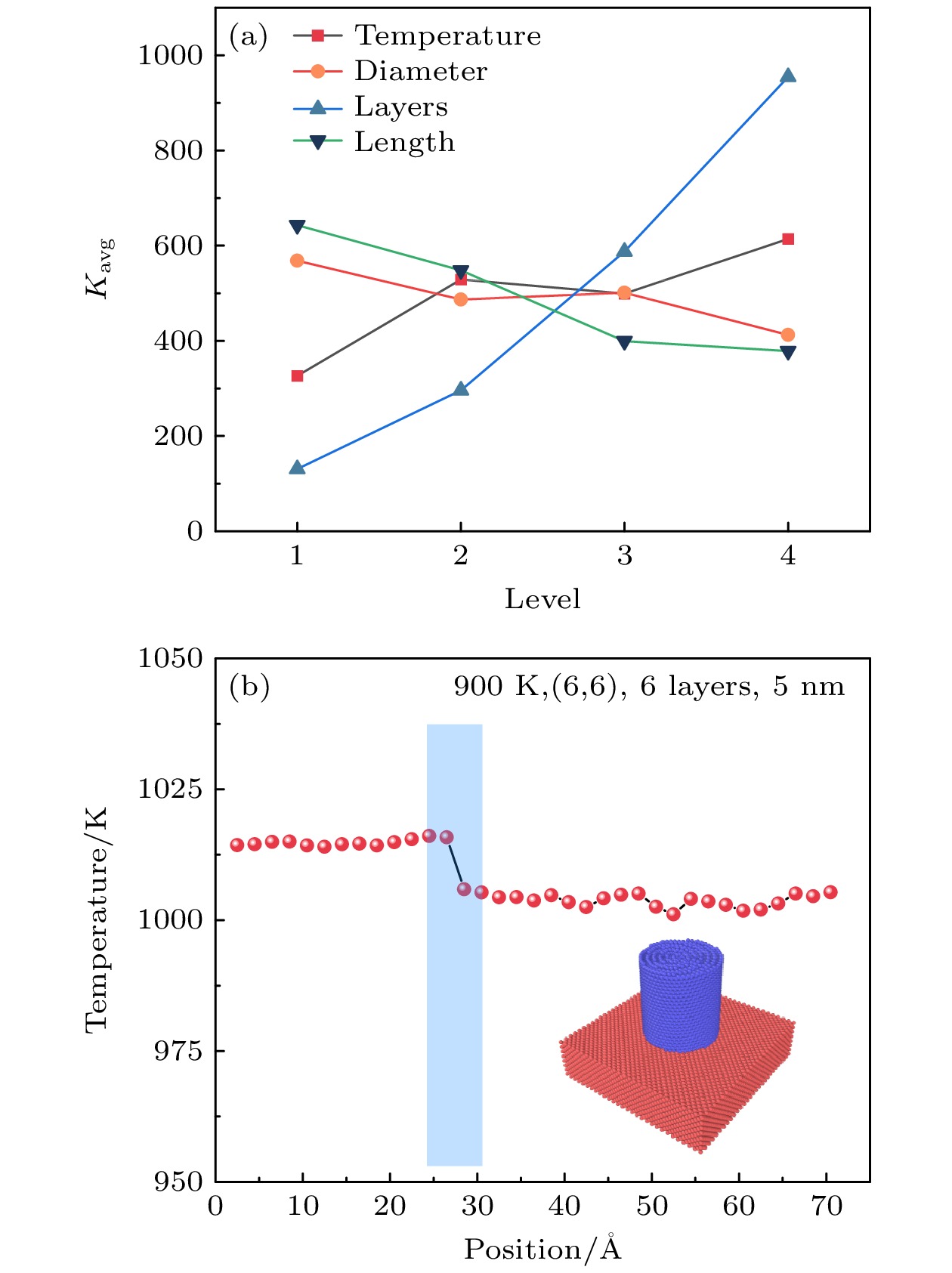

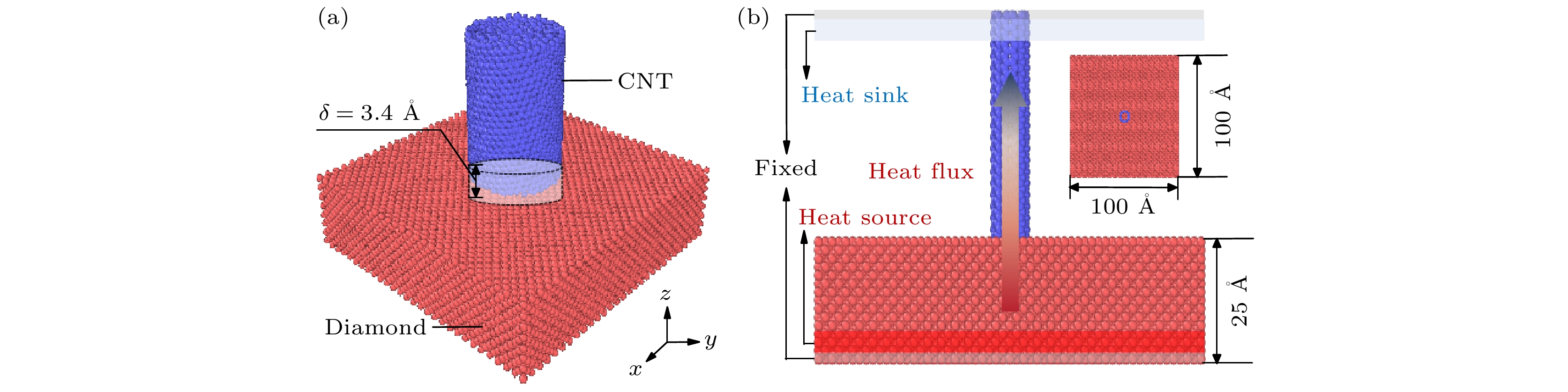

Diamond, an ultra-wide band gap semiconductor material, is an ideal material for high-power, high-frequency, high-temperature, and low-power loss electronic devices. However, high-frequency and high-power working environment leads to ultra-high local hot spots. Thermal interface material (TIM) is urgently needed to improve interface heat dissipation. Carbon nanotube (CNT), a brand-new generation of TIM, has ultra-high thermal conductivity (6000 W/(m·K)) and is expected to solve the heat dissipation problem of diamond semiconductor. Based on this, we first propose to combine diamond and CNT to improve the performance and stability of semiconductor device, reduce packaging size, and achieve miniaturized design of devices. Here we use reverse non-equilibrium molecular dynamics (RNEMD) method to study the thermal transport characteristics and interface thermal conductance (ITC) at the diamond/CNT interface. The results reveal that increasing CNT layers enhances the overall vibration density of states (VDOS) of CNT and shifts the peak value towards the low frequency band, which is more conducive to interface heat transfer. Alternatively, the enhancement of the phonon overlap energy strengthens the coupling vibration of phonon and thus improving the efficiency of the interfacial heat transfer. Moreover, in a certain range, the increase of system temperature and CNT length-to-diameter ratio can raise the cutoff frequency of the VDOS of diamond and CNT near the interface and the peak value of the low frequency band. This further improves the coupling vibration of phonon on both sides. Finally, by orthogonal test simulation, the optimal value of ITC is determined to be 2.65 GW/(m2·K) when the temperature, chirality, layers and length are 900 K, (6, 6), 6 layers and 5 nm respectively. This result greatly exceeds the current ITC of general semiconductors/metal. Compared with general composite materials, diamond/CNT composite material has great potential to enhance heat dissipation. Furthermore, according to P-value test, the number of layers has an extremely significant influence on interfacial thermal transport, while the influence of length, temperature and diameter decrease in turn. This work provides insights into optimizing heat transport at diamond/carbon nanotube interface and will be beneficial for device thermal management and chip material design. -

Keywords:

- carbon nanotube /

- diamond /

- interface thermal conductance /

- molecular dynamics

[1] 王权杰, 邓宇戈, 王仁宗, 刘向军 2023 72 226301

Google Scholar

Google Scholar

Wang Q J, Deng Y G, Wang R Z, Liu X J 2023 Acta Phys. Sin. 72 226301

Google Scholar

Google Scholar

[2] Hiraiwa A, Kawarada H 2015 J. Appl. Phys. 117 124503

Google Scholar

Google Scholar

[3] Berman R, Hudson P, Martinez M 1975 J. Phys. C: Solid State Phys. 8 L430

Google Scholar

Google Scholar

[4] Pernot J, Volpe P N, Omnès F, Muret P, Mortet V, Haenen K, Teraji T 2010 Phys. Rev. B 81 205203

Google Scholar

Google Scholar

[5] Chow T P, Omura I, Higashiwaki M, Kawarada H, Pala V 2017 IEEE Trans. Electron Devices 64 856

Google Scholar

Google Scholar

[6] Perez G, Maréchal A, Chicot G, Lefranc P, Jeannin P O, Eon D, Rouger N 2020 Diamond Relat. Mater. 110 108154

Google Scholar

Google Scholar

[7] Russell S A O, Sharabi S, Tallaire A, Moran D A J 2012 IEEE Electron Device Lett. 33 6291745

Google Scholar

Google Scholar

[8] Sato H, Kasu M 2013 Diamond Relat. Mater. 31 47

Google Scholar

Google Scholar

[9] Yang Y, Koeck F A, Dutta M, Wang X, Chowdhury S, Nemanich R J 2017 J. Appl. Phys. 122 155304

Google Scholar

Google Scholar

[10] Hodgson M, Lohstroh A, Sellin P, Thomas D 2017 Meas. Sci. Technol. 28 105501

Google Scholar

Google Scholar

[11] Bodie C S, Lioliou G, Lefeuvre G, Barnett A M 2022 Appl. Radiat. Isot. 180 110027

Google Scholar

Google Scholar

[12] Chaudhuri S K, Kleppinger J W, Karadavut O, Mandal K C 2021 IEEE Electron Device Lett. 42 200

Google Scholar

Google Scholar

[13] Yang Z, Zhou L H, Luo W, Wan J Y, Dai J Q, Han X G, Fu K, Henderson D, Yang B, Hu L B 2016 Nanoscale 8 19326

Google Scholar

Google Scholar

[14] Due J, Robinson A J 2013 Appl. Therm. Eng. 50 455

Google Scholar

Google Scholar

[15] Hone J, Whitney M, Piskoti C, Zettl A 1999 Phys. Rev. B 59 R2514

Google Scholar

Google Scholar

[16] Marconnet A M, Panzer M A, Goodson K E 2013 Rev. Mod. Phys. 85 1295

Google Scholar

Google Scholar

[17] Sho H, Takuma H, Takuma S, James E, Junichiro S 2013 Int. J. Heat Mass Transfer 67 1024

Google Scholar

Google Scholar

[18] 常国, 段佳良, 王鲁华, 王西涛, 张海龙 2017 材料导报 31 72

Chang G, Duan J L, Wang L H, Wang X T, Zhang H L 2017 Mater. Rep. 31 72

[19] Lee S, Lee A, Baek S, Sung Y, Jeong H 2022 Diamond Relat. Mater. 130 109428

Google Scholar

Google Scholar

[20] Yu H T, Feng Y Y, Chen C, Zhang Z X, Cai Y, Qin M M, Feng W 2021 Carbon 179 348

Google Scholar

Google Scholar

[21] Ma J K, Shang T Y, Ren L L, Yao Y M, Zhang T, Xie J Q, Zhang B T, Zeng X L, Sun R, Xu J B, Wong C P 2020 Chem. Eng. J. 380 122550

Google Scholar

Google Scholar

[22] Desai A, Mahajan S, Subbarayan G, Jones W, Geer J, Sammakia B 2005 J. Electron. Packag. 128 92

Google Scholar

Google Scholar

[23] Feng Y, Zhu J, Tang D W 2015 Phys. Lett. A 379 382

Google Scholar

Google Scholar

[24] Zhang D, Tang Y Z, Wang S, Lin H, He Y 2022 Compos. Interfaces 29 899

Google Scholar

Google Scholar

[25] 潘东楷, 宗志成, 杨诺 2022 71 086302

Google Scholar

Google Scholar

Pan D K, Zong Z C, Yang N 2022 Acta Phys. Sin. 71 086302

Google Scholar

Google Scholar

[26] Thompson A P, Aktulga H M, Berger R, et al. 2022 Comput. Phys. Commun. 271 108171

Google Scholar

Google Scholar

[27] Sha Z D, Branicio P S, Pei Q X, Sorkin V, Zhang Y W 2013 Comput. Mater. Sci 67 146

Google Scholar

Google Scholar

[28] Heinz H, Vaia R A, Farmer B L, Naik R R 2008 J. Phys. Chem. 112 17281

Google Scholar

Google Scholar

[29] Liu Y Z, Yue J C, Liu Y N, Nian L L, Hu S Q 2023 Chin. Phys. Lett. 40 086301

Google Scholar

Google Scholar

[30] Jund P, Jullien R 1999 Phys. Rev. B 59 13707

Google Scholar

Google Scholar

[31] 秦成龙, 罗祥燕, 谢泉, 吴乔丹 2022 71 030202

Google Scholar

Google Scholar

Qin C L, Luo X Y, Xie Q, Wu Q D 2022 Acta Phys. Sin. 71 030202

Google Scholar

Google Scholar

[32] Yao Z H, Wang J S, Li B W, Liu G R 2005 Phys. Rev. B 71 085417

Google Scholar

Google Scholar

[33] Li J Q, Shen H J 2018 Mol. Phys. 116 1297

Google Scholar

Google Scholar

[34] 朱亚波, 鲍振, 蔡存金, 杨玉杰 2009 58 7833

Google Scholar

Google Scholar

Zhu Y B, Bao Z, Cai C J, Yang Y J 2009 Acta Phys. Sin. 58 7833

Google Scholar

Google Scholar

[35] Seberry J 2017 Orthogonal Designs (Wollongong: Springer Cham) pp1–430

[36] 宗志成, 潘东楷, 邓世琛, 万骁, 杨哩娜, 马登科, 杨诺 2023 72 034401

Google Scholar

Google Scholar

Zong Z C, Pan D K, Deng S C, Wan X, Yang L N, Ma D K, Yang N 2023 Acta Phys. Sin. 72 034401

Google Scholar

Google Scholar

-

图 3 不同温度下近界面处金刚石和碳纳米管的声子态密度 (a) 300 K; (b) 500 K; (c) 700 K; (d) 900 K. (e) 不同温度下体系界面处的声子态密度; (f) 不同温度下近界面处金刚石和碳纳米管的重叠能

Fig. 3. VDOS of diamond and CNT close to interface at different temperatures: (a) 300 K; (b) 500 K; (c) 700 K; (d) 900 K. (e) VDOS at system interface at different temperatures; (f) overlap energy of diamond and CNT close to interface at different temperatures.

图 5 不同碳纳米管层数对应近界面处的金刚石和碳纳米管的声子态密度 (a) 2层; (b) 3层; (c) 4层; (d) 6层; (e) 8层. (f) 不同碳纳米管层数对应金刚石/碳纳米管界面处的声子态密度; (g) 不同碳纳米管层数对应体系中近界面处金刚石和碳纳米管的重叠能

Fig. 5. VDOS of diamond and CNT close to interface with different layers of CNT: (a) 2 layers; (b) 3 layers; (c) 4 layers; (d) 6 layers; (e) 8 layers. (f) VDOS at diamond/CNT interface with different CNT layers; (g) overlap energy of diamond and CNT close to interface with different CNT layers.

图 7 不同碳纳米管长径比对应近界面处的金刚石和碳纳米管的声子态密度 (a) L/d = 2.3; (b) L/d = 2.6; (c) L/d = 3.0; (d) L/d = 4.5; (e) L/d = 6.0; (f) L/d = 12.4. (g) 不同碳纳米管长径比对应金刚石/碳纳米管界面处的声子态密度; (h) 不同碳纳米管长径比对应体系中近界面处金刚石和碳纳米管的重叠能

Fig. 7. VDOS of diamond and CNT close to interface with different CNT length-to-diameter ratio: (a) L/d = 2.3; (b) L/d = 2.6; (c) L/d = 3.0; (d) L/d = 4.5; (e) L/d = 6.0; (f) L/d = 12.4. (g) VDOS at diamond/CNT interface with different CNT length-to-diameter ratio; (h) overlap energy of diamond and CNT close to interface with different CNT length-to-diameter ratio.

表 1 正交试验界面热导结果

Table 1. ITC results of orthogonal test.

Number ITC/(MW·m–2·K–1) Number ITC/(MW·m–2·K–1) 1 146.21 9 614.33 2 237.72 10 816.90 3 394.06 11 135.93 4 528.635 12 430.075 5 249.165 13 1264.37 6 103.735 14 788.3 7 1208.075 15 267.035 8 553.91 16 137.12 表 2 正交试验极值分析

Table 2. Range analysis of orthogonal test.

Level Temperature

/KDiameter

/nmLayers Length

/nmK1 326.66 568.52 130.75 643.16 K2 528.72 486.66 296.00 547.98 K3 499.31 501.28 587.65 399.31 K4 614.21 412.44 954.50 378.43 R 287.55 156.08 823.75 264.73 Optimum level 4 1 4 1 -

[1] 王权杰, 邓宇戈, 王仁宗, 刘向军 2023 72 226301

Google Scholar

Google Scholar

Wang Q J, Deng Y G, Wang R Z, Liu X J 2023 Acta Phys. Sin. 72 226301

Google Scholar

Google Scholar

[2] Hiraiwa A, Kawarada H 2015 J. Appl. Phys. 117 124503

Google Scholar

Google Scholar

[3] Berman R, Hudson P, Martinez M 1975 J. Phys. C: Solid State Phys. 8 L430

Google Scholar

Google Scholar

[4] Pernot J, Volpe P N, Omnès F, Muret P, Mortet V, Haenen K, Teraji T 2010 Phys. Rev. B 81 205203

Google Scholar

Google Scholar

[5] Chow T P, Omura I, Higashiwaki M, Kawarada H, Pala V 2017 IEEE Trans. Electron Devices 64 856

Google Scholar

Google Scholar

[6] Perez G, Maréchal A, Chicot G, Lefranc P, Jeannin P O, Eon D, Rouger N 2020 Diamond Relat. Mater. 110 108154

Google Scholar

Google Scholar

[7] Russell S A O, Sharabi S, Tallaire A, Moran D A J 2012 IEEE Electron Device Lett. 33 6291745

Google Scholar

Google Scholar

[8] Sato H, Kasu M 2013 Diamond Relat. Mater. 31 47

Google Scholar

Google Scholar

[9] Yang Y, Koeck F A, Dutta M, Wang X, Chowdhury S, Nemanich R J 2017 J. Appl. Phys. 122 155304

Google Scholar

Google Scholar

[10] Hodgson M, Lohstroh A, Sellin P, Thomas D 2017 Meas. Sci. Technol. 28 105501

Google Scholar

Google Scholar

[11] Bodie C S, Lioliou G, Lefeuvre G, Barnett A M 2022 Appl. Radiat. Isot. 180 110027

Google Scholar

Google Scholar

[12] Chaudhuri S K, Kleppinger J W, Karadavut O, Mandal K C 2021 IEEE Electron Device Lett. 42 200

Google Scholar

Google Scholar

[13] Yang Z, Zhou L H, Luo W, Wan J Y, Dai J Q, Han X G, Fu K, Henderson D, Yang B, Hu L B 2016 Nanoscale 8 19326

Google Scholar

Google Scholar

[14] Due J, Robinson A J 2013 Appl. Therm. Eng. 50 455

Google Scholar

Google Scholar

[15] Hone J, Whitney M, Piskoti C, Zettl A 1999 Phys. Rev. B 59 R2514

Google Scholar

Google Scholar

[16] Marconnet A M, Panzer M A, Goodson K E 2013 Rev. Mod. Phys. 85 1295

Google Scholar

Google Scholar

[17] Sho H, Takuma H, Takuma S, James E, Junichiro S 2013 Int. J. Heat Mass Transfer 67 1024

Google Scholar

Google Scholar

[18] 常国, 段佳良, 王鲁华, 王西涛, 张海龙 2017 材料导报 31 72

Chang G, Duan J L, Wang L H, Wang X T, Zhang H L 2017 Mater. Rep. 31 72

[19] Lee S, Lee A, Baek S, Sung Y, Jeong H 2022 Diamond Relat. Mater. 130 109428

Google Scholar

Google Scholar

[20] Yu H T, Feng Y Y, Chen C, Zhang Z X, Cai Y, Qin M M, Feng W 2021 Carbon 179 348

Google Scholar

Google Scholar

[21] Ma J K, Shang T Y, Ren L L, Yao Y M, Zhang T, Xie J Q, Zhang B T, Zeng X L, Sun R, Xu J B, Wong C P 2020 Chem. Eng. J. 380 122550

Google Scholar

Google Scholar

[22] Desai A, Mahajan S, Subbarayan G, Jones W, Geer J, Sammakia B 2005 J. Electron. Packag. 128 92

Google Scholar

Google Scholar

[23] Feng Y, Zhu J, Tang D W 2015 Phys. Lett. A 379 382

Google Scholar

Google Scholar

[24] Zhang D, Tang Y Z, Wang S, Lin H, He Y 2022 Compos. Interfaces 29 899

Google Scholar

Google Scholar

[25] 潘东楷, 宗志成, 杨诺 2022 71 086302

Google Scholar

Google Scholar

Pan D K, Zong Z C, Yang N 2022 Acta Phys. Sin. 71 086302

Google Scholar

Google Scholar

[26] Thompson A P, Aktulga H M, Berger R, et al. 2022 Comput. Phys. Commun. 271 108171

Google Scholar

Google Scholar

[27] Sha Z D, Branicio P S, Pei Q X, Sorkin V, Zhang Y W 2013 Comput. Mater. Sci 67 146

Google Scholar

Google Scholar

[28] Heinz H, Vaia R A, Farmer B L, Naik R R 2008 J. Phys. Chem. 112 17281

Google Scholar

Google Scholar

[29] Liu Y Z, Yue J C, Liu Y N, Nian L L, Hu S Q 2023 Chin. Phys. Lett. 40 086301

Google Scholar

Google Scholar

[30] Jund P, Jullien R 1999 Phys. Rev. B 59 13707

Google Scholar

Google Scholar

[31] 秦成龙, 罗祥燕, 谢泉, 吴乔丹 2022 71 030202

Google Scholar

Google Scholar

Qin C L, Luo X Y, Xie Q, Wu Q D 2022 Acta Phys. Sin. 71 030202

Google Scholar

Google Scholar

[32] Yao Z H, Wang J S, Li B W, Liu G R 2005 Phys. Rev. B 71 085417

Google Scholar

Google Scholar

[33] Li J Q, Shen H J 2018 Mol. Phys. 116 1297

Google Scholar

Google Scholar

[34] 朱亚波, 鲍振, 蔡存金, 杨玉杰 2009 58 7833

Google Scholar

Google Scholar

Zhu Y B, Bao Z, Cai C J, Yang Y J 2009 Acta Phys. Sin. 58 7833

Google Scholar

Google Scholar

[35] Seberry J 2017 Orthogonal Designs (Wollongong: Springer Cham) pp1–430

[36] 宗志成, 潘东楷, 邓世琛, 万骁, 杨哩娜, 马登科, 杨诺 2023 72 034401

Google Scholar

Google Scholar

Zong Z C, Pan D K, Deng S C, Wan X, Yang L N, Ma D K, Yang N 2023 Acta Phys. Sin. 72 034401

Google Scholar

Google Scholar

计量

- 文章访问数: 997

- PDF下载量: 37

- 被引次数: 0

下载:

下载: